Patents

Literature

50results about How to "Precise process control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

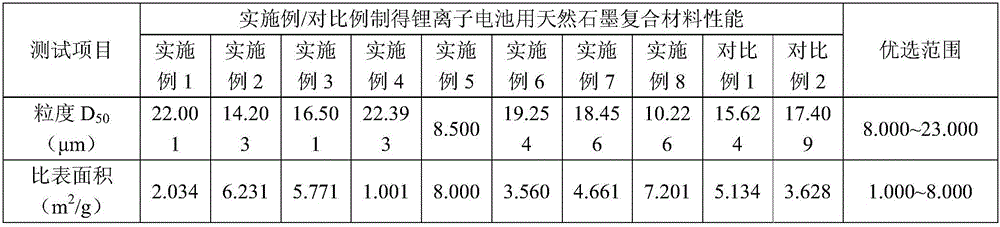

Natural graphite composite material, preparation method thereof and lithium ion battery

ActiveCN106058211AIncrease capacityImprove compactionCell electrodesSecondary cellsLithium-ion batteryThermal treatment

The invention relates to a natural graphite composite material, a preparation method thereof and a lithium ion battery. The natural graphite composite material comprises natural graphite and an amorphous carbon shell coating the surface of natural graphite, wherein the amorphous carbon shell is made from a bonding agent and an additive through thermal treatment. The amorphous carbon shell is made from the bonding agent and the additive through thermal treatment, can uniformly coat the surface of natural graphite, and provides the natural graphite composite material with characteristics of high capacity, good compaction, low circulation expansion ratio and long circulation life. The natural graphite composite material is stable in performance and excellent in overall performance. The preparation method of the natural graphite composite material is mild in condition, simple in process and low in cost.

Owner:贝特瑞(江苏)新能源材料有限公司

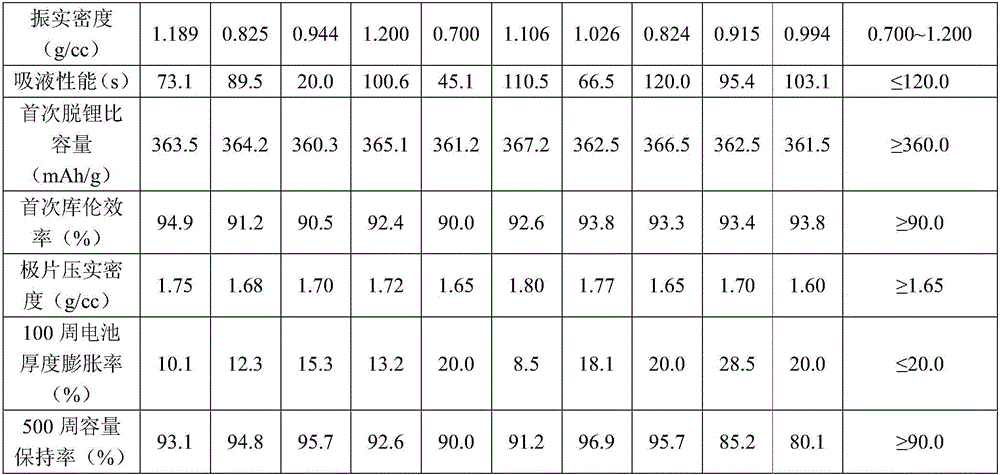

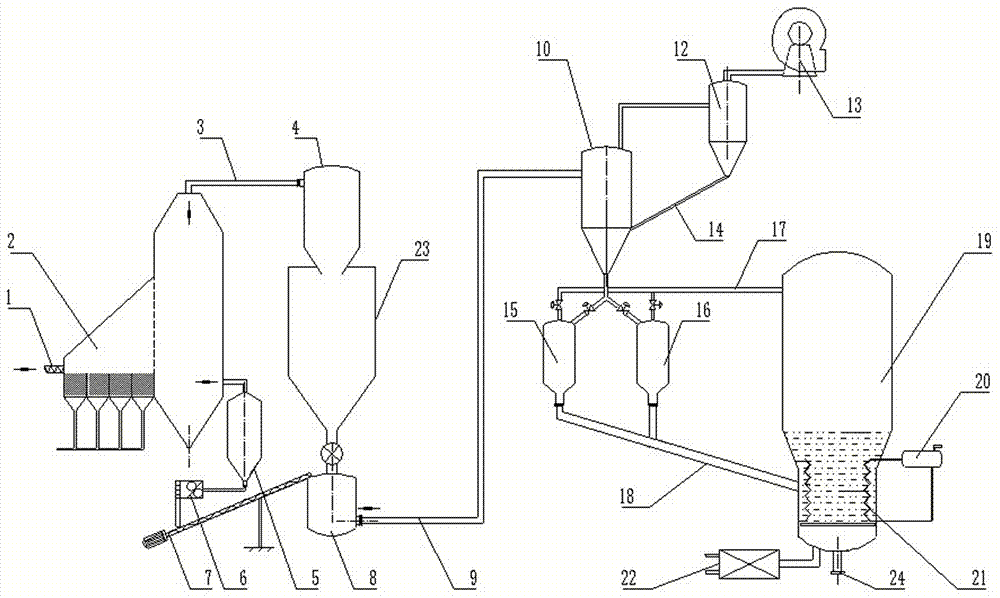

Cold disinfection method for cip center control system of milk product production line

ActiveCN104971373AImprove disinfection efficiencyReduce waiting timeCleaning using liquidsChemicalsControl systemProcess engineering

The invention discloses a cold disinfection method for a cip center control system of a milk product production line. The cold disinfection method is used for carrying out cold disinfection on a milk collecting pipeline, a milk tank car, a raw material storage tank and a homogenizing machine and comprises the following steps of (1) starting the cip center control system to primarily clean a production line; (2) emptying an acid liquor in an acid pickling tank in the cip center control system, and inputting a cold disinfectant; (3) regulating the acid pickling temperature to normal temperature through the cip center control system, and setting the acid pickling process time within 8-15 minutes; starting the cip center control system to carry out an independent acid pickling process; (4) flushing with water for 3-5 minutes after ending the acid pickling operation in the step (3); and (5) emptying the cold disinfectant in the acid pickling tank, flushing to be clean, and then, conveying the acid liquor discharged in the step (2) to the acid pickling tank. By using the cold disinfection method for the center control system, automatic cold disinfection is realized, both the disinfection process waiting time and the disinfection time are greatly shortened, and the cip disinfection efficiency in the production process is increased.

Owner:四川新华西乳业有限公司

Method for reducing manganese oxide by internal-heat rotary kiln

The invention relates to a method for reducing manganese oxide by an internal-heat rotary kiln. The method comprises the following steps: crushing manganese oxide and mixing the crushed manganese oxide with pulverized coal according to a certain proportion; transferring the obtained mixed material into a rotary kiln which is arranged aslant; heating and igniting the mixed material in the rotary kiln by using a pulverized coal burner with multiple air channels, keeping the temperature of 800-900 DEG C, roasting for 3-8 hours, and cooling the material to the temperature of 40-70 DEG C; and polishing the material into powder with over 90 meshes with a ball mill for producing electrolytic manganese. The method for reducing a manganese oxide ore has the advantages of high reduction rate up to over 95%, low energy consumption, accurate process control and stable product quality; and the reduced manganese oxide ore can replace a manganese carbonate ore for producing electrolytic manganese metal.

Owner:陈德根 +2

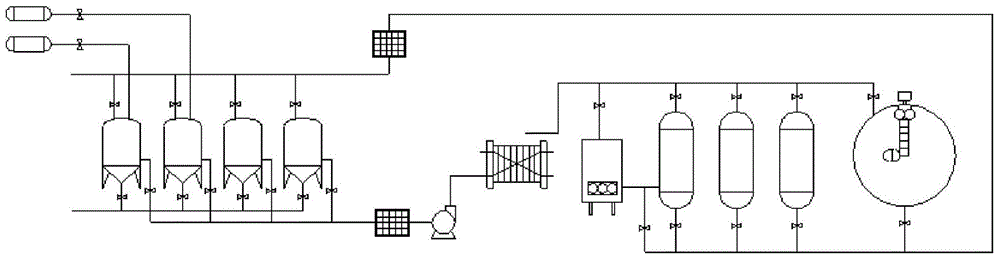

Production process for preparing high-nitrogen vanadium nitride by using vacuum furnace method

InactiveCN103303880AReduce energy consumptionPrecise process controlNitrogen-metal/silicon/boron binary compoundsVacuum furnaceVanadium pentoxide dust

The invention discloses a production process for preparing high-nitrogen vanadium nitride by using a vacuum furnace method, and relates to a production process for producing a high-nitrogen vanadium nitride product in a vacuum resistance furnace by taking high-purity vanadium pentoxide powder as the raw material through a nitridation sintering method. According to the production process, the process procedures of reduction, nitridation and sintering are carried out in a vacuum furnace, so that the energy consumption is low, the process control is accurate, the production efficiency of the product is high and stable, and the environment is not polluted.

Owner:湘西自治州丰达合金科技有限公司

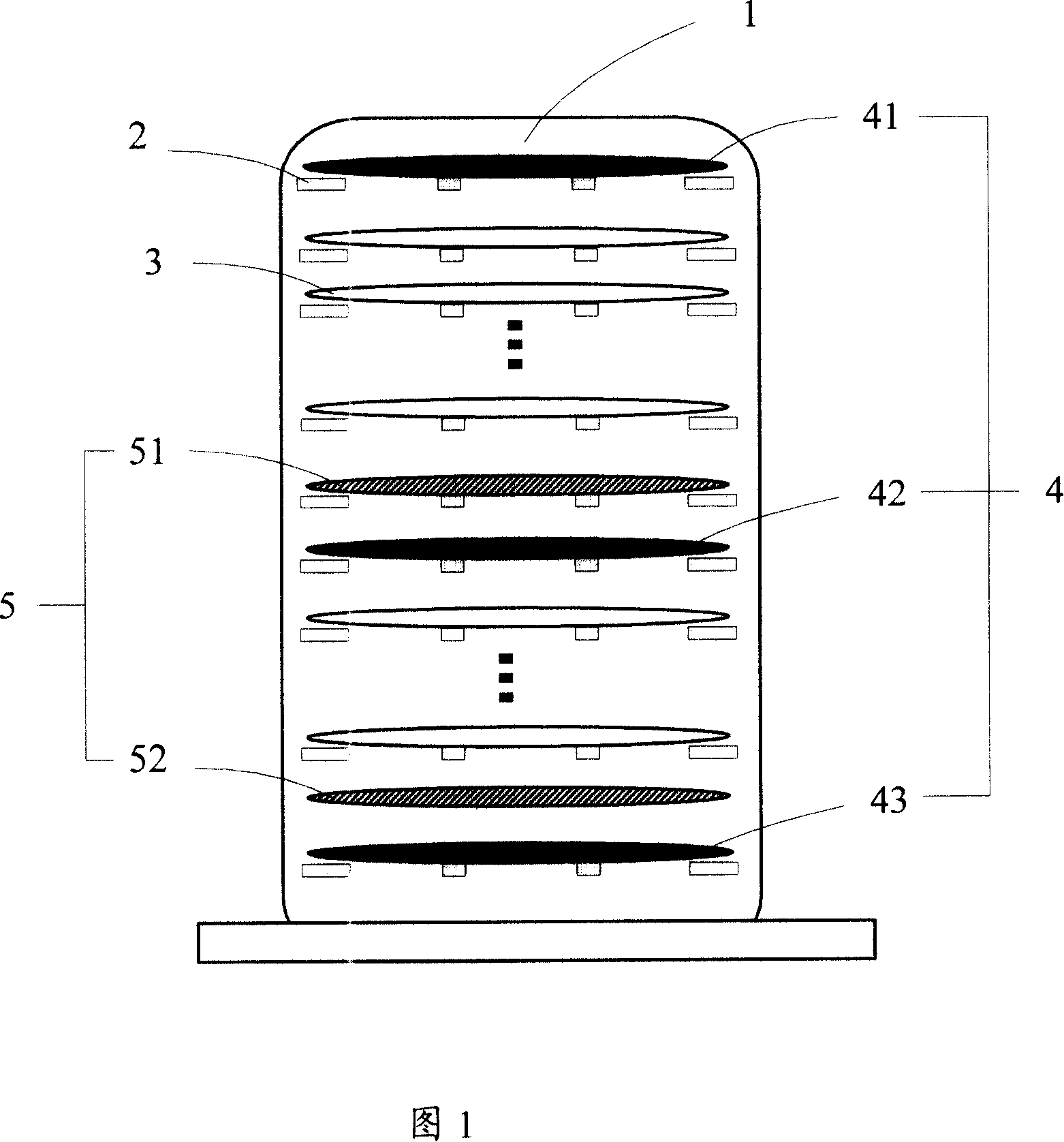

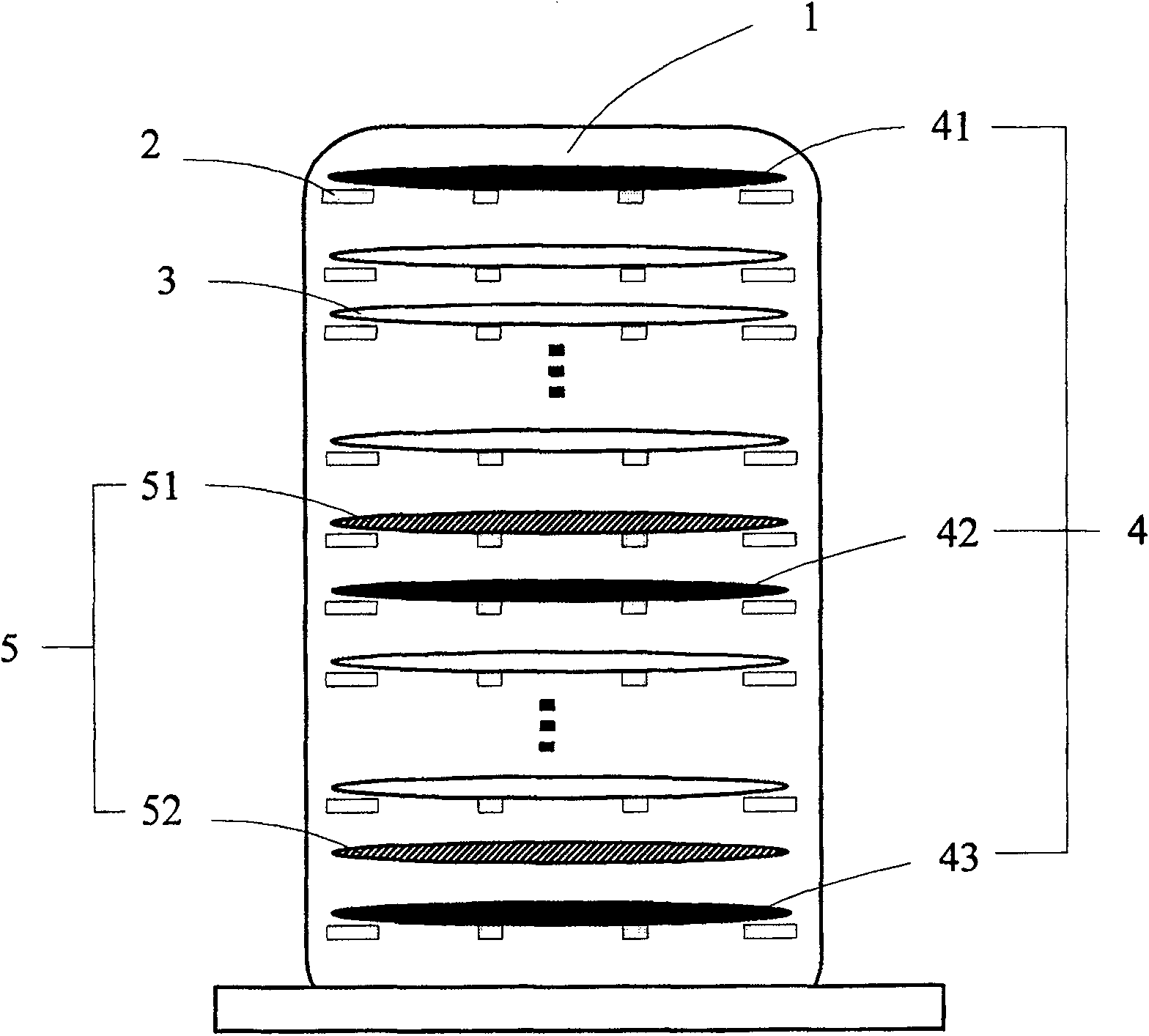

A device and method for improving detection precision of oxidated layer thickness

InactiveCN101150083AAffect growthStable thicknessSemiconductor/solid-state device testing/measurementEngineeringLayer thickness

This invention relates to a device for increasing accuracy of testing thickness of oxidation layer including a tube, a crystal boat, several wafers and three control sheets at the top, middle and the bottom of the boat, and the wafers and the control sheets are arrayed on the boat, two blocking sheets are set above the control sheets at the middle and bottom separately. This invention also provides a method including: putting several wafers and three control plates in the boat and putting blocking sheets above the control sheets at the middle and the bottom then putting the boat in the tube to be oxidized, in which, the blocking sheets above the control sheets can avoid that the film of the lower surface of the wafer will influence growth of the oxidation layer of the control sheet during oxidation.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

