Patents

Literature

30results about How to "Reduce high temperature time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing, packing and storing hickory

ActiveCN101243892AReduce high temperature timeReduce the degree of oxidationFruit and vegetables preservationFood preparationFlavorHydrolysis

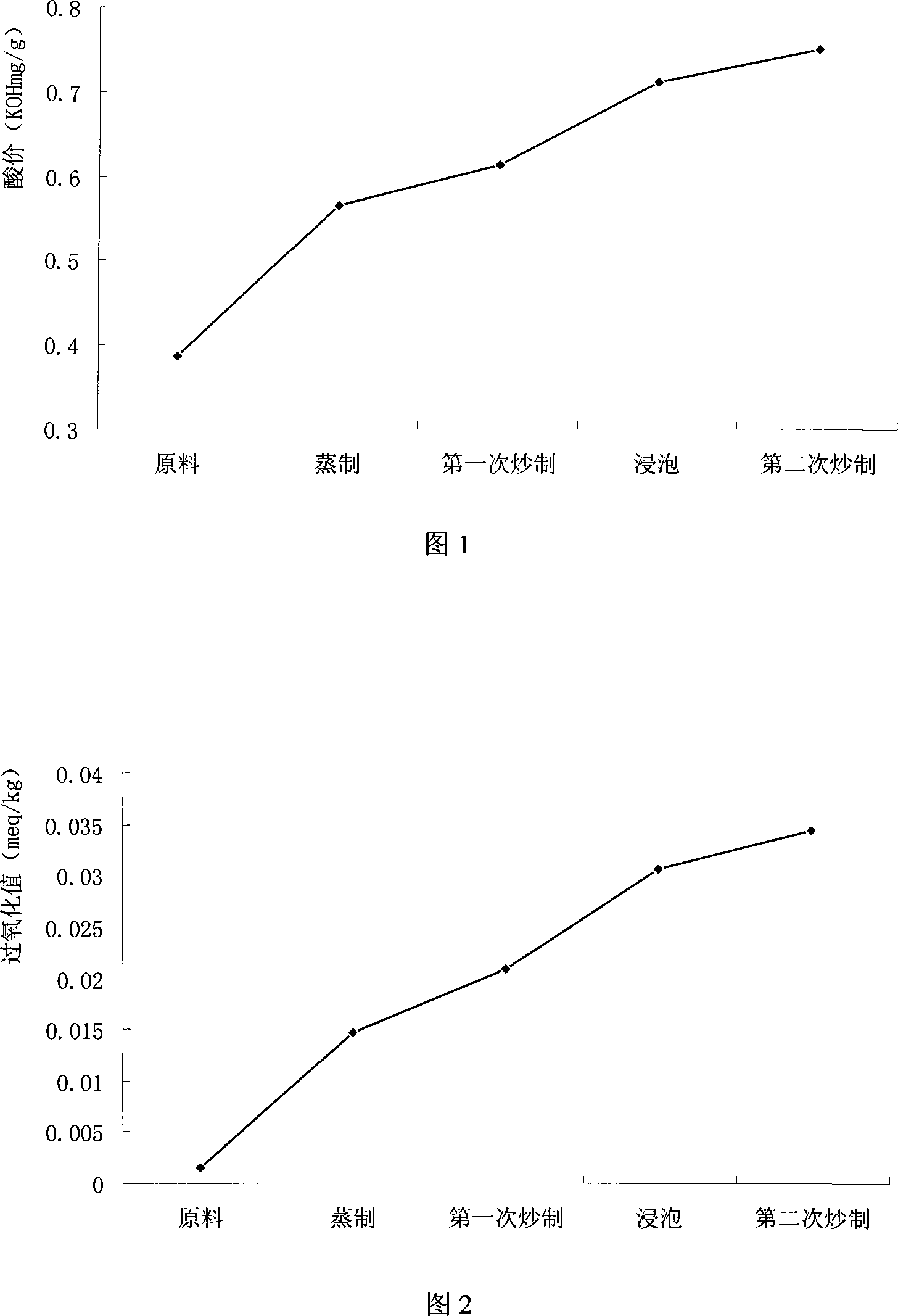

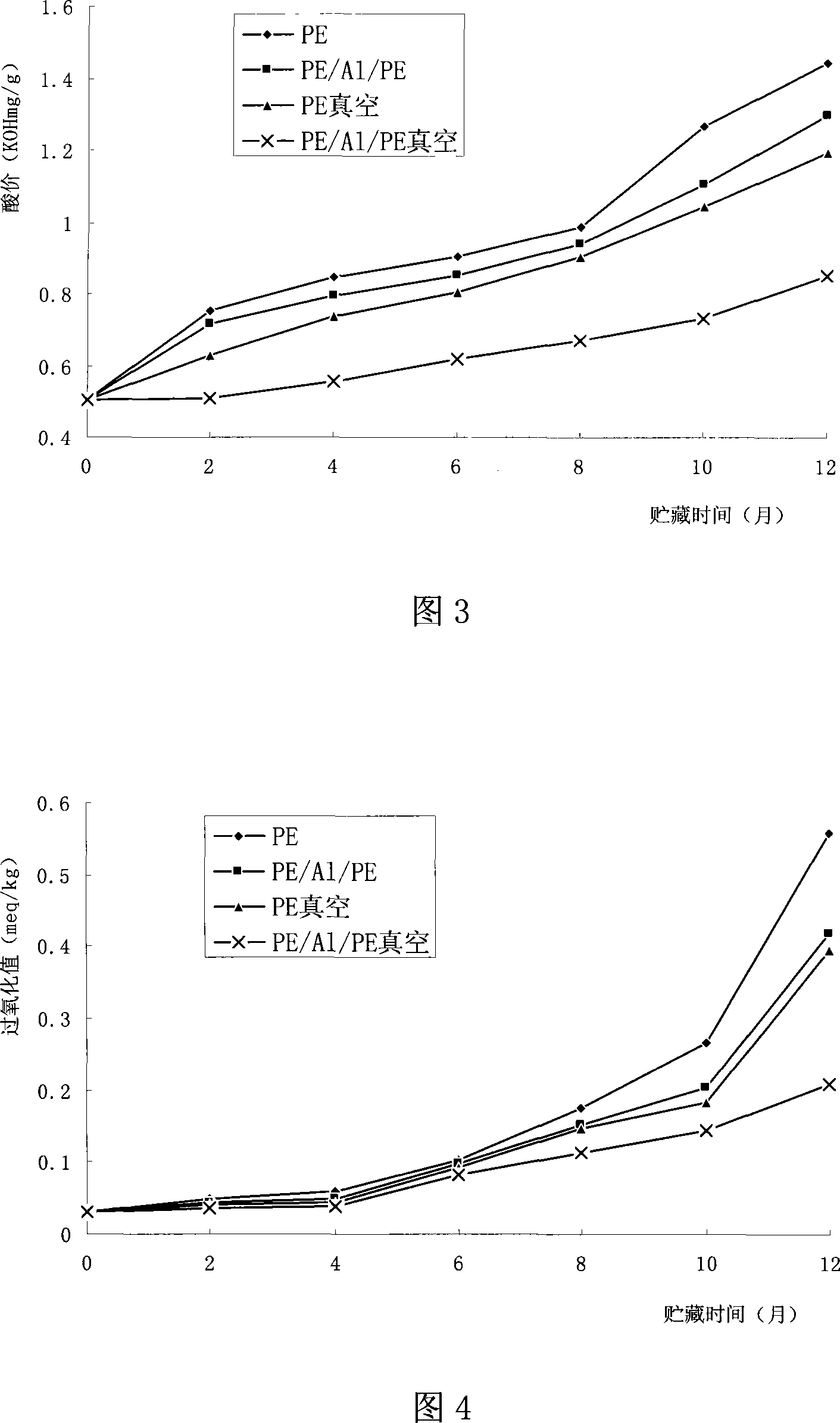

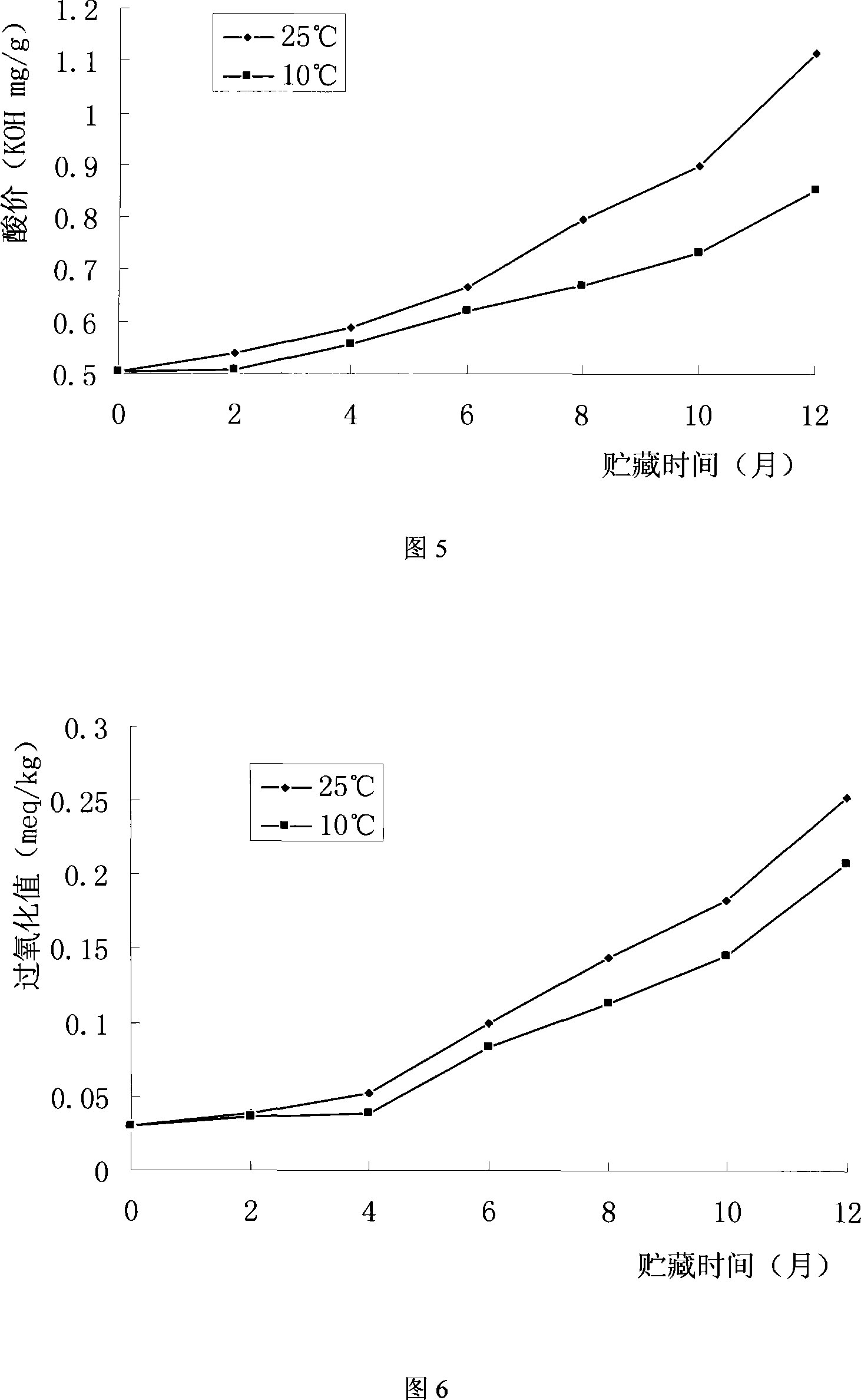

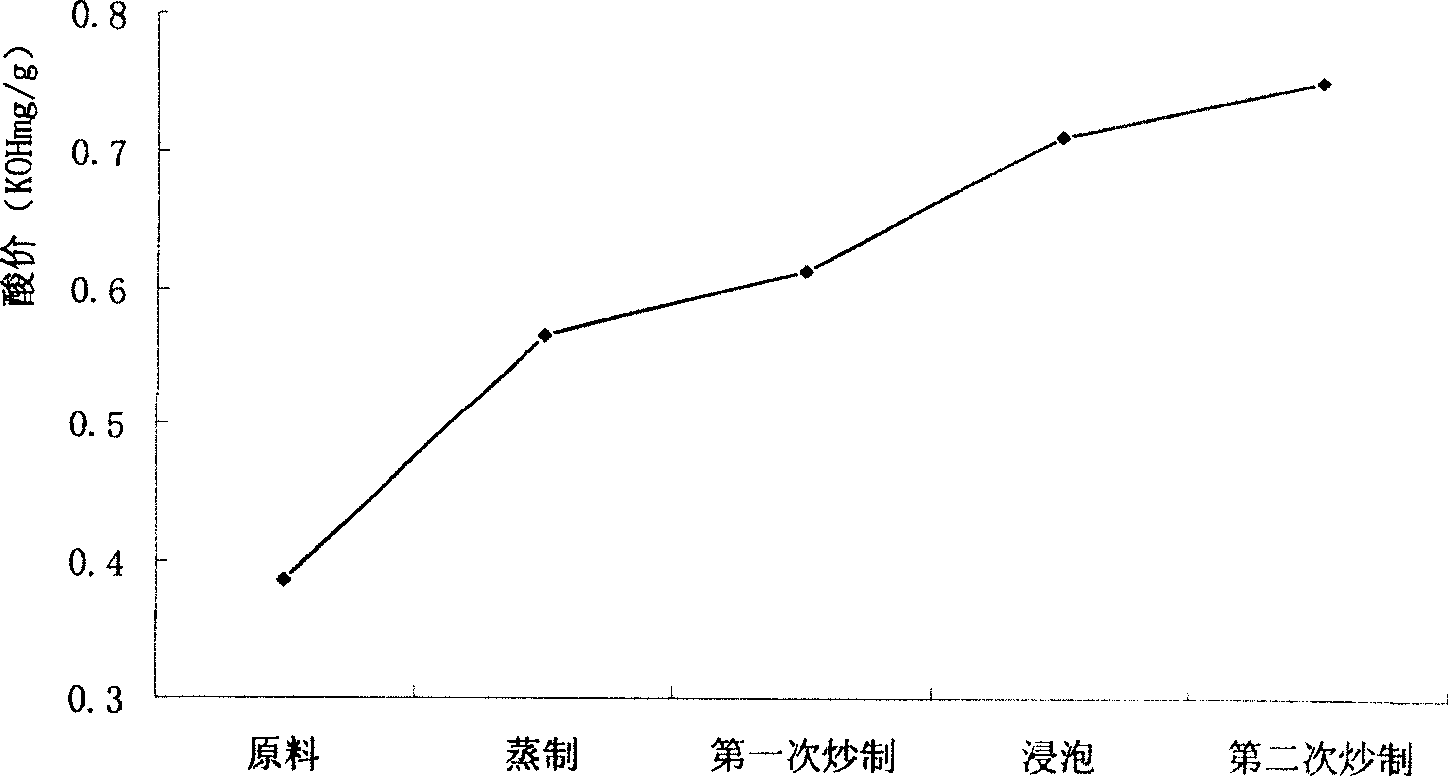

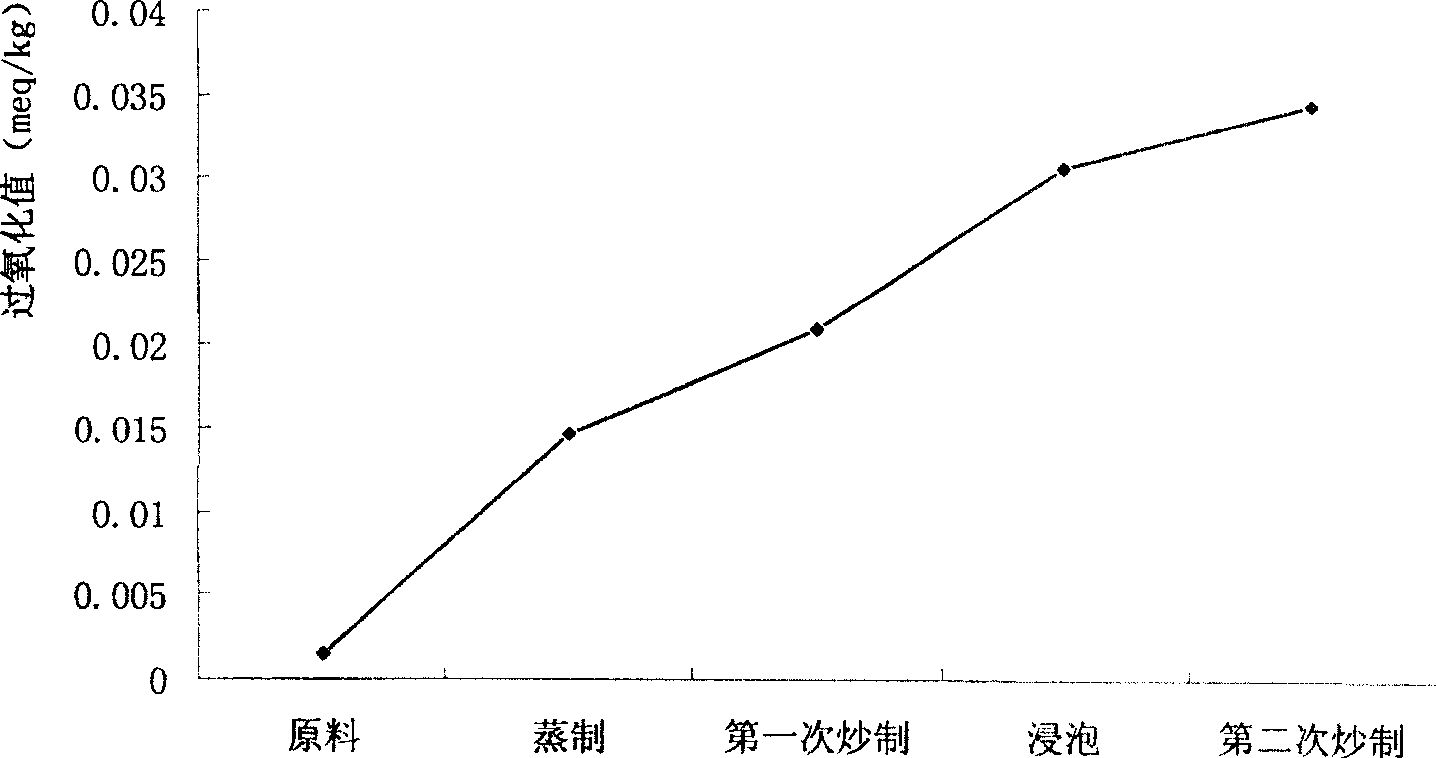

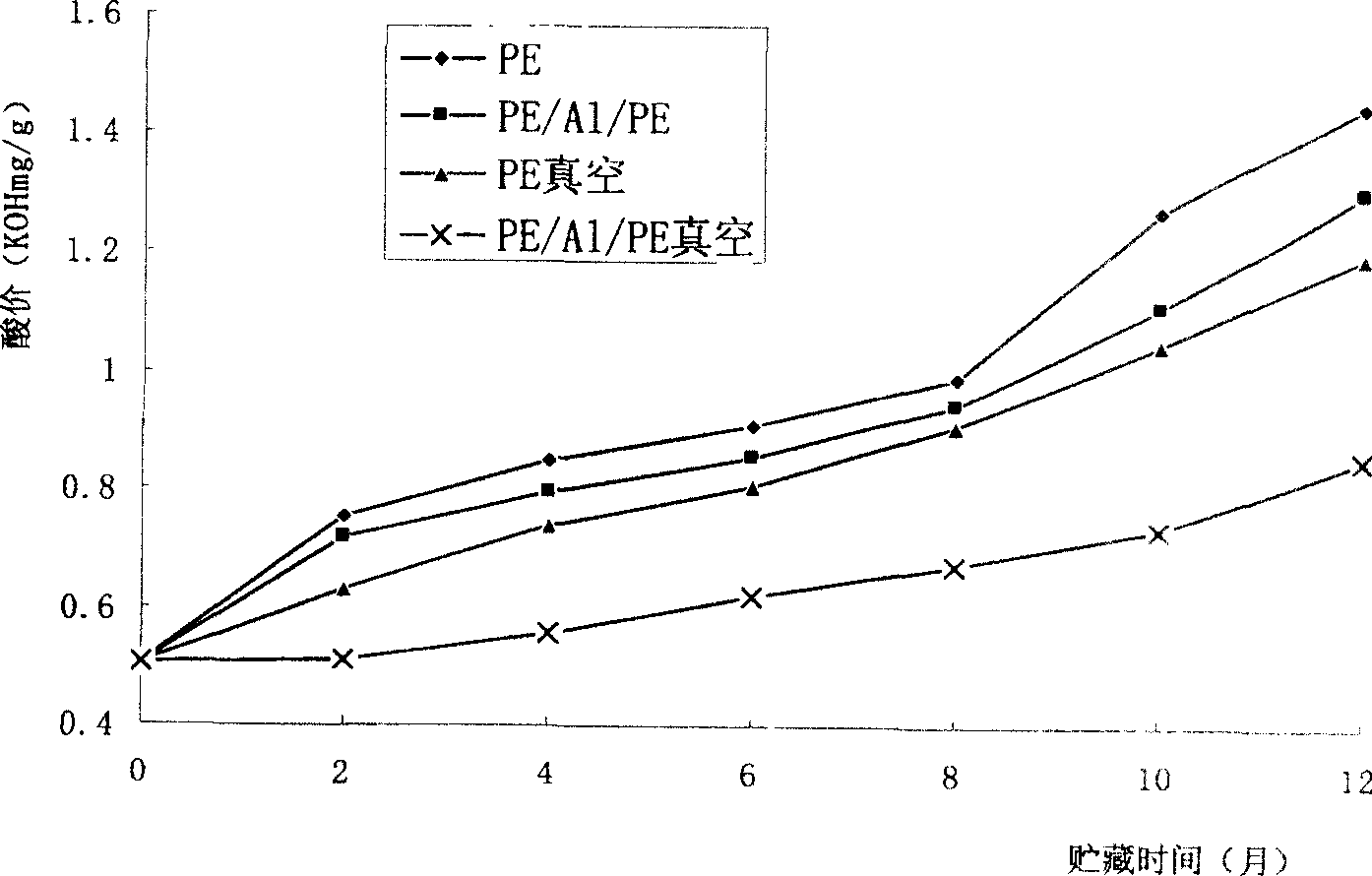

The invention discloses processing, packaging and storage methods of pecans, and belongs to the technical field of processing and storage of nut foods. The method includes: (1) preparation of raw materials; (2) preparation of seasoning liquid; (3) steaming, frying and seasoning of raw materials; (4) composite film, iron-based deoxidizer, vacuum packaging; (5) bagging The product is directly marketed or stored in a warehouse at 7-13°C until the end of the storage period. This method greatly improves the steaming and soaking process of the traditional method, is low in cost, simple and easy to implement, and has a significant effect on inhibiting the hydrolytic rancidity and oxidative rancidity of hickory oil, so that the shelf life of its products is changed from 4 to 4 times that of the traditional method. -6 months extended to 10-12 months, all physical and chemical indicators have reached industry standards. This method is suitable for popularization and application by hickory processing factories and large sellers.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

