Method for processing, packing and storing hickory

A hickory nut and debrading technology, which is applied in the field of food processing and storage, can solve the problems of short shelf life and rapid quality decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The processing, packaging and storage method of pecans are carried out as follows:

[0032] (1) Raw material preparation: Harvest fully mature hickory nuts, remove the buds by a debrading machine, screen out the ones with full grains by the water flotation method, and drain them for later use;

[0033] (2) Preparation of seasoning liquid: first mix table salt and Chinese prickly ash by weight 10:1 to make seasoning; then prepare seasoning by weight and volume of 1:100 by mixing the seasoning and water for later use;

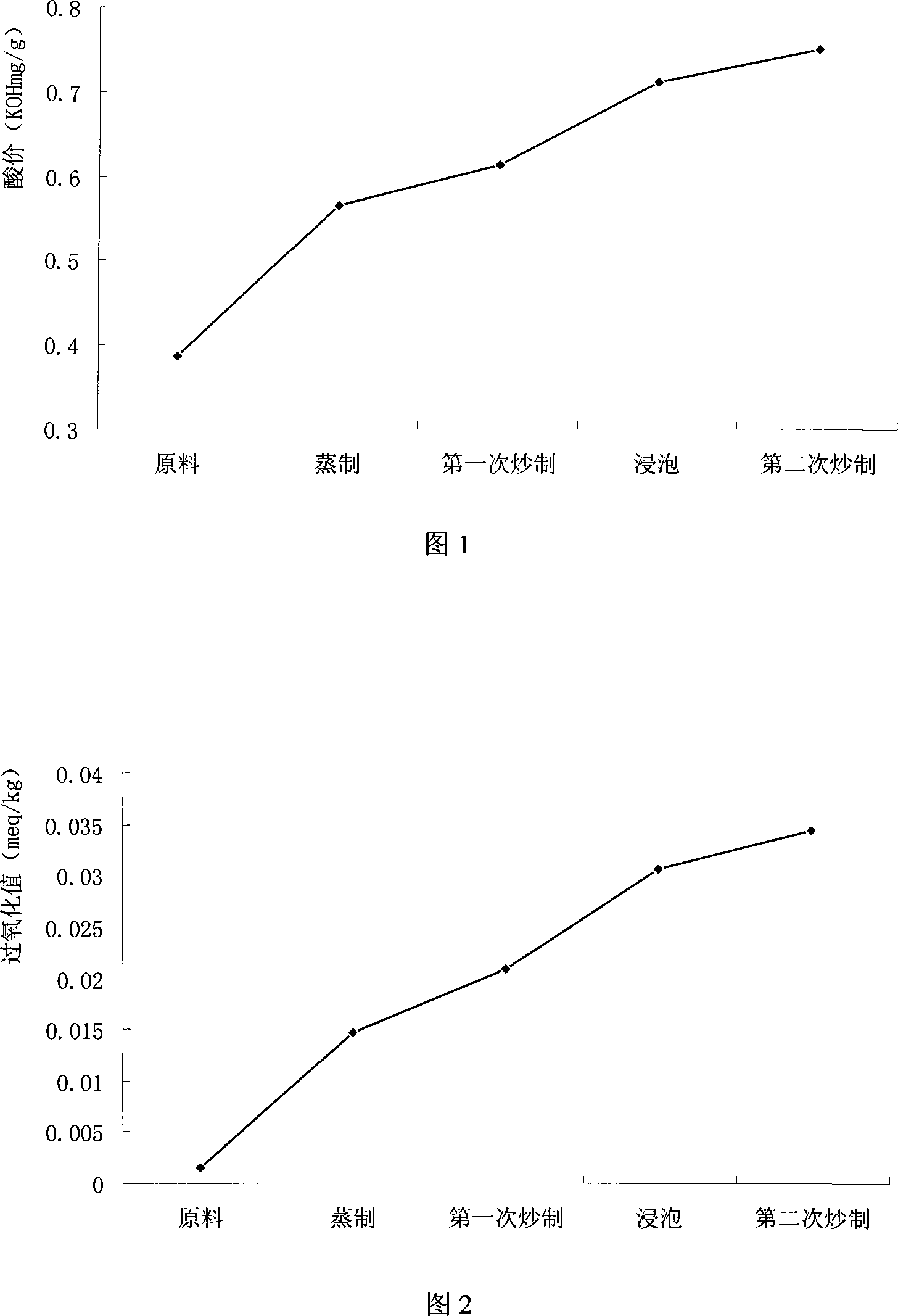

[0034] (3) Steaming, frying and seasoning of raw materials: first steam the raw materials in step (1) at 121°C and 1.010 atmosphere pressure for 10 minutes, then steam at 100°C and normal atmospheric pressure for 2.5 hours, and then stir fry for 15 minutes with high heat. -25min until the fruit surface cracks; soak the cracked hickory nuts in the seasoning liquid of step (2) for 5-10min, then stir-fry until the fruit surface is dry;