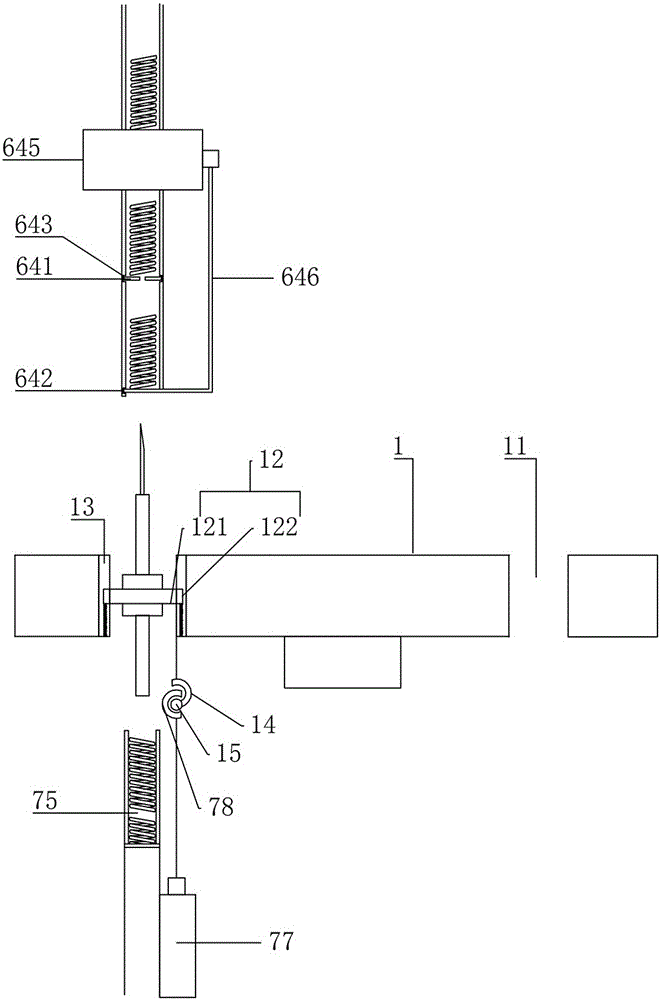

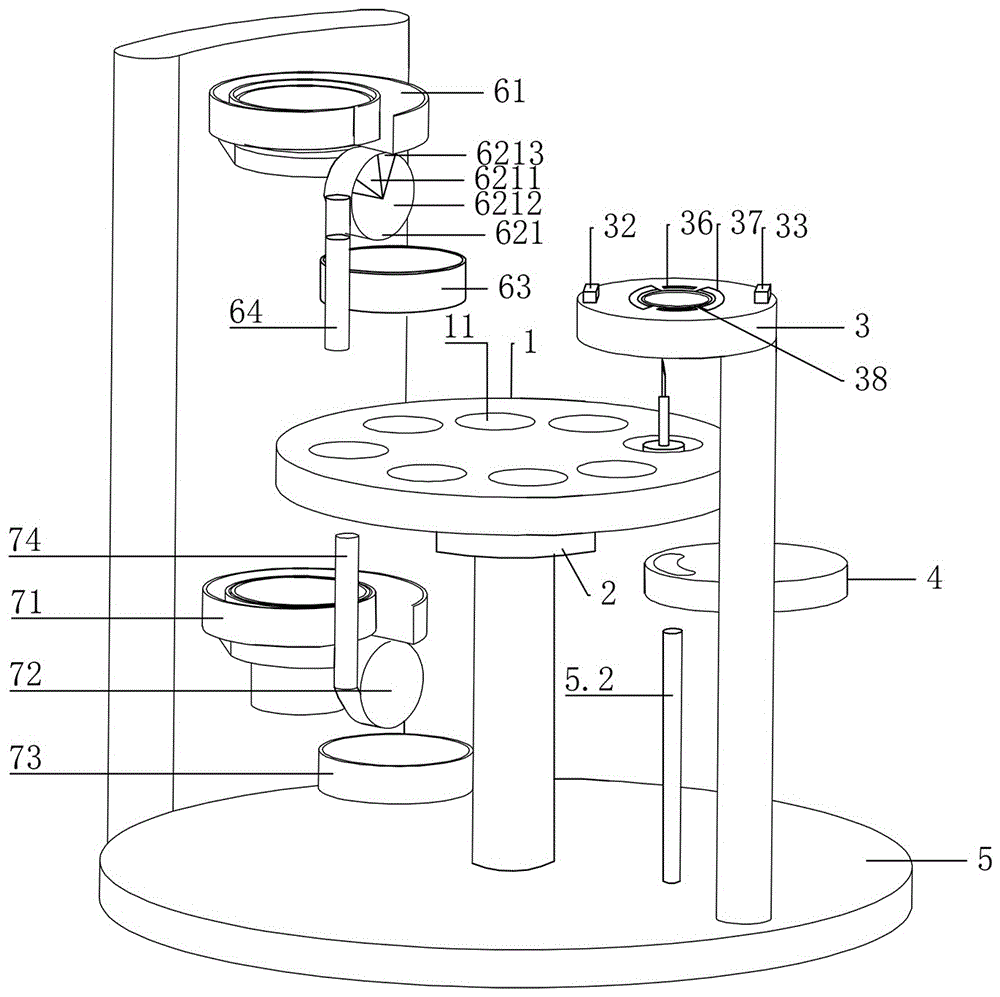

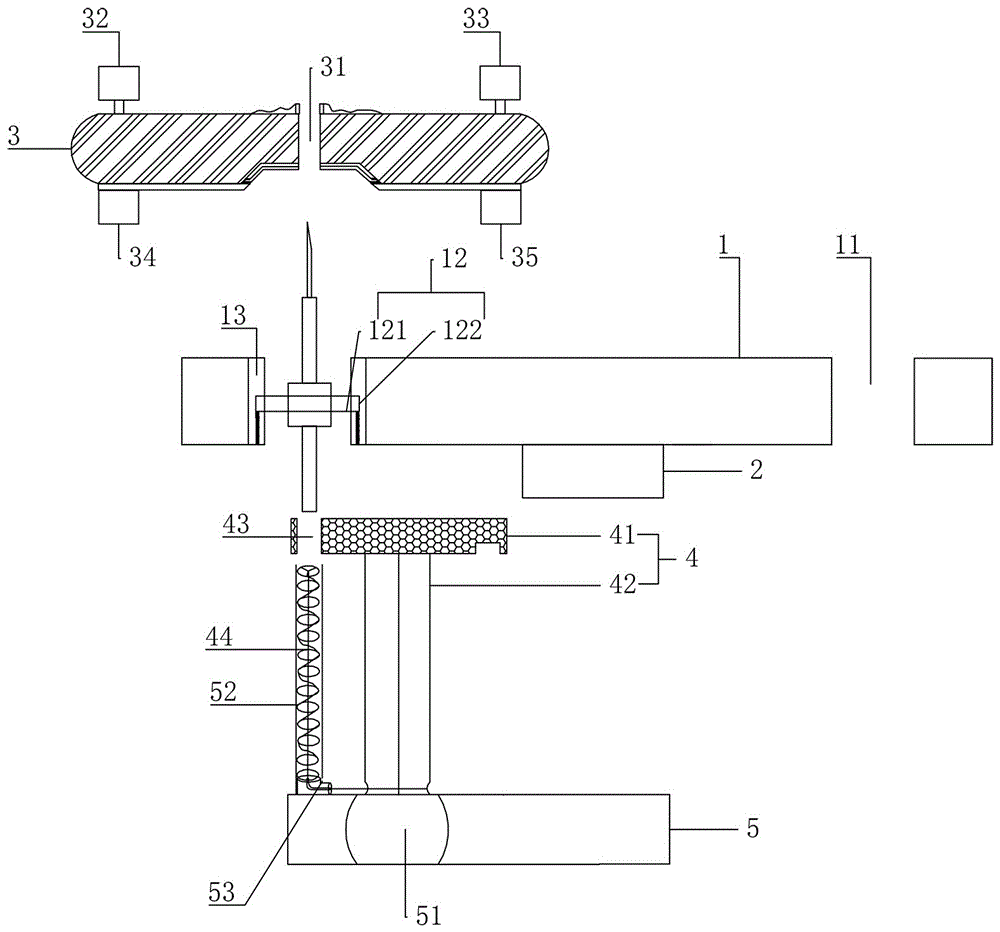

Control system for blood taking needle assembly machine

ActiveCN106217030AImprove pass rateEasy to operateAssembly machinesControl systemAgricultural engineering

The invention discloses a control system for a blood taking needle assembly machine. The control system comprises a detecting mechanism, an assembling mechanism, an index plate feeding mechanism, a mechanical arm mechanism and an upper computer. The index plate feeding mechanism, the mechanical arm mechanism, an outer sleeve feeding mechanism, an inner sleeve feeding mechanism, a front spring feeding mechanism, a rear spring feeding mechanism, a rear cover feeding mechanism and a front cover feeding mechanism are internally provided with PLCs correspondingly, and the PLCs are in network communication connection with control modules in the upper computer correspondingly. According to the control system, the seven parts are automatically assembled according to different sequences, the PLC microcomputer control technology is adopted, each functional unit uses an independent control system, and connection between the PLCs of the functional units and connection between the PLCs and the upper computer are realized through the PLC network communication function modules. The control system has the advantages of being high in degree of automation, accurate in process control, convenient to operate, stable in operation and high in product percent of pass.

Owner:唐山启奥科技股份有限公司

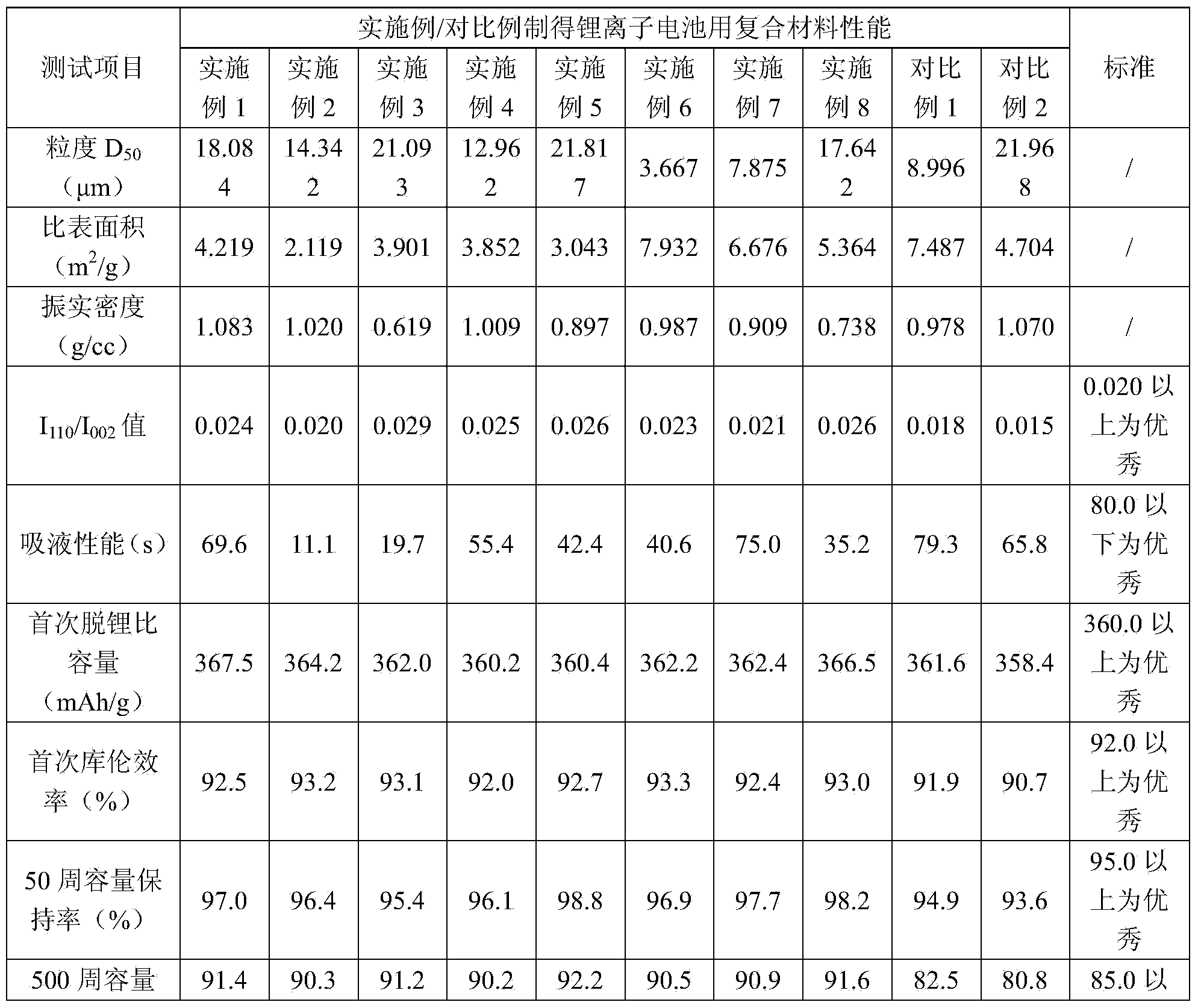

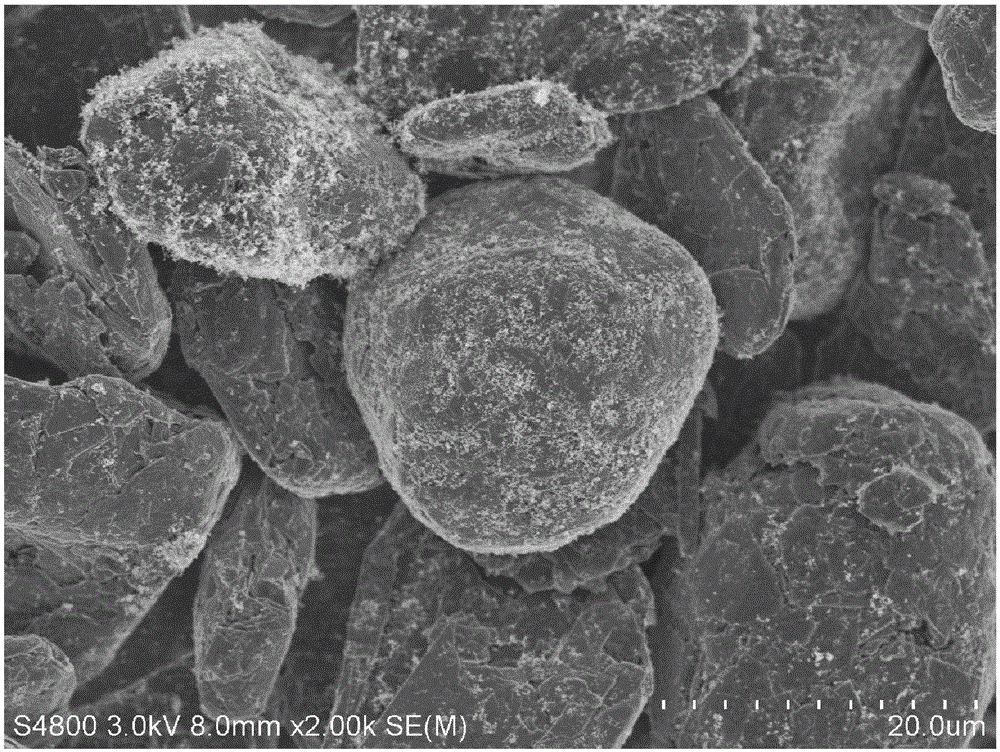

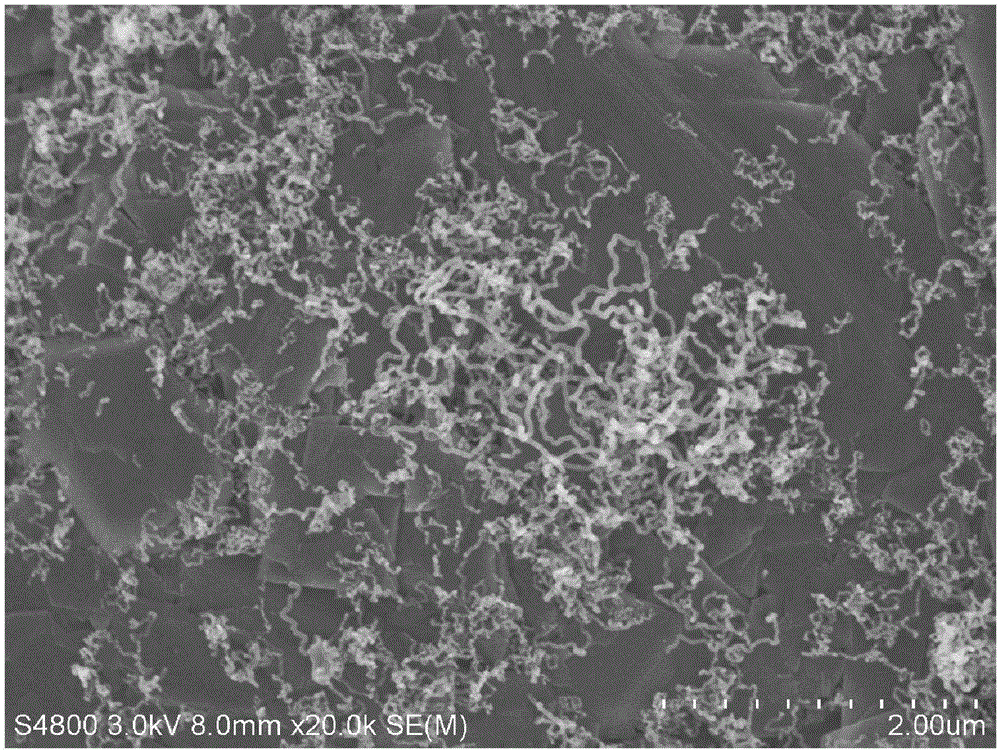

Composite material of lithium ion battery, preparation method thereof and lithium ion battery

InactiveCN103872294AGood orientationIncrease capacityCell electrodesSecondary cellsSodium-ion batteryLithium-ion battery

The invention relates to a composite material of a lithium ion battery, a preparation method thereof and the lithium ion battery. The composite material of the lithium ion battery is isotropic and comprises a carbon material which is used as a supporting skeleton and graphite particles which are embedded into the carbon material, wherein the carbon material is a product from thermal treatment of a binder; the graphite particles are formed by natural graphite or natural composite graphite which is formed by compounding natural graphite and auxiliary materials, and the mass of the graphite particles accounts for 50.0 to 99.9 percent of the total mass of the composite material. The composite material is high in orientation, high in capacity, high in rate capacity and long in service life; the preparation method is moderate in condition, simple in process and low in cost.

Owner:BTR NEW MATERIAL GRP CO LTD +1

Preparation method of seasoned poached eggs

InactiveCN106036545AGreat tasteRich structureFood thermal treatmentFood ingredient as flavour affecting agentFood flavorPoached egg

A preparation method of seasoned poached eggs comprises the following steps: (1) eggs are graded according to the quality standard; (2) a heat transfer medium is heated to 80-95 DEG C; (3) the eggs are totally immersed in the heat transfer medium and boiled for 7-10 min; (4) the boiled eggs are cooled in water at 10-20 DEG C; (5) the cooled eggs are totally immersed in a prepared seasoning liquid, the mixture is placed in vacuum decompression equipment for 2-4 days, the vacuum degree is kept from subzero 0.09 Mpa to subzero 0.1 Mpa, and the temperature is set to be 25 DEG C; (6) the poached eggs prepared through the steps are subjected to cold storage in a low-temperature environment at 0-10 DEG C. The egg white of the prepared poached eggs is denaturalized completely, and the hardness and the elasticity reach the states of normal hard boiled eggs; while the texture of yolk is in a soft sate and colloidal, the yolk is in bright deep yellow and tastes fine and soft, and small-molecular flavor substances of the prepared seasoning liquid enter the eggs completely without damaging the inside forms of the poached eggs, so that the poached eggs are good in color, flavor and taste.

Owner:SICHUAN UNIV

Method for preparing nitrided ferrovanadium by using vacuum furnace

The invention discloses a method for preparing nitrided ferrovanadium by using a vacuum furnace. A material is pretreated to realize quick heating in the vacuum furnace and to finish the drying, the carbonization and the nitriding within 7-8 hours, so that the time is effectively saved, and the production cost is largely reduced while the production efficiency of the vacuum furnace is improved. The method is used for preparing a nitrided ferrovanadium alloy to achieve the advantages of simple operation, low cost, accurate process control, stable product production and no environmental pollution. The vanadium content of the prepared nitrided ferrovanadium alloy is more than 45%, the nitrogen content can be more than 9%, and the impurity content is low.

Owner:SICHUAN ZHANXIANG SPECIAL ALLOY TECH

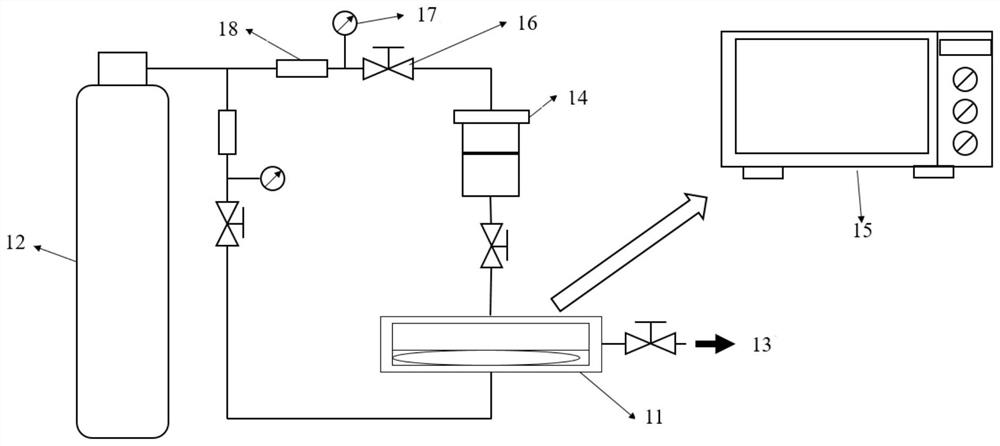

Bag compression resin transfer molding (RTM) mold, device and method

The invention relates to a bag compression resin transfer molding (RTM) mold, device and method. The bag compression RTM mold comprises an outer mold and further comprises an upper mold, a lower mold,an air bag and a guiding piece which are located in the outer mold; the upper mold is of a convex block structure, and the lower mold is of a groove structure, wherein the convex block structure andthe groove structure are mutually matched; the lower mold is located blow the upper mold, the air bag is located below the lower mold, the guiding piece is used for limiting the movement direction ofthe lower mold to the up-down direction, communicating resin inlets are formed in the upper mold and the outer mold, a vacuum pump connector and an air inlet which is connected with an air bag inlet are formed in the outer mold, and a resin outlet is formed in the lower mold. The device is composed of the molding mold, an air storage tank, a vacuum pump, a pressure tank and a heating deice. The method comprises the steps: a reinforced material is placed into the mold to be heated firstly, then a closed space between the upper mold and the lower mold is vacuumized and then fully filled with resin, then when heating is conducted to a resin gel point, the air bag is inflated to compress the lower mold, and finally curing and demolding are conducted. The molding mold and device are simple in structure, and the production efficiency of the method is high.

