Composite material of lithium ion battery, preparation method thereof and lithium ion battery

A lithium-ion battery and composite material technology, applied in the field of lithium-ion batteries, can solve the problem that the isotropy of graphite negative electrode materials cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

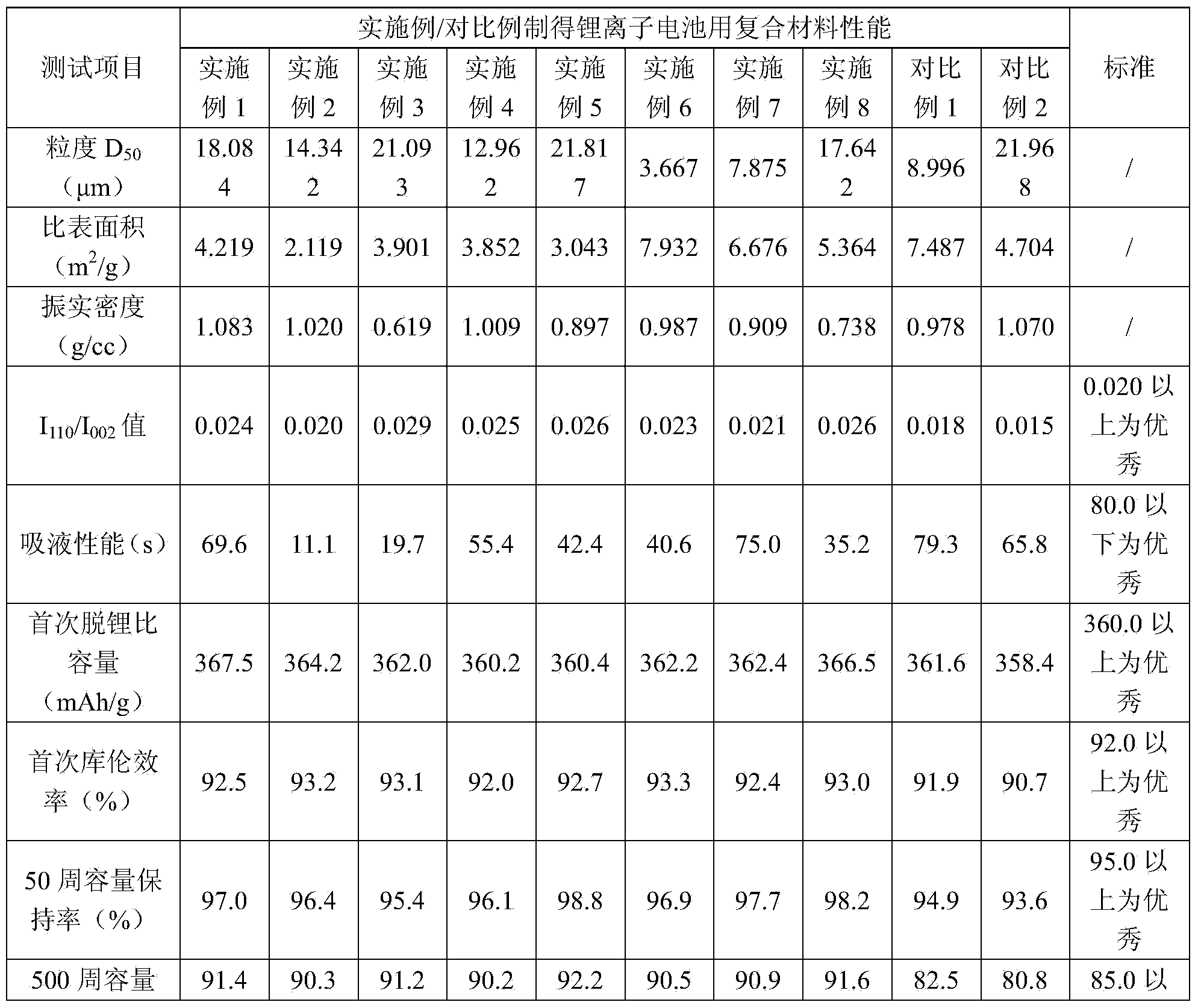

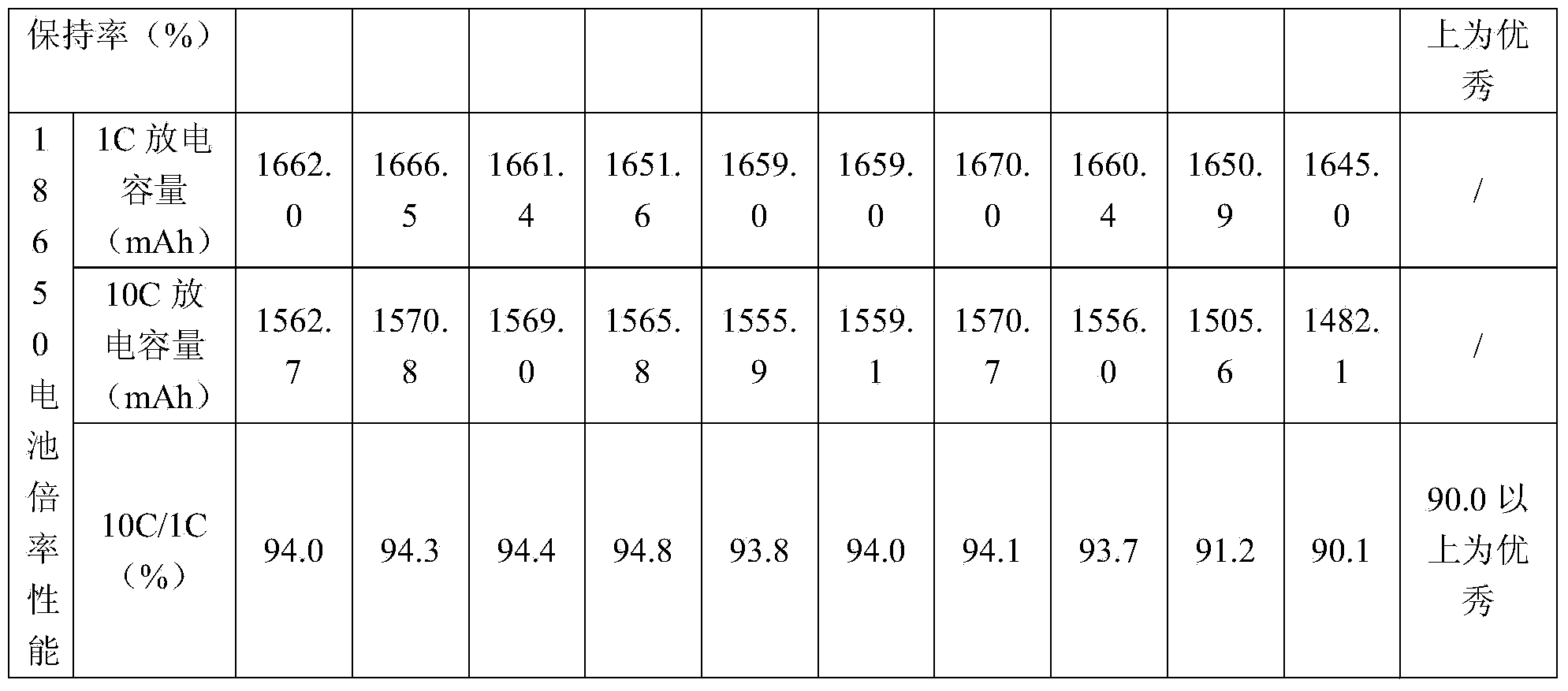

Examples

Embodiment 1

[0068] The natural graphite is pulverized and spheroidized by an internal classification micropowder in a continuous feeding mode, the pulverization speed is 4000rpm, and the time is 2min to obtain graphite particles; the obtained graphite particles and mesophase pitch are mixed with VC at a mass ratio of 80.0:20.0 , the mixing time is 3min, the temperature is 80°C, and the graphite-pitch mixture is obtained; the graphite-pitch mixture is extruded, the pressure is 5000KN, the temperature is 20°C, and the pressurization treatment time is 30min, the compacted density of the block is obtained 1.500g / cc; then carry out isostatic pressing treatment, the pressure is 8000KN, the temperature is 200℃, the pressure treatment time is 180min, and the compacted density of the obtained block is 1.800g / cc; Heat treatment in the heat treatment process, the heating rate during the heat treatment process is 3.0°C / min, the treatment temperature is 3200°C, and the treatment time is 240.0h; the pro...

Embodiment 2

[0070] The natural composite graphite (obtained by uniformly mixing natural graphite and artificial graphite at a mass ratio of 80.0:20.0) is fused for 20 minutes, the rotation speed is 2500 rpm, the cavity gap is 0.5 cm, and the processing temperature is 40 ° C to obtain graphite particles; Mix