Natural graphite composite material, preparation method thereof and lithium ion battery

A technology of lithium ion battery and natural graphite, which is applied to the preparation method thereof and the field of lithium ion battery and natural graphite composite material, can solve the problems of low capacity, non-uniform amorphous carbon and high cycle expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

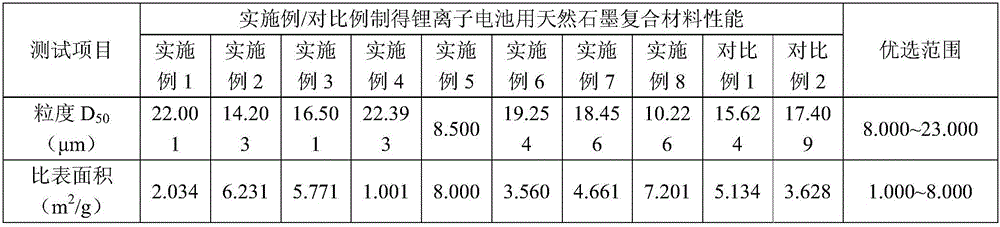

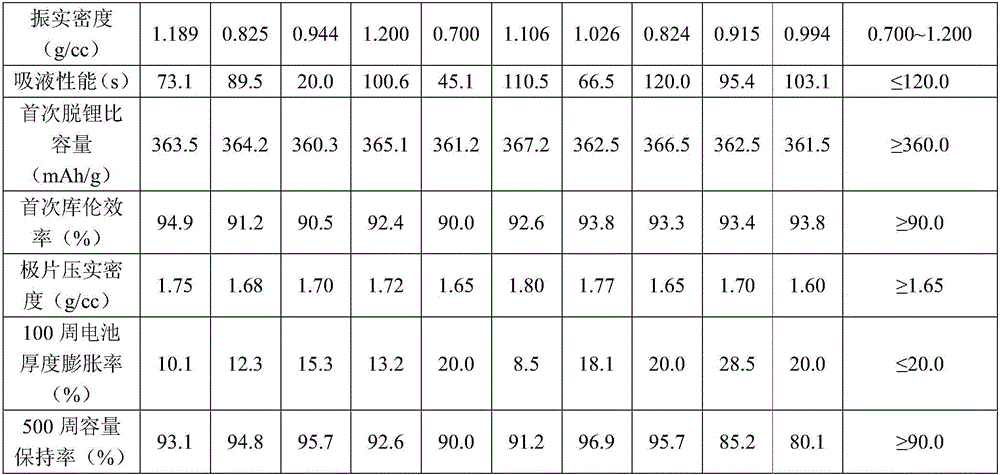

Examples

Embodiment 1

[0072] In this embodiment, the natural graphite composite material includes spherical natural graphite and an amorphous carbon shell coated on the surface of the spherical natural graphite. The amorphous carbon shell is obtained by high-temperature treatment of mesophase pitch and pyromellitic dianhydride, and the mesophase The mass ratio of pitch to pyromellitic dianhydride is 3:1, and the mass of spherical natural graphite is 80% of the natural graphite composite material.

[0073] The preparation method of the above-mentioned natural graphite composite material is as follows.

[0074] Spherical natural graphite is pulverized and spheroidized using an internal classification micropowder machine in a continuous feeding mode, the pulverization speed is 4000rpm, and the time is 2min to obtain graphite particles; the obtained graphite particles are mixed with mesophase pitch and pyromellitic dianhydride by The mass ratio is 80.0:15.0:5.0 for VC mixing, the mixing time is 3min, t...

Embodiment 2

[0076] In this embodiment, the natural graphite composite material includes spherical natural graphite and an amorphous carbon shell coated on the surface of the spherical natural graphite. The amorphous carbon shell is obtained through high-temperature treatment of coal tar pitch and trimellitic anhydride, and coal tar pitch and pyrene The mass ratio of triformic anhydride is 3:1, and the mass of spherical natural graphite is 90% of the natural graphite composite material.

[0077] The preparation method of the above-mentioned natural graphite composite material is as follows.

[0078] Spherical natural graphite is graded to obtain graphite particles; the graphite particles are mixed with coal tar pitch and trimellitic anhydride at a mass ratio of 90.0:8.0:2.0 in a mass ratio of 90.0:8.0:2.0. The mixing time is 20 minutes and the temperature is 45°C. The graphite-binder-additive mixture powder is obtained; the mixture powder is subjected to hot molding treatment, the treatmen...

Embodiment 3

[0080] In this embodiment, the natural graphite composite material includes spherical natural graphite and an amorphous carbon shell coated on the surface of the spherical natural graphite. The amorphous carbon shell is obtained through high-temperature treatment of coal tar pitch and trimellitic anhydride, and coal tar pitch and pyrene The mass ratio of triformic anhydride is 3:1, and the mass of spherical natural graphite is 90% of the natural graphite composite material.

[0081] The preparation method of the above-mentioned natural graphite composite material is as follows.

[0082] Carry out ball milling treatment with flaky natural graphite, the ball milling time is 60min, the instrument rotating speed is 300rpm, the diameter of adopting corundum ball is 5mm, obtains graphite particle; The obtained graphite particle and water-soluble resin are carried out liquid phase stirring according to mass ratio 85.0:15.0 and Dry to obtain a powder, and then carry out VC mixing of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com