Process for inhibiting low-temperature deodorization and high-temperature deacidification of peanut oil trans fatty acid

A technology of oil trans and fatty acid, applied in the field of low temperature deodorization and high temperature deacidification, can solve the problems of high trans fatty acid, high deodorization temperature, long deodorization time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

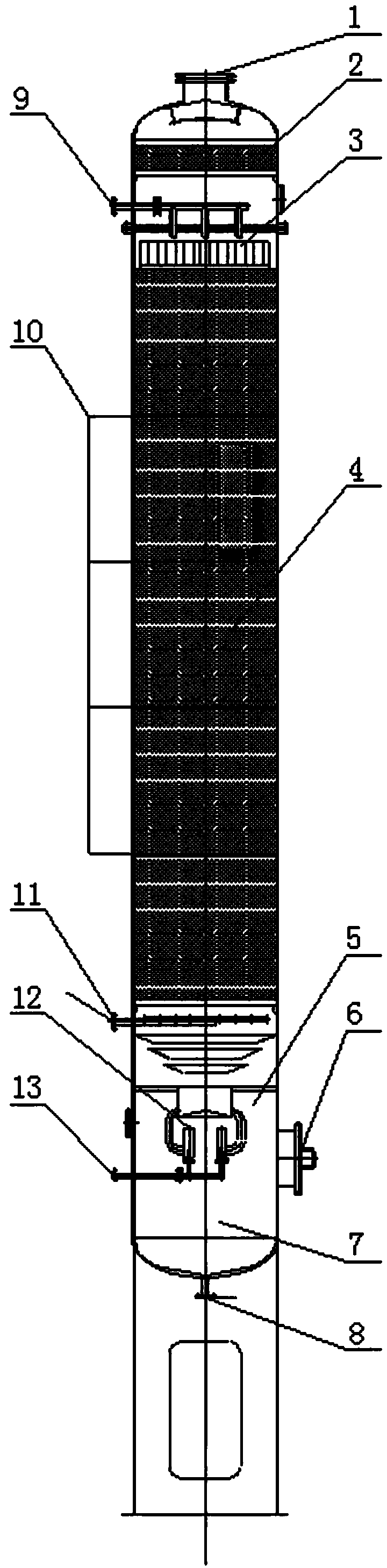

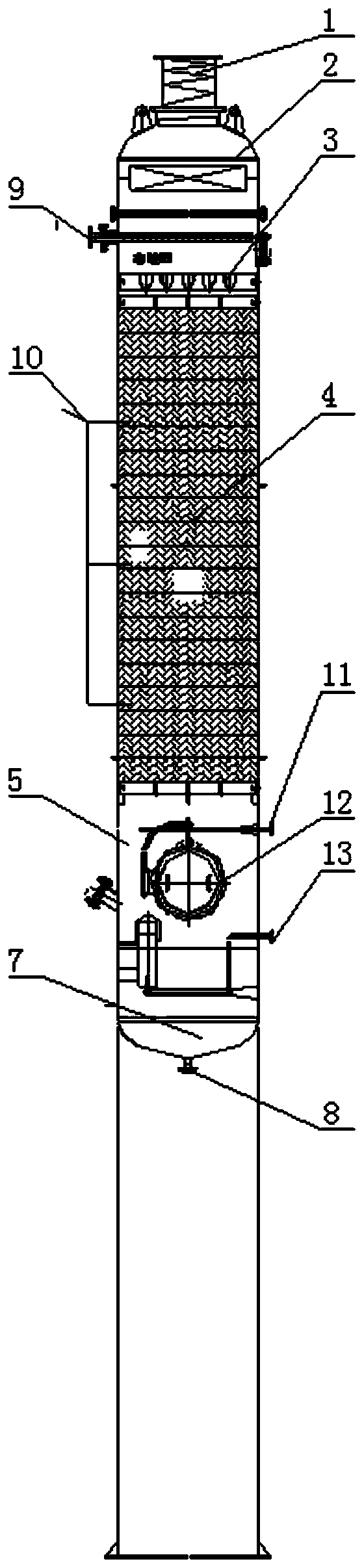

[0030] The deodorization equipment used in the deodorization process will be further described below in conjunction with the accompanying drawings.

[0031] Such as figure 1 and figure 2 As shown, the deodorization equipment used for the deodorization process includes a plate tower, 1# deacidification tower and 2# deacidification tower, the top of the 1# deacidification tower and 2# deacidification tower is provided with a vacuum pipe port, and the deacidification tower The upper and lower ends of the tank are respectively provided with an oil inlet and an oil outlet, a liquid foam trap is installed on the inner wall of the tower between the vacuum pipe port and the oil inlet, and a rain distributor is installed on the inner wall of the tower at the lower end of the oil inlet. The middle and lower parts of the tower body of the deacidification tower are successively arranged as a packed tower and a distillation tower. The middle part of the packed tower is provided with anti...

