A device and method for improving detection precision of oxidated layer thickness

A technology of oxide layer thickness and detection accuracy, which is applied in the field of wafer oxide layer thickness detection, can solve the problems of oxide layer thickness thinning, inaccurate measurement, and slow growth rate of silicon dioxide, etc., to achieve stable thickness and precise process control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

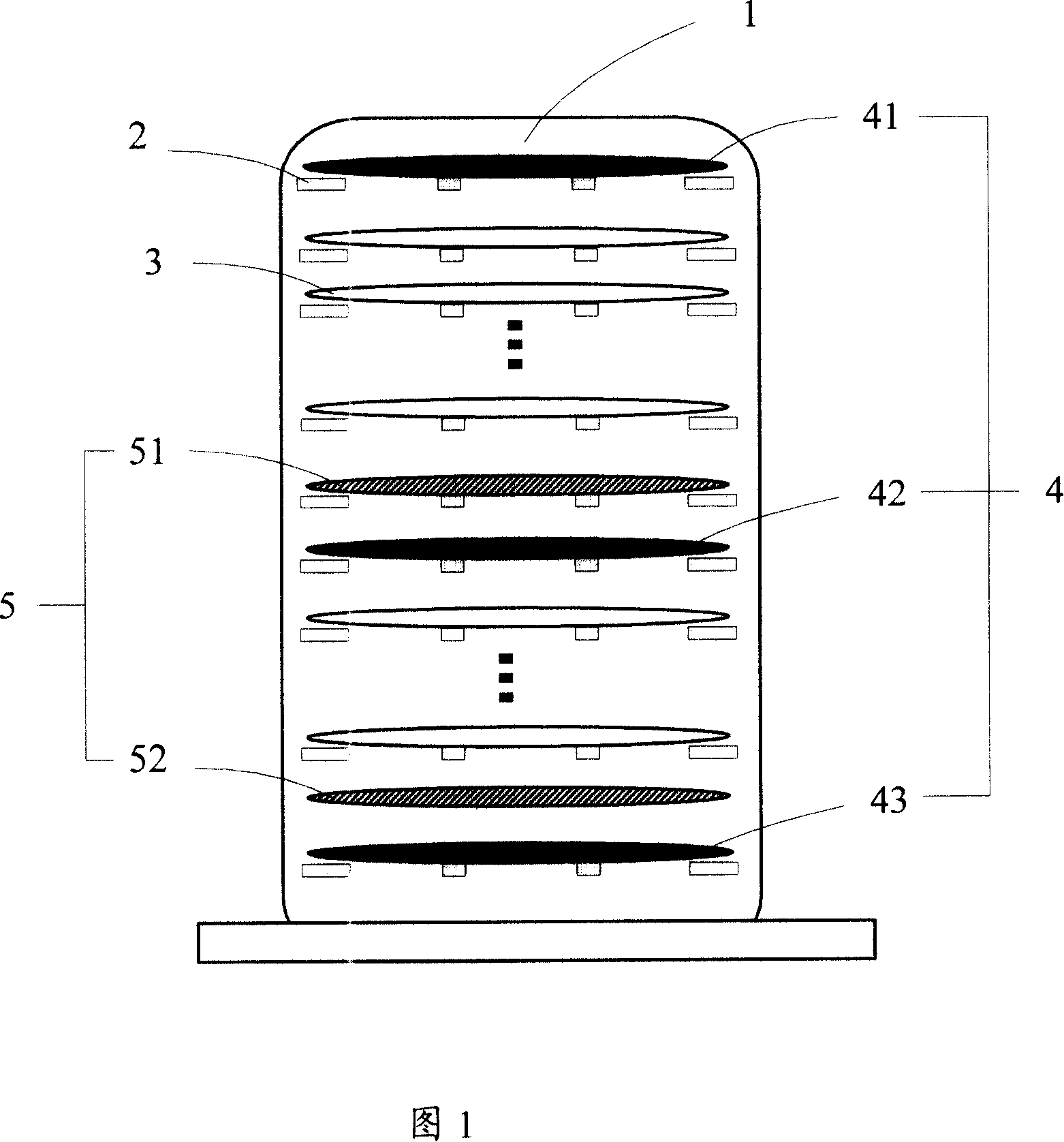

[0011] As shown in Figure 1, the device for improving the detection accuracy of oxide layer thickness according to the present invention includes a furnace tube 1, a crystal boat 2, several wafers 3, three control sheets 4 (41, 42, 43) and two blocking sheets 5 (51, 52).

[0012] Please refer to FIG. 1 , the wafer boat 2 is used to carry several wafers 3 , and the wafers 3 are arranged horizontally in the wafer boat 2 . The upper and lower surfaces of the three control sheets 4 and the two blocking sheets 5 are silicon oxide (SiO 2 ), the first control sheet 41 is located at the top of the wafer boat 2 , the second control sheet 42 is located at the middle of the wafer boat 2 , and the third control sheet 43 is located at the bottom of the wafer boat 2 .

[0013] At normal temperature, the machine (not shown) that loads the wafer 3 is set by the computer to reserve three vacancies for the upper, middle and lower wafer boat 2 for the control sheet 4, and the second control she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com