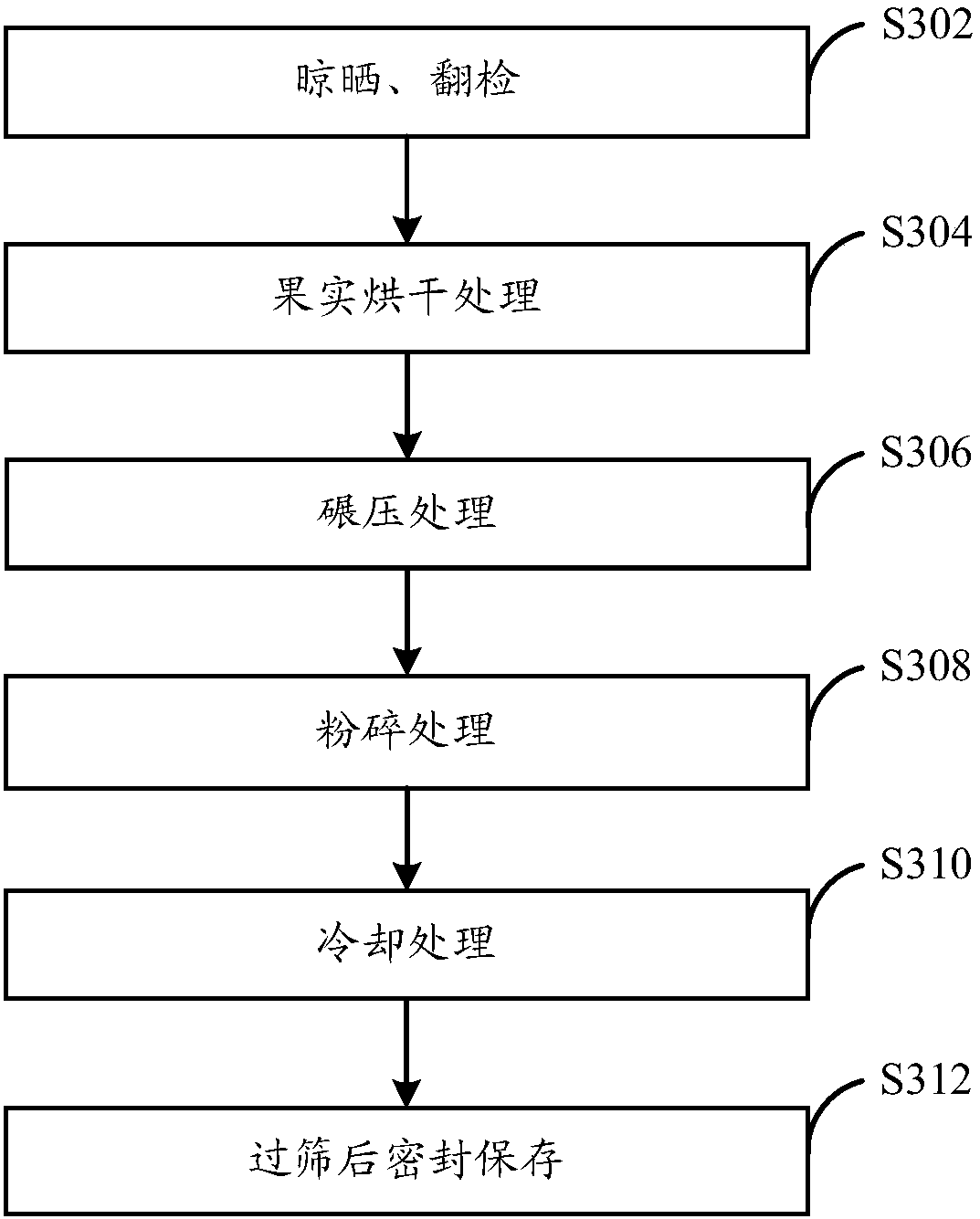

Method for making dried roxburgh rose fruit

InactiveCN102177955ARetain nutritionIncrease nutritionClimate change adaptationFruits/vegetable preservation by dehydrationHigh humidityVitamin C

The invention relates to a method for making dried roxburgh rose fruit. In the fabrication method, aiming at the defects of the existing roxburgh rose sun-drying and drying processing method such as oxidation of vitamin C under ultraviolet rays, great loss of nutrients and human health hazards caused by later-stage sulphur powder fumigation, a three-segment air-drying mode is adopted so that the fruit product is dried from inside to outside, the high temperature time is shortened, the probability of oxidation reaction is reduced, the greatest nutrient quantity of the fruit product is maintained, the problems such as cracked surface, poor appearance and high humidity in the fruit during the high-temperature sun-drying process are avoided, the sulphur fumigation procedure is not required, and the loss of the vitamin C is reduced to 3.2%-4.8% during the preservation period, thus solving the problems such as difficulty in preservation and nutrition loss.

Owner:陈贵恩

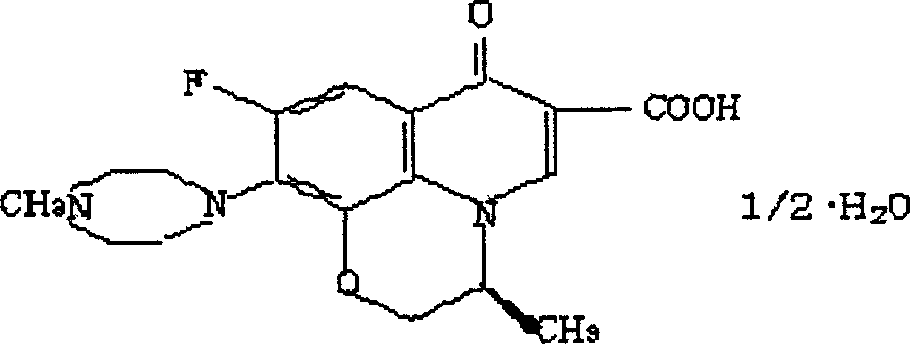

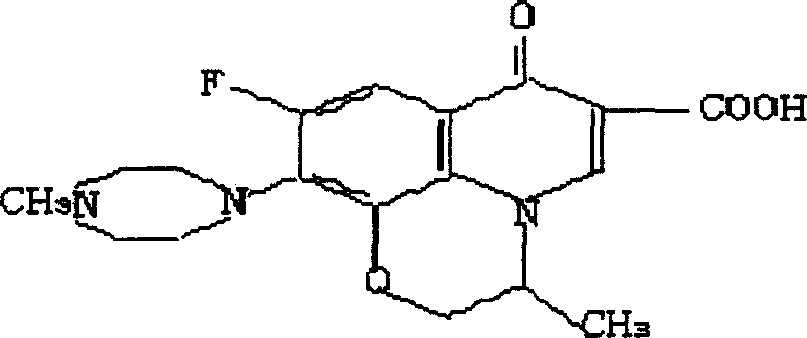

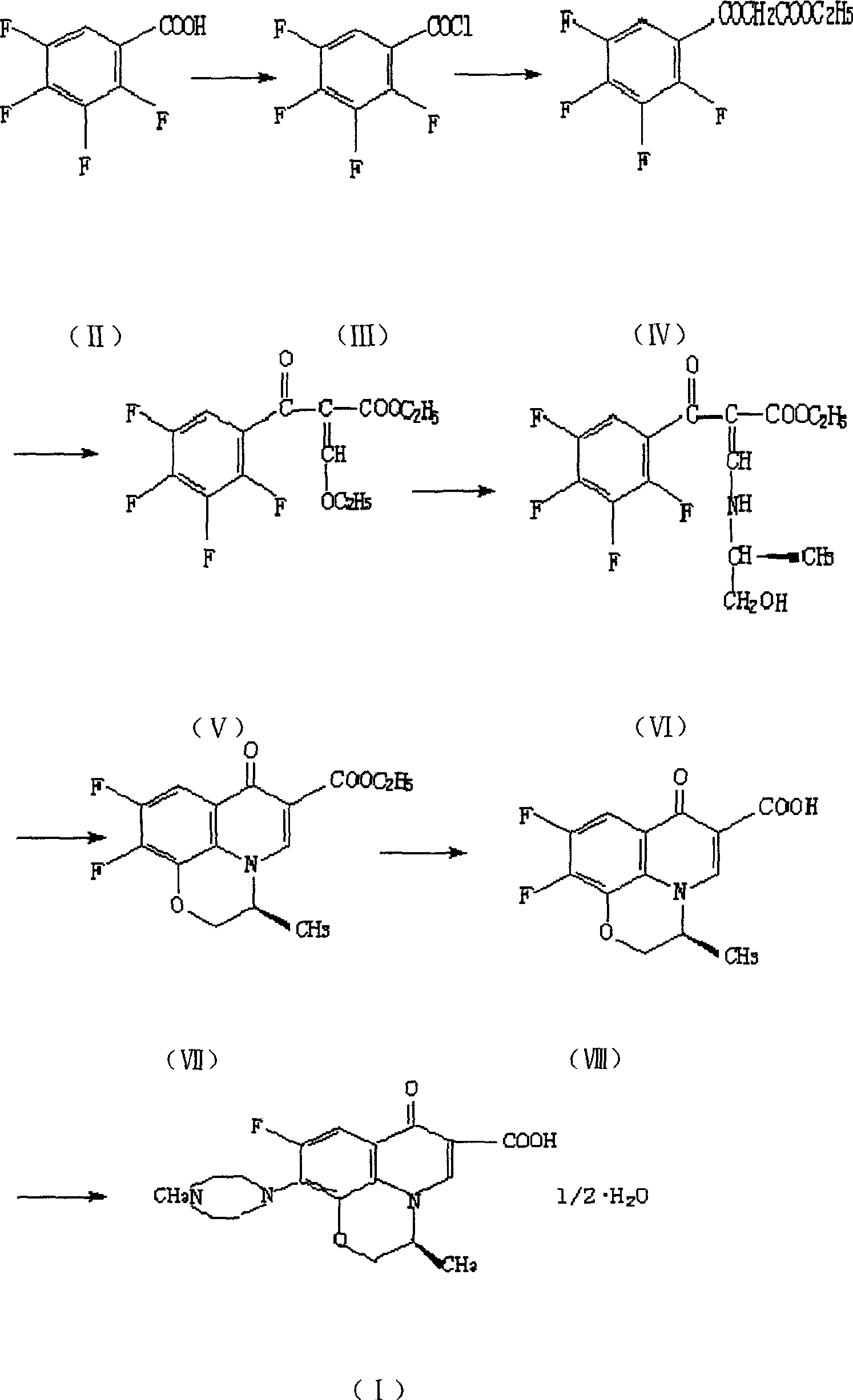

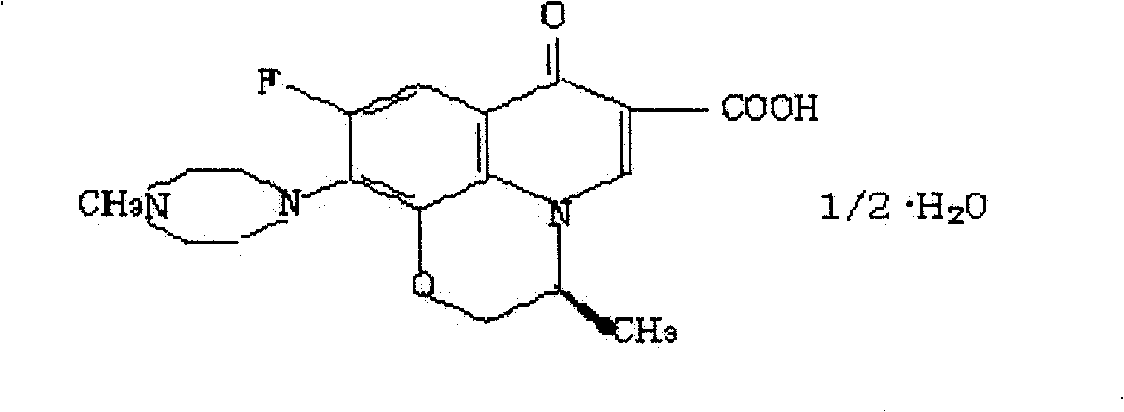

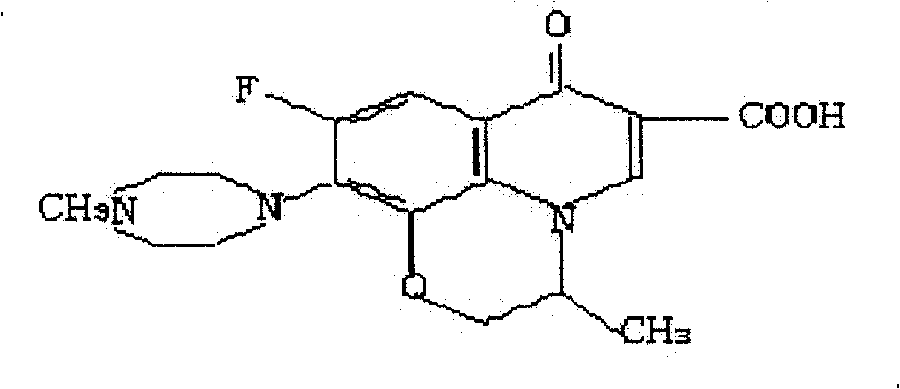

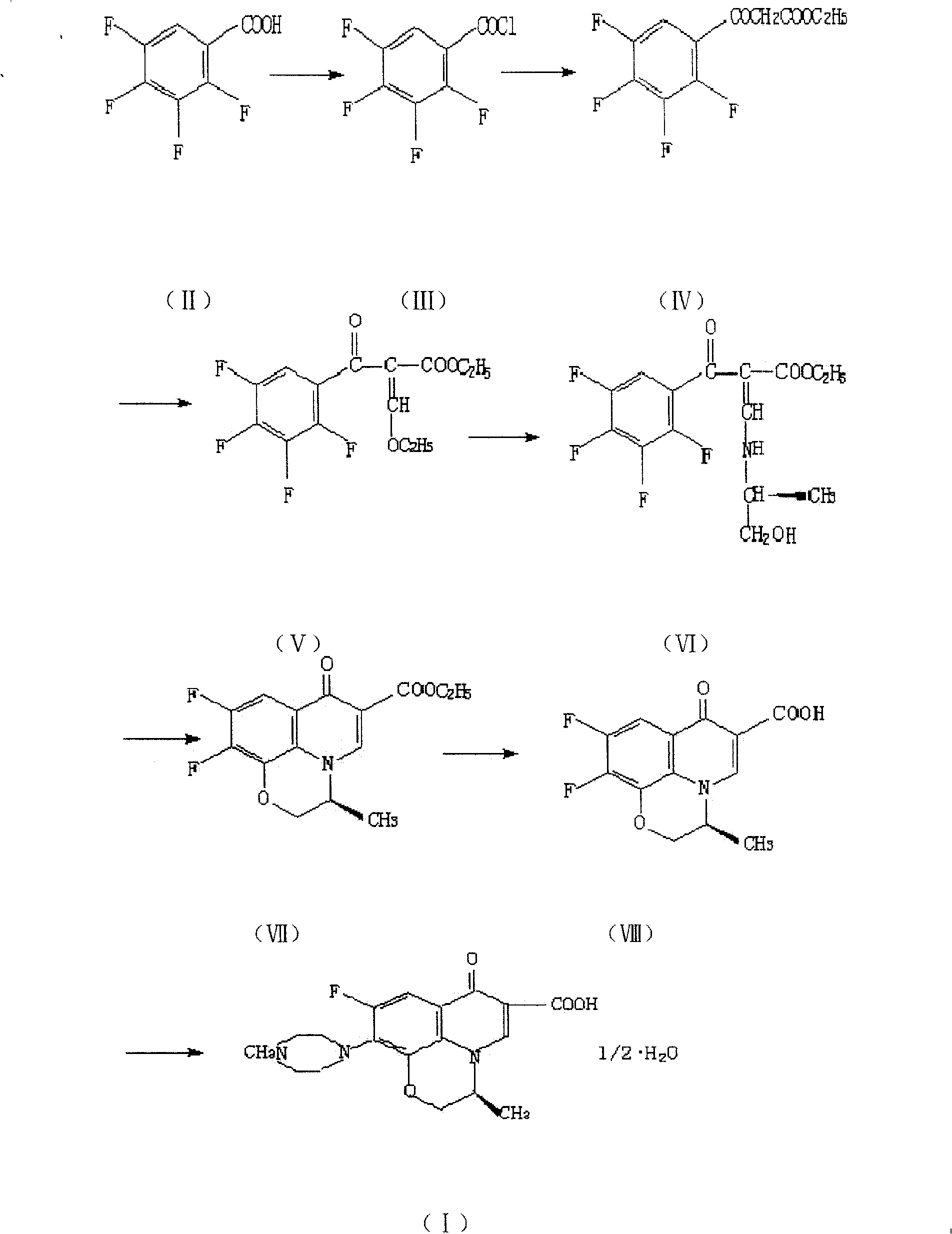

Process for preparing L-ofloxacin and ofloxacin

InactiveCN1594320AReduce high temperature timeFew reaction stepsOrganic chemistryPropanolReaction temperature

The invention relates to a process for preparing L-ofloxacin and ofloxacin which consists of, charging solution into 2-(2,3,4,5-tetrafluorobenzoyl-3-ethoxy-ethyl acrylate crude product, freezing, dropping L-amino propanol or DL-amino propanol, thermal insulating till the completion of conversion, alkalizing, reacting at the temperature of 50-90 deg. C, charging N-methyl piperazine into mother liquor, stirring for reaction 1-3 hours at 55-95 deg. C, decompressing and reclaiming N-methyl piperazidine, thermal insulating, plunging reaction liquor into water, agitating, cooling down and filtering, charging water and acid into filtrate, stirring, inversing flow till the completion of hydrolysis, adjusting the pH=7.0 with alkali liquor, extracting by adding in solvent extraction reagent, and concentrating the extract layer.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