Owner:DONGHUA UNIV

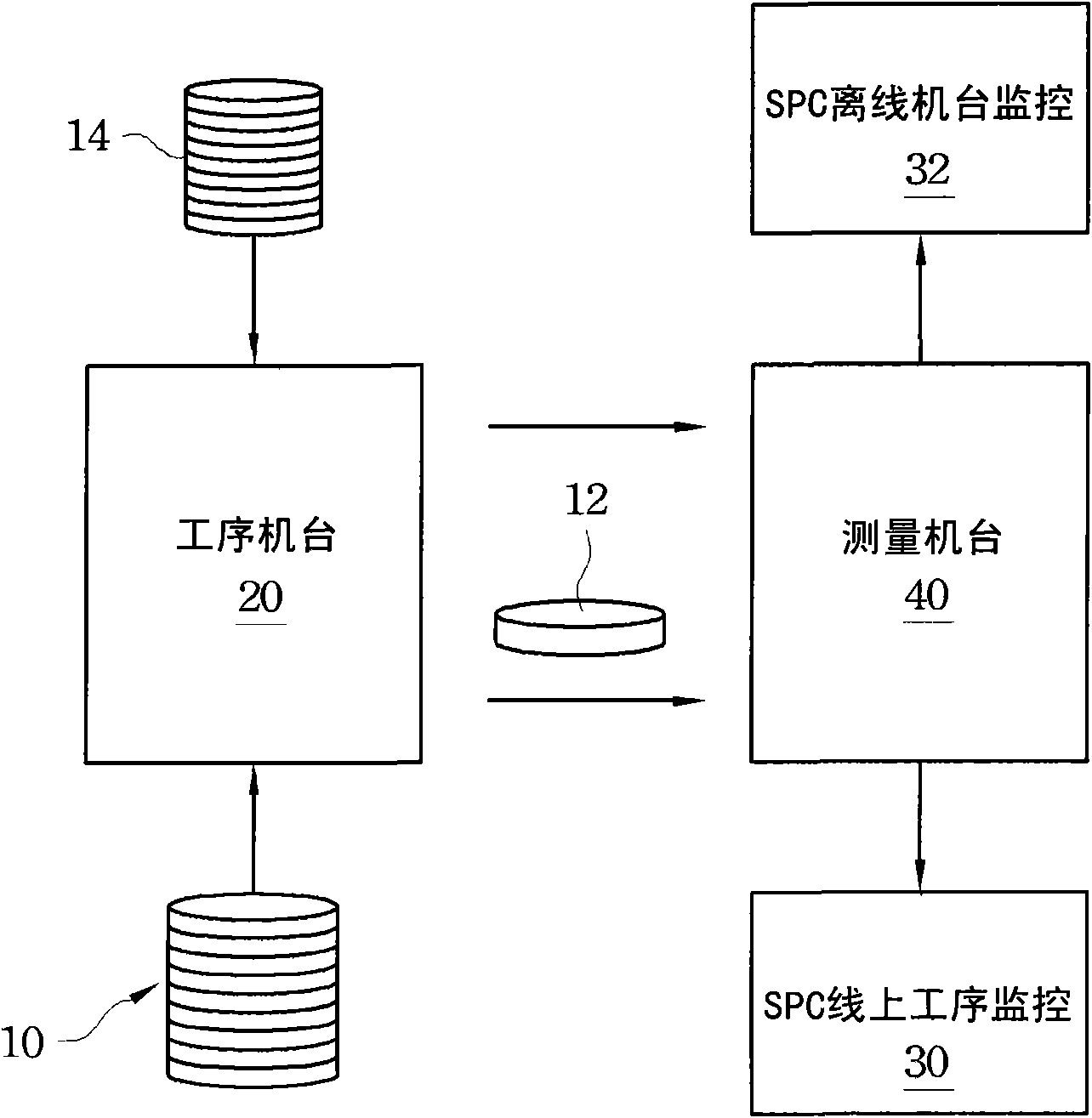

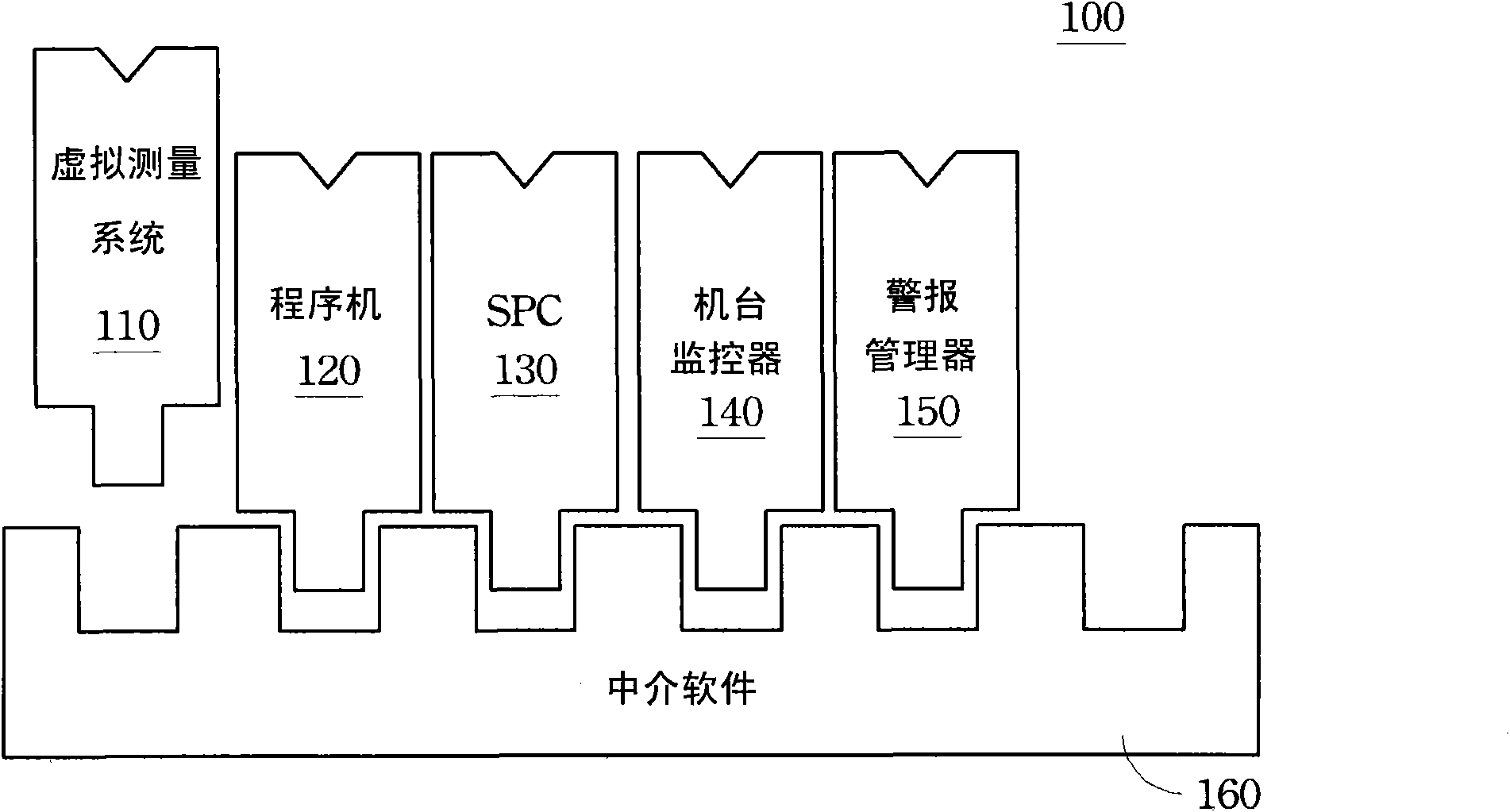

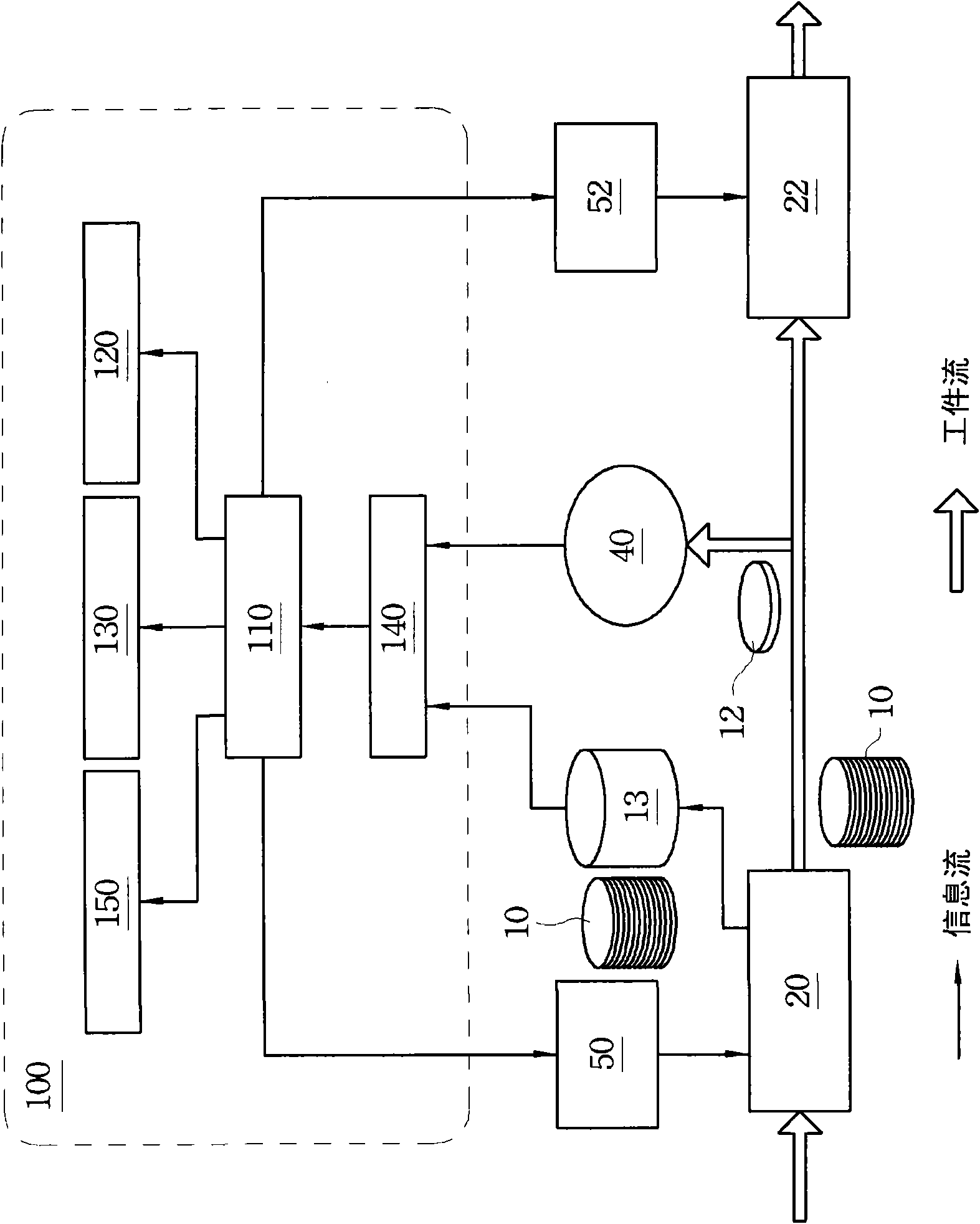

Manufacturing execution system and manufacturing system having virtual measuring function

ActiveCN102254788AReal-time monitoring of production healthLow costSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingManufacture execution systemStatistical process control

The invention discloses a manufacturing execution system and a manufacturing system having a virtual measuring function. The manufacturing execution system is established on the basis of configurations of middleware, such as an object request broker, an equipment manager, a virtual measuring system, a statistical process control (SPC) system, an alarm manager, a scheduler and the like. The manufacturing system comprises a first process cabinet, a second process cabinet, a measuring cabinet, the manufacturing execution system, a first run-to-run (R2R) controller and a second R2R controller.

Owner:NAT CHENG KUNG UNIV

Method for preparing nitrided ferrovanadium

The invention discloses a method for preparing nitrided ferrovanadium. The method disclosed by the invention comprises the following steps: evenly mixing ferrovanadium powder with water glass serving as a binder according to a certain ratio, then pressing and molding; putting into a vacuumized vacuum tube type resistance furnace, and then charging pure nitrogen into the vacuum tube type resistance furnace at a certain speed; simultaneously, electrifying and heating the vacuum tube type resistance furnace to 800-950 DEG C for sintering and nitriding and then gradually cooling to obtain the product. According to the nitrided ferrovanadium prepared by the method disclosed by the invention, the nitrogen content can be over 10% and the apparent density can be over 3.5g / cm<3>; in addition, the method is low in energy consumption, and accurate in process control, stable in product production and free of pollution to environment.

