Industrial slag salt harmless treatment device and application method thereof

A technology for harmless treatment and industrial slag, which is applied in chemical instruments and methods, transportation and packaging, and solid waste removal. The effect of replenishing and removing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

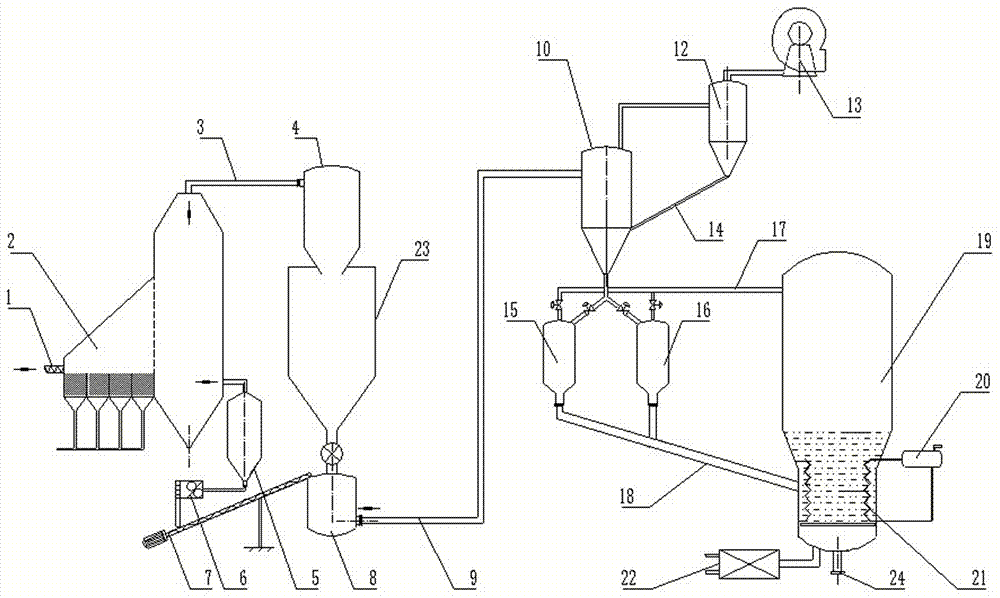

[0023] a. The waste salt is introduced into the vulcanization dryer 2 by the first screw conveyor 1, and the fan 13 is operated after the vulcanization dryer 2 is started;

[0024] b. The dried fine waste salt particles are introduced into the first cyclone separator 4 and the first intermediate tank 23 in sequence with the flowing gas through the first conveying pipeline 3 and then enter the feeding tank 8; the coarse waste salt particles are introduced into the temporary storage tank 5 and then After being crushed and screened by the crushing screen 6, it is introduced into the feeding trough 8 by the second screw conveyor 7;

[0025] c, the waste salt of preliminary treatment is introduced into the third intermediate tank 15 and the fourth intermediate tank 16 after entering the second intermediate tank 10, the waste salt particles flowing with the air flow of the fan 13 are introduced into the second cyclone separator 12, the waste gas is exported, the waste salt And then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com