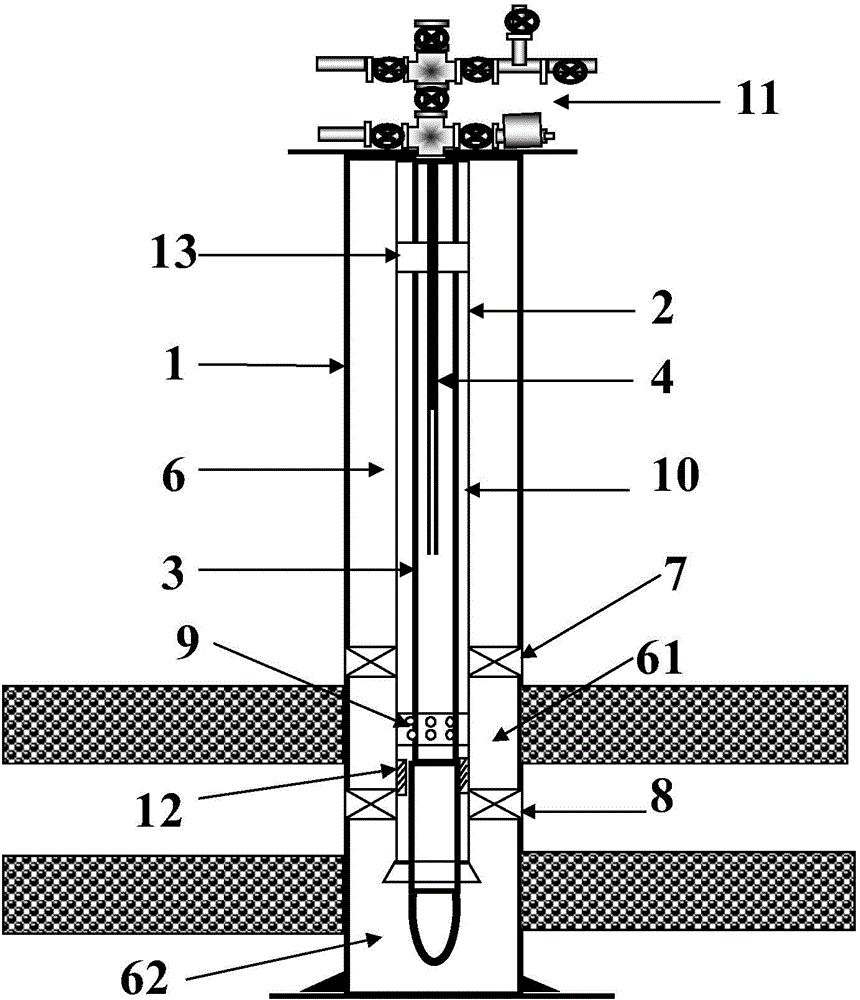

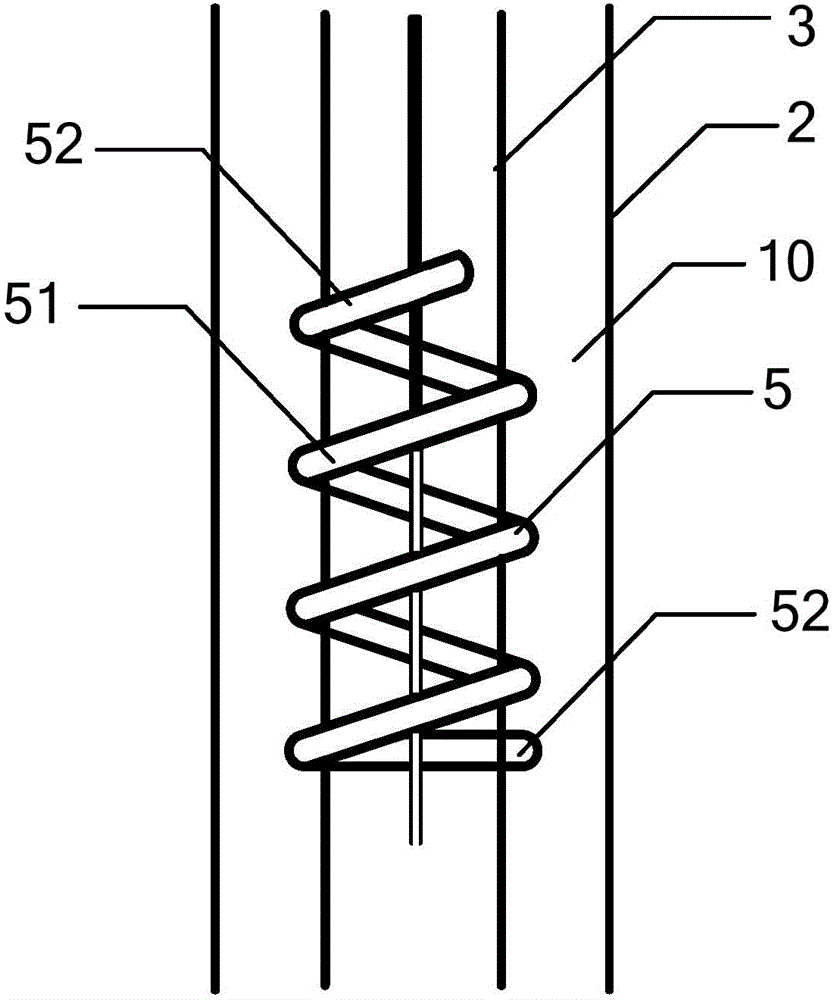

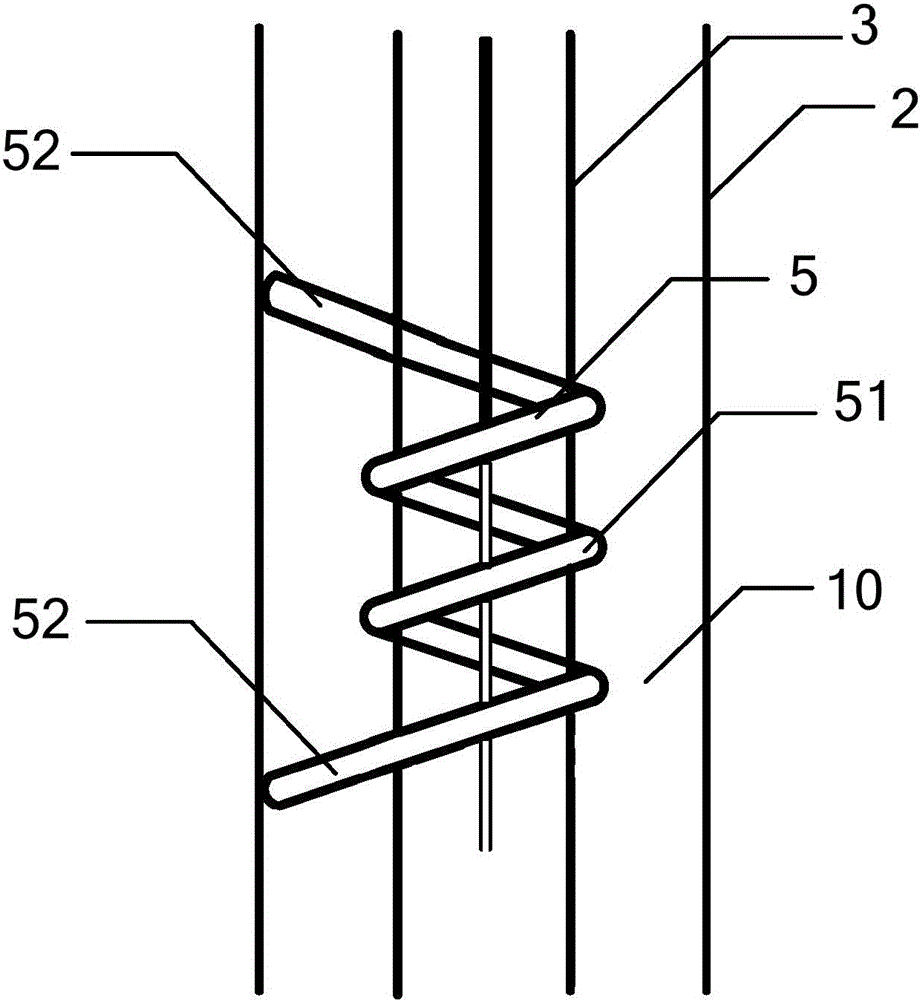

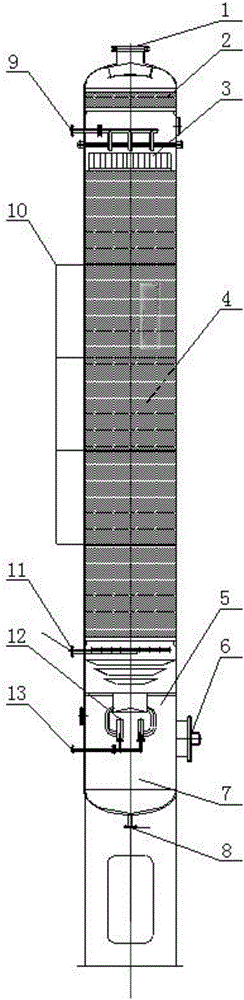

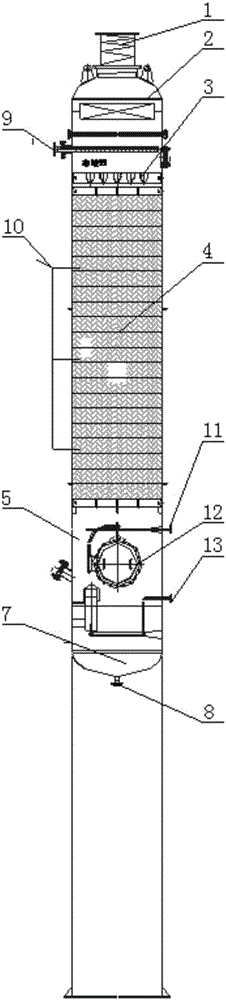

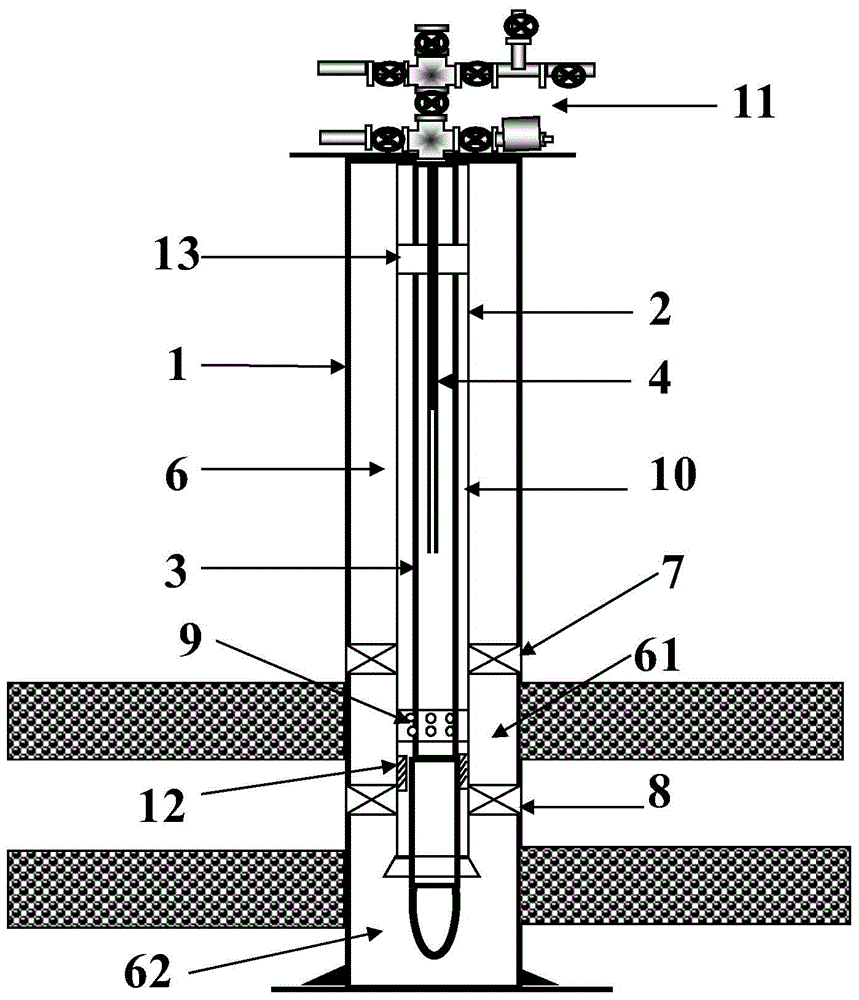

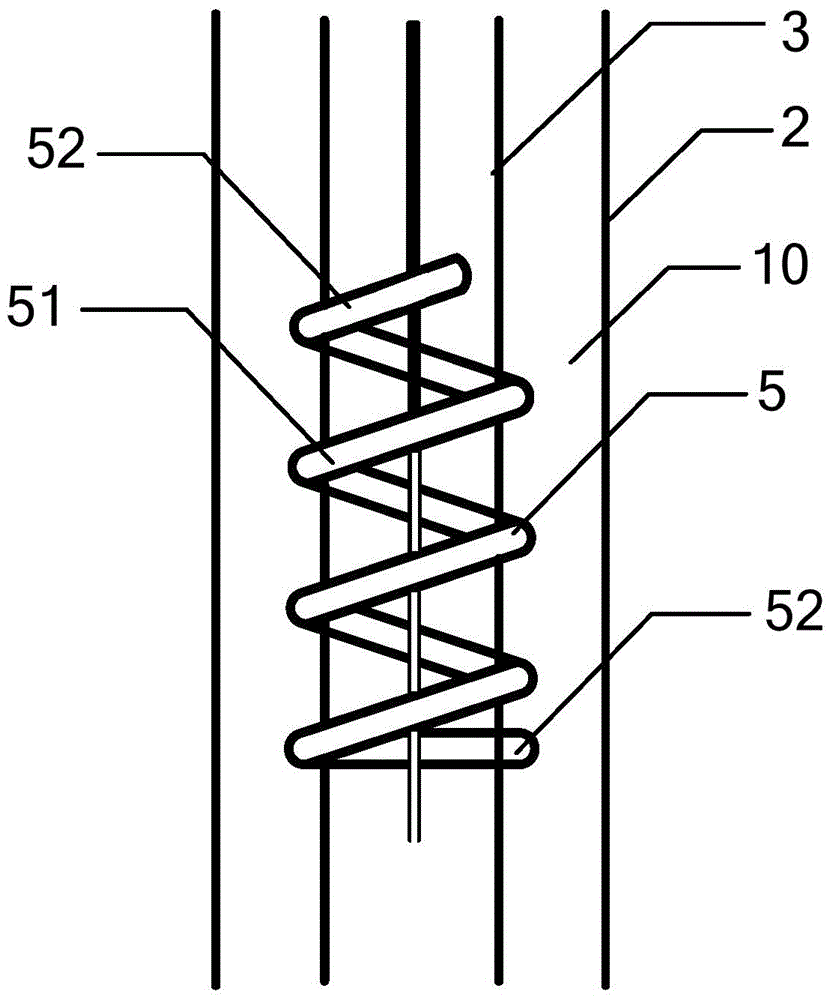

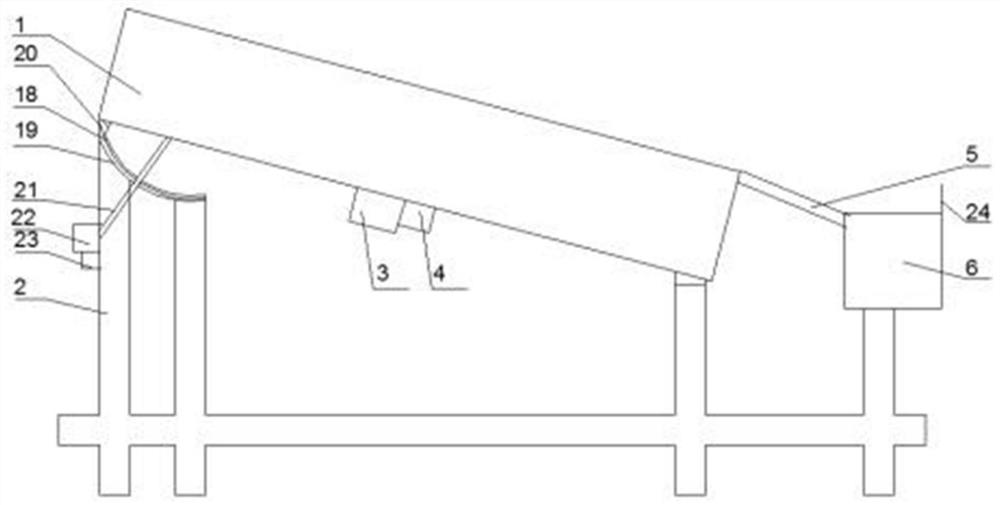

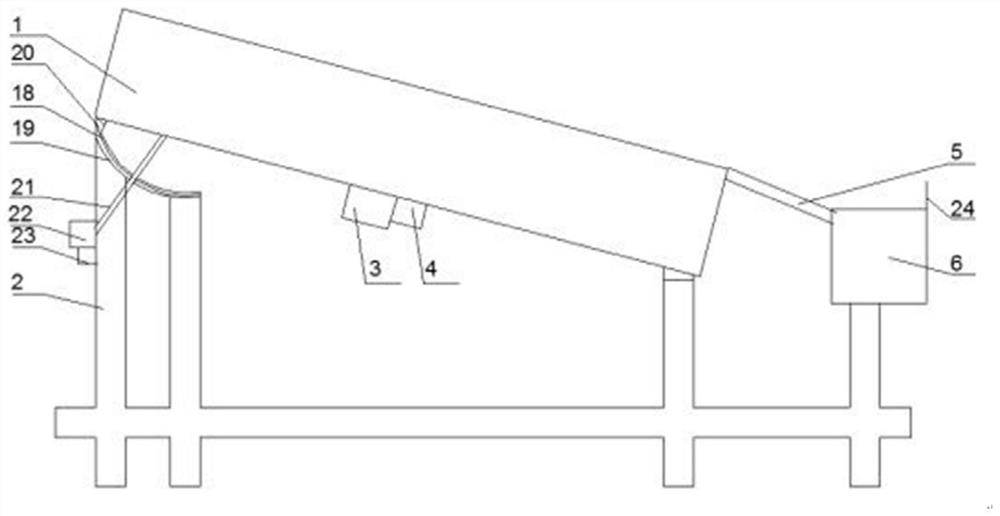

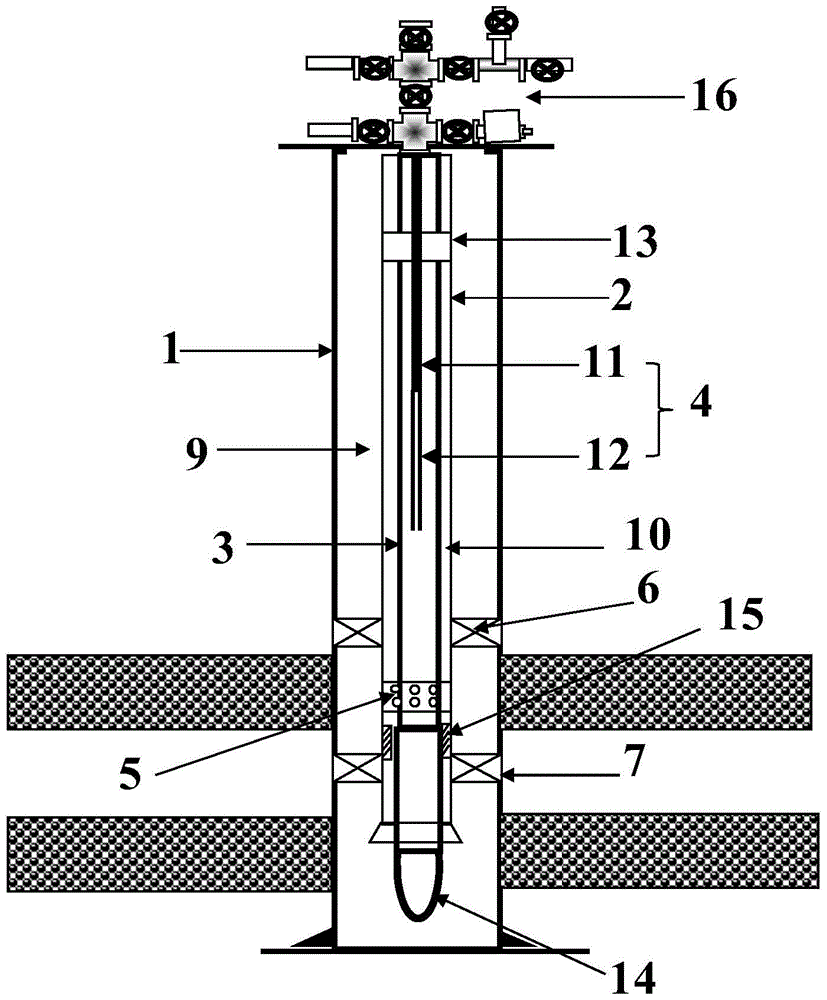

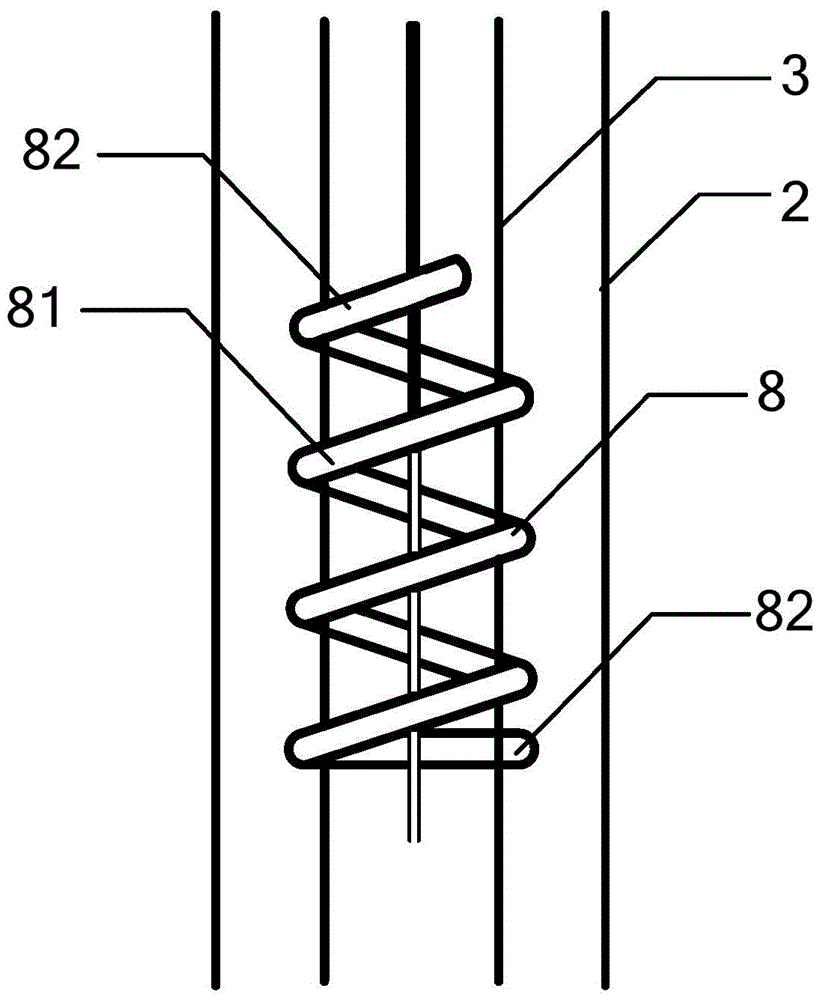

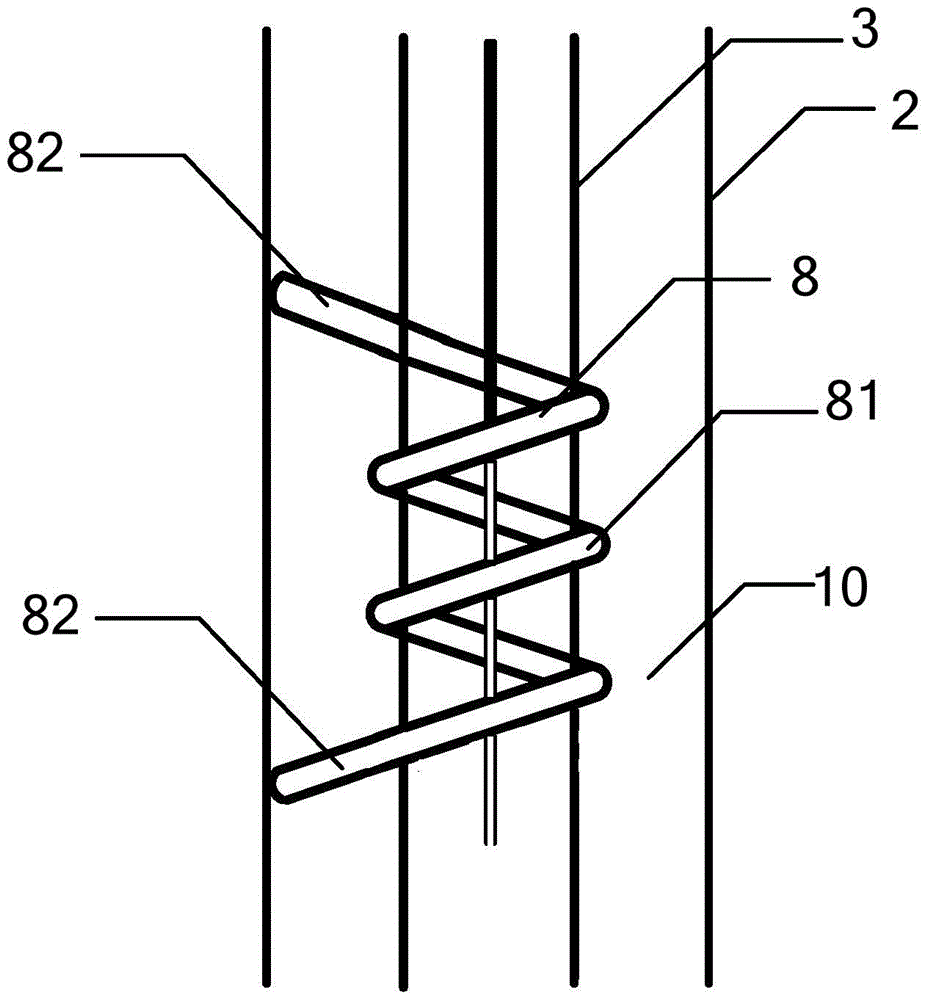

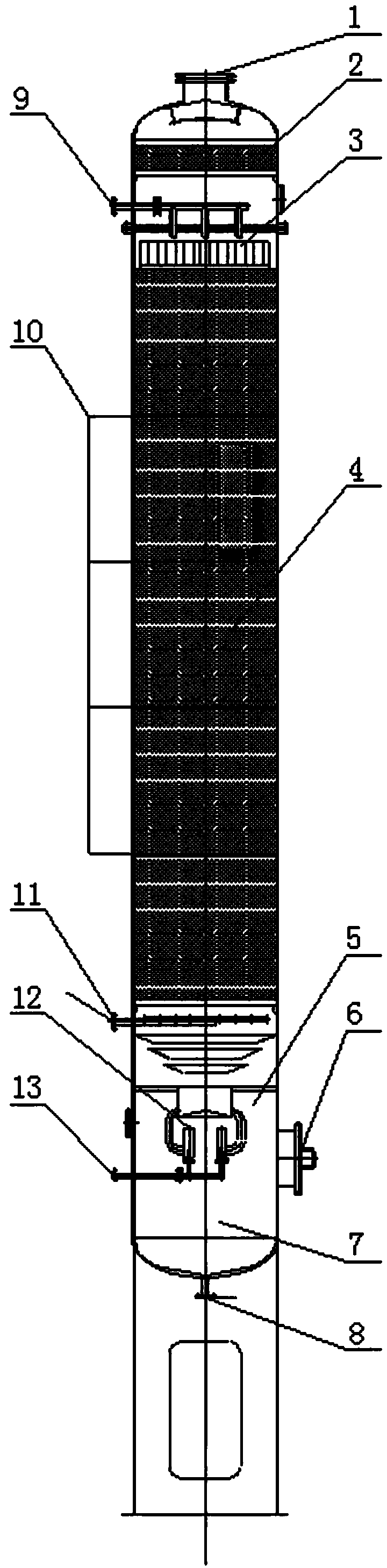

In-situ combustion layered ignition method

ActiveCN104453821AImprove power efficiencyImprove ignition efficiencyFluid removalCombustionThermal insulation

The invention provides an in-situ combustion layered ignition method. The method includes the steps that a casing pipe is landed into an oil well and extends to the well bottom; a thermal insulation pipe is landed into the casing pipe and a first annular space is formed between the thermal insulation pipe and the casing pipe; the first annular space is sealed through a first packer and a second packer, so that an upper-layer gas injection space and a lower-layer gas injection space are formed; an upper-layer gas distribution device located in the upper-layer gas injection space is arranged on the thermal insulation pipe; a Pupin oil pipe is landed into the thermal insulation pipe, a second annular space is formed between the Pupin oil pipe and the thermal insulation pipe, and an enhanced heat transfer device is arranged in the second annular space; an electric ignition device is landed in an inner cavity of the Pupin oil pipe; air is injected in the inner cavity and the second annular space and nitrogen is injected into the first annular space; the electric ignition device is started; heated gas in the thermal insulation pipe is injected into the upper-layer gas injection space through the upper-layer gas distribution device and an upper oil layer is heated and ignited; heated gas in the Pupin oil pipe is injected into the lower-layer gas injection space through the tail end of the Pupin oil pipe and a lower oil layer is heated and ignited.

Owner:PETROCHINA CO LTD

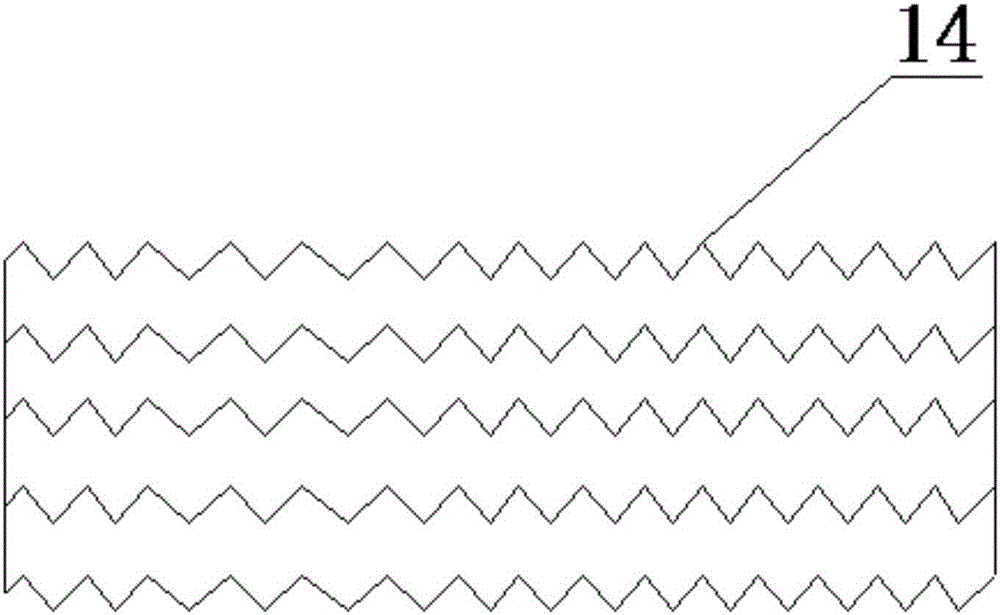