Owner:陈治勇

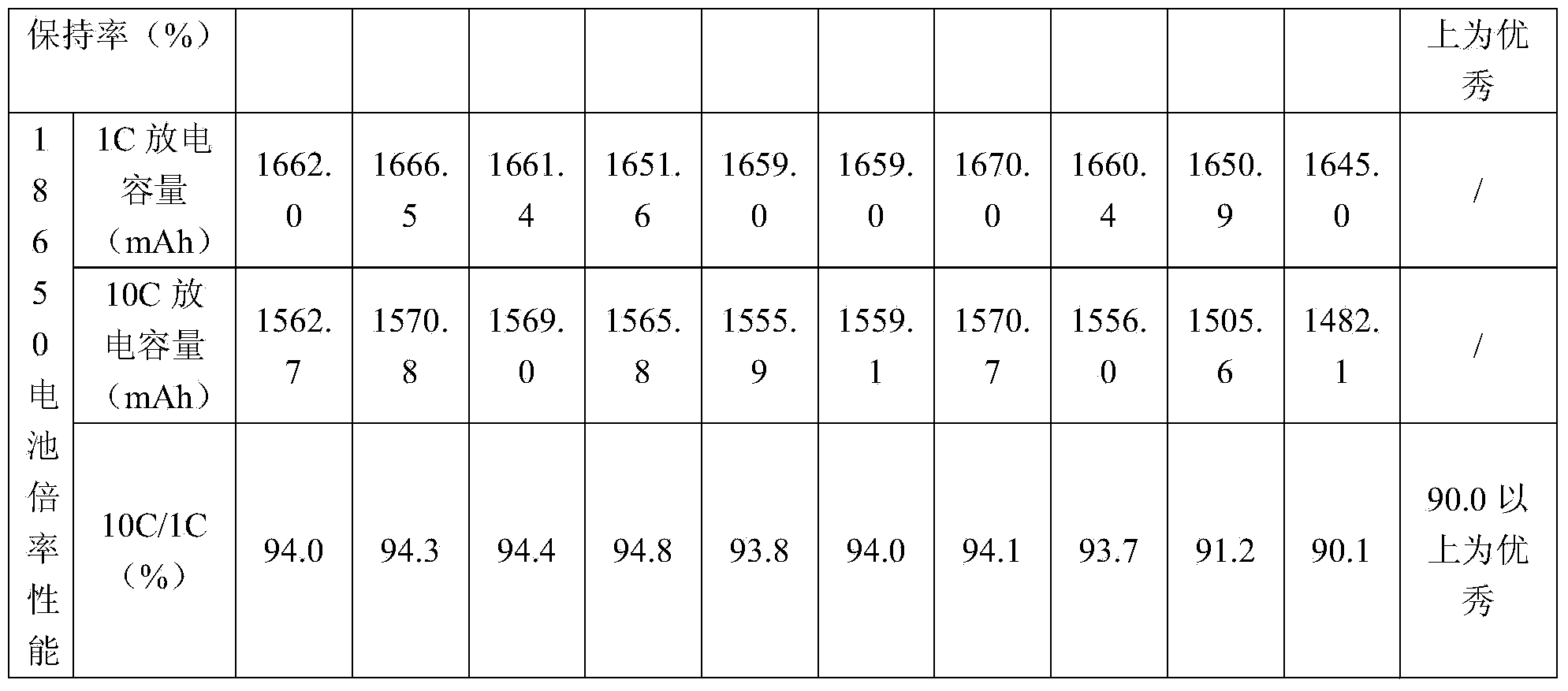

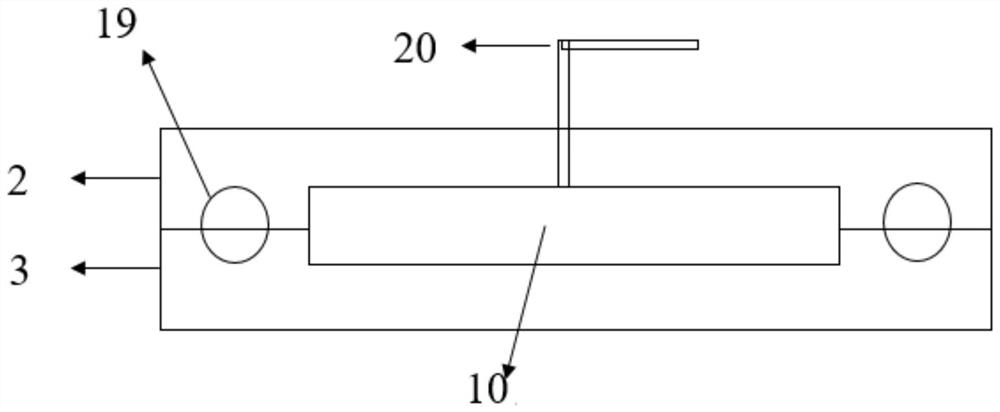

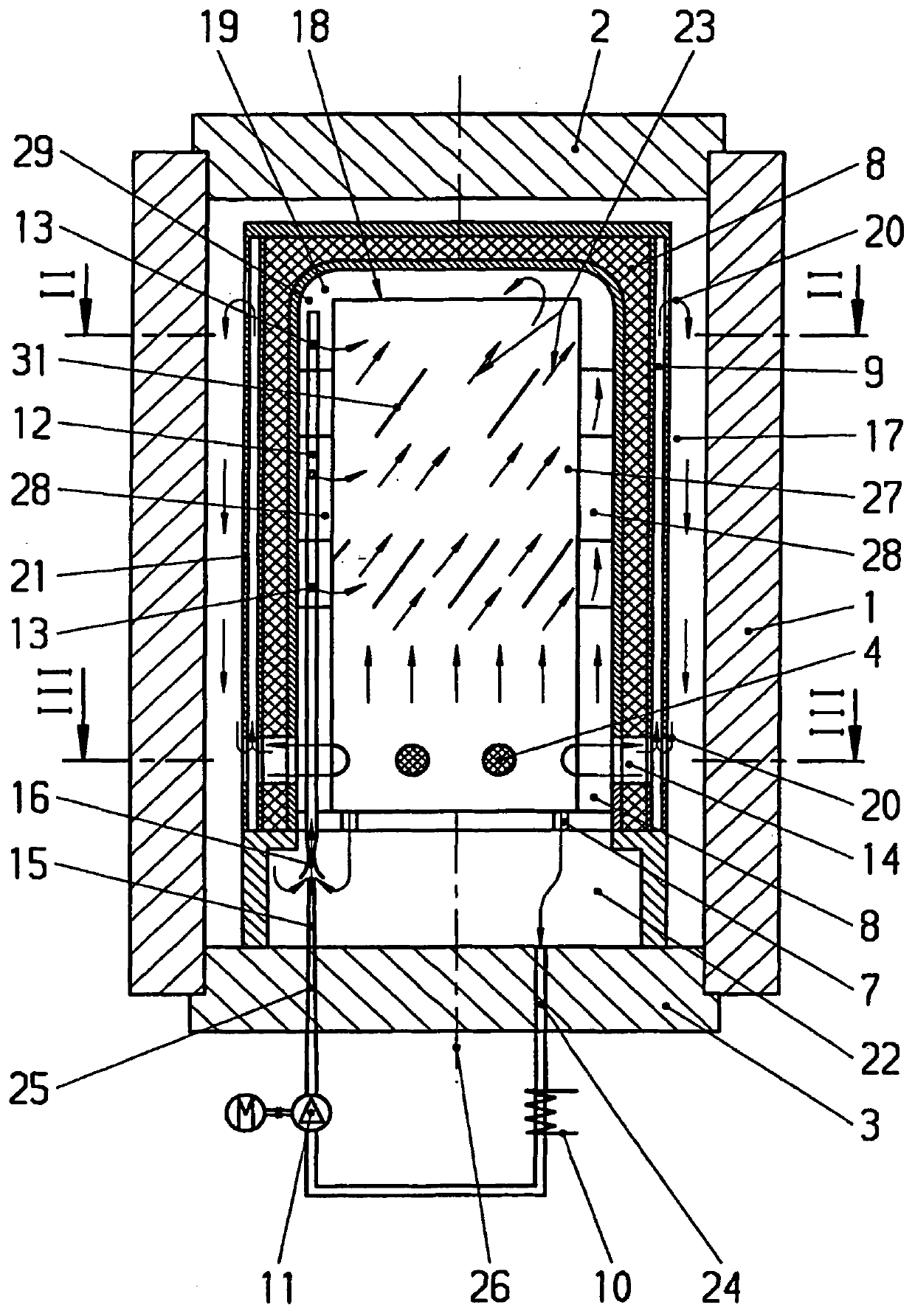

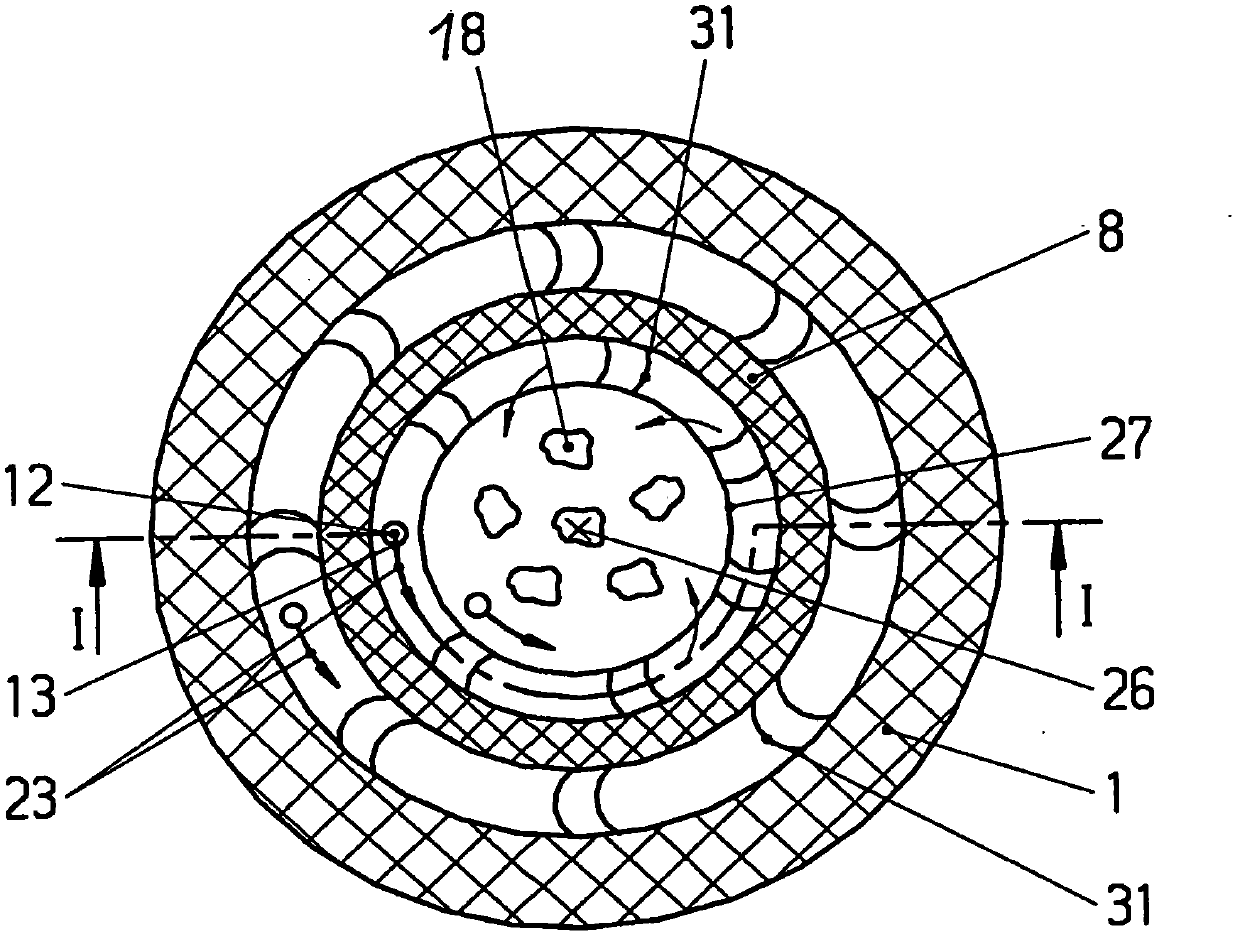

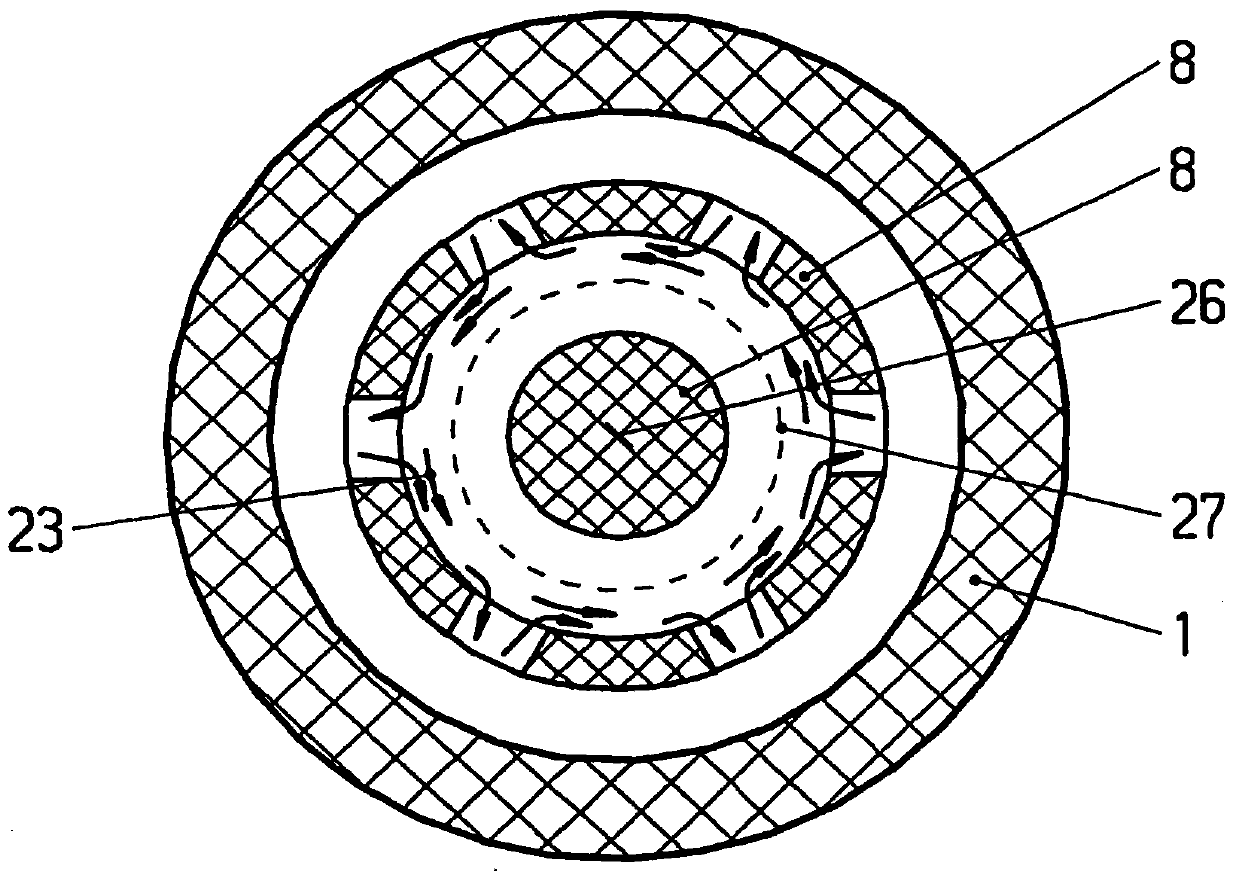

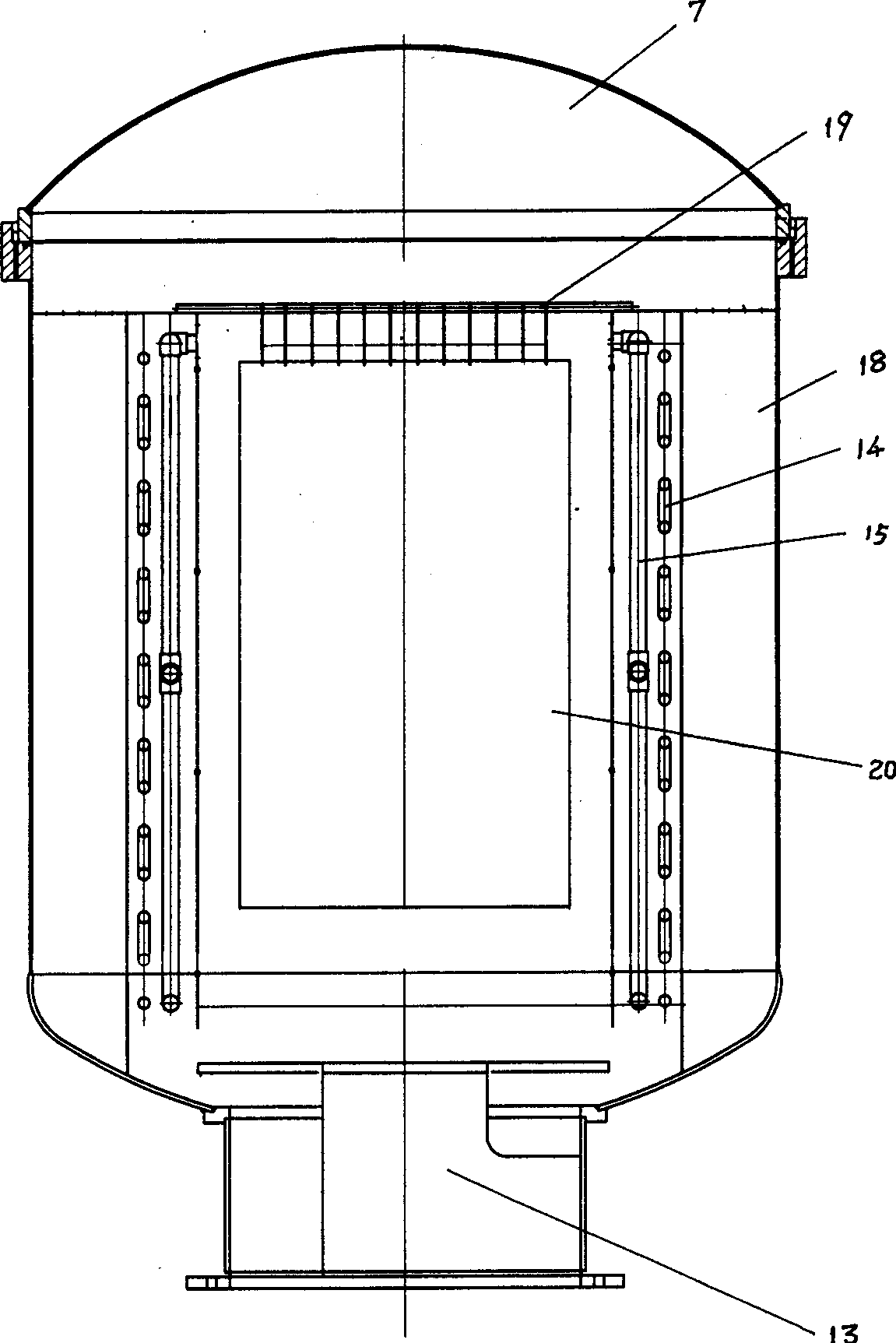

Method for controlling temperature of hot isobaric press and hot isobaric press

InactiveCN102282010APrecise process controlExcellent and uniform temperature changeMuffle furnacesRetort furnacesEngineeringHeating element

A method for controlling the temperature of a hot isobaric press comprising a pressure vessel (1) having a charging zone (19) located inside and being arranged between the charging zone and the pressure vessel The heat insulator (8) between them, wherein, the heating element (4) and the charging area (19) with the charging device (18) are arranged in the heat insulator (8). Therein, in addition to at least one existing natural or activated convection for heating or cooling or for maintaining the temperature level, at least one swirl (23) is actively or passively formed in the pressure vessel (1). An independent or also suitable hot isobaric press for this method is characterized in that in the pressure vessel (1) there are arranged active or passive means for forming a swirl (23) which occurs essentially at an angle to the convection device.

Owner:克莱默热处理设备公司

Industrial slag salt harmless treatment device and application method thereof

ActiveCN107262506ACompact structureGuaranteed uptimeSolid waste disposalTransportation and packagingVulcanizationSlag

The invention discloses an industrial slag salt harmless treatment device. A vulcanization dryer is connected with a first spiral conveyor and a first middle tank, and communicates with a first cyclone separator by a first conveying pipe; the top of a temporary storage tank communicates with the vulcanization dryer; a crushing screener is arranged under the temporary storage tank, and communicates with the same; a second middle tank is arranged on one side of a feeding tank, and communicates with a second cyclone separator and a fan in sequence; the bottom of the second cyclone separator communicates with the second middle tank; a third middle tank, a fourth middle tank and a calcining tower are arranged under the second middle tank; the third middle tank and the fourth middle tank respectively communicate with the second middle tank; the bottoms of the third middle tank and the fourth middle tank both communicate with the calcining tower by sixth conveying pipes; the sixth conveying pipes are aslant arranged; and the third middle tank and the fourth middle tank both communicate with the calcining tower by pressure guide pipes. The device is simple in structure and stable and efficient in equipment operation. The invention further discloses an application method of the device.

Owner:安徽今朝环保科技有限公司

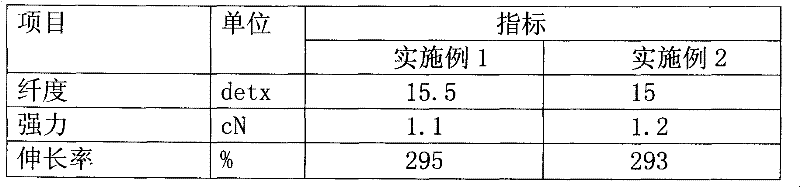

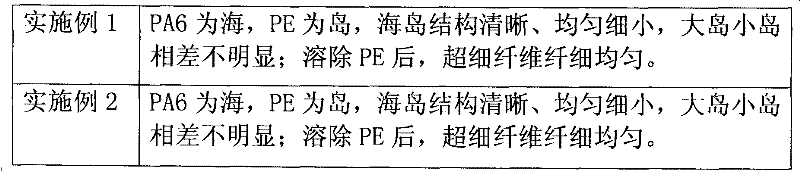

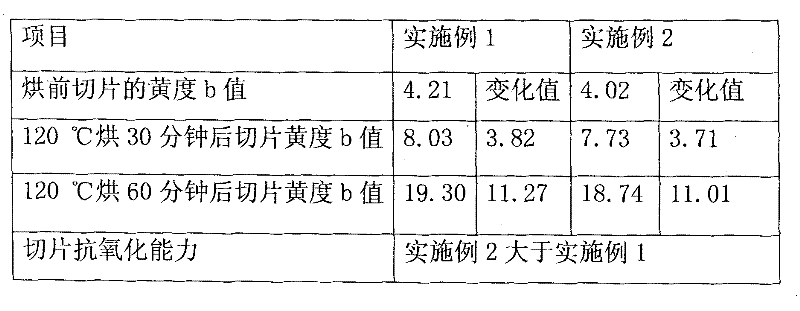

Nylon 6 slices for superfine sea-island fibers and manufacturing method thereof

InactiveCN102199285AGood matching of melt viscositySimple preparation processConjugated synthetic polymer artificial filamentsFiberNylon 6

The invention belongs to the field of spinning slices, and particularly relates to nylon 6 slices for superfine sea-island fibers and a manufacturing method thereof. The nylon 6 slices are formed by polymerizing caprolactam and an aid in a ratio of 1,000:(7-10), wherein the aid is prepared from a dicarboxylic acid end-capping reagent, water, an amine end-capping reagent and isophthaloyl dipiperidino amine according to a ratio of (3-6):(40-60):(3-6):(10-40). The method is simple in a preparation process, high in operability, reasonable in proportioning of each component and accurate in process control in the polymerization process, and the compounded end-capping reagents are adopted, so the nylon 6 slices for the superfine sea-island fibers are high in matching with polyethylene melt viscosity and stable in performance and have a wide market prospect.

Owner:WEIHAI HUAWANG NYLON CHEM

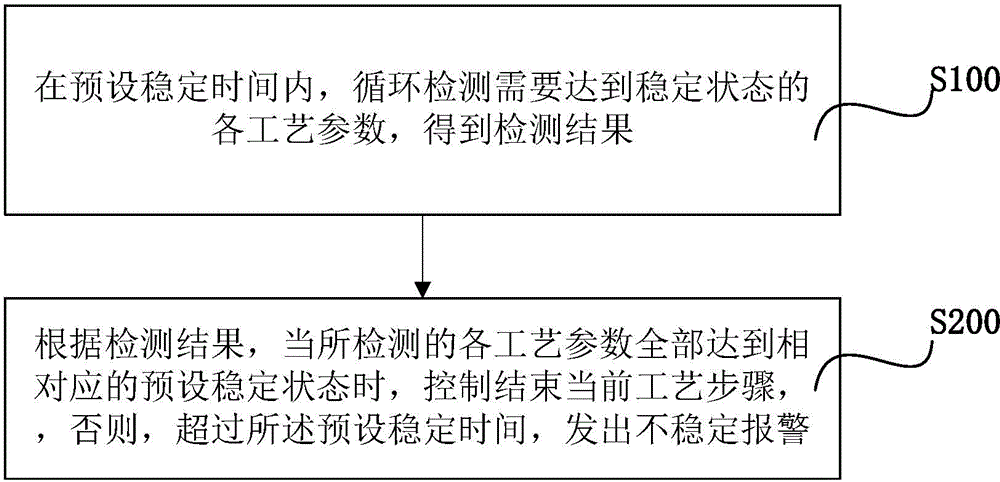

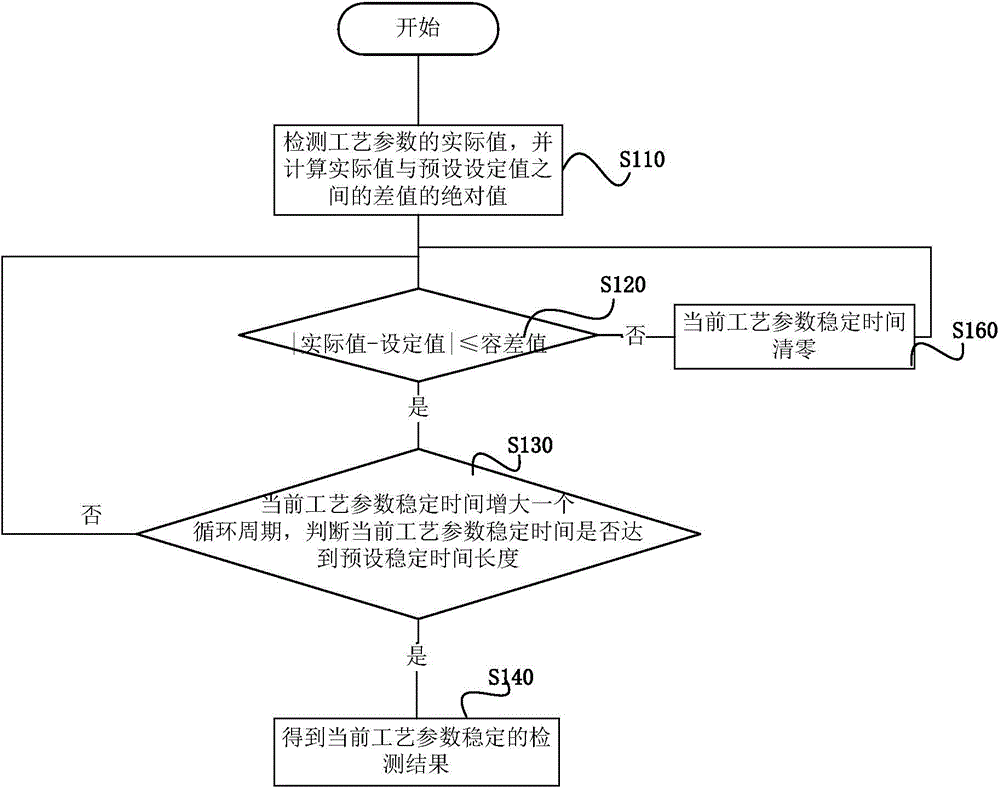

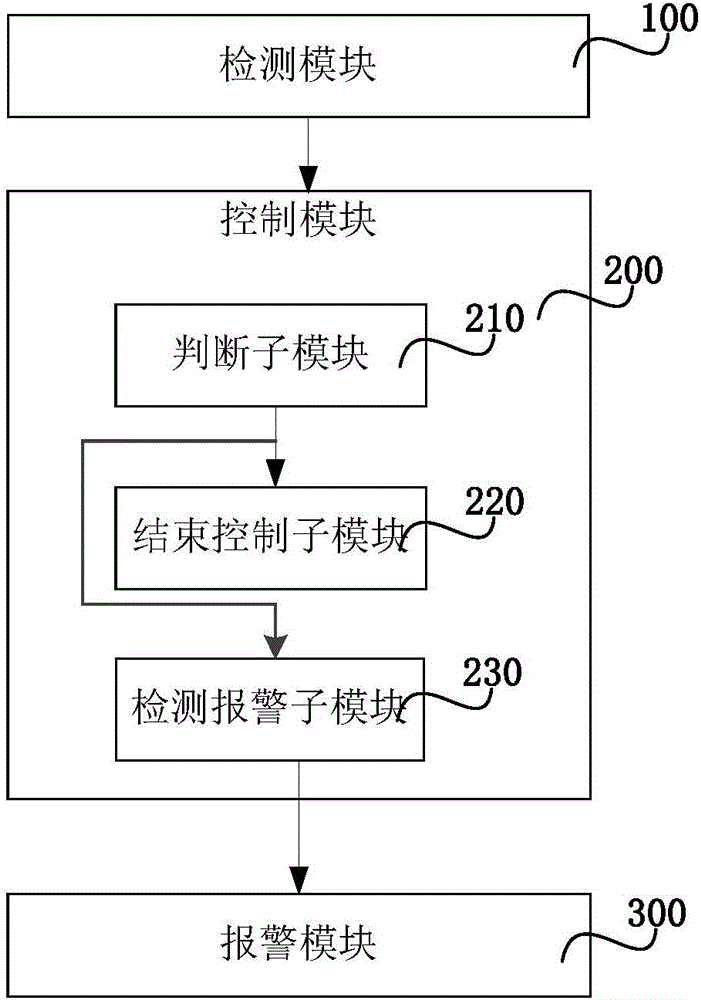

Method and system for technological control

ActiveCN104950828AReduce processing timeIncrease productivitySemiconductor/solid-state device manufacturingTotal factory controlStable stateSimulation

