High-temperature sterilization machine

A technology of high-temperature sterilization and steam, which is applied in the field of food processing, can solve the problems of lower product quality, change of hue and taste, poor fluidity, etc., and achieve the effects of reducing influence, mixing fully, and shortening high-temperature time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

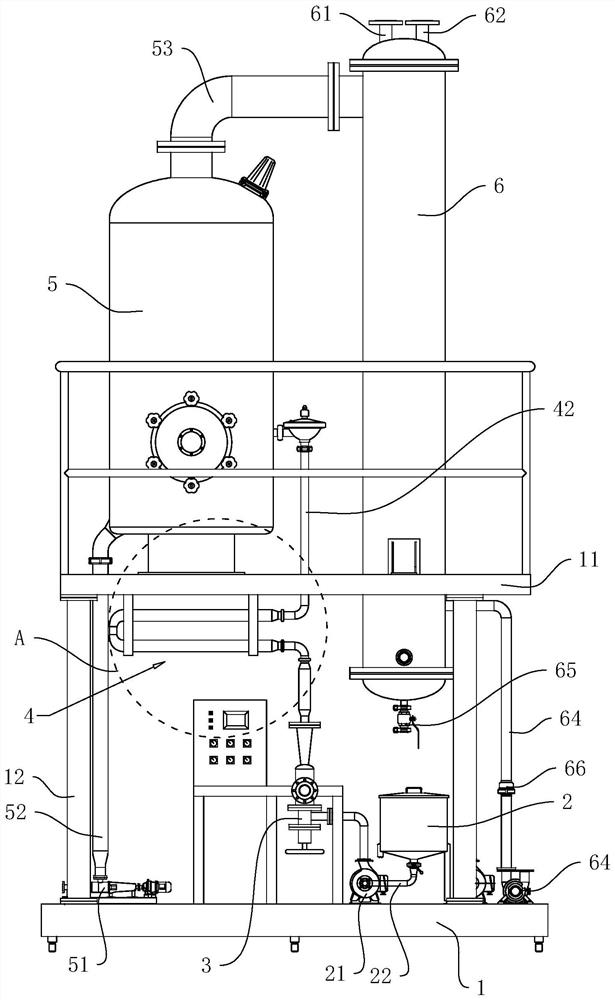

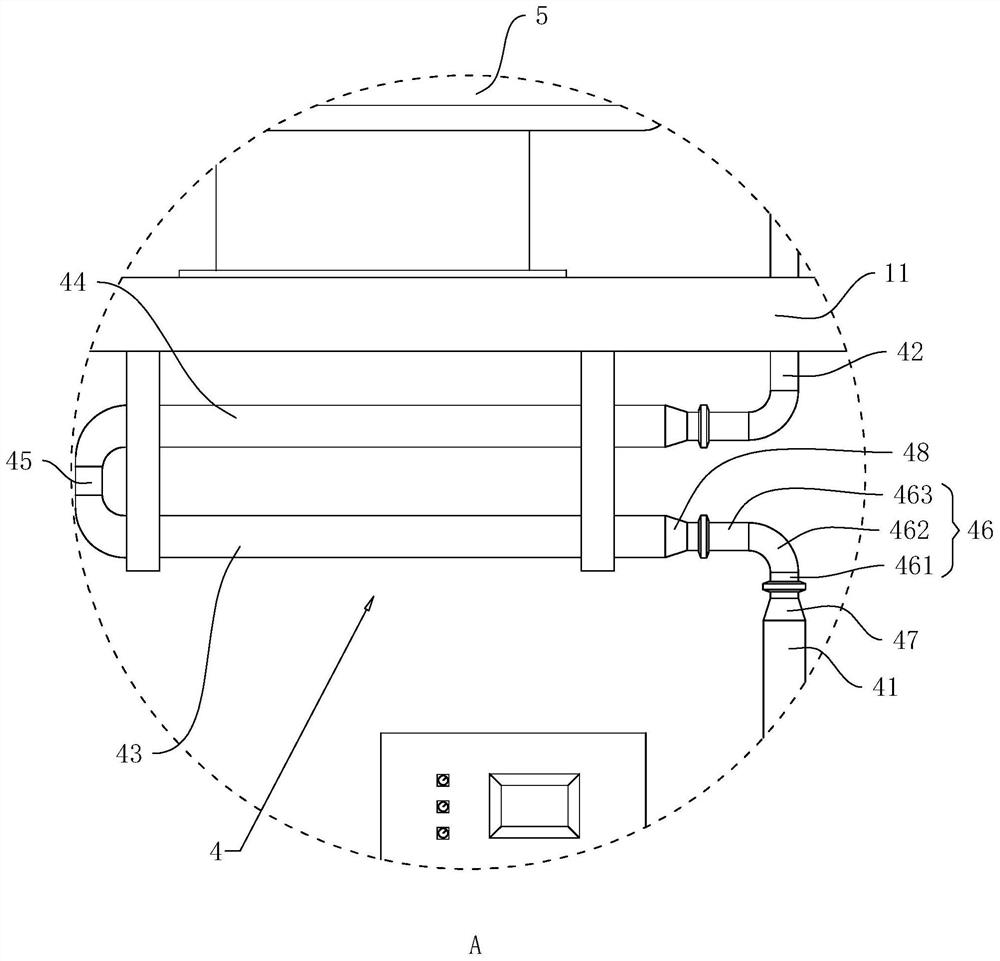

[0036] The embodiment of the present application discloses a high-temperature sterilizer. Such as figure 1 As shown, a high-temperature sterilizer includes a lower platform 1 and an upper platform 11, the upper platform 11 is located above the lower platform 1, a column 12 is fixedly connected between the upper platform 11 and the lower platform 1, and the lower platform 1 is equipped with a material container 2 , Feed pump 21 and steam injector 3, upper platform 11 is equipped with flash evaporator 5, material reaches steam injector 3 from material container 2 through feed pump 21, then reaches flash evaporator 5 from steam injector 3.