Low-temperature deodorization and high-temperature deacidification process capable of inhibiting trans-fatty acid of peanut oil

ActiveCN106118875AReduce high temperature timeInhibitory conditionsFatty-oils/fats refiningEdible oils/fatsPlasticizerAcid value

The invention discloses a low-temperature deodorization and high-temperature deacidification process capable of inhibiting trans-fatty acid of peanut oil. The process specifically comprises the following steps: (1) degumming; (2) de-coloring; (3) carrying out low-temperature deodorization; (4) carrying out high-temperature deacidification. A packing tower is additionally arranged behind a plate tower of a deodorization and deacidification process, and an alkali refining neutralization reaction section is removed; oil is uniformly distributed in a thin film form and a manner of directly adding saturated steam from the bottom is adopted to effectively remove undesirable odor; high-temperature time of an oil product is shortened; two sets of packing deacidification towers are additionally arranged, wherein the temperature of the #1 deacidification tower is controlled to be 260 DEG C and is used for instantly distilling to remove a large part of acid value, and the temperature of the #2 deacidification tower is controlled to be 265 DEG C and is used for removing the acid value in the oil again, so that the acid value of finished-product oil is reasonably controlled; furthermore, the time of staying at a high-temperature section of the oil is short, the content of the trans-fatty acid is only increased by 0.2 percent to 0.3 percent and the acid value can be controlled to be about 0.1; the alkali refining neutralization section is removed so that the loss of neutral oil is reduced and the yield is improved; the consumption is reduced by about 0.03 percent to 0.05 percent by one acid value; meanwhile, a plasticizer and the acid value in the oil product can be effectively removed.

Owner:青岛天祥食品集团有限公司

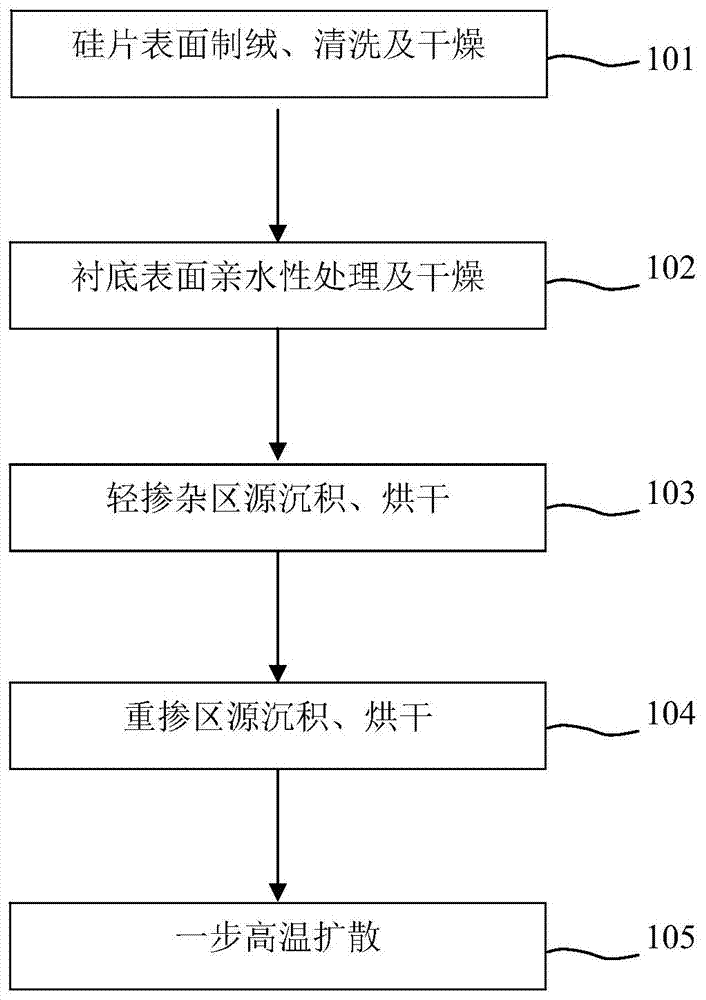

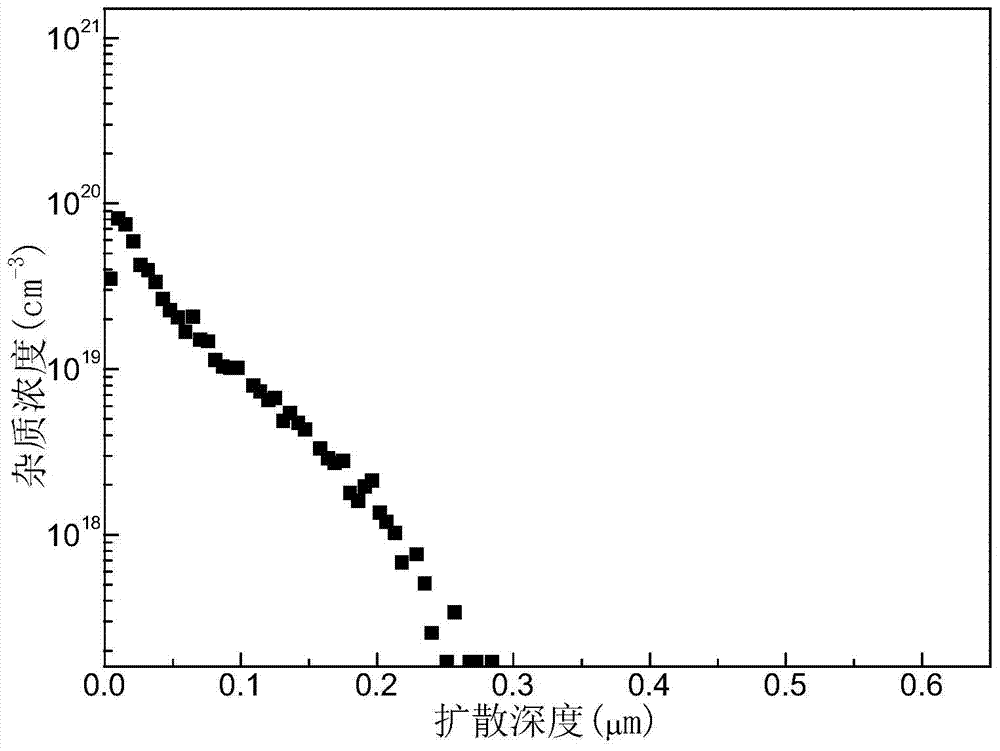

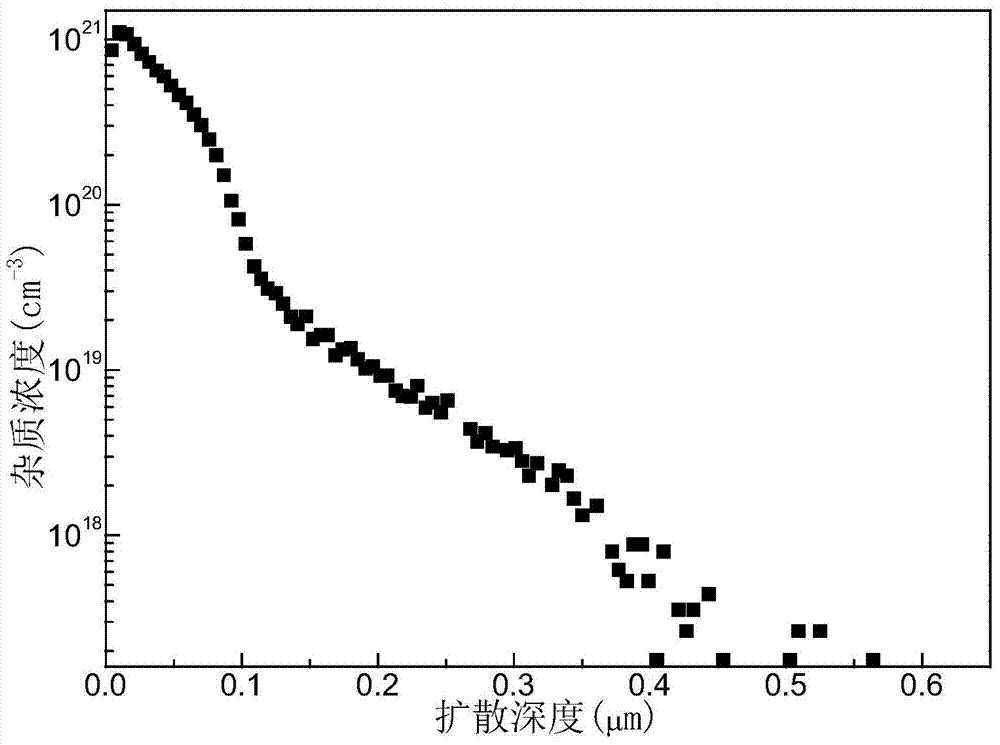

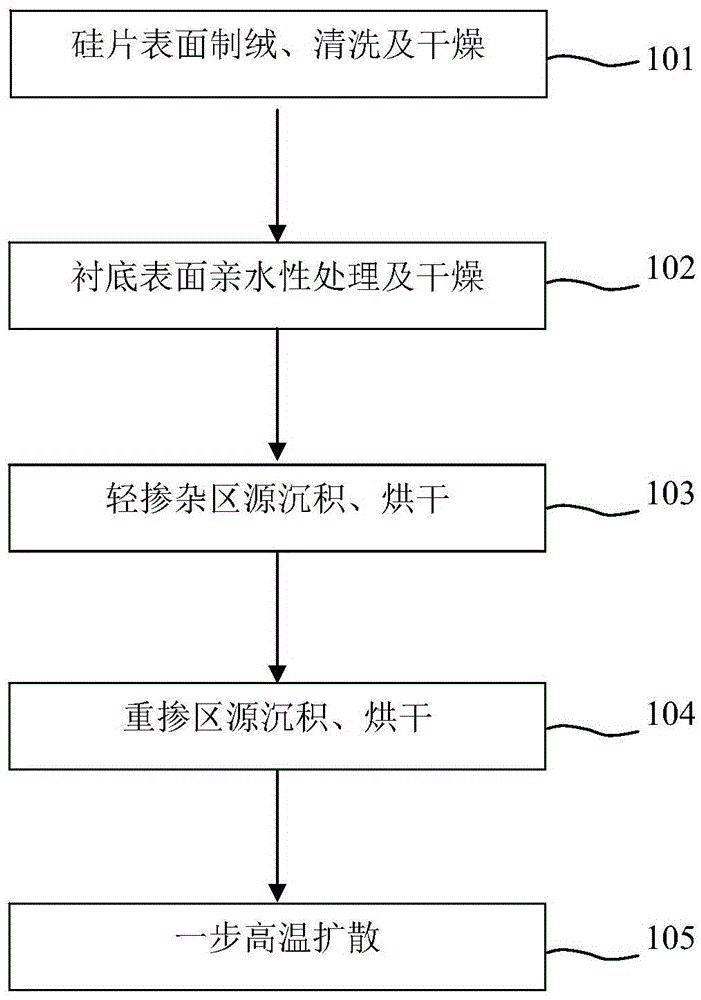

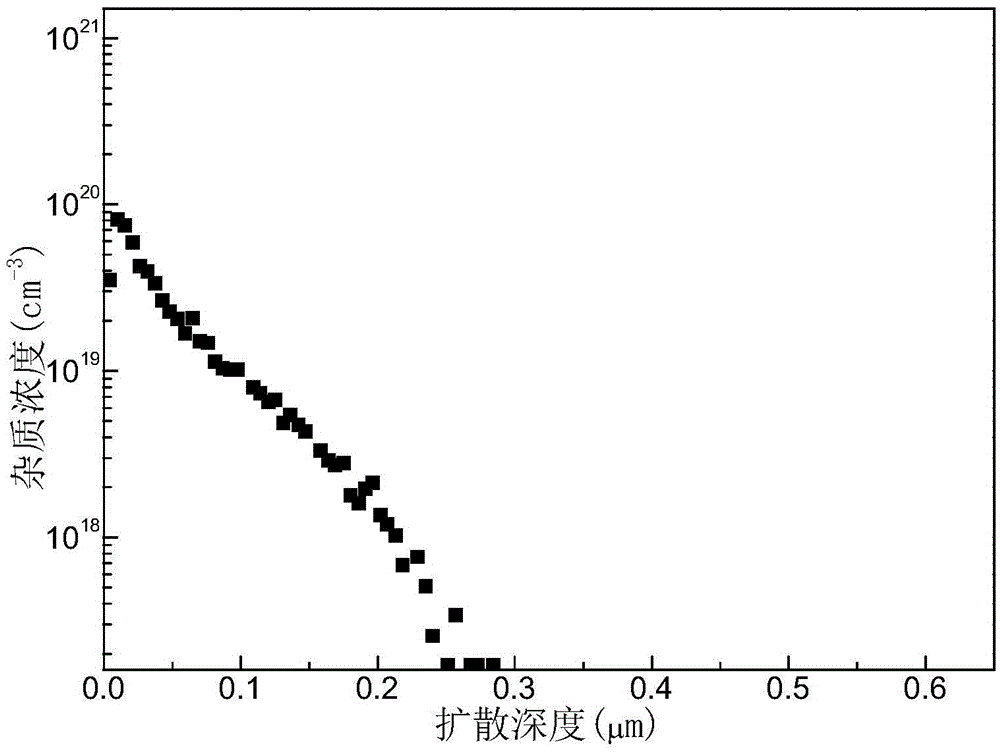

Method for manufacturing selective emitter structure with low surface concentration and soft doped zone