The invention discloses a method and system for technological control. The method comprises the following steps: detecting all technological parameters of a needed steady state in a preset stable time, and obtaining a detection result; controlling the ending of a current technological step according to the detection result when all the detected technological parameters reaches the corresponding preset steady state, or giving a unsteady alarm when the preset steady time is exceeded. According to the actual progress condition of the technological steps, the ending of the technological steps is controlled, and there is no need to preset a longer technological machining time, thereby shortening the technological machining time of a semiconductor, and improving the overall production efficiency. Meanwhile, the method and system prevent the setting of a fixed ending time from causing a condition of unsteady technological parameters under certain special conditions during the switching to a next step, and are more precise in technological ending control.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

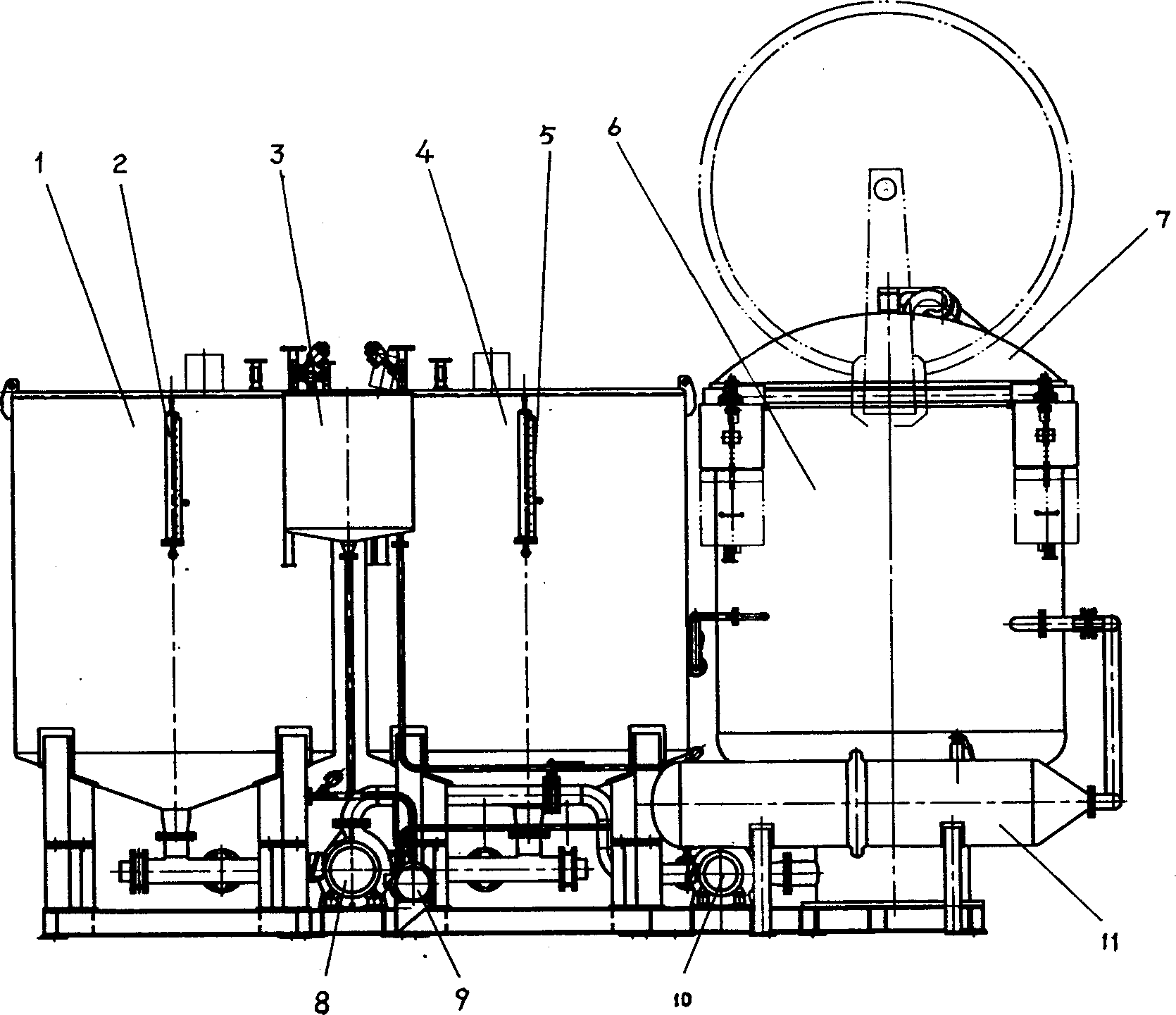

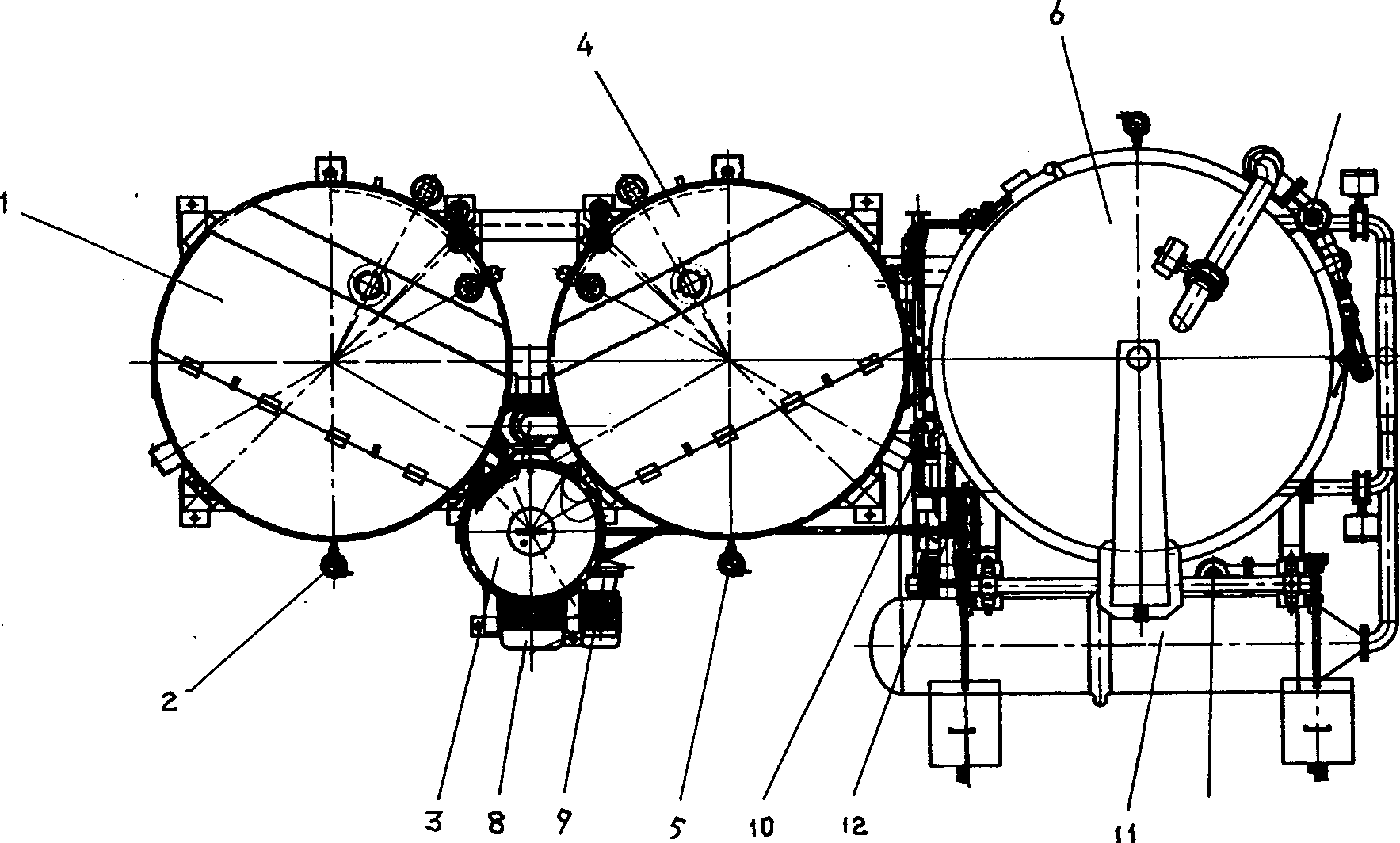

High temperature silk refining machine

InactiveCN1350084APrecise process controlRefining time shortenedLiquid/gas/vapor textile treatmentElectric controlVertical cylinder

The present invention relates to a real silk high-temp. intermittent refiner, including, including main refining cylinder, heat exchanger, main circulating pump, a rationing barrel, two preliminary cylinders, charging pump and preliminary cylinder pump, in which the main refining cylinder is a high-temp. one, including vertical cylinder body, cylinder cover and silk-hanging device. in the interior of cylinder body and nearby inner wall the hot-water intake pipes are distributed, and the cylinder bottom is equipped with a liquor outlet. All the components are connected by means of pipe, every pipeline is equipped with electric control valve, all the pumps and valves are controlled by microcomputer, and its highest working temp, can be to 126 deg.C. After the grey silk is hung in the refining cylinder ,its refining process includes the steps of refining, finishing scouring, rinsing, acid rinsing and water-washing.

Owner:浙江金达创业股份有限公司 +1

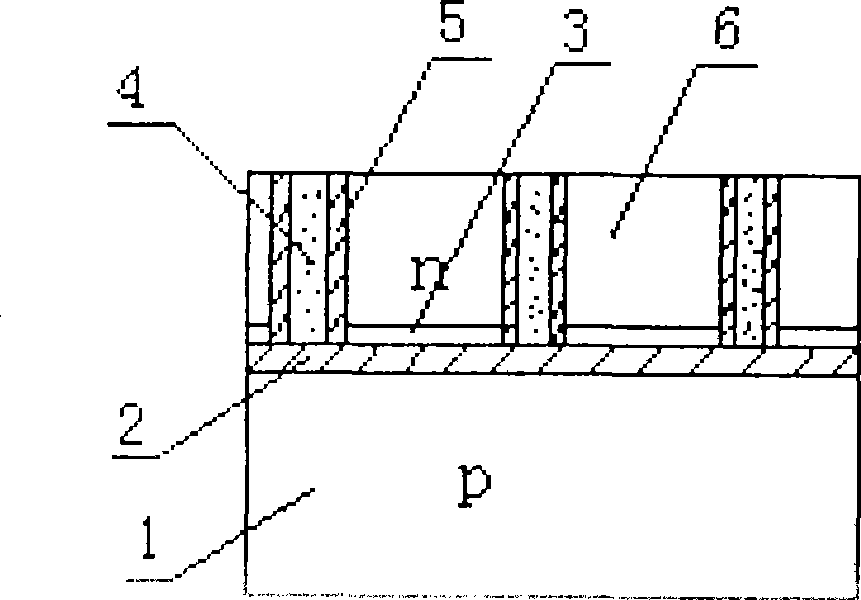

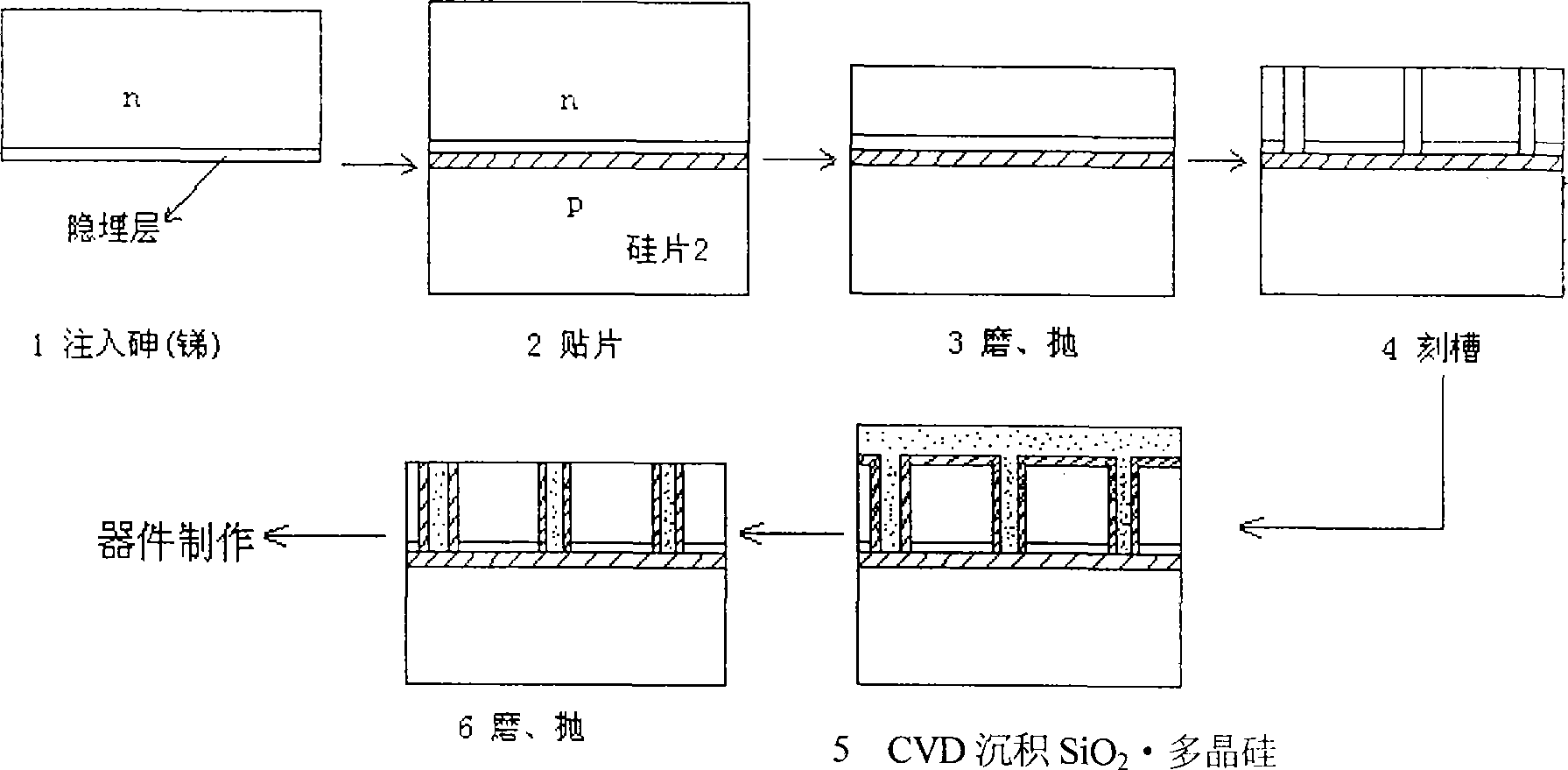

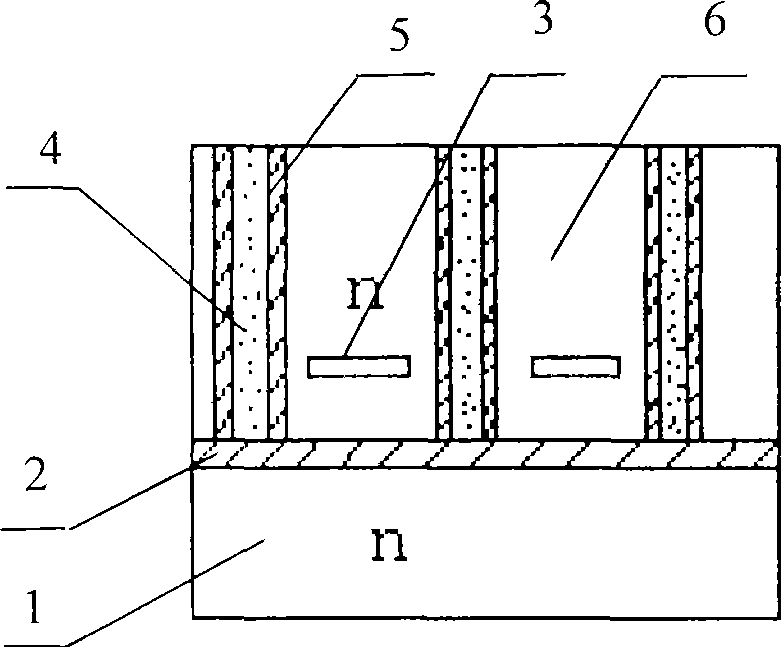

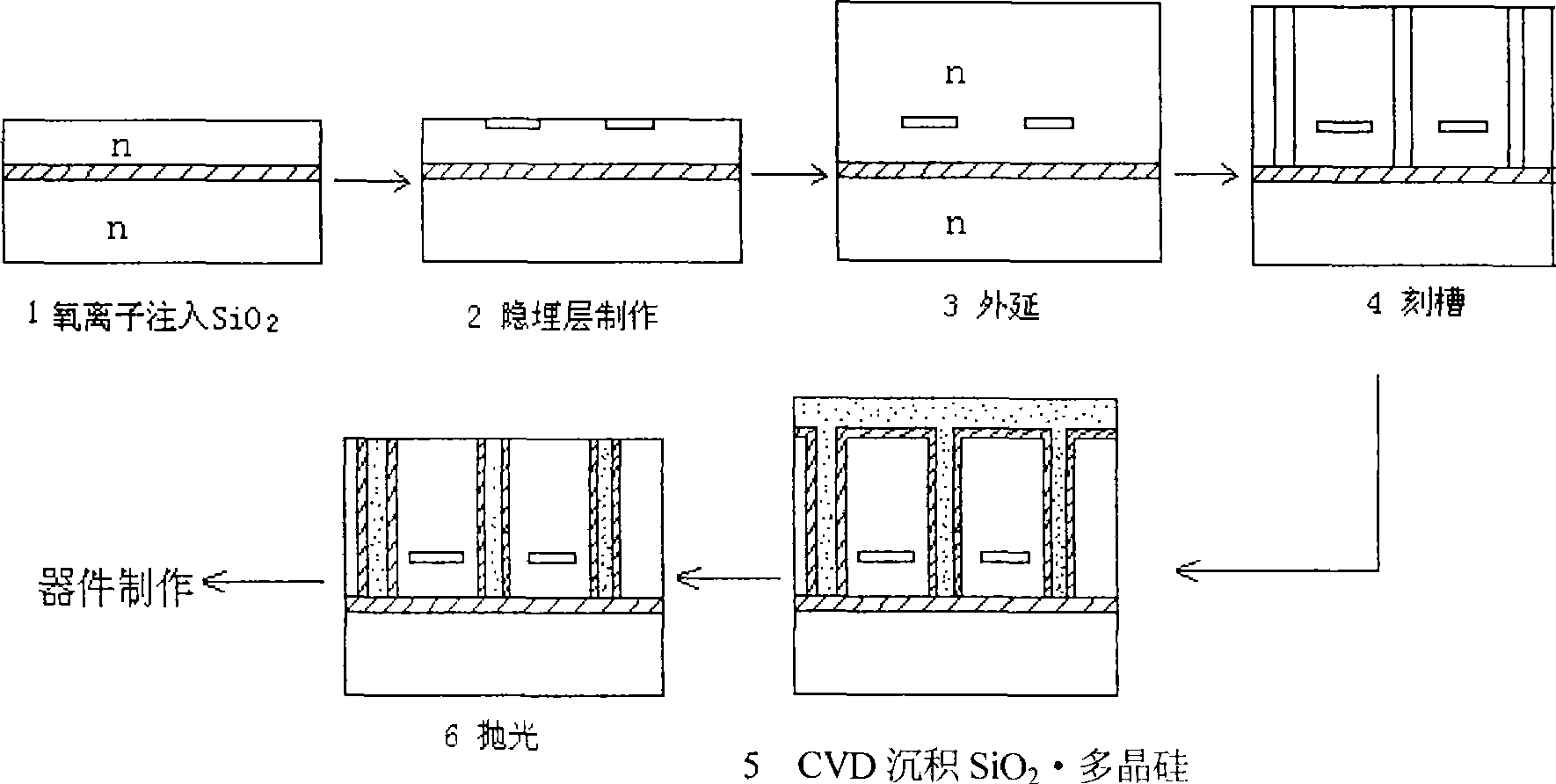

Dielectrically isolated integrated circuit silicon chip and preparation method thereof

InactiveCN101465357AImprove performanceImprove performance parametersSolid-state devicesSemiconductor/solid-state device manufacturingSingle crystalP type silicon

The invention mainly relates to a preparation method of a dielectric isolation silicon chip. An N-type / P-type dielectric isolation integrated circuit silicon chip is mainly characterized in that the integrated circuit silicon chip is provided with an N-type / P-type substrate silicon chip (1) and an N-type / P-type silicon monocrystal layer (6); a sandwiched oxide layer (2) is arranged on the N-type / P-type substrate silicon chip (1); a buried layer (3) is arranged inside the silicon monocrystal layer (6); the silicon monocrystal layer (6) is separated into mutually insulated isolation cubic blocks through silicon dioxide (5), polysilicon (4) and the sandwiched oxide layer (2). The invention also discloses a preparation method of the N-type / P-type dielectric isolation integrated circuit silicon chip; and the method comprises the steps of buried layer preparation, patching, grinding, polishing and grooving. Because the high-temperature time is greatly shortened in the preparation, the crystal structure is more integrated and the process control is more accurate, and high-performance circuits with special requirements can be produced. The resistivity of the single chip is appropriately increased, so that high (power)-voltage circuits can be produced with a certain power output.