Embodiment 2

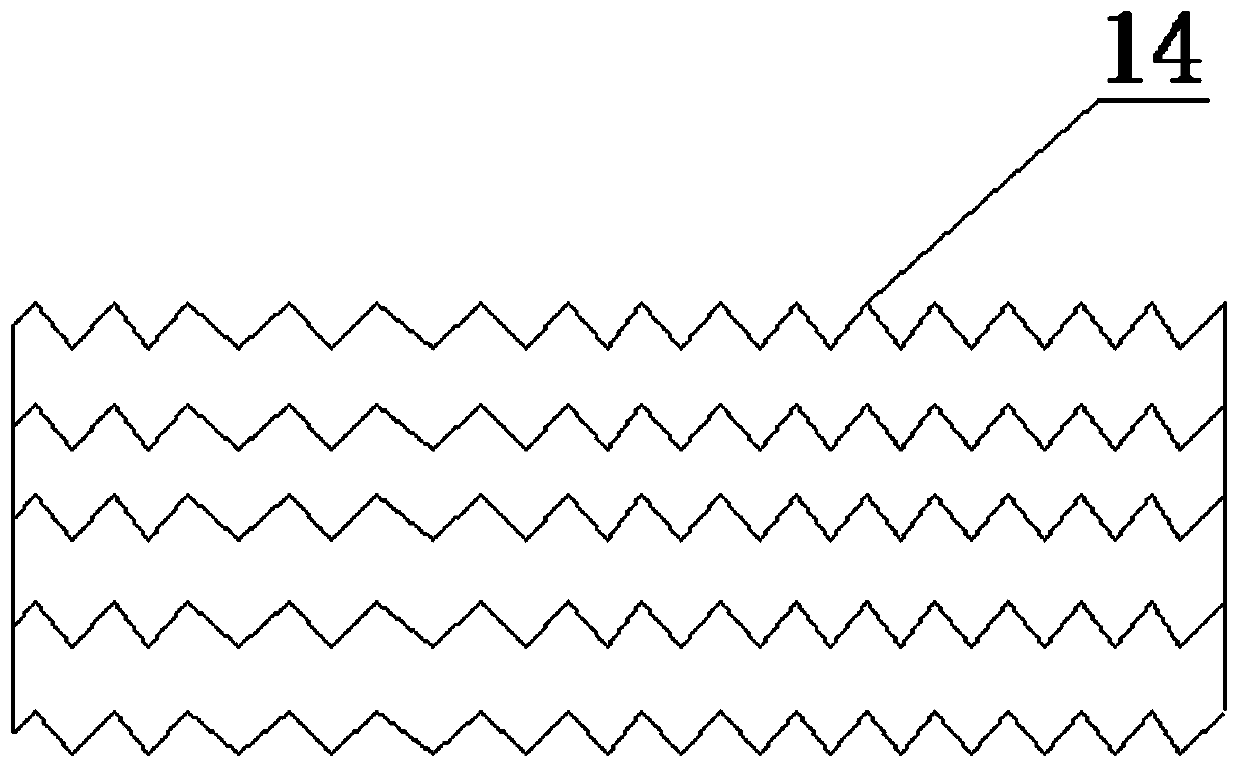

[0034] On the basis of Example 1, different from Example 1, such as image 3As shown in the deodorization equipment used in the deodorization process, the liquid foam trap is arranged along the inner wall of the deacidification tower, which is formed by several layers of liquid foam boards arranged in parallel and at equal intervals, and each layer of liquid foam boards is arranged in a wavy Z-shape The extension plate and the liquid foam plate are provided with micropores at equal intervals. The liquid foam at the top of the deacidification tower is continuously collected as droplets under the action of the liquid foam plate, and flows along the inner wall of the tower into the packed tower. The filler adsorption in the deodorization tower can adjust the number of plates of vegetable oil passing through the liquid foam plate in the deodorization tower, adjust the deodorization time, moderately refine the vegetable oil, reduce the use of steam and the generation of trans fatty ...

Embodiment 3

[0036] On the basis of Example 1, different from Example 1, such as Figure 4 As shown in the deodorization equipment used for the deodorization process, the rain distributor includes an upper support plate and a lower support plate arranged in parallel along the inner wall of the deacidification tower, and funnels are arranged longitudinally at equal intervals between the upper and lower support plates. , The lower support plate and the side wall of the funnel are provided with hollow holes at equal intervals. The funnel is an integrated bullet-shaped structure connected by a hollow cylinder at the upper end and an inverted hollow cone at the lower end. The material components are placed on the upper support plate. Tiling on the top, it flows down along the inner wall of the funnel through the hollow hole on the upper support plate. During the process of flowing down, part of the water overflows through the hollow hole on the inner wall of the funnel, and flows down along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com