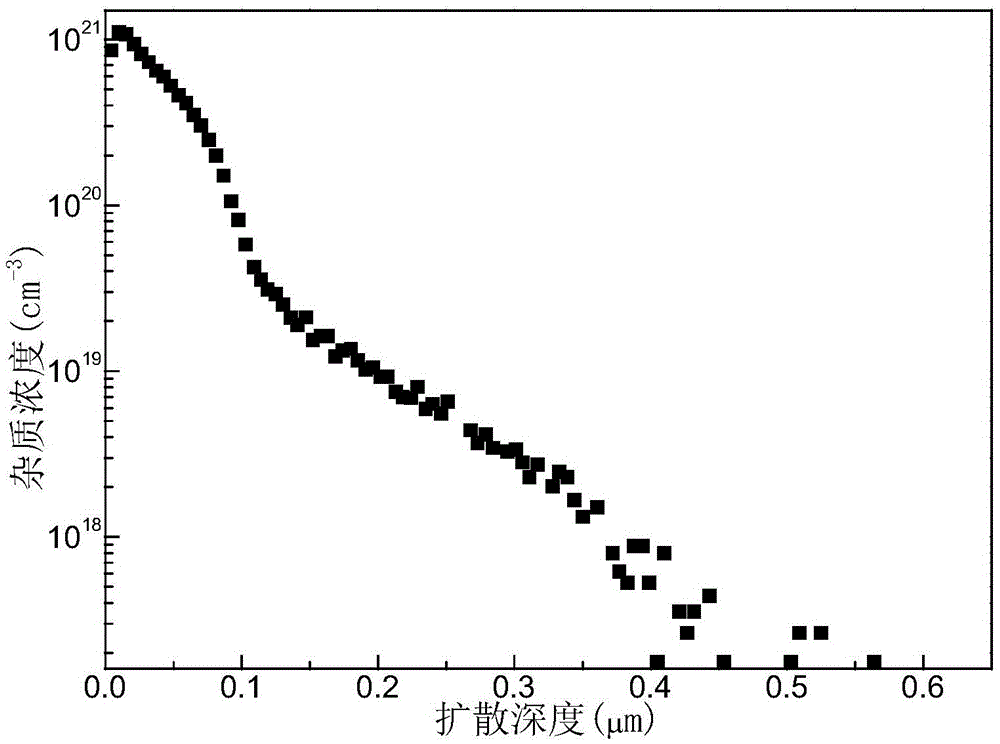

InactiveCN103904141AReduce surface concentrationImprove conversion efficiencyFinal product manufactureSemiconductor devicesOxygenSpin coating

A method for manufacturing a selective emitter structure with low surface concentration and a soft doped zone includes the steps that (1) the surface of a substrate to be prepared is corroded and cleaned, and the surface of the substrate is completely dried after cleaning; (2) the clean substrate prepared in the step (1) is soaked in a solution with high oxidability to carry out wet chemical oxidation on the surface of a silicon wafer, and then the surface of the substrate is completely dried; (3) a microcosmic salt aqueous solution of 0.5-20% is deposited on the surface of the substrate in a spin coating and spraying mode, and then the surface of the substrate is dried; (4) phosphorus ink or silicon ink is deposited on an electrode area on the surface of the substrate coated with a phosphorus source in the step (3) in a screen printing mode, and then the surface of the substrate is dried; (5) the temperature of a diffusion furnace rises, nitrogen is introduced into a diffusion quartz tube, when the temperature reaches 780-890 DEG C, the clean substrate prepared in the step (4) is placed into a constant-temperature area of the diffusion quartz tube, a fire door of the diffusion furnace is sealed, and after the temperature of the diffusion furnace is stable, oxygen is introduced into the diffusion quartz tube; (6) the substrate is taken out and cooled after the diffusion process is over.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

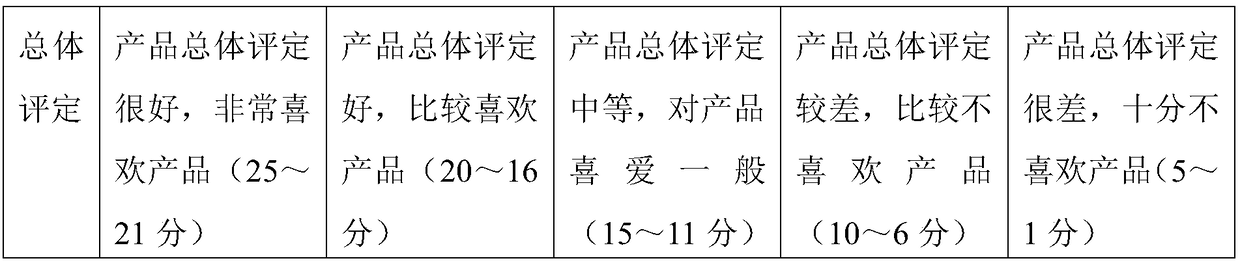

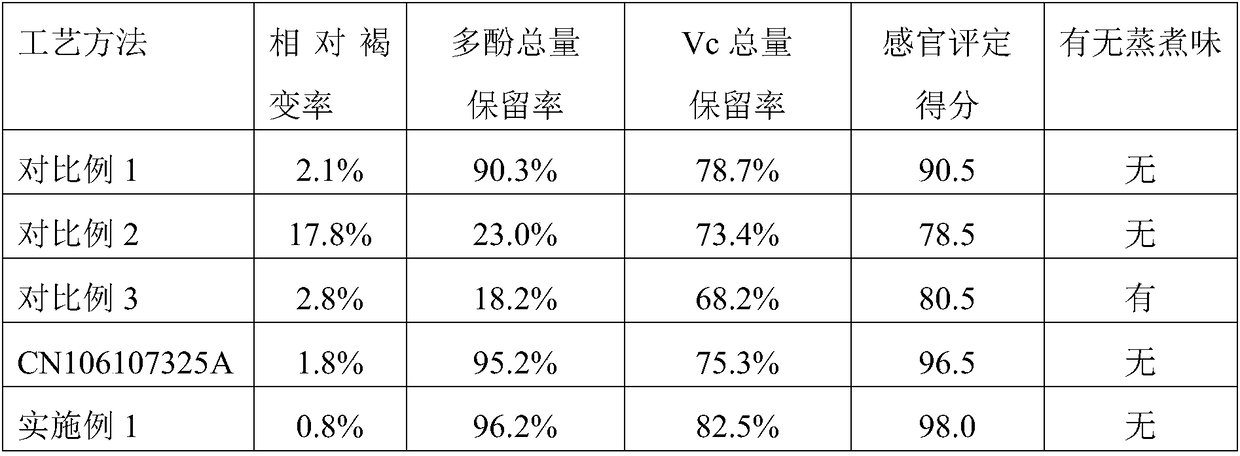

Method for inhibiting browning of freshly squeezed fruit and vegetable juice by ultra-high temperature instantaneous treatment

InactiveCN108771090AImprove stabilitySolubility adapts to a wide rangeFood ingredient functionsProtein food ingredientsFood flavorPolyphenol oxidase

The invention provides a method for inhibiting the browning of freshly squeezed fruit and vegetable juice by ultra-high temperature instantaneous treatment. The method includes the steps of: (1) raw material selection and pretreatment; (2) ultra-high temperature instantaneous treatment; and (3) rapid cooling. The method provided by the invention adopts coupling of ultra-high temperature steam enzyme deactivation technology and ultra-low temperature cooling technology, raises the steam temperature, achieves shorter deactivation treatment time and faster cooling speed, and also can more effectively lower the loss of fruit and vegetable nutritional quality and flavor substances while realizing the enzyme activity loss of polyphenol oxidase.

Owner:JIANGNAN UNIV

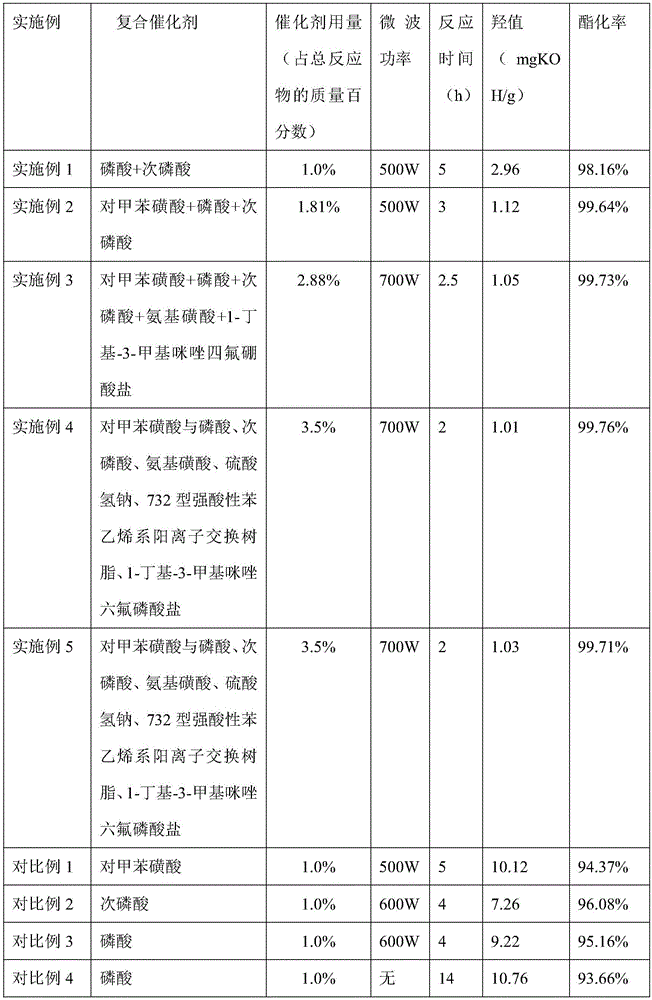

Method for microwave synthesis of glyceryl caprylate-caprate

InactiveCN106699555AImprove efficiencyReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationGLYCERYL CAPRYLATE-CAPRATEGlyceryl Caprate

The invention provides a preparation method for microwave synthesis of glyceryl caprylate-caprate. Caprylate-caprate and glycerin are reacted in the presence of a compound catalyst, and a glyceryl caprylate-caprate product is prepared by microwave synthesis. According to the method, the molar ratio of caprylate and caprate in the glyceryl caprylate-caprate is regulated, catalysis of the compound catalyst is combined, and a frequency band of 300 to 3,000MHz is adopted for microwave synthesis, so that the high-quality glyceryl caprylate-caprate of which the molar ratio of the caprylate and the caprate is controllable can be efficiently and rapidly prepared. According to the method, a high esterification rate can be achieved, and meanwhile, the energy consumption and the production cost of a reaction process can be remarkably reduced.

Owner:广州星业科技股份有限公司

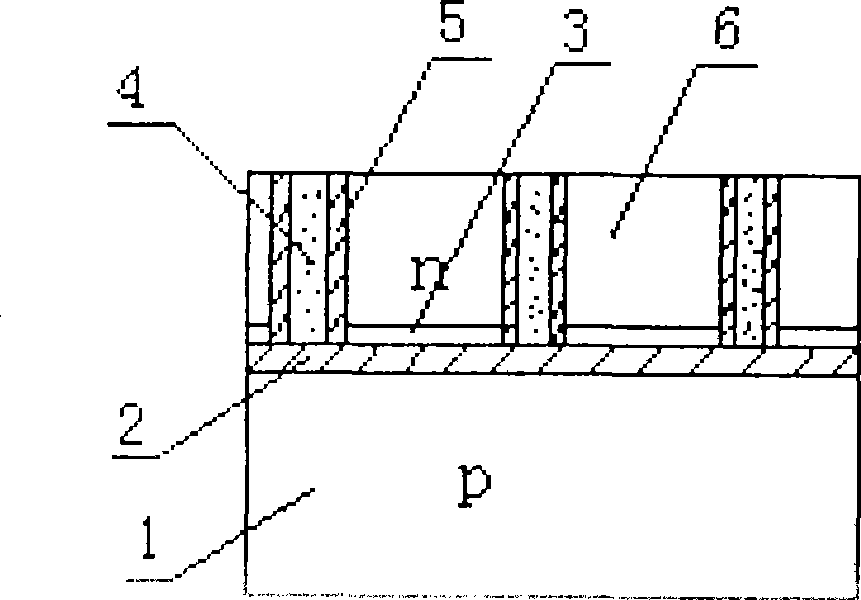

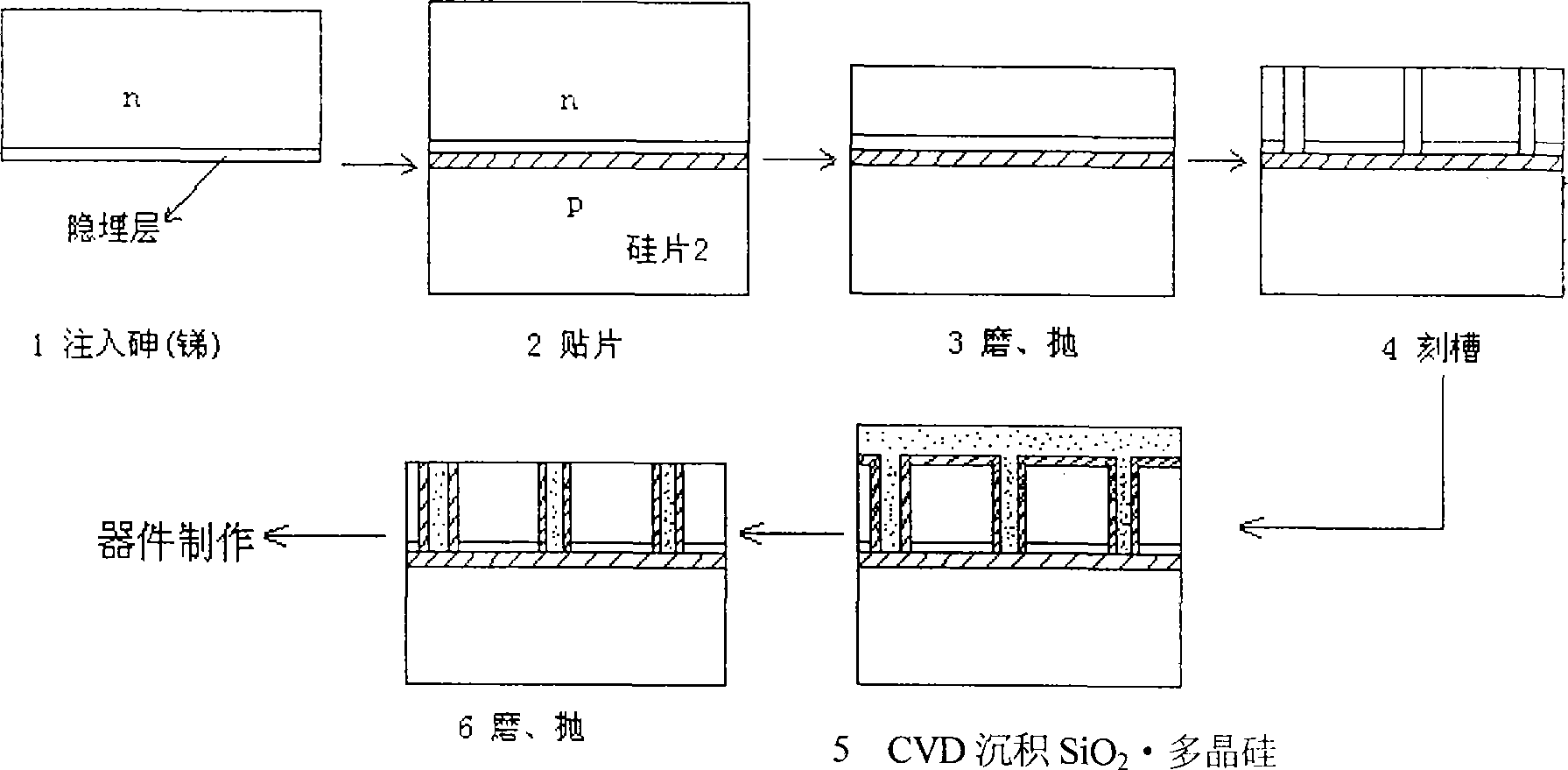

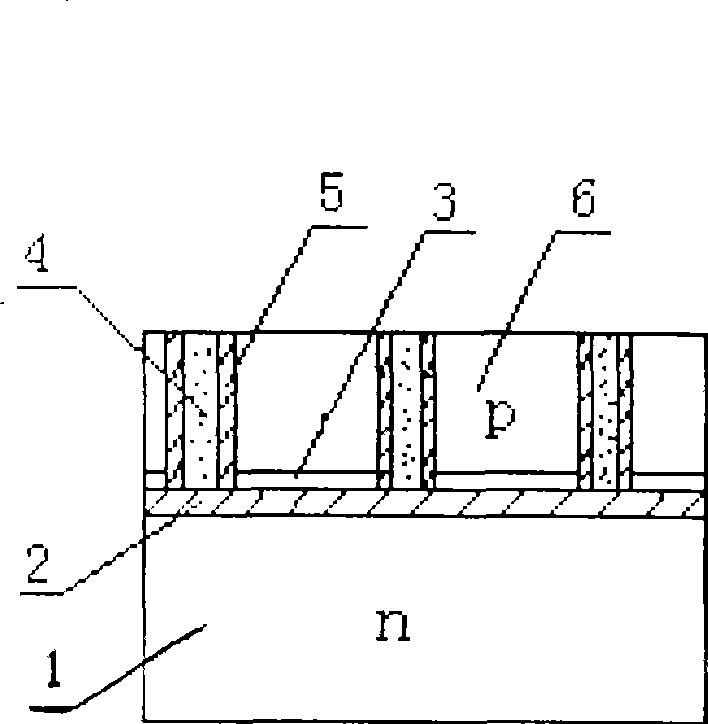

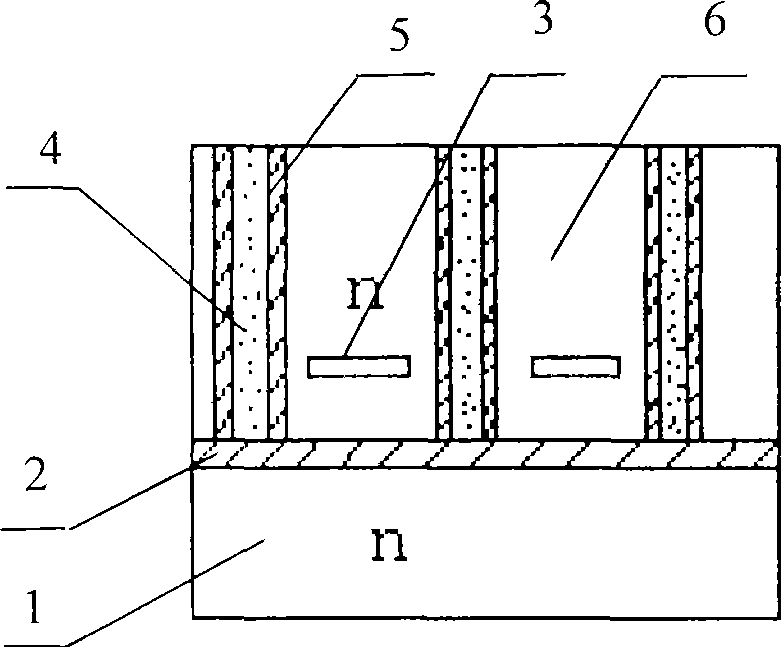

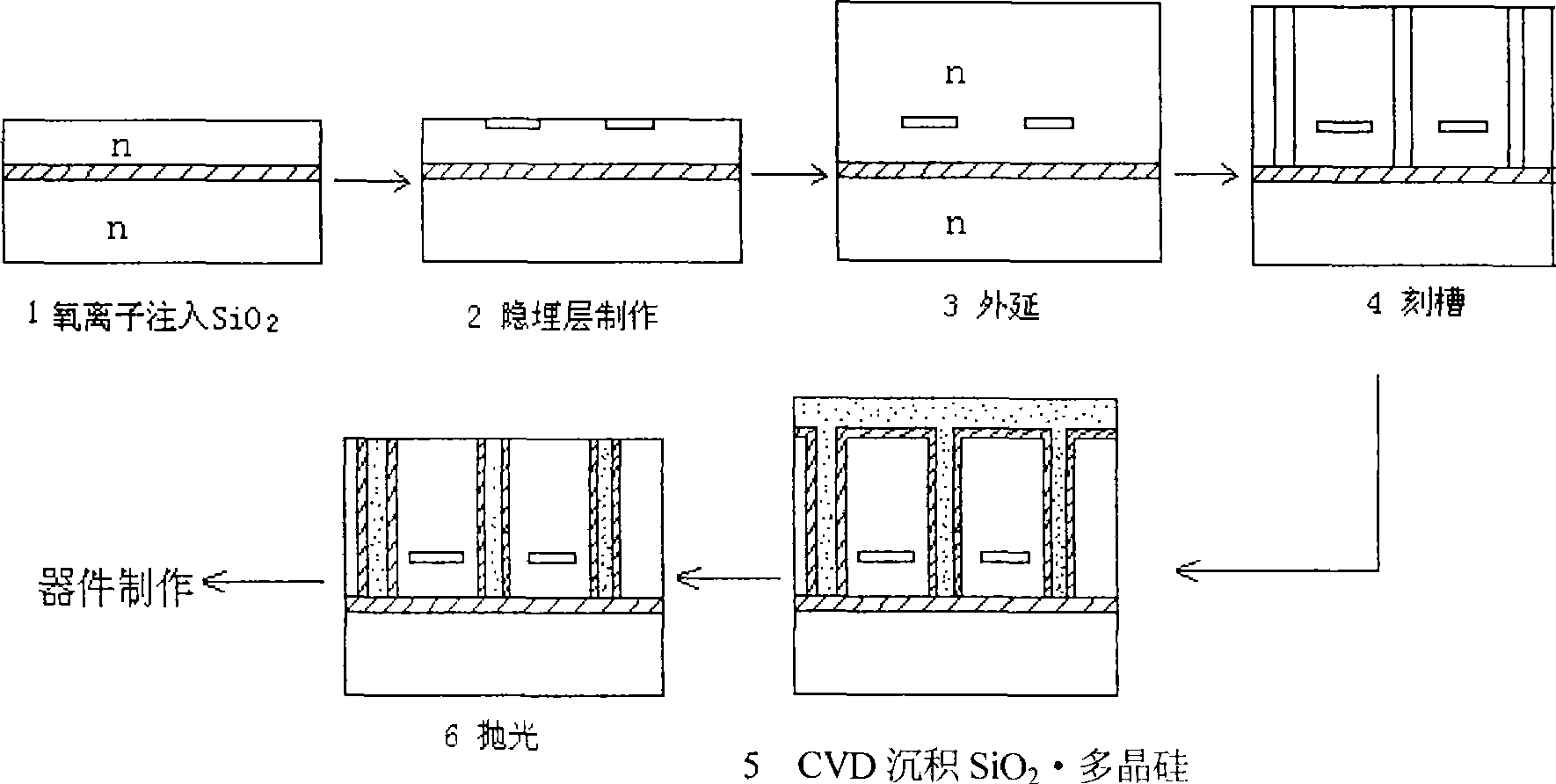

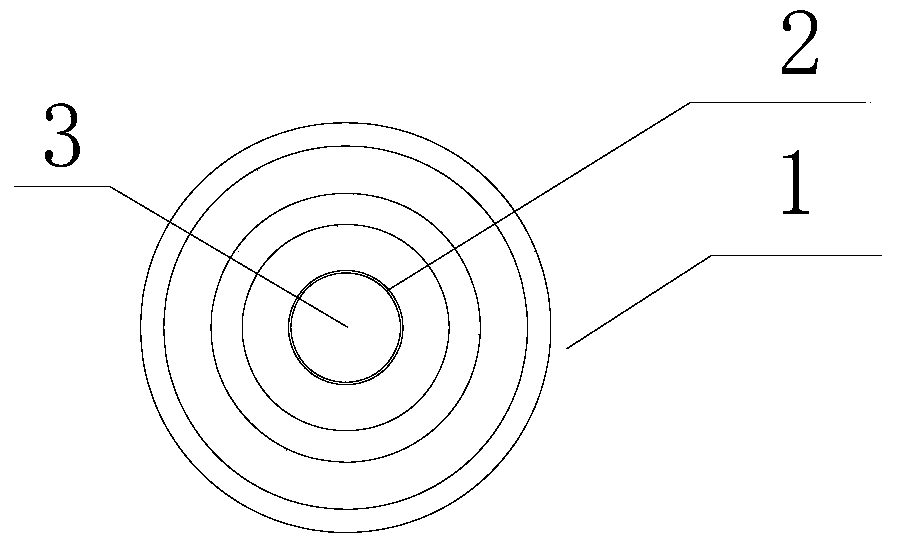

Dielectrically isolated integrated circuit silicon chip and preparation method thereof