[0037] The material container 2 is a barrel-shaped structure, and the material to be sterilized is loaded into the material container 2, and the gap between the outlet of the material container 2 and the inlet of the feed pump 21 and between the outlet of the feed pump 21 and the inlet of the steam injector 3 is uniform. The feed pipe 22 is ...

Embodiment 2

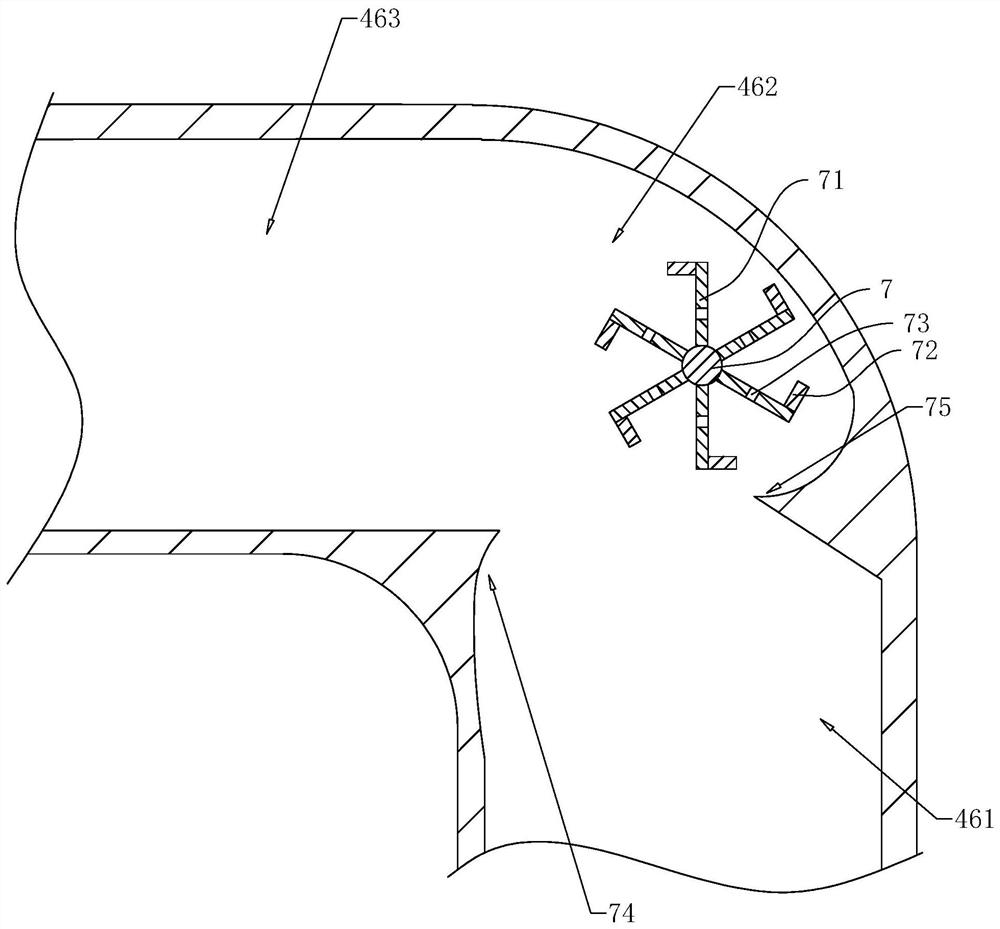

[0049] The difference between this embodiment and Embodiment 1 is that the internal structure of the transition section 46 is different. In this embodiment, a rotating rod 7 is rotatably installed in the bending part 462, and the rotating axis of the rotating rod 7 is perpendicular to the first vertical axis. In the extension direction of the straight section 41 and the extension direction of the first horizontal section 43, the side wall of the rotating rod 7 is fixed with stirring blades 71, and there are multiple stirring blades 71 arranged at intervals along the circumferential direction of the rotating rod 7, and the materials and steam pass through When bending part 462, the impact of material and steam can drive stirring blade 71 to rotate in bending part 462, and the rotation of stirring blade 71 promotes the mixing of material and steam in bending part 462, thereby improving the sterilization effect.

[0050] A side plate 72 is fixed on the end of the stirring blade 71...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com