Owner:TIANSHUI HUATIAN MICROELECTRONICS

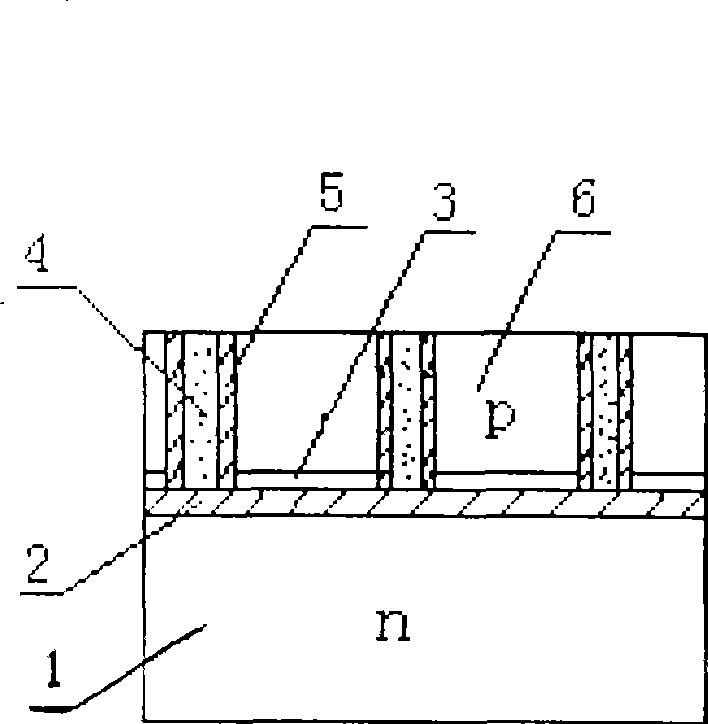

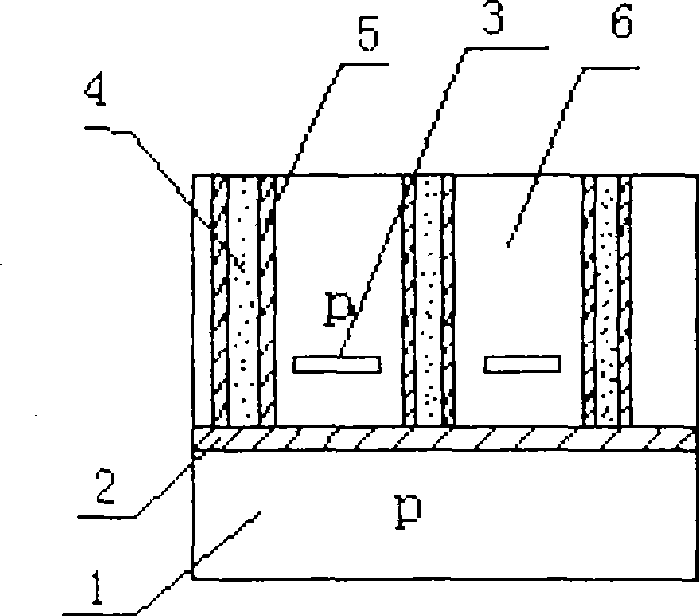

Dielectrically isolated integrated circuit extending wafer and preparation method thereof

InactiveCN101425522AImprove performanceImprove high temperature resistanceSolid-state devicesSemiconductor/solid-state device manufacturingCrystal structureSilicon dioxide

The invention mainly relates to a dielectric isolation epitaxial wafer and a preparation method thereof. The N-shaped / P-shaped dielectric isolation integrated circuit epitaxial wafer comprises N-shaped / P-shaped monocrystalline silicon (1) with backing material. A sandwich oxide layer (2) is arranged on the monocrystalline silicon (1). The invention is mainly characterized in that the dielectric isolation epitaxial wafer further comprises an N-shaped / P-shaped silicon epitaxial layer (6); a buried layer (3) is arranged in the silicon epitaxial layer (6); the silicon epitaxial layer (6) is divided into mutually-insulating isolation blocks by silicon dioxide (5), polysilicon (4) and the sandwich oxide layer (2). The invention also discloses a preparation method of the N-shaped / P-shaped dielectric isolation integrated circuit epitaxial wafer. The preparation method comprises the following steps: preparing a silicon chip on an insulating body, preparing the buried layer with low resistance, extending outwardly, notching, growing the silicon dioxide and the polysilicon, and polishing. Because the high temperature time is shortened greatly during the preparation, the invention has the advantages of more complete crystal structure and more accurate process control, and can be used for manufacturing circuits with high performance and special requirements.

Owner:TIANSHUI HUATIAN MICROELECTRONICS

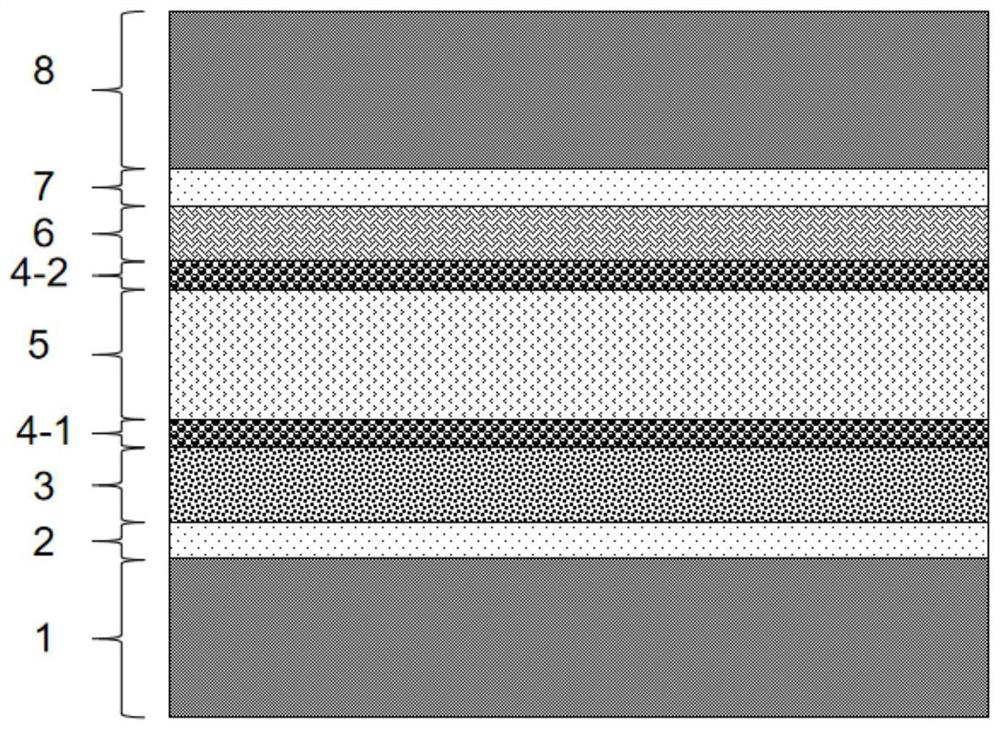

Flexible electrochromic device and preparation method thereof

ActiveCN113253533AQuality improvementImprove moisture resistanceNon-linear opticsSolid state electrolyteHeat resistance

The invention discloses a flexible electrochromic device and a preparation method thereof. The flexible electrochromic device comprises a first flexible base material, a first conductive layer, an electrochromic layer, a quasi-solid electrolyte layer, an ion storage layer, a second conductive layer and a second flexible base material which are sequentially laminated, and further comprises a buffer dielectric layer arranged on at least one side of the quasi-solid electrolyte layer. According to the flexible electrochromic device, the buffer dielectric layer is arranged on at least one side of the quasi-solid electrolyte layer, and the buffer dielectric layer can adsorb water, so that the influence of water on the flexible electrochromic device in the preparation and use processes of the flexible electrochromic device is prevented, and the quality, damp and heat resistance and other aging properties of the flexible electrochromic device are improved, so that the actual service life of the device is prolonged.

Owner:CHINA LUCKY FILM CORP

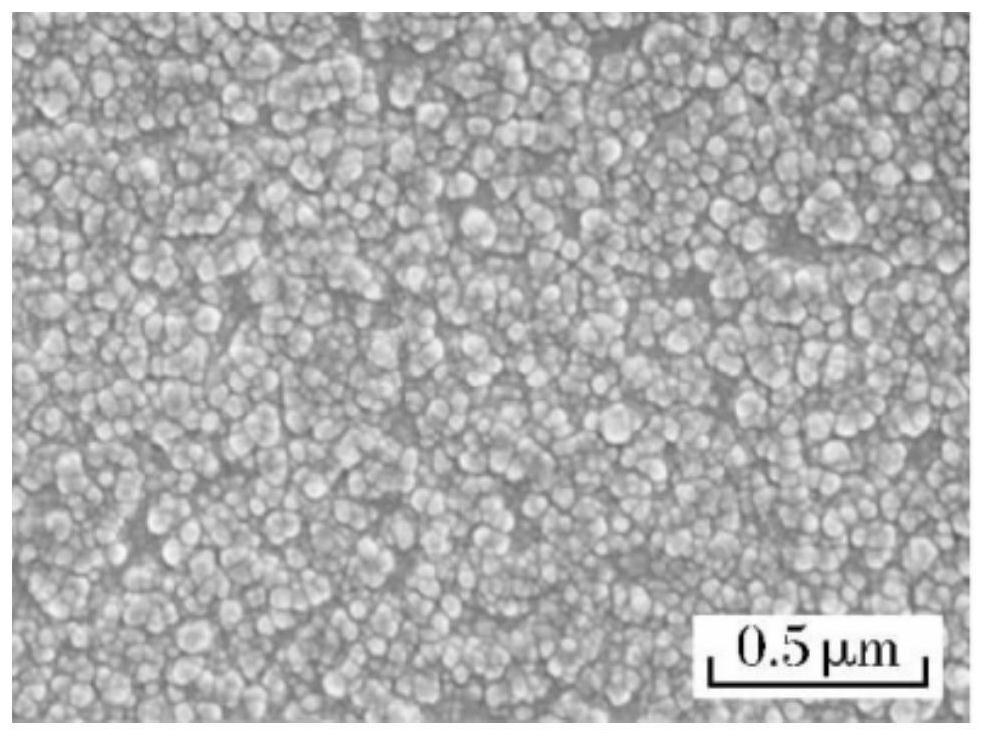

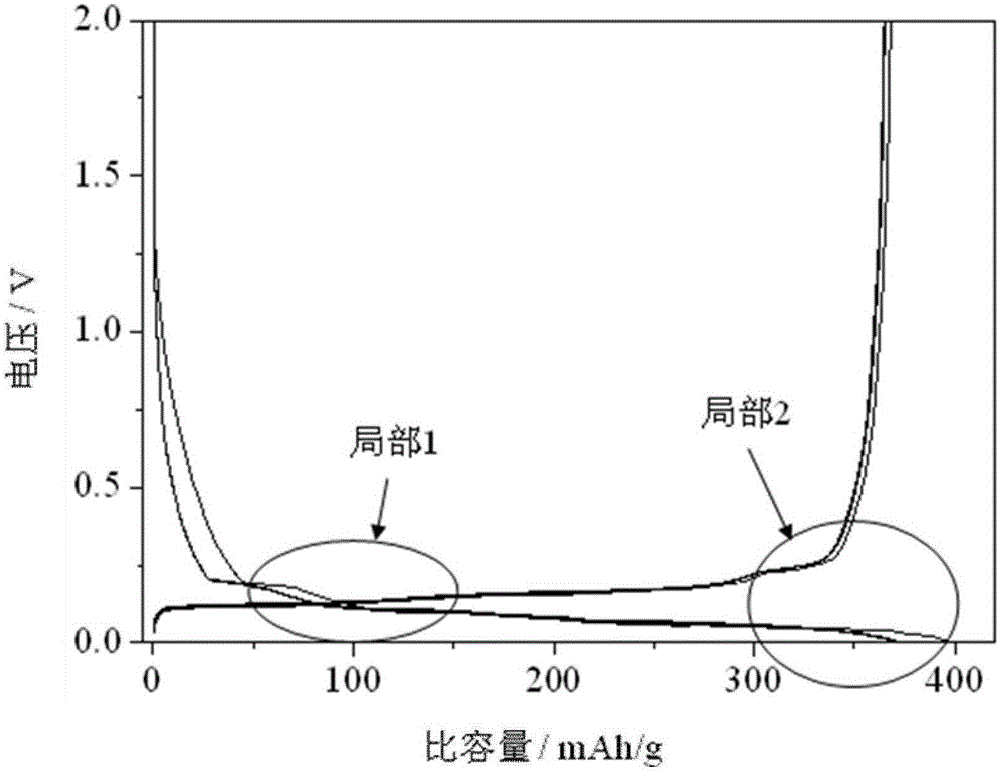

Graphite composite negative electrode material for lithium ion battery, preparation method and lithium ion battery

ActiveCN103247802BImprove conductivityIncrease specific energyCell electrodesSecondary cellsAluminium-ion batteryElectrical battery

The invention discloses a graphite composite negative electrode material for a lithium ion battery, a preparation method of the material, and the lithium ion battery. The graphite composite negative electrode material for the lithium ion battery has a core-shell structure, wherein graphite is used as an inner core; carbon nano tubes and / or carbon nanofibers which are uniformly distributed on the surface of the graphite and are in in-situ growth are used as the shell; the growth root points of the carbon nano tubes and / or the carbon nanofibers are in tight contact with the surface of the graphite; and the other ends of the carbon nano tubes and / or the carbon nanofibers are distributed on the surface of the graphite randomly. The preparation method comprises the following steps of: fully soaking the graphite as a raw material by a catalyst-containing solution, and drying to obtain a graphite composite material precursor; performing chemical vapor deposition to generate the carbon nano tubes and / or the carbon nanofibers; and finally performing the purification and annealing treatment. The graphite composite negative electrode material has high height ratio, conductivity, and rate capability, and excellent solution absorption performance and cycle performance; and the method is simple in production flow, accurate in process control, low in cost, free from severe conditions, and easy to realize the industrialization.

Owner:BTR NEW MATERIAL GRP CO LTD

Sodium pyroborate iron black crystalline glaze and preparation method thereof

The invention relates to a sodium pyroborate iron black crystalline glaze and a preparation method thereof, and belongs to the technical field of ceramics. The sodium pyroborate iron black crystalline glaze is prepared from the following raw material components in percentage by mass: 35.5 to 38.5 % of sodium pyroborate, 21.5 to 25.5% of potassium feldspar powder, 14.5 to 16.5% of silicon dioxide, 6.6 to 7.6% of lithium carbonate and 11.9 to 21.9% of ferric oxide; the sodium pyroborate iron black crystalline glaze can also be prepared from 1.9 to 2.5% of manganese dioxide and 1 to 1.5% of cobalt oxide. The sodium pyroborate iron black crystalline glaze has the advantages that the particular ceramic glaze art effect is realized, and the silver metal bright spot texture is formed on a black ceramic glaze surface; by adding the sodium pyroborate into the sodium pyroborate iron black crystalline glaze, the required amount of a melting agent is effectively reduced, and the amount of raw materials in the components is reduced; air bubbles on the glaze surface are also prevented by the sodium pyroborate; after long-time experiment at the temperature of minus 30 DEG C, the crack or falling of the glaze surface is avoided, and the corrosion by common acid and alkaline is resisted.

Owner:潮州市维欧陶瓷有限公司

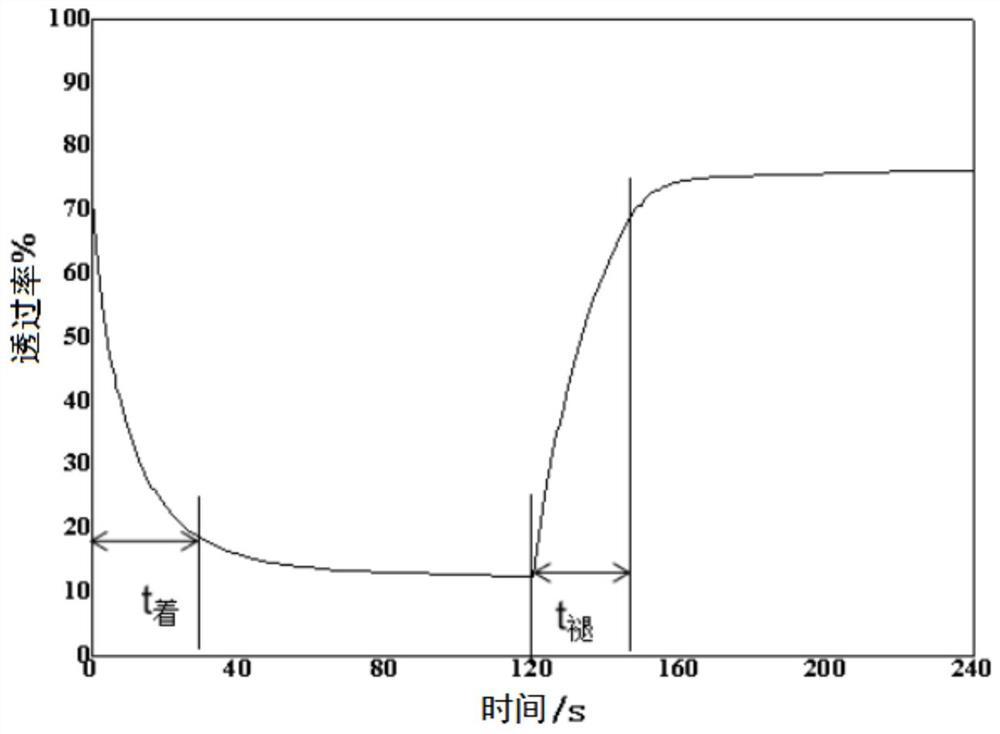

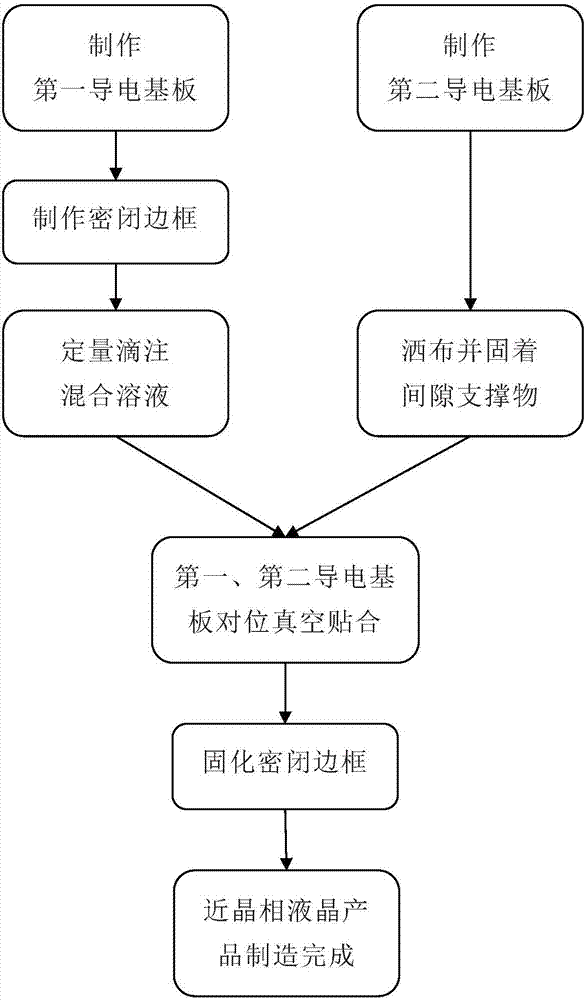

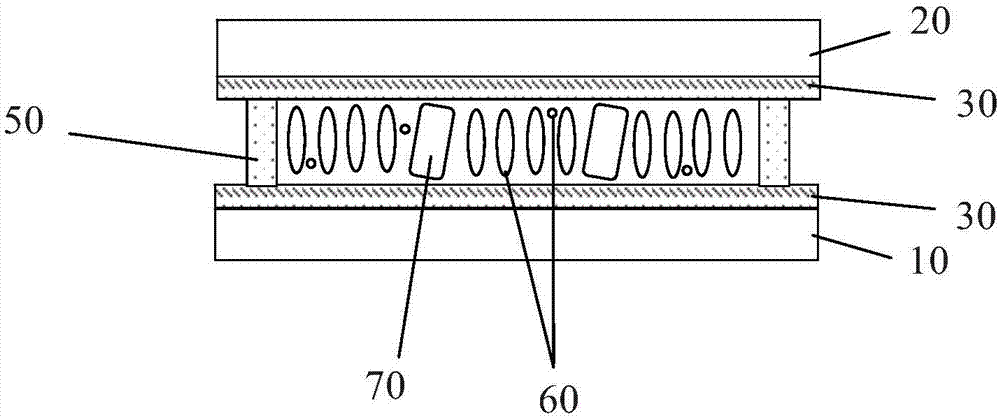

Manufacturing technology for smectic phase liquid crystal product

InactiveCN107402479AReduce consumptionPrecise process controlNon-linear opticsManufacturing technologyLiquid state

The invention discloses a manufacturing technology for a smectic phase liquid crystal product. The manufacturing technology comprises the followings steps of preparing a first and second conductive substrates, simultaneously executing the following two steps of coating side frame glue to the first conductive substrate to prepare a sealed side frame and dipping viscosity-reduced liquid-state mixed solution into the sealed side frame in a quantitative way, and spraying gap supporting articles on the second conductive substrate and enabling the gap supporting articles to be distributed and fixed on the second conductive substrate, heating the first and second conductive substrate, counter-pointing and applying the first and second conductive substrates in a vacuumized way after the viscosity of the liquid crystal-state mixture is reduced again, solidifying the sealed side frame, and accomplishing the manufacturing of the smectic phase liquid crystal product. Realization of the method is conducted via a low-viscosity and quantitative dipping way; the technology can be precisely controlled; high production efficiency and guaranteed product quality can be achieved; and the smectic phase liquid crystal consumption is little and the product size is free of limitations.