InactiveCN101465357AImprove performanceImprove performance parametersSolid-state devicesSemiconductor/solid-state device manufacturingSingle crystalP type silicon

The invention mainly relates to a preparation method of a dielectric isolation silicon chip. An N-type / P-type dielectric isolation integrated circuit silicon chip is mainly characterized in that the integrated circuit silicon chip is provided with an N-type / P-type substrate silicon chip (1) and an N-type / P-type silicon monocrystal layer (6); a sandwiched oxide layer (2) is arranged on the N-type / P-type substrate silicon chip (1); a buried layer (3) is arranged inside the silicon monocrystal layer (6); the silicon monocrystal layer (6) is separated into mutually insulated isolation cubic blocks through silicon dioxide (5), polysilicon (4) and the sandwiched oxide layer (2). The invention also discloses a preparation method of the N-type / P-type dielectric isolation integrated circuit silicon chip; and the method comprises the steps of buried layer preparation, patching, grinding, polishing and grooving. Because the high-temperature time is greatly shortened in the preparation, the crystal structure is more integrated and the process control is more accurate, and high-performance circuits with special requirements can be produced. The resistivity of the single chip is appropriately increased, so that high (power)-voltage circuits can be produced with a certain power output.

Owner:TIANSHUI HUATIAN MICROELECTRONICS

Process for preparing L-ofloxacin and ofloxacin

InactiveCN100412075CReduce high temperature timeFew reaction stepsOrganic chemistryPropanolReaction temperature

The invention relates to a process for preparing L-ofloxacin and ofloxacin which consists of, charging solution into 2-(2,3,4,5-tetrafluorobenzoyl-3-ethoxy-ethyl acrylate crude product, freezing, dropping L-amino propanol or DL-amino propanol, thermal insulating till the completion of conversion, alkalizing, reacting at the temperature of 50-90 deg. C, charging N-methyl piperazine into mother liquor, stirring for reaction 1-3 hours at 55-95 deg. C, decompressing and reclaiming N-methyl piperazidine, thermal insulating, plunging reaction liquor into water, agitating, cooling down and filtering, charging water and acid into filtrate, stirring, inversing flow till the completion of hydrolysis, adjusting the pH=7.0 with alkali liquor, extracting by adding in solvent extraction reagent, and concentrating the extract layer.

Owner:ZHE JIANG MEDICINE CO LTD XINCHANG PHARMA FAB

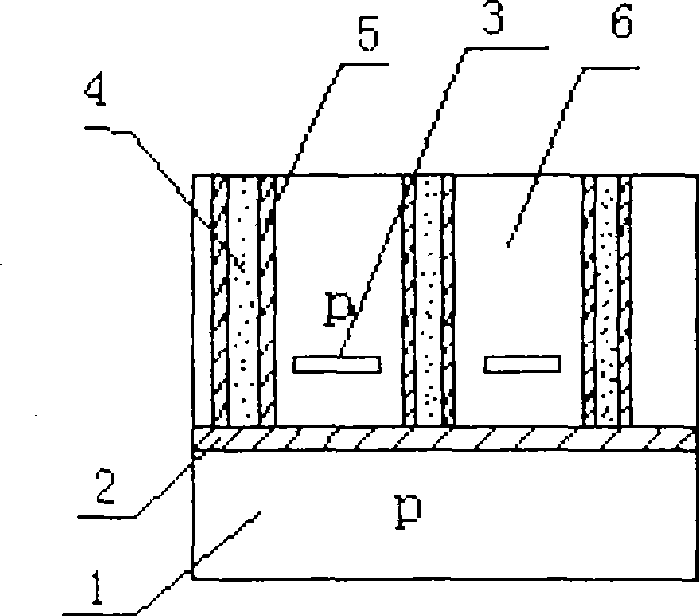

Dielectrically isolated integrated circuit extending wafer and preparation method thereof

InactiveCN101425522AImprove performanceImprove high temperature resistanceSolid-state devicesSemiconductor/solid-state device manufacturingCrystal structureSilicon dioxide

The invention mainly relates to a dielectric isolation epitaxial wafer and a preparation method thereof. The N-shaped / P-shaped dielectric isolation integrated circuit epitaxial wafer comprises N-shaped / P-shaped monocrystalline silicon (1) with backing material. A sandwich oxide layer (2) is arranged on the monocrystalline silicon (1). The invention is mainly characterized in that the dielectric isolation epitaxial wafer further comprises an N-shaped / P-shaped silicon epitaxial layer (6); a buried layer (3) is arranged in the silicon epitaxial layer (6); the silicon epitaxial layer (6) is divided into mutually-insulating isolation blocks by silicon dioxide (5), polysilicon (4) and the sandwich oxide layer (2). The invention also discloses a preparation method of the N-shaped / P-shaped dielectric isolation integrated circuit epitaxial wafer. The preparation method comprises the following steps: preparing a silicon chip on an insulating body, preparing the buried layer with low resistance, extending outwardly, notching, growing the silicon dioxide and the polysilicon, and polishing. Because the high temperature time is shortened greatly during the preparation, the invention has the advantages of more complete crystal structure and more accurate process control, and can be used for manufacturing circuits with high performance and special requirements.

Owner:TIANSHUI HUATIAN MICROELECTRONICS

Processing method of fruity black tea

PendingCN112167383AIncreased phenolic aroma componentsReduce degradationPre-extraction tea treatmentBiotechnologyFermentation

The invention relates to the technical field of black tea processing, in particular to a processing method of fruity black tea. The processing method comprises the following operation steps: raw material selection, withering, rolling, fermentation and high-temperature treatment. Tea leaves and fruity substance components are fully compatible through rolling, the fruity substance components can permeate into the tea leaves, the aroma components in the tea leaves are solidified and cannot be decomposed through multiple times of high-temperature treatment, long-time storage is facilitated, and mango is mixed again in fermentation, so that phenol aroma components in the tea leaves are further increased, finally, through high-temperature rapid treatment and drying, the high-temperature time isshortened, and degradation of nutritional ingredients in the tea leaves is reduced.

Owner:贵州晴隆五月茶业有限公司

Method for processing, packing and storing hickory

ActiveCN100521979CReduce high temperature timeReduce the degree of oxidationFruit and vegetables preservationFood preparationComposite filmHydrolysis

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Method for making dried roxburgh rose fruit

InactiveCN102177955BRetain nutritionIncrease nutritionClimate change adaptationFruits/vegetable preservation by dehydrationHigh humidityVitamin C

The invention relates to a method for making dried roxburgh rose fruit. In the fabrication method, aiming at the defects of the existing roxburgh rose sun-drying and drying processing method such as oxidation of vitamin C under ultraviolet rays, great loss of nutrients and human health hazards caused by later-stage sulphur powder fumigation, a three-segment air-drying mode is adopted so that the fruit product is dried from inside to outside, the high temperature time is shortened, the probability of oxidation reaction is reduced, the greatest nutrient quantity of the fruit product is maintained, the problems such as cracked surface, poor appearance and high humidity in the fruit during the high-temperature sun-drying process are avoided, the sulphur fumigation procedure is not required, and the loss of the vitamin C is reduced to 3.2%-4.8% during the preservation period, thus solving the problems such as difficulty in preservation and nutrition loss.

Owner:陈贵恩

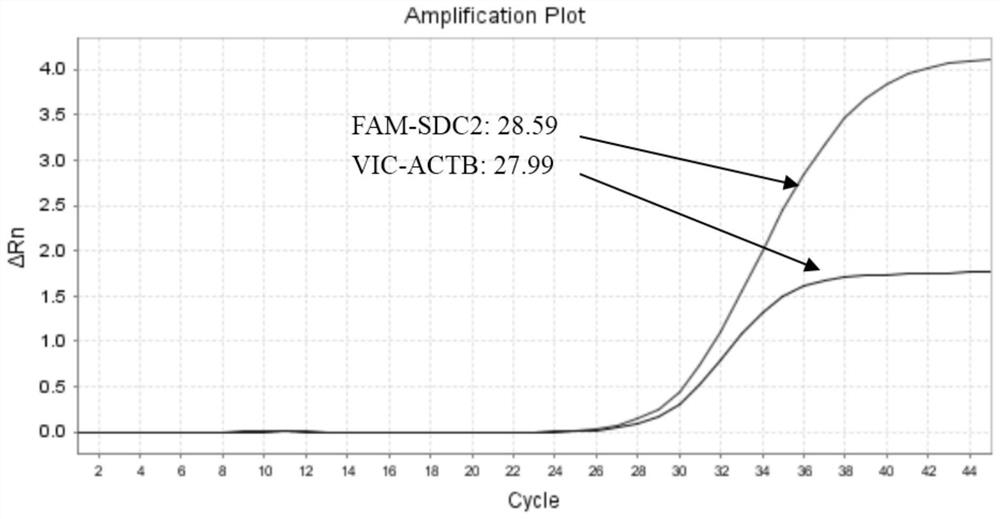

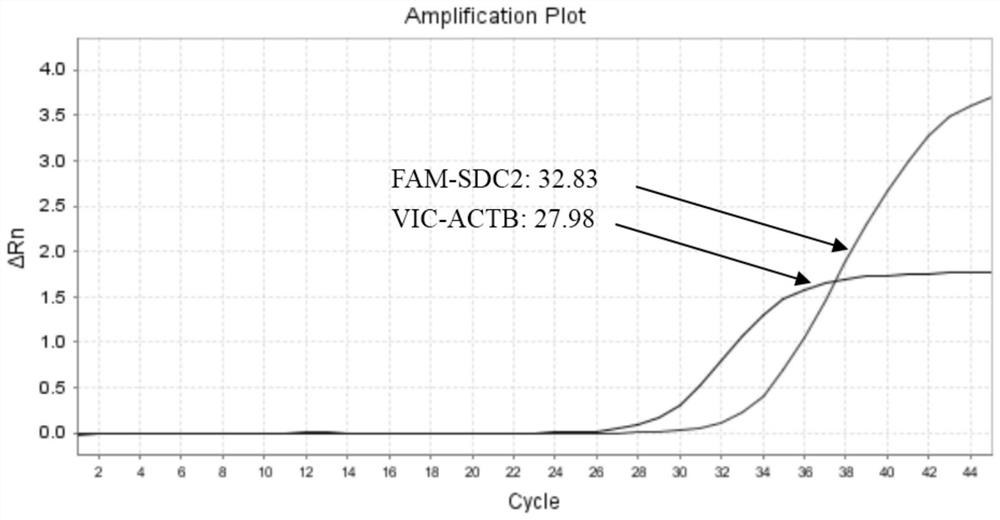

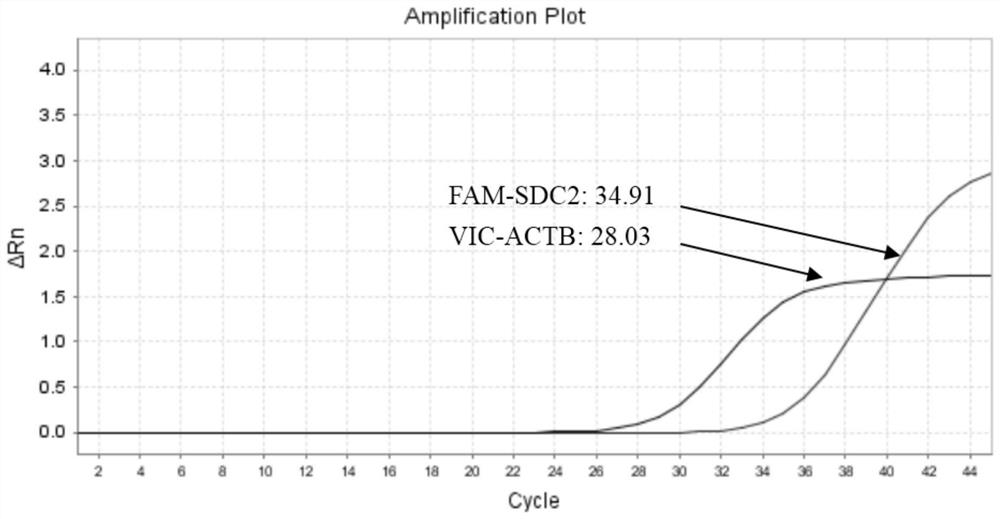

DNA protective agent and DNA sulfite conversion method

The invention discloses a DNA protective agent and a DNA sulfite conversion method, and relates to the technical field of DNA methylation state analysis and detection. The DNA protective agent comprises hydroquinone, dimethyl sulfoxide and a DNA anti-degradation agent, and the DNA anti-degradation agent is glucomannan and / or arabic gum. The DNA protective agent can obviously reduce damage to DNA in the transformation process, avoid DNA degradation and maintain the integrity of the DNA. Besides, the high conversion rate of the non-methylated cytosine can be realized to a great extent, and the melting temperature of the DNA can be reduced to a great extent, so that the high-temperature denaturation time is indirectly shortened, and the problems of breakage and degradation caused by high-temperature damage of the DNA are solved.

Owner:WUHAN YZY MEDICAL SCI & TECH

A kind of layered ignition method of burning oil layer

ActiveCN104453821BImprove power efficiencyImprove ignition efficiencyFluid removalCombustionThermal insulation

The invention provides an in-situ combustion layered ignition method. The method includes the steps that a casing pipe is landed into an oil well and extends to the well bottom; a thermal insulation pipe is landed into the casing pipe and a first annular space is formed between the thermal insulation pipe and the casing pipe; the first annular space is sealed through a first packer and a second packer, so that an upper-layer gas injection space and a lower-layer gas injection space are formed; an upper-layer gas distribution device located in the upper-layer gas injection space is arranged on the thermal insulation pipe; a Pupin oil pipe is landed into the thermal insulation pipe, a second annular space is formed between the Pupin oil pipe and the thermal insulation pipe, and an enhanced heat transfer device is arranged in the second annular space; an electric ignition device is landed in an inner cavity of the Pupin oil pipe; air is injected in the inner cavity and the second annular space and nitrogen is injected into the first annular space; the electric ignition device is started; heated gas in the thermal insulation pipe is injected into the upper-layer gas injection space through the upper-layer gas distribution device and an upper oil layer is heated and ignited; heated gas in the Pupin oil pipe is injected into the lower-layer gas injection space through the tail end of the Pupin oil pipe and a lower oil layer is heated and ignited.

Owner:PETROCHINA CO LTD

Production method of original waxberry leisure food

ActiveCN103444858BKeep the flavorGreat tasteFruits/vegetable preservation by dehydrationBiotechnologyFood additive

The invention discloses a production method of an original waxberry leisure food. The production method comprises the steps of carrying out ozone water treatment on fresh fruits, soaking the treated fruits into a 5% salt solution, draining, drying at three temperatures until the content of water is 10%-18%, cooling, placing into an aluminizing foil bag and then sealing to obtain the finished product. In the production method, the loss of original nutrition ingredients of waxberry, caused by production methods of salting, sugaring or adding other food additives, is reduced, a large quantity of pesticide residues are removed, and three-temperature drying is combined to remain the nutrition of the waxberry fruit well. The produced dried waxberry fruit remains the original taste of the waxberry and is good in mouthfeel, green, safe and good in commodity.

