Dielectrically isolated integrated circuit extending wafer and preparation method thereof

A dielectric isolation and integrated circuit technology, applied in the field of dielectric isolation epitaxial wafers and its preparation, can solve the problems of parasitic radiation resistance, poor isolation performance, and no performance, and achieve shortening of high temperature time, high temperature resistance and radiation resistance Performance improvement, the effect of improving circuit performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

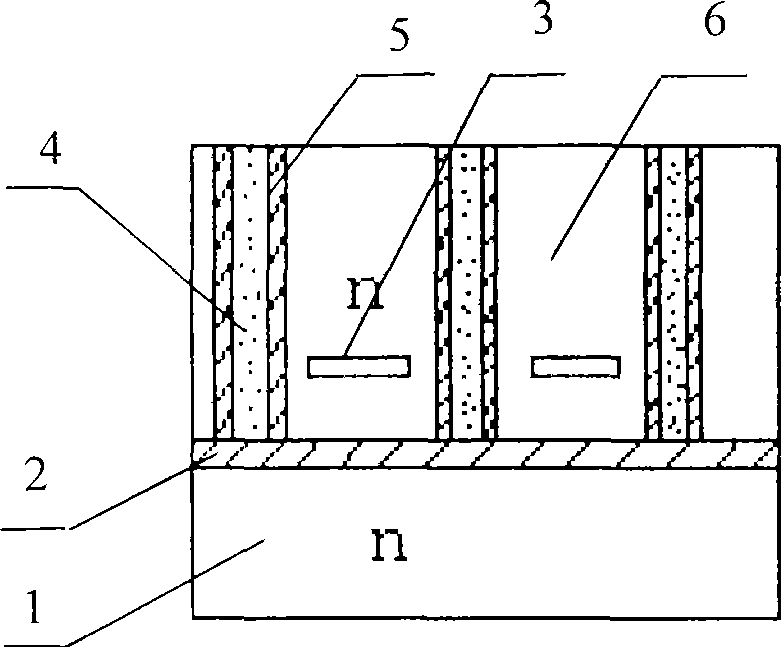

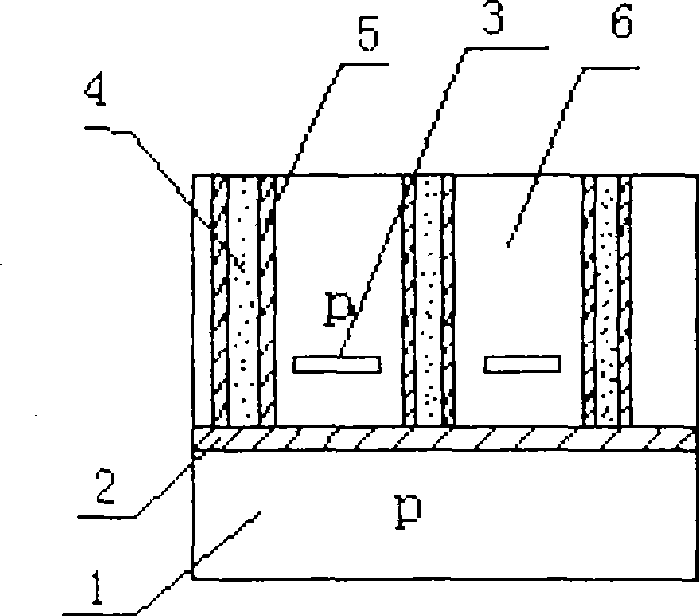

[0041] Example 1, see figure 1 , an N-type dielectric isolation integrated circuit epitaxial wafer, including a substrate material N-type single crystal silicon 1, on which a sandwich oxide layer 2 is arranged, and an N-type silicon epitaxial layer 6, which is provided in the silicon epitaxial layer 6. There is a buried layer 3; its silicon epitaxial layer 6 is separated into isolated squares insulated from each other by silicon dioxide 5, polysilicon 4 and sandwich oxide layer 2. The thickness of the N-type silicon epitaxial layer 6 is 0.5-16 μm; the sheet resistance of the buried layer 3 is 10-15Ω / □ for the N-type and 8-20Ω / □ for the P-type.