Owner:HALATION PHOTONICS CORP

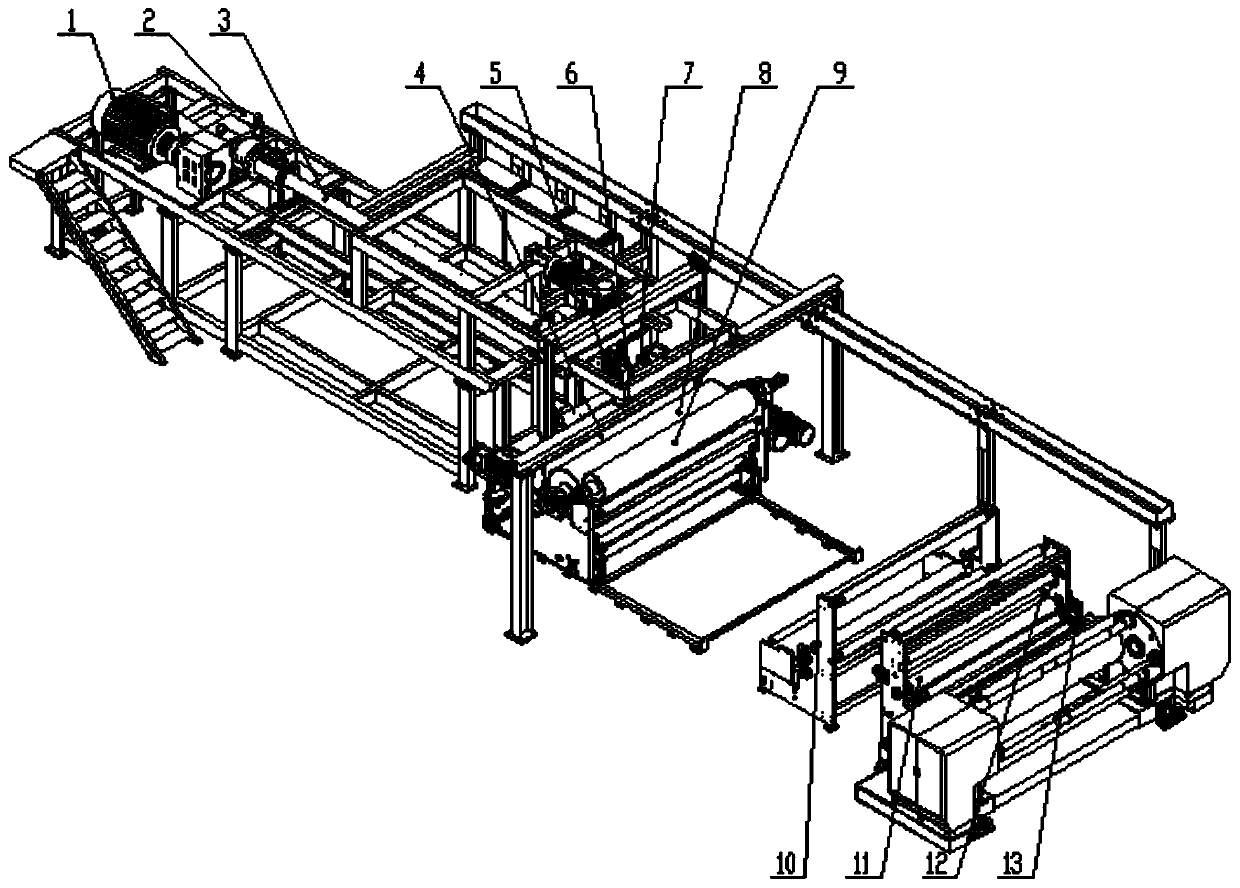

PE casting machine capable of realizing longitudinal drawing

The invention discloses a PE casting machine capable of realizing longitudinal drawing. The PE casting machine comprises a main machine unit, a casting unit, a corona cooling unit and a traction winding unit; the main machine unit comprises a main motor arranged at the upper end of a main machine support; the output end of one side of the main motor is in transmission connection with a transmission gearbox; an extruding machine is mounted at one end of the transmission gearbox; a screw sleeve is mounted at the discharging end of the extruding machine; a hopper is mounted on the upper side of the extruding machine; a continuous net changer is mounted at one end of the screw sleeve; a metering pump is mounted at one end of the continuous net changer; a compact type connecting elbow is arranged at the discharging end of the metering pump. According to the PE casting machine capable of realizing longitudinal drawing, the main extruding structure of the machine is compact, and the whole machine flow is designed in an optimized manner; full-closed-loop control is performed on the extrusion pressure and temperature, so that the stable conveying pressure is guaranteed; the whole machine adopts PLC for centralized control, data are monitored by the aid of a touch screen in real time, and remote maintenance and diagnosis are realized; and a non-stop pulse type automatic net drawing device is adopted, so that the pressure is constant during production, the quality is high, and waste products are few.

Owner:佛山市顺德区精卫科技有限公司

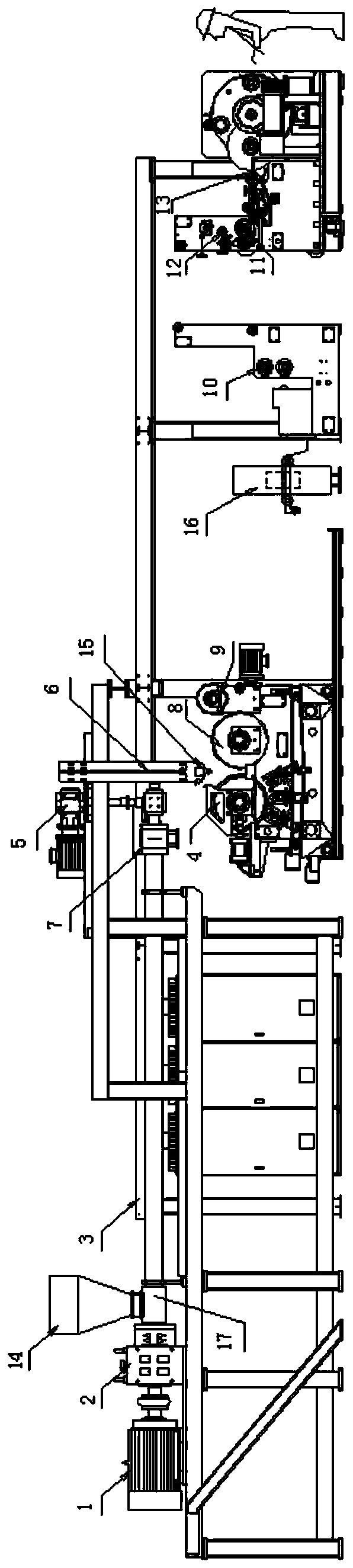

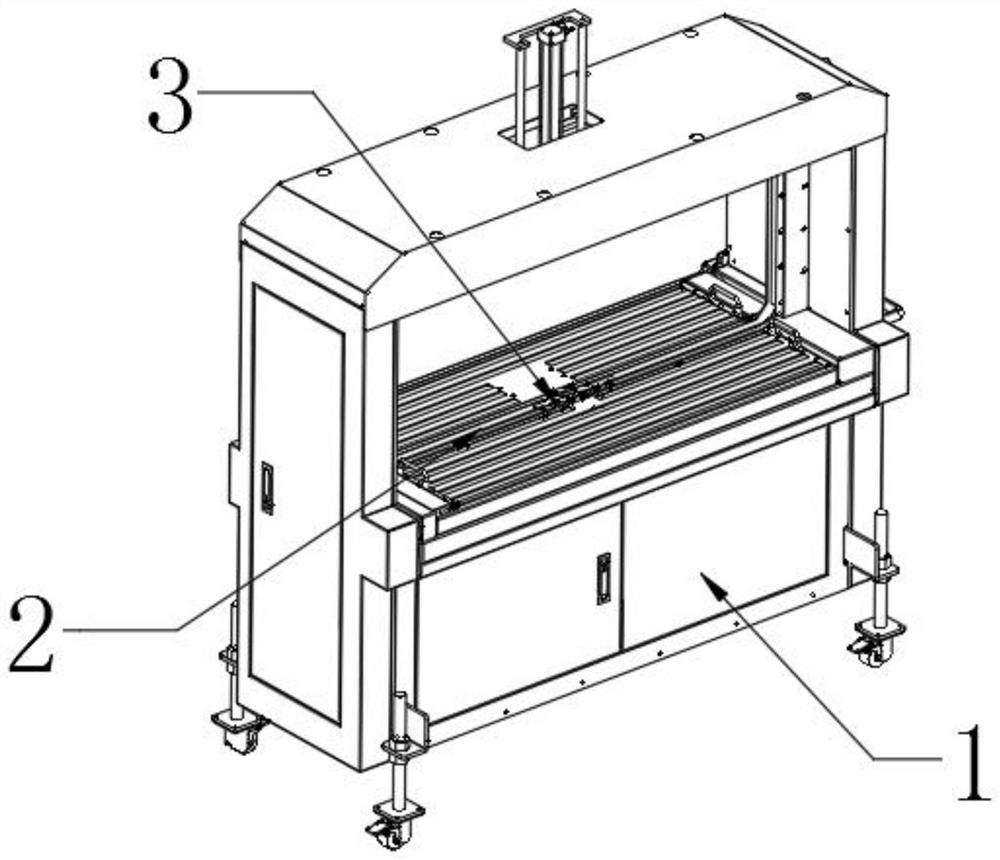

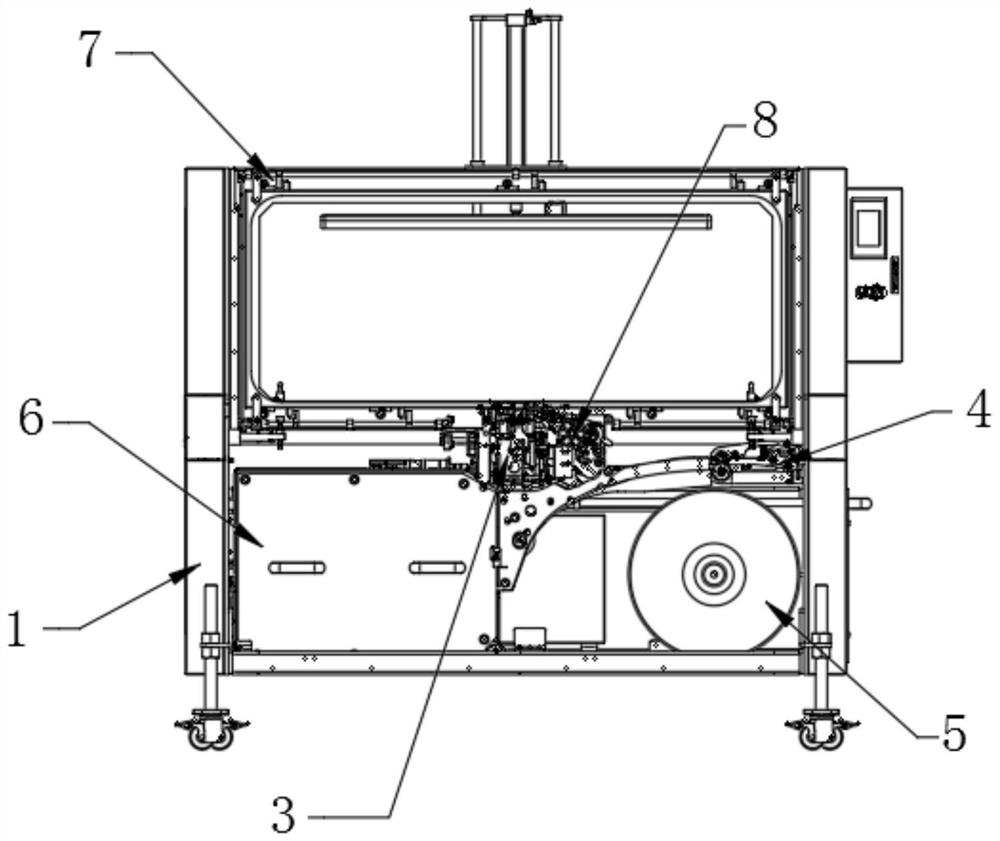

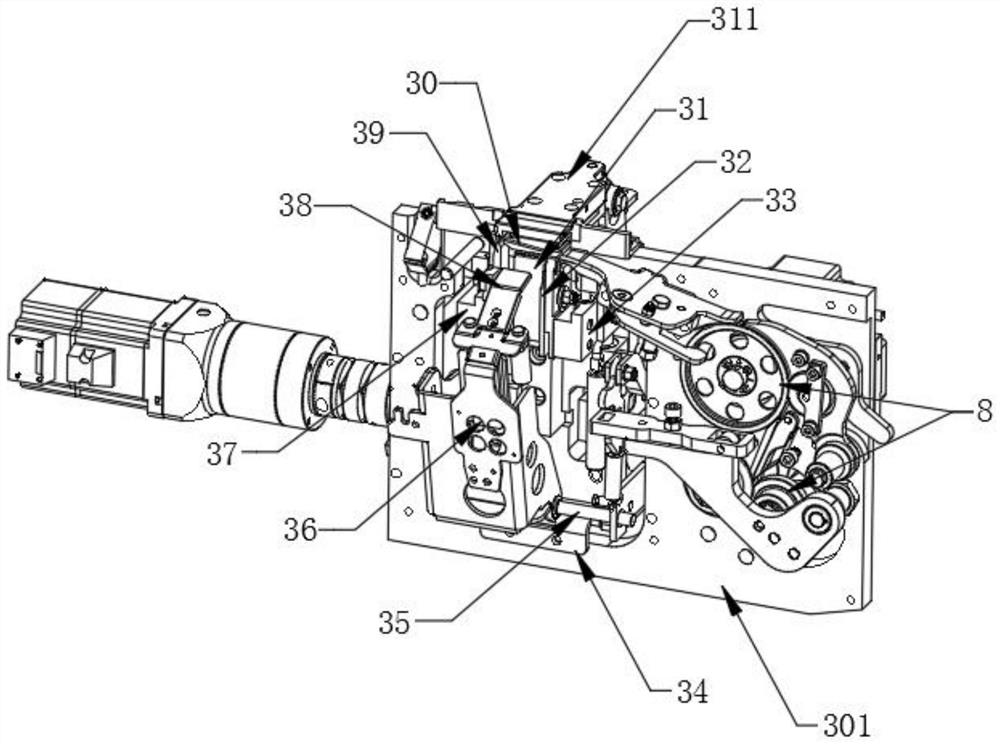

Full-automatic bundling and packing machine

PendingCN114194448ALow application costImprove work efficiencyBinding material applicationBundling machine detailsPhysicsEngineering

A full-automatic bundling and packing machine comprises a machine frame, a machine head module, a belt winding module, a belt advancing and retreating tensioning module, a belt feeding and penetrating module, a belt fence module and a belt rolling module, wherein the machine head module comprises a working group, the working group comprises a clamp arranged at the rear end of a belt conveying groove, a clamping die and a cutting die which are arranged on the two sides of the clamp respectively, a pressing die arranged at the lower end of the clamp, and a heating ironing head arranged on the front side of the clamp; the transmission set comprises a sliding connecting base used for enabling the clamp to move backwards to retreat from the belt conveying groove, a clamping connecting base used for driving the clamping die to eject upwards, a cutting connecting base used for driving the cutting die to eject upwards, a pressing connecting base used for driving the pressing die to eject upwards, and an ironing head swing rod used for driving the heating ironing head to be close to the clamp. The packaging machine has the characteristics of high speed, high efficiency and high reliability, meets the requirements of production lines of enterprises, and realizes rapid packaging of products.

Owner:广东科兴智能装备有限公司

A device and method for improving detection precision of oxidated layer thickness

InactiveCN100547754CAffect growthStable thicknessSemiconductor/solid-state device testing/measurementEngineeringLayer thickness

