A preparation device for amorphous boron powder and method for preparing amorphous boron powder

A technology for the preparation of amorphous boron powder and equipment, which is applied in the direction of boron/boride, boron, etc., can solve the problems of low yield of boron powder and increase in the amount of chemical sewage, so as to improve the purity, reduce the reaction between boron powder and impurities, The effect of improving combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

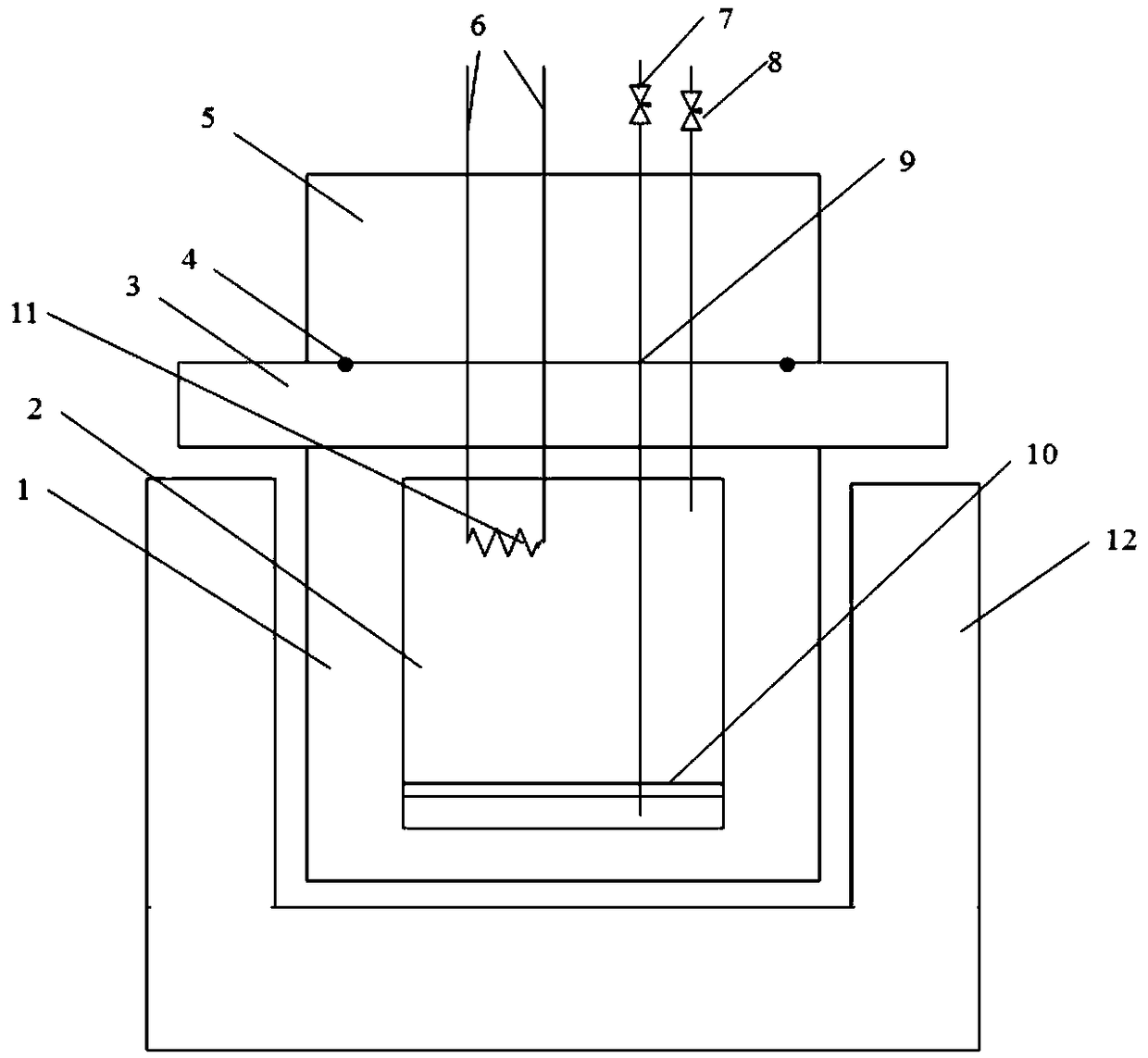

[0056] Embodiment 1: A kind of amorphous boron powder preparation device

[0057] A preparation device for amorphous boron powder, as attached figure 1 As shown, it includes: stainless steel tank 1, reactor 2, cooling pipe 3, rubber sealing ring 4, upper end cover 5, copper ignition electrode 6, inflation valve 7, deflation valve 8, air guide pipe 9, metal sintered mesh 10, Tungsten wire 11 and electric resistance furnace 12, interconnection relationship and function are as follows:

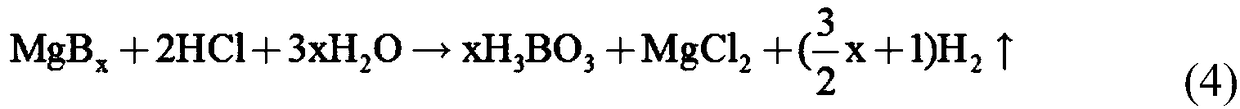

[0058] The reactor 2 is a crucible, and the material of the crucible is one selected from stainless steel, tungsten, molybdenum, boron nitride or silicon nitride. The crucible is used to hold the reaction raw materials; the bottom of the crucible is provided with a metal sintered mesh 10, and the reaction raw materials are stacked on Metal sintering mesh 10 to prevent the reactants from sintering at the bottom of the crucible; the stainless steel tank body 1 and the upper end cover 5 form a seal...

Embodiment 2

[0060] Embodiment 2: the method for preparing amorphous boron powder

[0061] Use as attached figure 1 The preparation device for amorphous boron powder shown, according to the implementation steps described in the preparation method part of the invention, boron oxide, magnesium powder, sodium chloride, and potassium perchlorate are mixed according to the mass ratio of 1.2:1:1:0.05, and the electric resistance furnace Heat up to 350°C and ignite to trigger a self-propagating reaction. The mass ratio of solid to liquid for the first wash is 1:3, heated to 50°C, and stirred for 2 hours; the mass ratio of solid to liquid for the second wash is 1:10, heated to 50°C, and stirred for 1 hour; pickling The temperature is 50°C; for one pickling, add hydrochloric acid with a concentration of 2mol / L according to the solid-liquid mass ratio of 1:3, stir for 2 hours, add deionized water with the same quality as dilute hydrochloric acid, and continue stirring for 1 hour at 50°C; According ...

Embodiment 3

[0062] Embodiment 3: the method for preparing amorphous boron powder

[0063] Use as attached figure 1The shown amorphous boron powder preparation device, according to the implementation steps described in the preparation method part of the invention, boron oxide, magnesium powder, potassium chloride, and magnesium perchlorate are mixed according to the mass ratio of 1.5:1:1:0.05, The resistance furnace is heated to 260°C and then ignited to initiate a self-propagating reaction. The mass ratio of solid to liquid for the first wash is 1:3, heated to 80°C, and stirred for 2 hours; the mass ratio of solid to liquid for the second wash is 1:6, heated to 80°C, and stirred for 1 hour; The pickling temperature is 60°C; for one pickling, add hydrochloric acid with a concentration of 3mol / L according to the solid-liquid mass ratio of 1:4, stir for 2 hours, then add deionized water with the same quality as dilute hydrochloric acid, and continue stirring for 1 hour at 60°C; For the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com