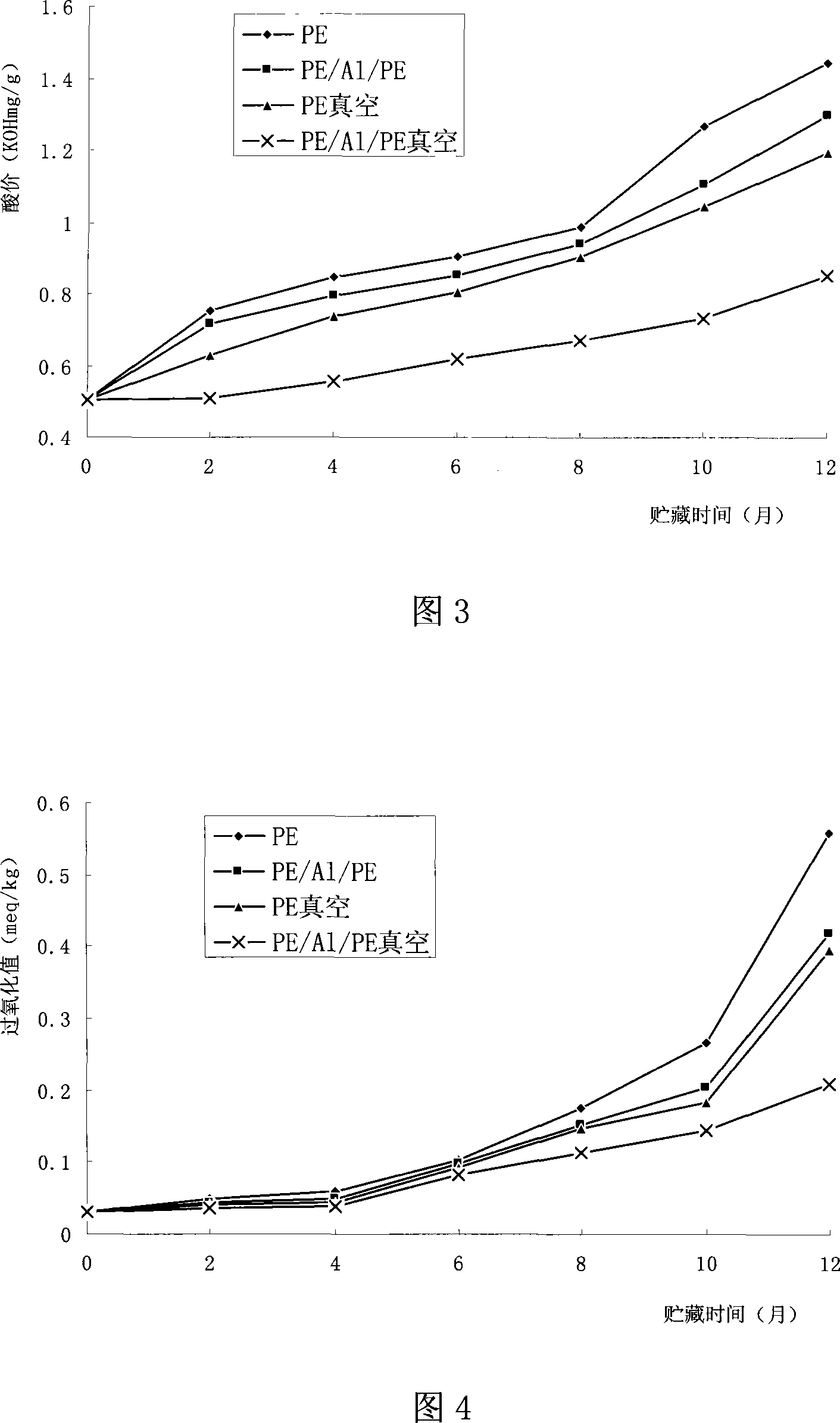

[0035] (4) Composite...