Owner:POMOLOGY RES INST FUJIAN ACAD OF AGRI SCI

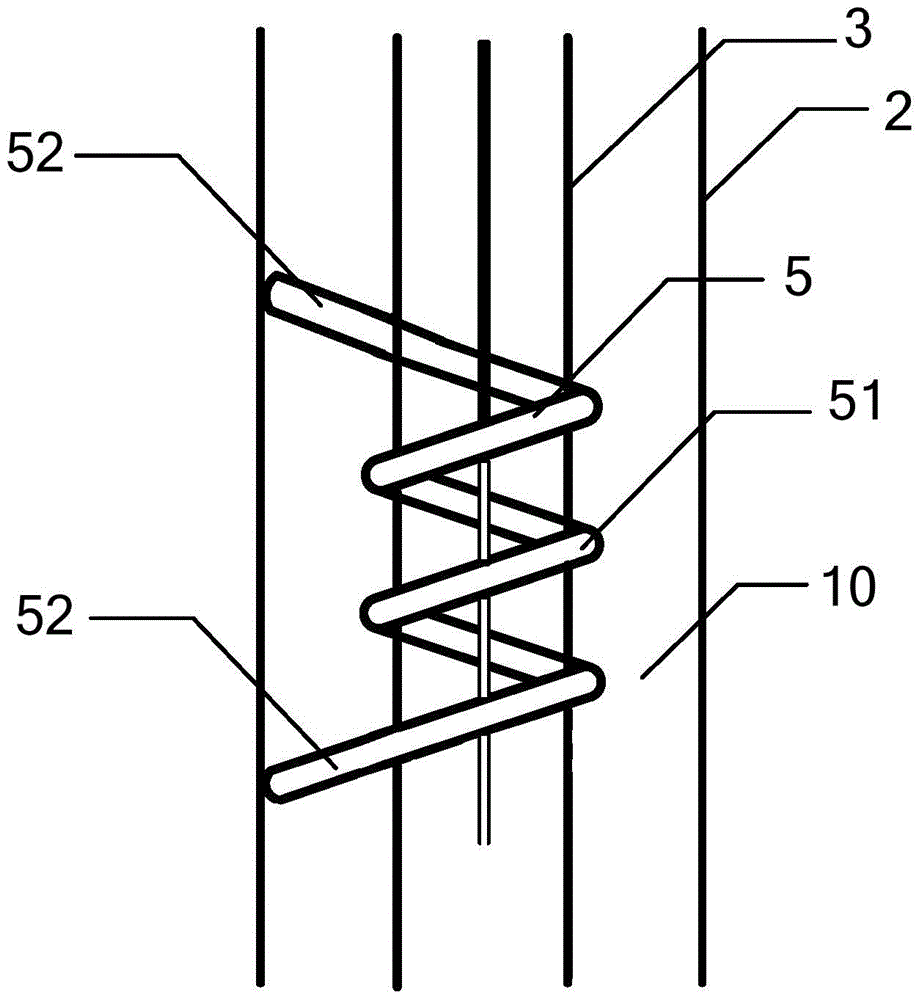

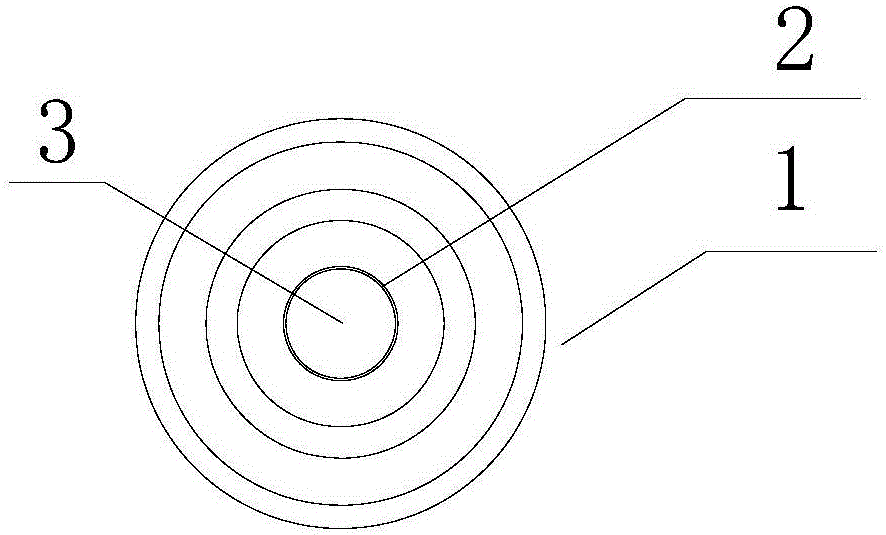

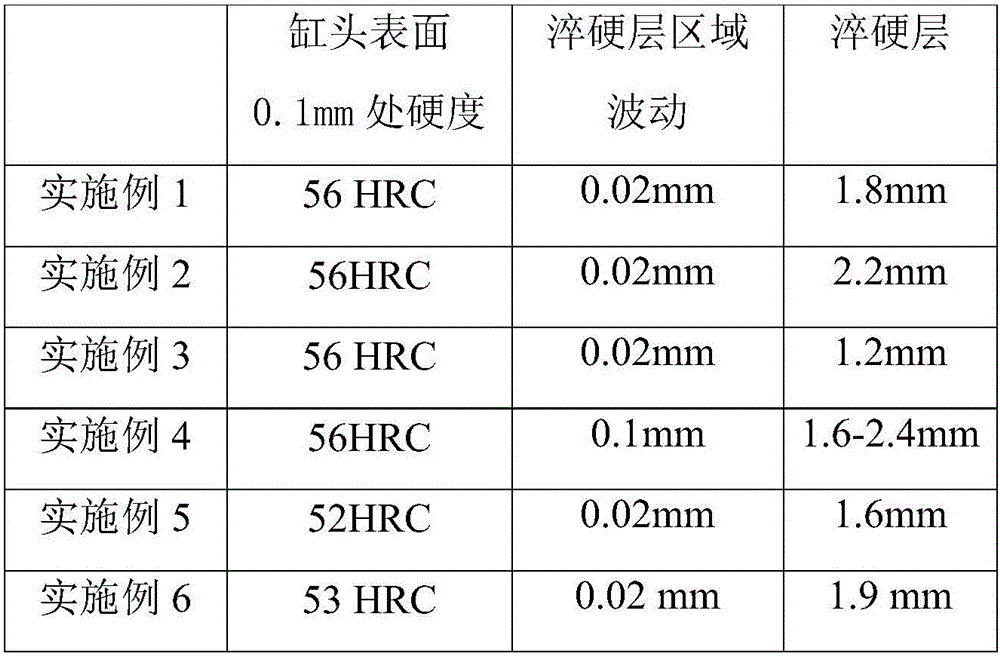

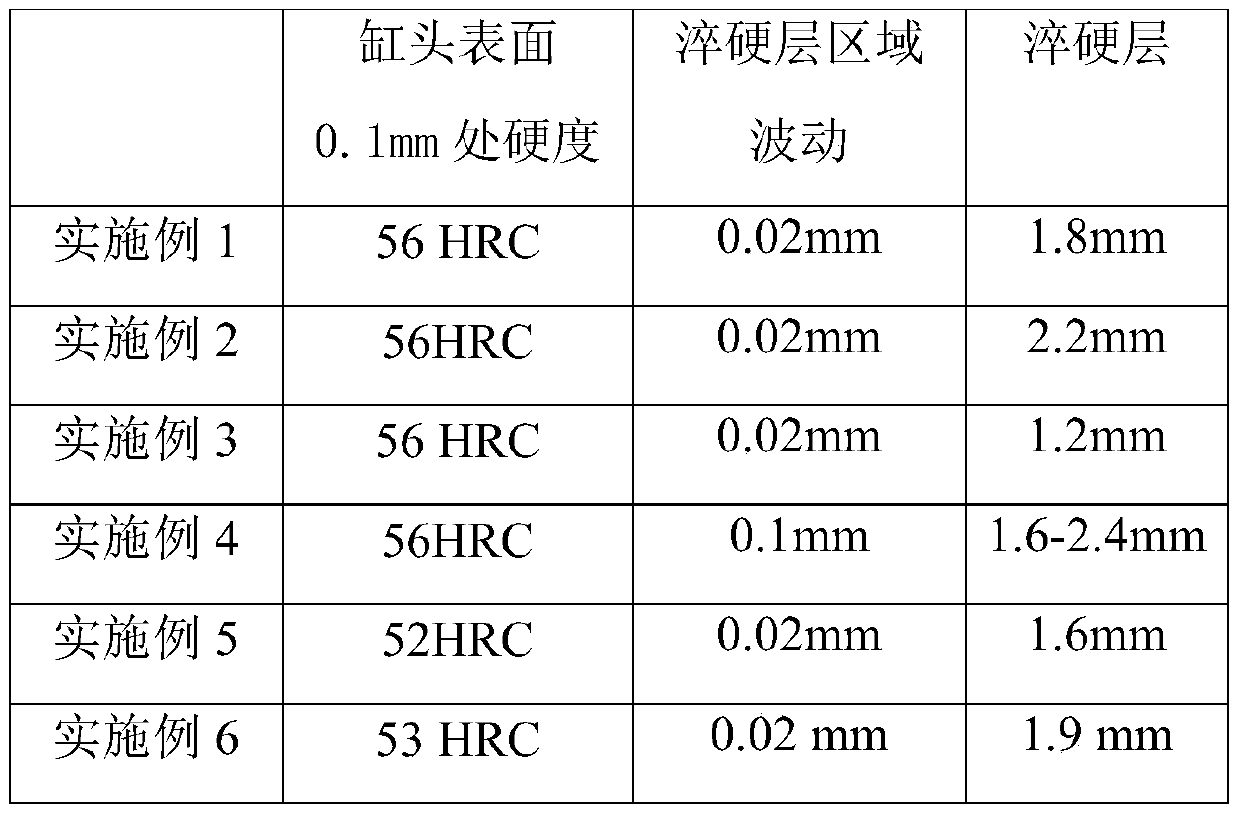

Surface modification treatment method for car inner cylinder

ActiveCN106191412ASimple processing methodShort processing cycleFurnace typesIncreasing energy efficiencyHardnessWater spray

The invention discloses a surface modification treatment method for a car inner cylinder. The method sequentially comprises the steps of cooling water introduction, heating and cooling. Heating and water spraying cooling are conducted continuously. A cylinder end of the car inner cylinder is subjected to water spraying cooling immediately when being heated to the quenching temperature. According to the method, the cylinder end of the car inner cylinder is centered and continuously heated and cooled simultaneously, so that the whole workpiece is evenly heated and evenly cooled, an obtained product is good in quality, and the defect that in an existing high-frequency quenching process, the hardness of the position, with the thickness being 0.1mm, of the surface of the car inner cylinder workpiece is lower than 55 HRC is overcome. In addition, by the adoption of the surface modification treatment method, machining is convenient, the production cycle is short, and energy consumption is low.

Owner:上海朋泰机械科技有限公司

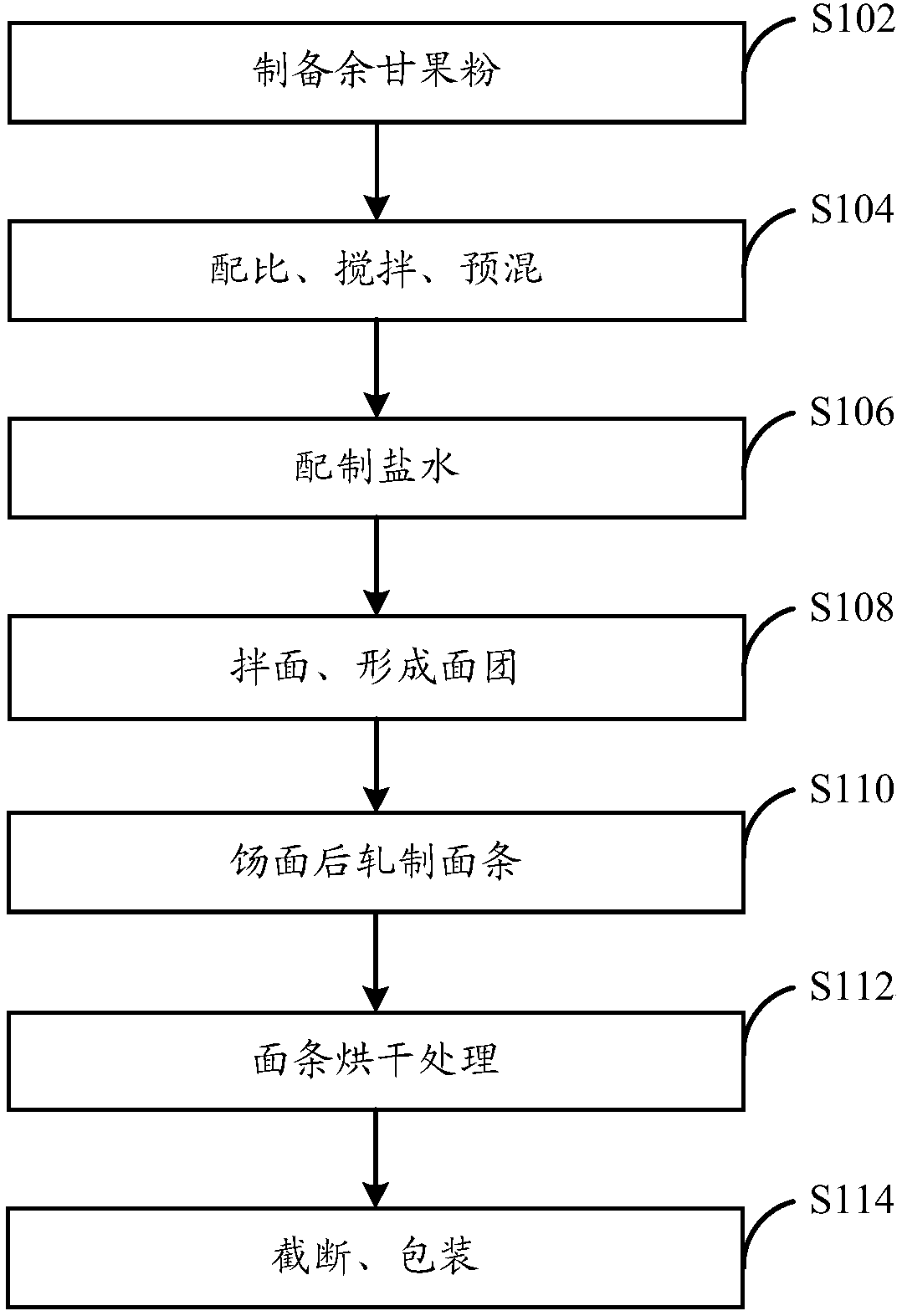

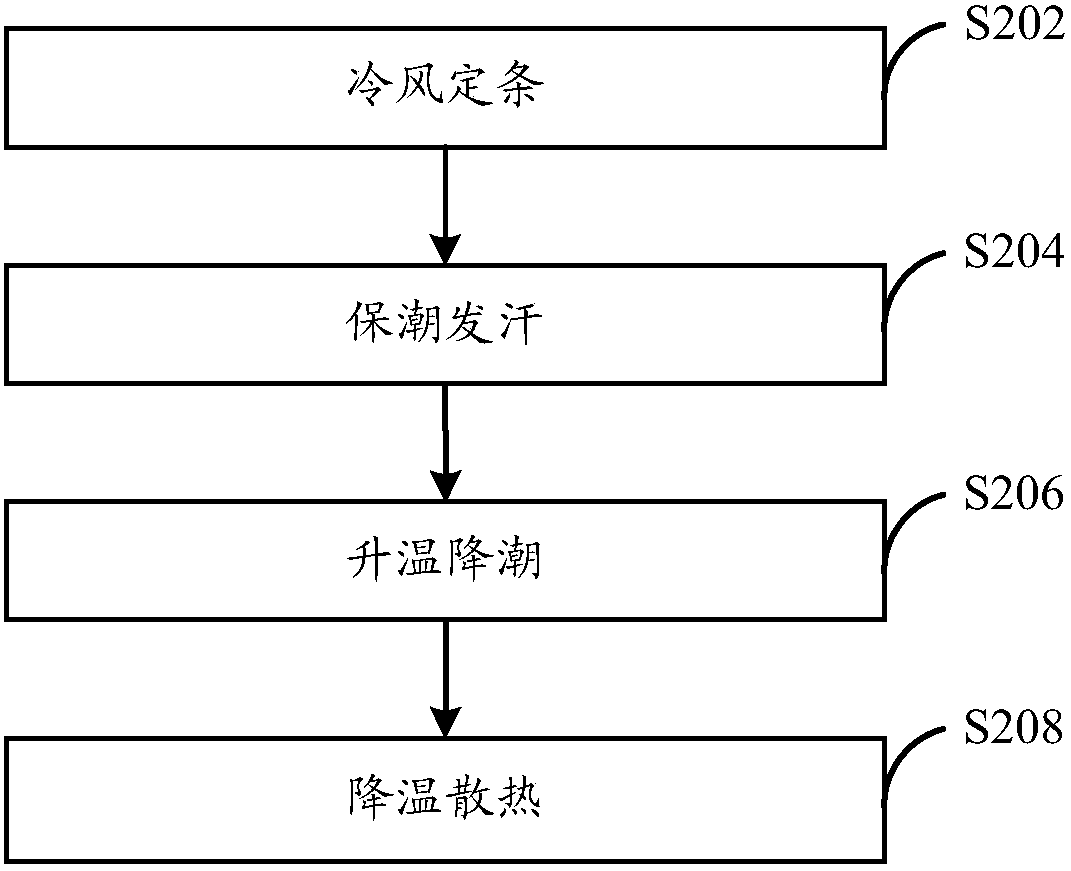

Phyllanthus emblica L. fine dried noodles and preparation method thereof

InactiveCN107865308AAvoid churnTechnical pitfalls to avoid loss of biological activityFood dryingFood ingredient functionsBiotechnologySalt water

The invention discloses Phyllanthus emblica L. fine dried noodles and a preparation method thereof. The Phyllanthus emblica L. fine dried noodles comprises, by weight, 96 to 105 parts of wheat flour,1 to 3 parts of Phyllanthus emblica L. powder, 0.5 to 1.5 parts of table salt and 0.01 to 0.025 parts of edible alkali. The preparation method comprises preparing Phyllanthus emblica L. powder, pre-mixing the Phyllanthus emblica L. powder and wheat flour according to a weight part ratio through stirring, dissolving the mixture with edible water according to a certain ratio, carrying out uniform mixing, adding salt water into the pre-mixed flour, carrying out stirring, carrying out standing, carrying out rolling through a continuous calender to obtain noodles, drying the noodles, cutting the noodles and carrying out quantitative packing.

Owner:想念食品股份有限公司

A surface modification treatment method for an automobile inner cylinder

ActiveCN106191412BSimple processing methodShort processing cycleIncreasing energy efficiencyFurnace typesHardnessQuenching

The invention discloses a surface modification treatment method for a car inner cylinder. The method sequentially comprises the steps of cooling water introduction, heating and cooling. Heating and water spraying cooling are conducted continuously. A cylinder end of the car inner cylinder is subjected to water spraying cooling immediately when being heated to the quenching temperature. According to the method, the cylinder end of the car inner cylinder is centered and continuously heated and cooled simultaneously, so that the whole workpiece is evenly heated and evenly cooled, an obtained product is good in quality, and the defect that in an existing high-frequency quenching process, the hardness of the position, with the thickness being 0.1mm, of the surface of the car inner cylinder workpiece is lower than 55 HRC is overcome. In addition, by the adoption of the surface modification treatment method, machining is convenient, the production cycle is short, and energy consumption is low.

Owner:上海朋泰机械科技有限公司

Terpene resin hydrogenation method

ActiveCN112341571ALow softening pointHigh softening pointChemical recyclingMetal/metal-oxides/metal-hydroxide catalystsMolecular sievePtru catalyst

The invention discloses a terpene resin hydrogenation method, and the method comprises: carrying out resin synthesis, and activating a hydrogenation catalyst in a first fixed bed hydrogenation reactorand a second fixed bed hydrogenation reactor; adding a cyclohexane solvent into the reactor at a speed of 0.1-5 ml / min, adjusting the hydrogen introduction speed to 300-400 ml / min, changing the cyclohexane solvent into the molecular sieve dehydrated reaction solution obtained in the step 1) after a liquid material exists in the product liquid separation tank, and carrying out a reaction to obtainhydrogenated terpene resin, thereby obtaining terpene hydrogenated resin. The method has the advantages that the production cost can be reduced, the reaction temperature is low, the reaction efficiency is improved, and the obtained hydrogenated terpene resin is stable in performance, not prone to discoloring and the like.

Owner:PUYANG XINYU PETROCHEM IND

A kind of lycopene production process

ActiveCN105541538BReduce pollutionEasy to operateHydrocarbon purification/separationNatural dyesFluidized bed dryingSlag

The invention discloses a lycopene production process, wherein tomato skin slag is taken as a raw material, and subjected to squeezing, roller-drying, seed skin separating, fluidized bed drying, grinding and extracting. The lycopene production process is simple in operation and mild in conditions, the process takes the tomato skin slag in ketchup production of a ketchup plant as the raw material, cost is reduced, and pollution to the environment is reduced by using the wastes.

Owner:晨光生物科技集团焉耆有限公司

Preparation method of selective emitter structure in lightly doped region with low surface concentration

InactiveCN103904141BImprove uniformityImprove output performanceFinal product manufactureSemiconductor devicesScreen printingMicrocosmic salt

A method for manufacturing a selective emitter structure with low surface concentration and a soft doped zone includes the steps that (1) the surface of a substrate to be prepared is corroded and cleaned, and the surface of the substrate is completely dried after cleaning; (2) the clean substrate prepared in the step (1) is soaked in a solution with high oxidability to carry out wet chemical oxidation on the surface of a silicon wafer, and then the surface of the substrate is completely dried; (3) a microcosmic salt aqueous solution of 0.5-20% is deposited on the surface of the substrate in a spin coating and spraying mode, and then the surface of the substrate is dried; (4) phosphorus ink or silicon ink is deposited on an electrode area on the surface of the substrate coated with a phosphorus source in the step (3) in a screen printing mode, and then the surface of the substrate is dried; (5) the temperature of a diffusion furnace rises, nitrogen is introduced into a diffusion quartz tube, when the temperature reaches 780-890 DEG C, the clean substrate prepared in the step (4) is placed into a constant-temperature area of the diffusion quartz tube, a fire door of the diffusion furnace is sealed, and after the temperature of the diffusion furnace is stable, oxygen is introduced into the diffusion quartz tube; (6) the substrate is taken out and cooled after the diffusion process is over.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