graphite particles with modified asphalt with a softening point of 130°C at a mass ratio of 90.0:10.0. The mixing method is liquid phase mixing and spray drying. The solvent is a combination of phase IV furan and ethanol. The speed of the mixer is 3000rpm and the mixing time is 120min. , the solid content of the suspension is 45%, the inlet temperature of the spray dryer is 150°C, the outlet temperature is 80°C, and the pressure is 80MPa to obtain a powder; the powder is subjected to hot molding treatment with a processing pressure of 6000KN and a processing temperature of 100 ℃, pressurized treatment time is 60min, and the compacted density of the obtained block is 1.400g / cc; then isos...

Embodiment 3

[0072] The natural composite graphite (obtained by uniformly mixing natural graphite and mesophase carbon microspheres at a mass ratio of 55.0:45.0) was subjected to ball milling, the ball milling time was 60min, the instrument speed was 200rpm, and the diameter of the corundum ball was 8mm to obtain graphite particles; The obtained graphite particles and the high molecular weight polymer were stirred in the liquid phase according to the mass ratio of 85.0:15.0 and then dried to obtain a powder; the obtained powder was subjected to cold molding treatment with a pressure of 10000KN, a temperature of 25°C, and a pressure treatment time of 6 minutes. The obtained block has a compacted density of 1.600g / cc; then isostatic pressing is carried out at a pressure of 8000KN, a temperature of 200°C, and a pressurized treatment time of 180min to obtain a block with a compacted density of 2.000g / cc; the obtained block is The body is placed in a tunnel kiln for heat treatment, the treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com