Embodiment 2

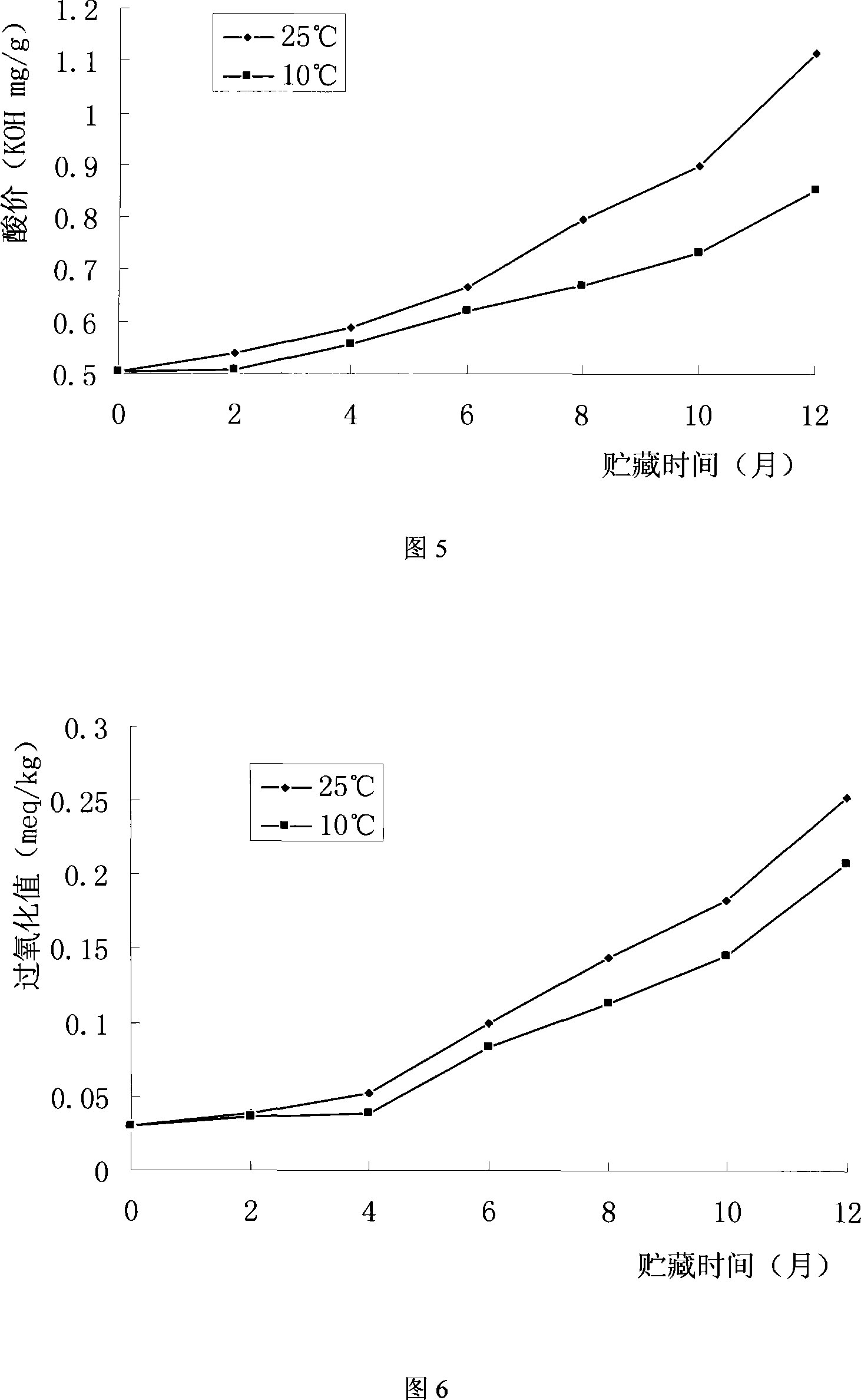

[0039] In this example, the seasoning is a 1:15 mixture of cream spices and sugar by weight; the pecan raw material is steamed at 121°C and 1.015 atmospheres for 10 minutes, and then steamed at 100°C and normal atmospheric pressure for 2.0 hours; the PE / AI used The thickness of the / PE composite film is 90μm; the iron-based deoxidizer used is a mixture of iron powder, sodium sulfite and diatomaceous earth in a weight ratio of 3:1:3; the vacuum in the packaging bag is 0.095Mpa; the temperature of the bagged product storage room is 10°C , the storage period is as long as 10-11 months; all the other processes and conditions are the same as in Example 1.

Embodiment 3

[0041] In this example, the seasoning is a 10:1 mixture of salt and Chinese prickly ash by weight; the pecan raw material is steamed at 121°C and 1.013 atmospheres for 10 minutes, and then steamed at 100°C and normal atmospheric pressure for 3 hours; the PE / AI / PE used The thickness of the composite film is 110 μm; the iron-based deoxidizer used is a mixture of iron powder, sodium chloride, activated carbon and calcium chloride in a weight ratio of 1:0.9:1:0.2; the vacuum in the packaging bag is evacuated to 0.08Mpa; the bagged product storage The temperature is 13° C., and the storage period is as long as 10 months; the remaining processes and conditions are the same as in Example 1.

[0042] Description of the following tests:

[0043] 1. Test material:

[0044]Lin'an Chuanghui Food Factory produces Changhua pecans according to the new technology, and chooses pecans with uniform size and full grains.

[0045] Iron powder: 100-200 mesh, purity ≥ 99.0%, Sinopharm Chemical Rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com