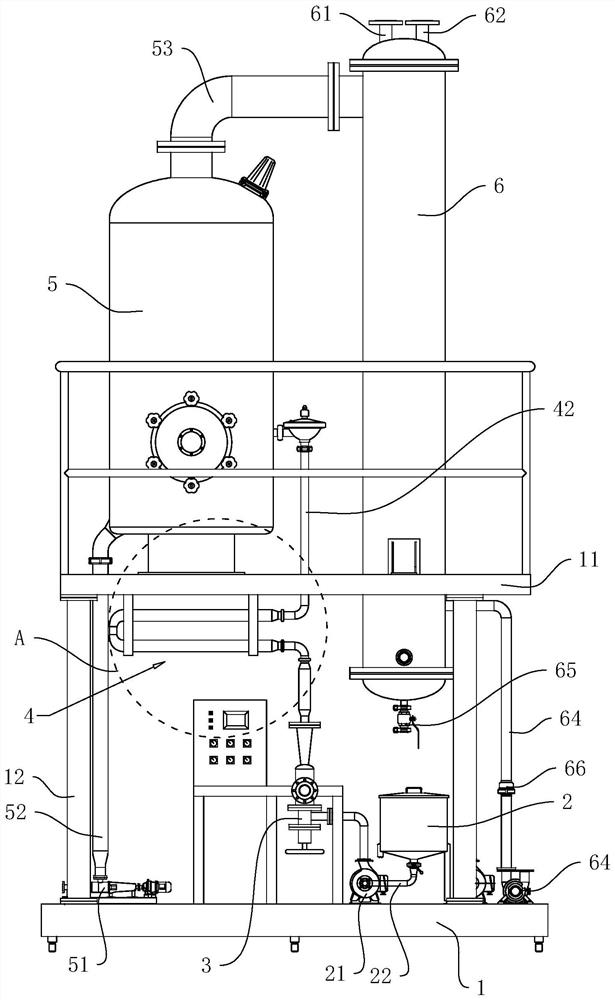

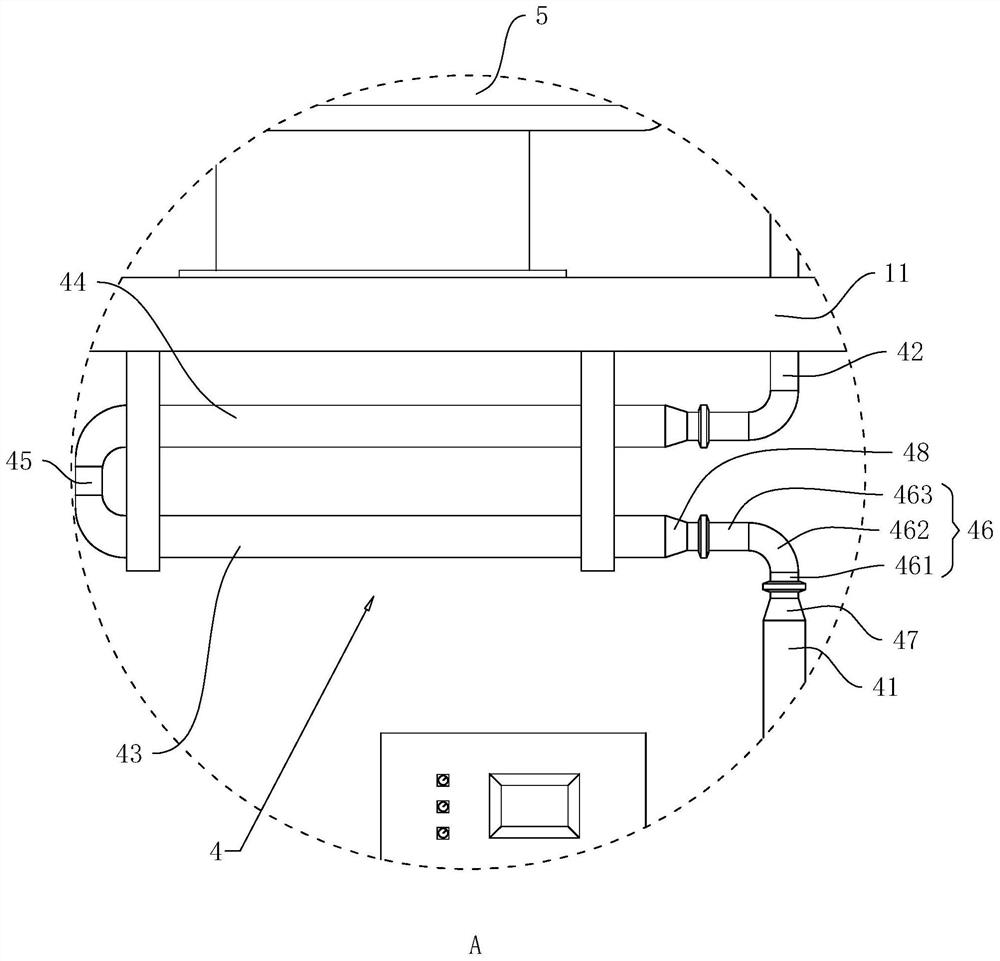

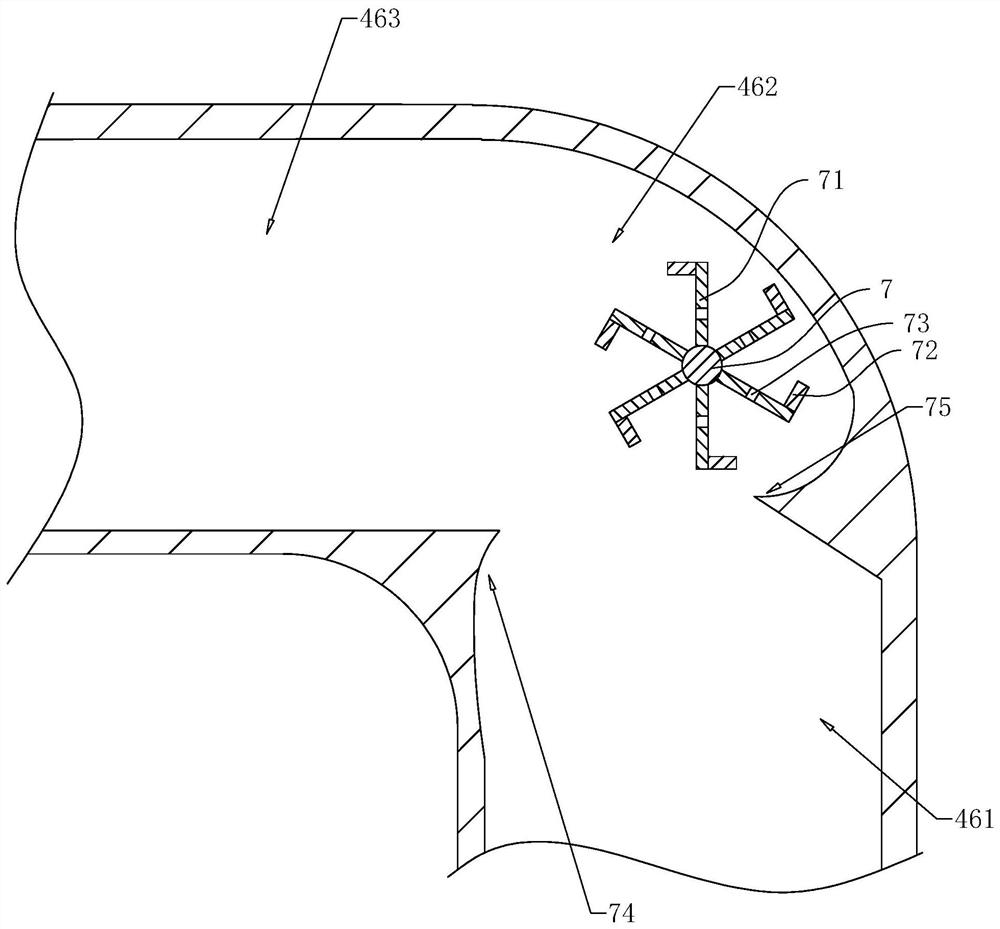

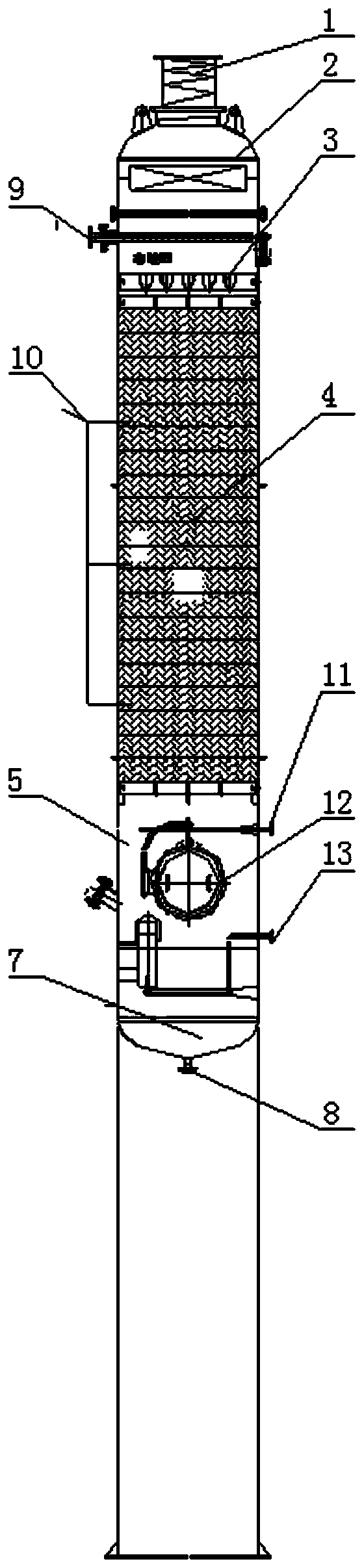

High-temperature sterilization machine

PendingCN113615791AImprove energy utilizationReduce high temperature timeFood scienceFood processingInjectorProcess engineering

The invention discloses a high-temperature sterilization machine, and belongs to the field of food processing. The high-temperature sterilization machine comprises a material container and a steam ejector, a feeding pump communicates with the space between the material container and the steam ejector, a flash evaporator is arranged above the steam ejector, a maintaining pipe communicates with the space between the steam ejector and the flash evaporator, and the flash evaporator is connected with a condenser. The high-temperature sterilization machine has the effect of keeping the quality of a product while sterilizing.

Owner:上海永德食品机械有限公司

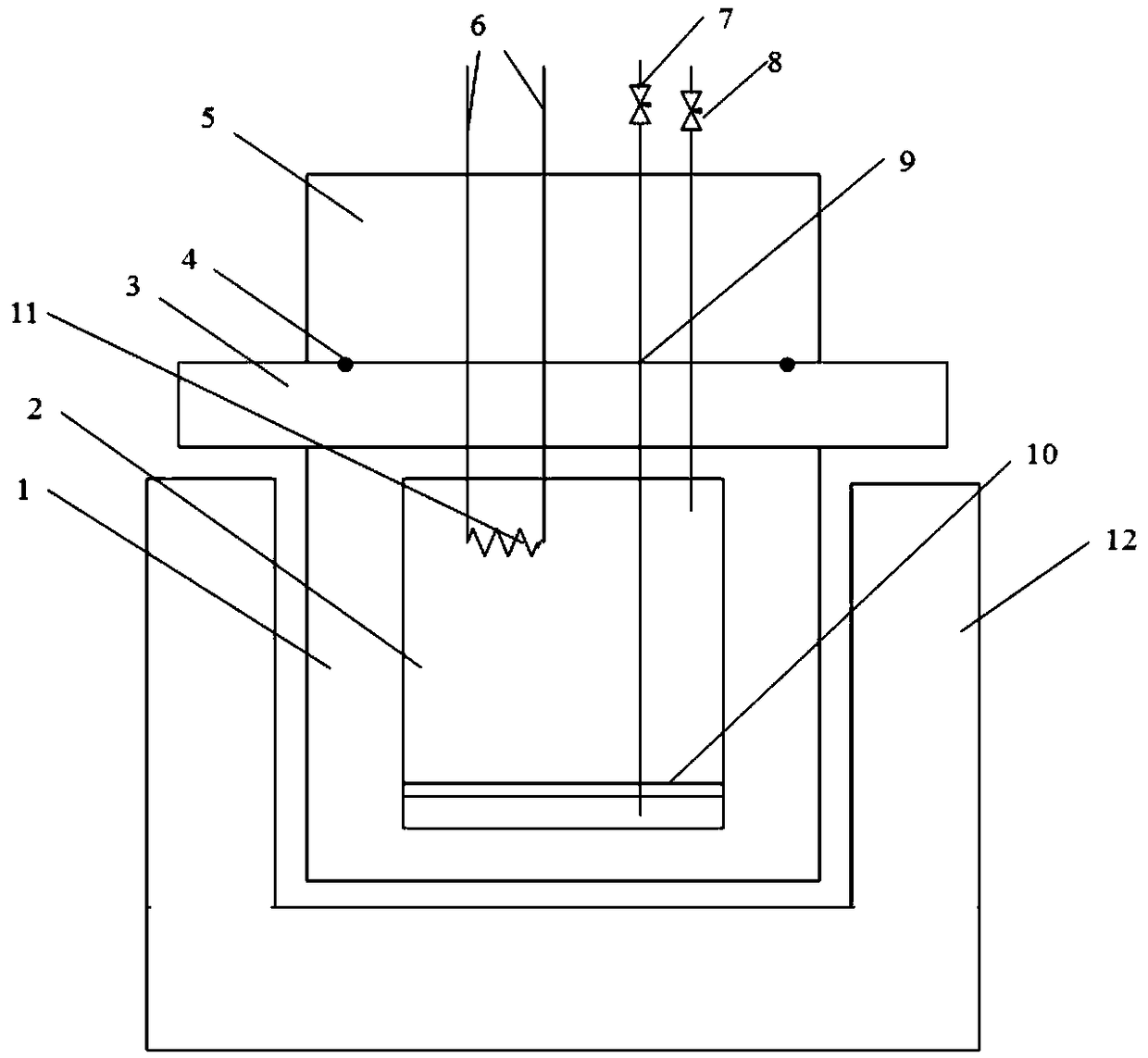

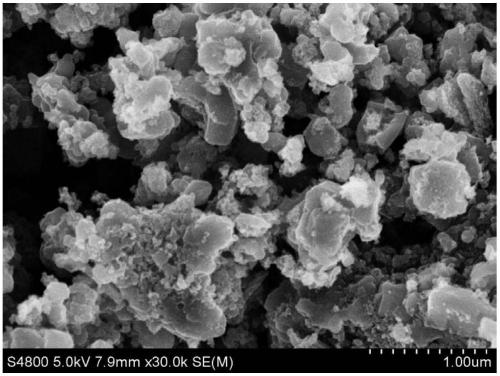

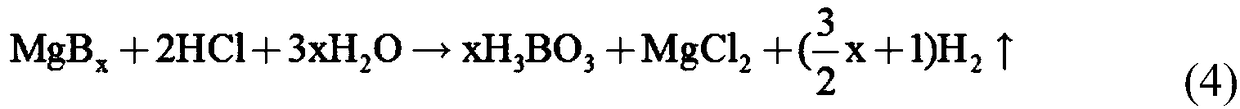

A preparation device for amorphous boron powder and method for preparing amorphous boron powder

The invention relates to an amorphous boron powder preparation device. The device comprises a sealing body, a reactor (2), a self-propagating reaction initiation assembly, an air inflation valve (7),an air release valve (8), an air guide pipe (9) and a heating body (12); the reactor (2) is used for containing reaction raw materials; the sealing body is used for placing the reactor (2), and the reaction raw materials in the reactor are subjected to heat insulation from the exterior and located in a sealing space in a reaction process; the self-propagating reaction initiation assembly is used for initiating a self-propagating reaction of the reaction raw materials; two air through holes are formed in the sealing body, the air guide pipe (9) penetrates through the air through holes and is connected with the interior and the exterior of the sealing body, and the air inflation valve (7) and the air release valve (8) are arranged on the air guide pipe (9) of the exterior of the sealing body; the heating body (12) is used for heating the sealing body, and accordingly the reaction raw materials in the reactor (2) are pre-heated.

Owner:NAT UNIV OF DEFENSE TECH

Microbial fertilizer taking rabbit manure as base material and fermentation device thereof

InactiveCN111689819ALong churnReduce churnBio-organic fraction processingExcrement fertilisersBiotechnologyCellulose

The invention relates to a microbial fertilizer taking rabbit manure as a base material. The microbial fertilizer comprises rabbit manure; the rabbit manure is prepared by a fermentation process, andthe fermentation process specifically comprises the following steps of: (1) compounding: adding 1% of cellulose flora into 80%-90% of rabbit manure and 9-19% of biochemical fulvic acid by weight, andadjusting the moisture to 55%-65%; 2) fermentation: performing stacking into a large stack with a height of 2.5m and a width of 6-7m for fermentation; turning over the stack once every 5 days, performing stacking into a large stack of 6-7 meters again, and turning over the stack once every 5 days. The method has the advantages of fast heating, long high temperature maintaining time, conversion ofprotein in the rabbit manure into amino acids, conversion of cellulose, absorption of humic acid and fulvic acid by crops, and fast fermentation speed of about 10 days for maturation. Aerobic fermentation and anaerobic fermentation are carried out at the same time. Stable fermentation and low nutrient loss are achieved.

Owner:曲靖凯美冠有机肥生产有限公司

A kind of method of terpene resin hydrogenation

ActiveCN112341571BLow softening pointHigh softening pointChemical recyclingMetal/metal-oxides/metal-hydroxide catalystsMolecular sievePtru catalyst

The invention discloses a method for hydrogenating terpene resin. In the invention, the resin is synthesized first, and the hydrogenation catalyst is activated in the first fixed-bed hydrogenation reactor and the second fixed-bed hydrogenation reactor; The hexane solvent enters the reactor at a rate of 0.1-5 ml / min, and at the same time adjusts the hydrogen gas feed rate to 300-400 ml / min. The obtained molecular sieve dehydrated reaction solution is reacted to obtain a hydrogenated hydrogenated terpene resin to obtain a terpene hydrogenated resin. The invention can reduce the production cost, has low reaction temperature, improves the reaction efficiency, has the advantages of stable performance of the obtained hydrogenated terpene resin, is not easy to change color, and the like.

Owner:PUYANG XINYU PETROCHEM IND

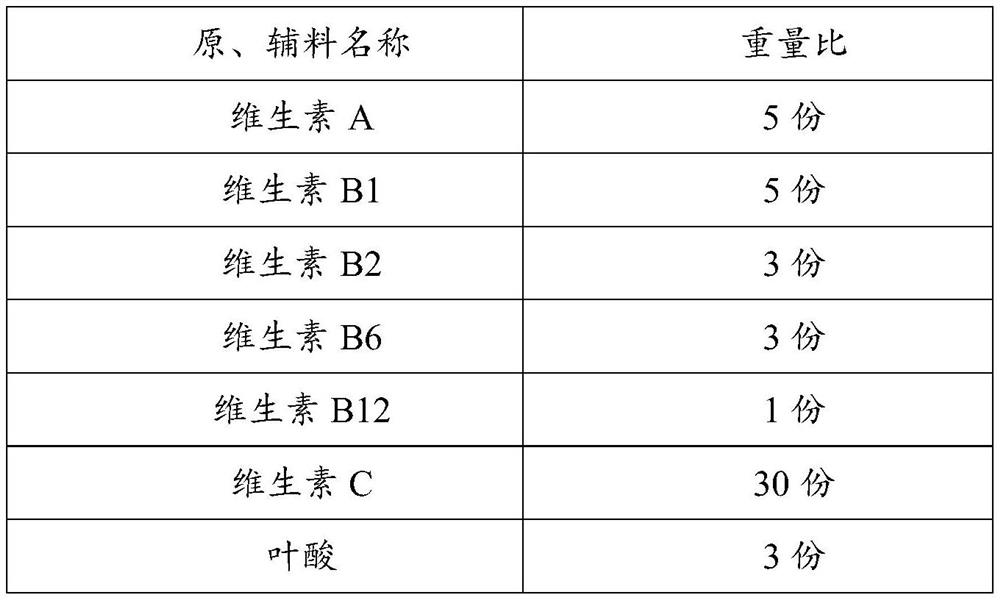

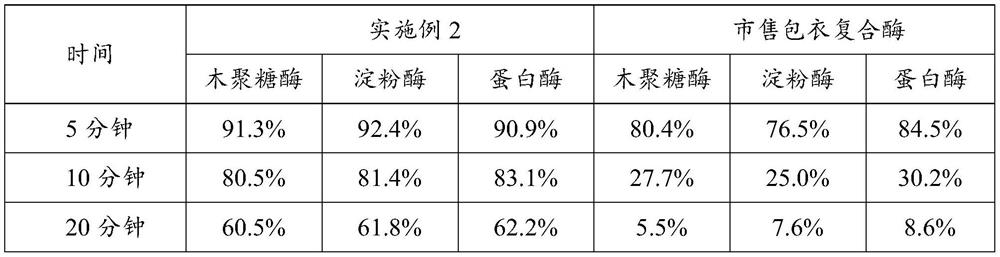

Preparation method and application of coated granules

PendingCN112106889AAvoid direct contactAvoid interactionFood preservationAccessory food factorsCelluloseMixed materials

The invention belongs to the technical field of food, medicine and feed processing, and discloses a preparation method and application of the coated granules. The preparation method of the coated granules comprises the following steps: (1) weighing main granulation raw materials and auxiliary materials (including glyceryl behenate, hydroxypropyl methylcellulose and a heat-sensitive material), andcarrying out mixing to obtain a mixed material; and (2) performing rolling granulation on the mixed material prepared in the step (1), and carrying out screening so as to obtain the coated granules. Being adopted, the preparation method is capable of avoiding direct contact and mutual influence of the various materials, such as foods, medicines and feeds, in the coated granules, thereby greatly shortening high-temperature time of the materials; and thus, the coated granules are endowed with good processing stability and storage stability as well as prolonged shelf life. In addition, the raw materials can be slowly and continuously released so as to have utilization rate improved. The preparation method can be applied to preparation of foods, medicines and feeds.

Owner:珠海天凯生物科技有限公司

A layered ignition device for burning oil layers

ActiveCN104481485BImprove power efficiencyImprove ignition efficiencyFluid removalElectricityCombustion

Owner:PETROCHINA CO LTD

Process for inhibiting low-temperature deodorization and high-temperature deacidification of peanut oil trans fatty acid

ActiveCN106118875BReduce high temperature timeInhibitory conditionsFatty-oils/fats refiningEdible oils/fatsPlasticizerAcid value

The invention discloses a low-temperature deodorization and high-temperature deacidification process capable of inhibiting trans-fatty acid of peanut oil. The process specifically comprises the following steps: (1) degumming; (2) de-coloring; (3) carrying out low-temperature deodorization; (4) carrying out high-temperature deacidification. A packing tower is additionally arranged behind a plate tower of a deodorization and deacidification process, and an alkali refining neutralization reaction section is removed; oil is uniformly distributed in a thin film form and a manner of directly adding saturated steam from the bottom is adopted to effectively remove undesirable odor; high-temperature time of an oil product is shortened; two sets of packing deacidification towers are additionally arranged, wherein the temperature of the #1 deacidification tower is controlled to be 260 DEG C and is used for instantly distilling to remove a large part of acid value, and the temperature of the #2 deacidification tower is controlled to be 265 DEG C and is used for removing the acid value in the oil again, so that the acid value of finished-product oil is reasonably controlled; furthermore, the time of staying at a high-temperature section of the oil is short, the content of the trans-fatty acid is only increased by 0.2 percent to 0.3 percent and the acid value can be controlled to be about 0.1; the alkali refining neutralization section is removed so that the loss of neutral oil is reduced and the yield is improved; the consumption is reduced by about 0.03 percent to 0.05 percent by one acid value; meanwhile, a plasticizer and the acid value in the oil product can be effectively removed.

Owner:青岛天祥食品集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com