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

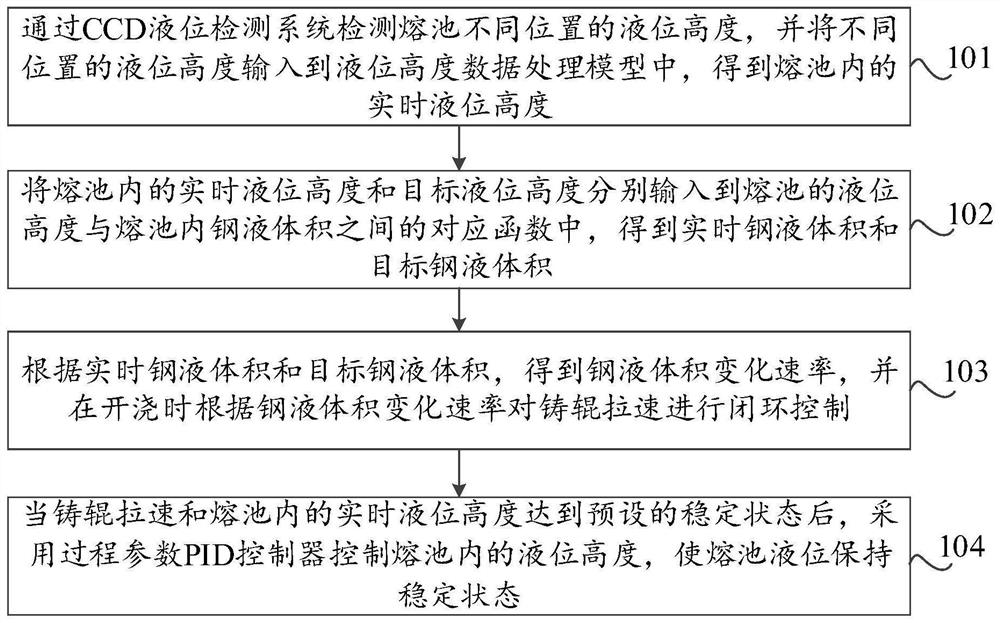

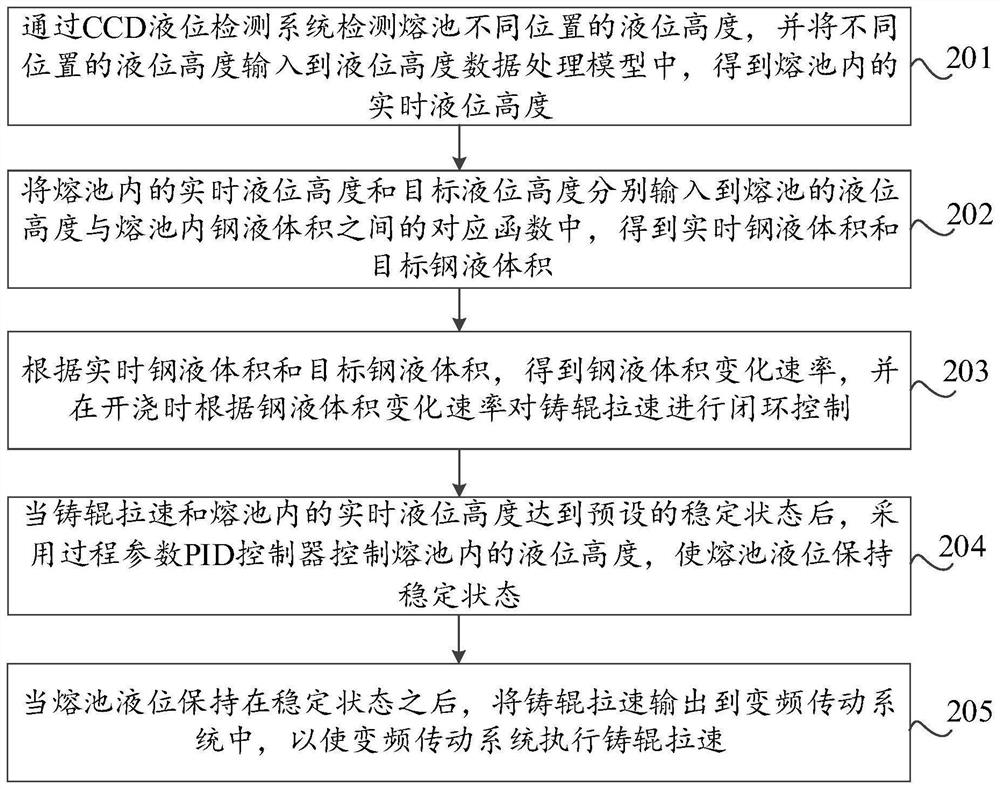

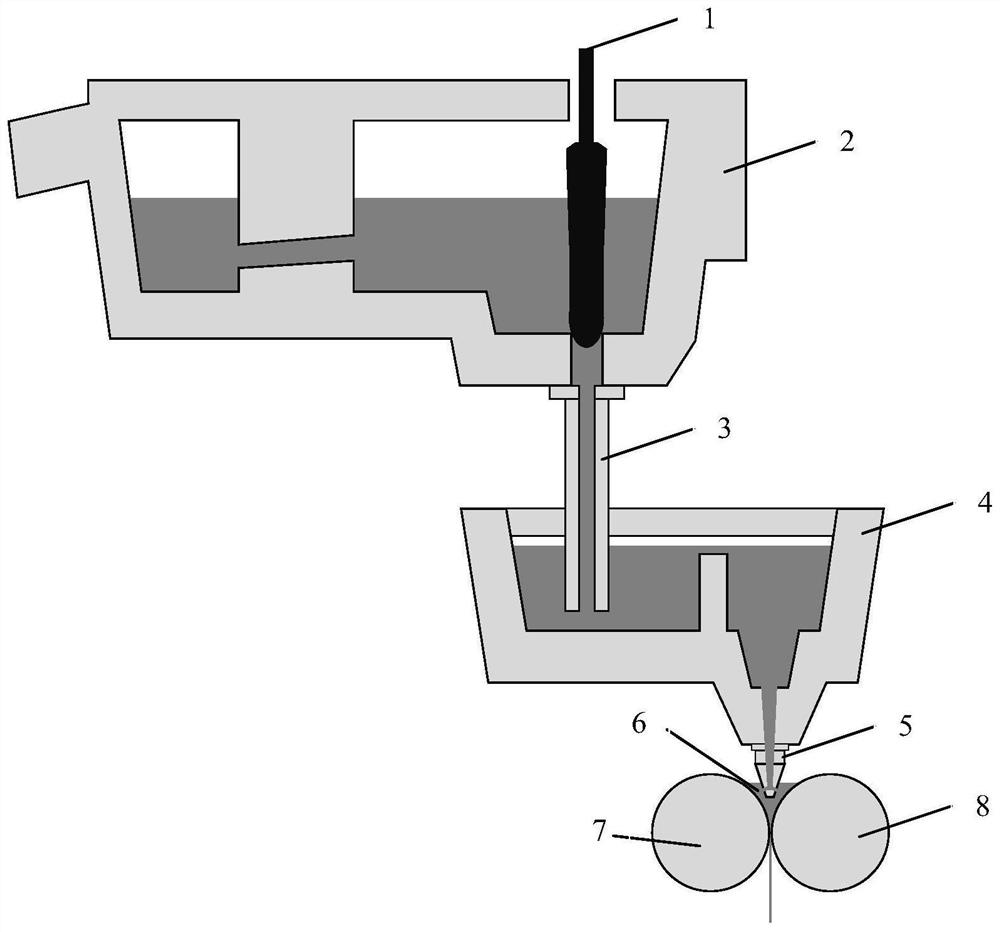

Thin-strip continuous casting molten pool liquid level control method and device based on CCD liquid level detection

The invention discloses a thin-strip continuous casting molten pool liquid level control method and device based on CCD liquid level detection, a storage medium and computer equipment. The method comprises the steps of: detecting the liquid level heights of different positions of a molten pool through a CCD liquid level detection system, inputting the liquid level heights of the different positions into a liquid level height data processing model to obtain the real-time liquid level height in the molten pool; respectively inputting the real-time liquid level height and a target liquid level height in the molten pool into a corresponding function between the molten pool liquid level height and the molten steel volume in the molten pool to obtain a real-time molten steel volume and a targetmolten steel volume; acquiring a molten steel volume change rate according to the real-time molten steel volume and the target molten steel volume, and carrying out closed-loop control on the castingspeed of a casting roller according to the molten steel volume change rate during casting; and after the casting roller pulling speed and the real-time liquid level height in the molten pool reach a preset stable state, a process parameter PID controller is adopted for controlling the liquid level height in the molten pool, and the liquid level of the molten pool is kept in the stable state. The method can improve the molten pool liquid level control precision.

Owner:NORTHEASTERN UNIV

A cold disinfection method for cip central control system of dairy product production line

ActiveCN104971373BImprove disinfection efficiencyReduce waiting timeCleaning using liquidsChemicalsProduction lineDisinfectant

The invention discloses a cold disinfection method for the central control system of a dairy product production line, which is used for cold disinfection treatment of milk collection pipelines, milk tank cars, raw material storage tanks and homogenizing machines, comprising the following steps: (1) opening the CIP central control system Carry out original cleaning of the production line, (2) empty the acid solution in the pickling tank in the CIP central control system, and input cold disinfectant; (3) adjust the pickling temperature to normal temperature through the CIP central control system, set the acid The washing process takes 8 to 15 minutes; the CIP central control system is turned on for a separate pickling process. (4) After the pickling in step 3, rinse with water for 3 to 5 minutes; (5) Drain the cold disinfectant in the pickling tank, rinse it, and then transport the acid solution discharged in step 2 back to the pickling tank . The cold disinfection method of the central control system of the present invention realizes automatic cold disinfection, greatly reduces the waiting time and disinfection time of the disinfection process, and improves the efficiency of CIP disinfection in the production process.

Owner:四川新华西乳业有限公司

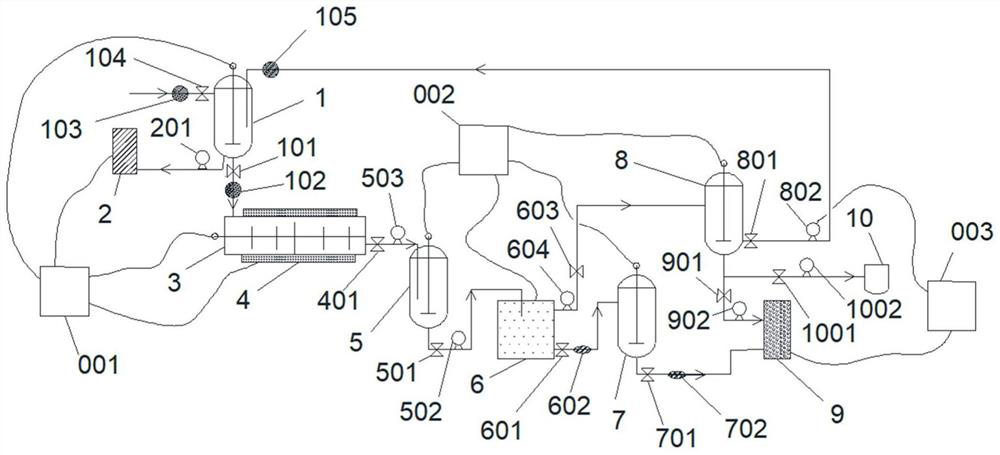

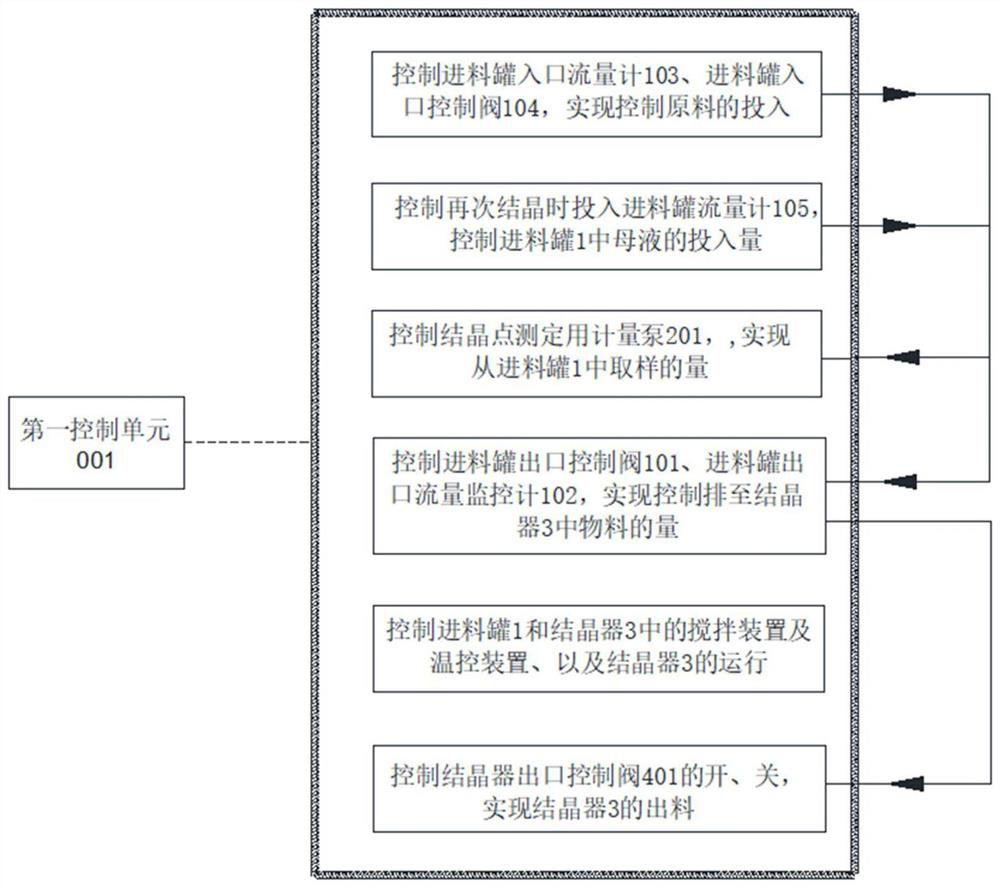

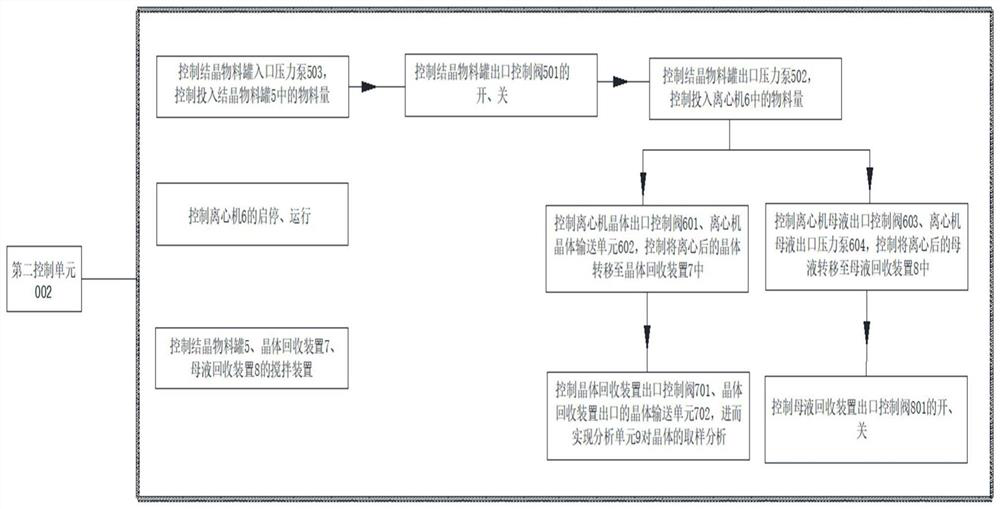

Automatic continuous thymol crystallization system and method

PendingCN114748888ASimple equipment structureImprove the scope of application of the processOrganic chemistryOrganic compound preparationProcess engineeringMother liquor

The invention provides an automatic continuous thymol crystallization system which comprises a feeding tank, a crystallizer, a temperature control device, a crystallized material tank, a centrifugal machine, a crystal recovery device, a mother liquor recovery device, a thymol content analysis unit and a waste liquor recovery tank which are connected with a control system, an outlet of the feeding tank is connected with a crystallization point measuring unit and an inlet of a crystallizer through pipelines, an outlet of the crystallizer is sequentially connected with a post-crystallization material tank and a centrifugal machine through pipelines, an outlet of the centrifugal machine is connected with a crystal recovery device and a mother liquor recovery device through pipelines, and an outlet of the crystal recovery device is connected with a thymol content analysis unit through a pipeline. An outlet of the mother liquor recovery device is connected with an inlet of the feeding tank, the thymol content analysis unit and the waste liquor recovery tank through pipelines; each pipeline is provided with one or more of a valve, a flow monitoring meter or a pump which are controlled to be opened and closed. The automatic continuous crystallization system provided by the invention realizes automation and continuity of multiple crystallization and purification processes, and is simple and efficient in system setting and convenient to operate.

Owner:ANHUI HAIHUA CHEM

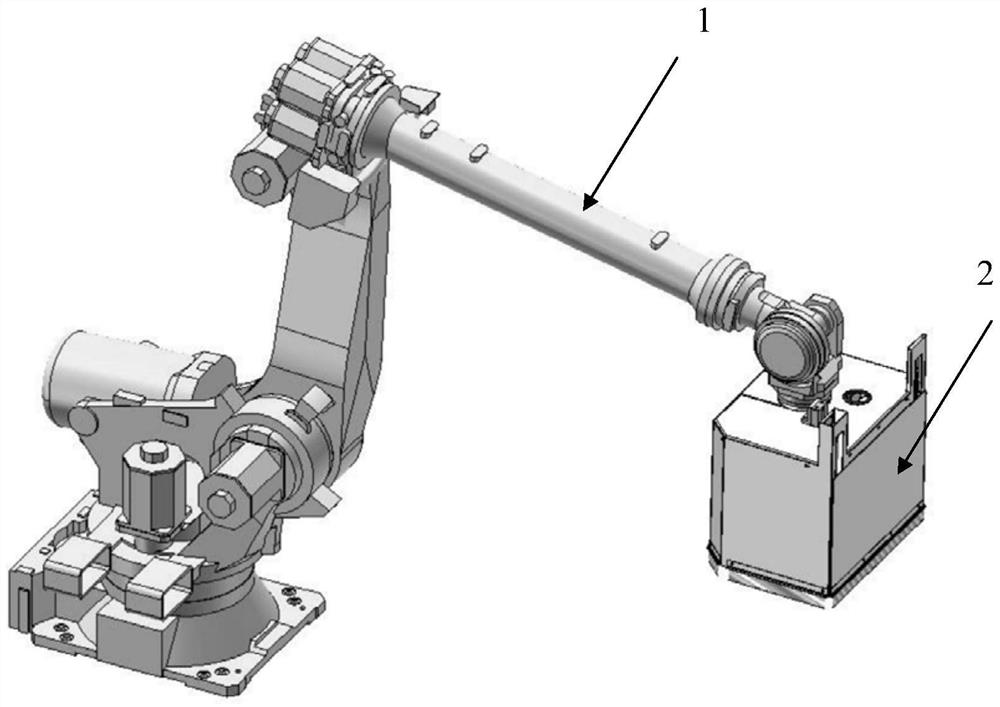

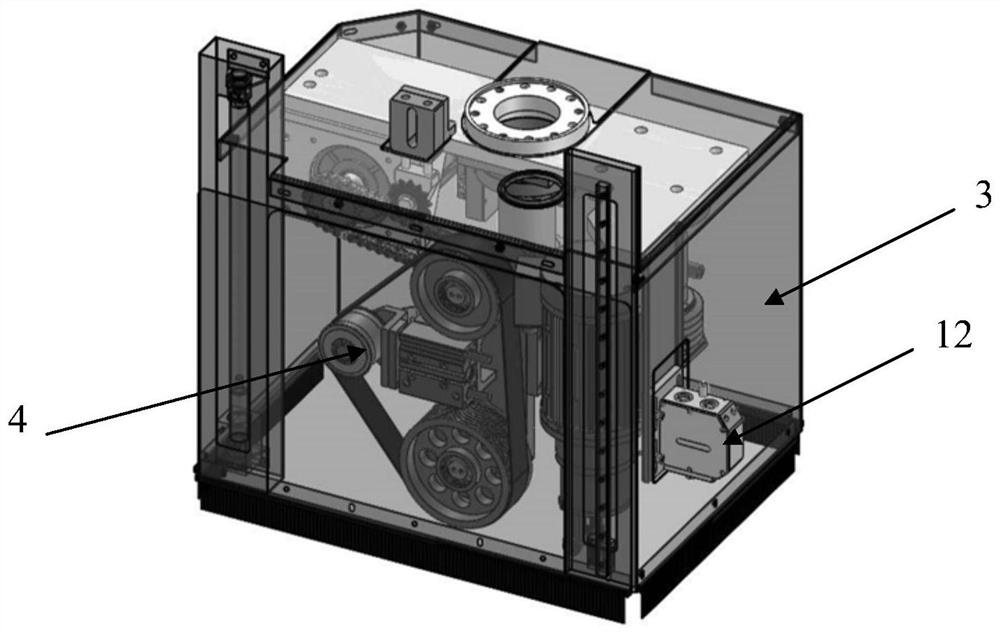

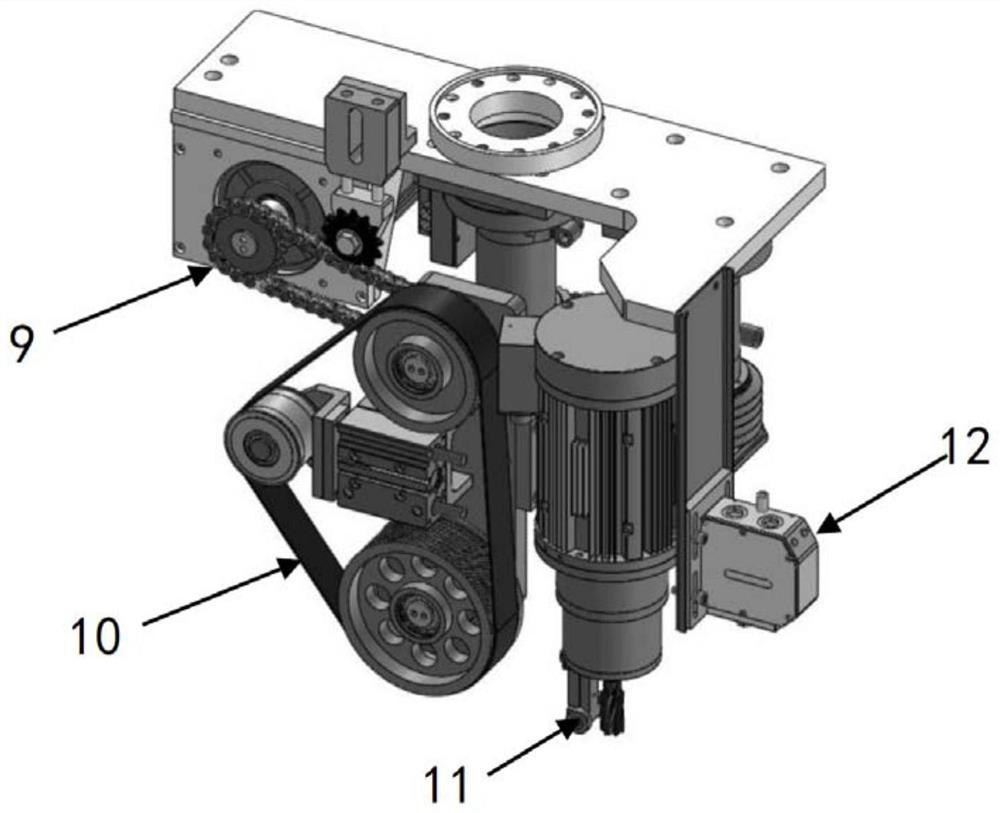

Detecting, milling and polishing equipment for workpiece welding seams

PendingCN113857965AOvercoming Inconsistent Weld PositionsPrecise process controlEdge grinding machinesBelt grinding machinesWeld seamPolishing

The invention provides detecting, milling and polishing equipment for workpiece welding seams, and belongs to the field of milling of large-allowance welding seams. The detecting, milling and polishing equipment comprises a manipulator, a polishing part, a workpiece detection assembly, a milling assembly, an abrasive belt polishing assembly and a chain rotating assembly, wherein the polishing part is connected to the head end of a manipulator body and used for polishing the surfaces of workpieces under the driving of the manipulator body so as to control the removal depth of welding seams, and the polishing part comprises a polishing mechanism and a protection mechanism; the polishing mechanism comprises a rack; the workpiece detection assembly is used for detecting the surfaces of the workpieces; the milling assembly is used for milling the surfaces of the workpieces according to detection results of the workpiece detection assembly; the abrasive belt polishing assembly is used for polishing the surfaces of the workpieces according to the detection results of the workpiece detection assembly; and the chain rotating assembly is used for driving the abrasive belt polishing assembly in real time according to the detection results of the workpiece detection assembly. By means of the treatment scheme, fine milling and polishing are conducted on the large-allowance welding seams in a targeted mode.

Owner:ANWHA SHANGHAI AUTOMATION ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com