Embodiment 2

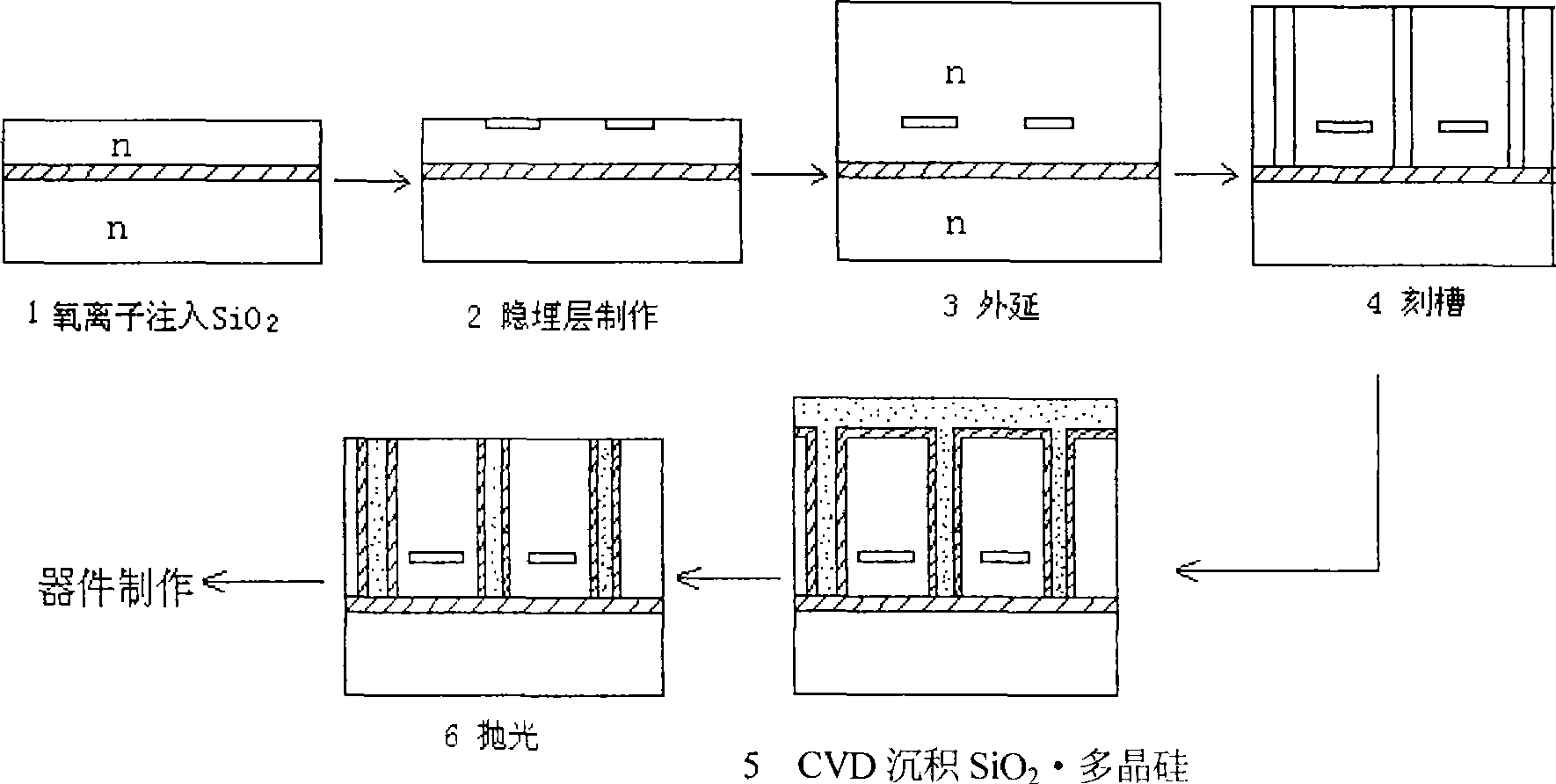

[0043] Example 2, see figure 2 , a preparation method of an N-type dielectric isolation integrated circuit epitaxial wafer, the preparation steps are:

[0044] (1) Preparation of silicon SOI silicon wafers on insulators: Oxygen ions are implanted on the surface of N-type 2-4Ωcm polished single crystal silicon wafers, and annealed at a high temperature at a temperature of 25-1200°C to form a sandwich oxide layer with a depth of 2-4μm; During implantation, the substrate temperature is 400-700℃, the implantation energy is 150-200kev, and the dose is 10 17 -10 18 / cm 2 :

[0045] (2) Preparation of low-resistance buried layer: in the above step (1), the surface of the SOI silicon wafer is oxidized first, then photolithography is performed, and then a local high concentration of arsenic is performed 8×10 19 -10 20 / cm 3 Ion implantation, after high temperature annealing, the temperature is 25-1200℃, the sheet resistance is controlled at 10-15Ω / □, and the junction depth is co...

Embodiment 3

[0051] Embodiment 3, the preparation method of the N-type dielectric isolation integrated circuit epitaxial wafer, the preparation step (2) also includes: forming N + After the buried layer, the local high concentration of boron is 2-5×10 19 / cm 3 Ion implantation, after high temperature annealing, the temperature is 25-1200 ℃, the sheet resistance is controlled at 8-20Ω / port, and the junction depth is controlled at 2.0-3.0μm; the formation of P + Buried layer, the implantation process substrate temperature is 400-700℃, the implantation energy is 100-150kev, and the dose is 10 15 -10 16 / cm 2 . The rest of the steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com