High temperature silk refining machine

A scouring machine, high temperature technology, applied in the structural field of silk high temperature scouring machine, can solve problems such as uneven degumming rate, and achieve the effects of precise process control, reduced labor intensity, and shortened scouring time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

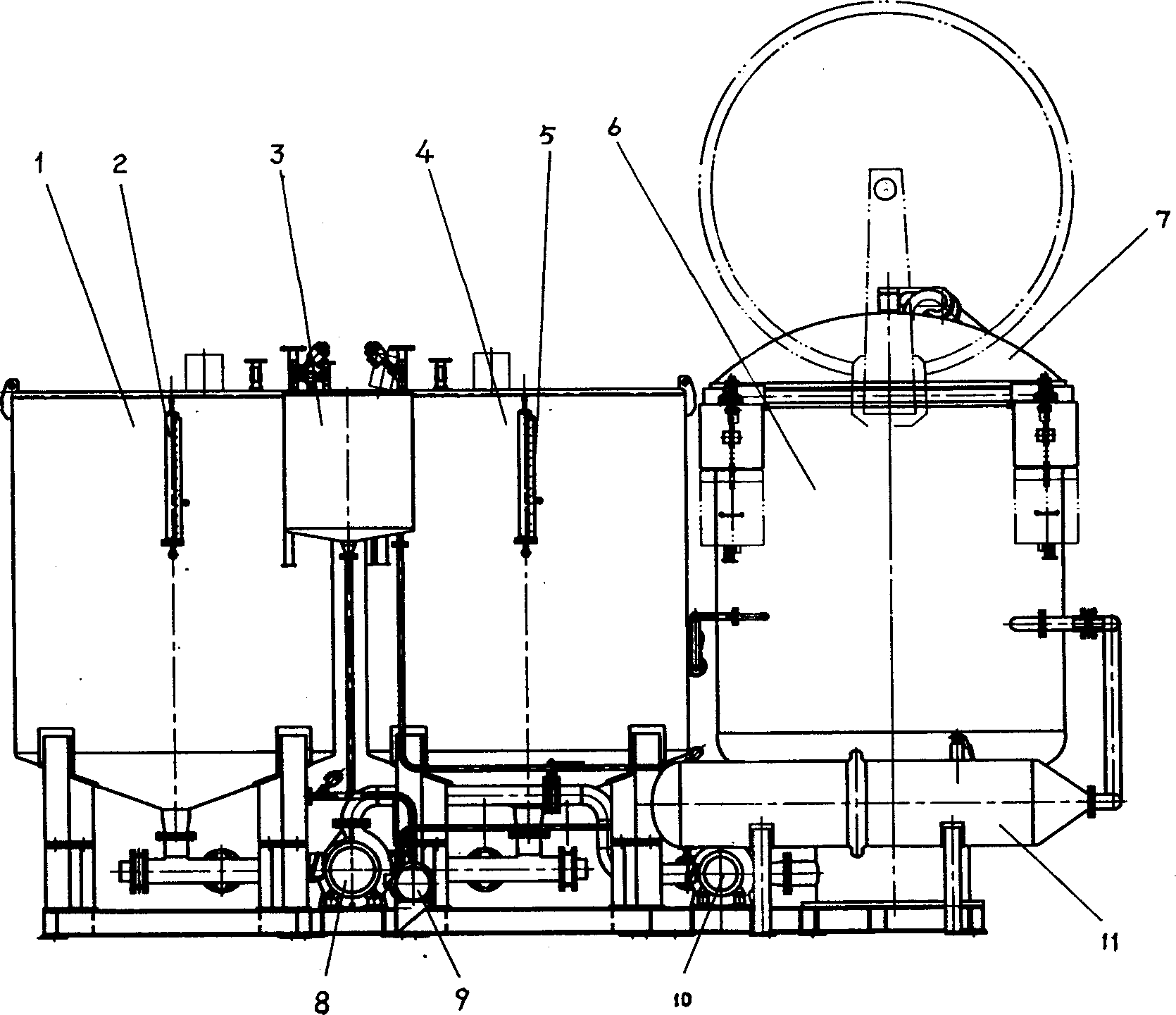

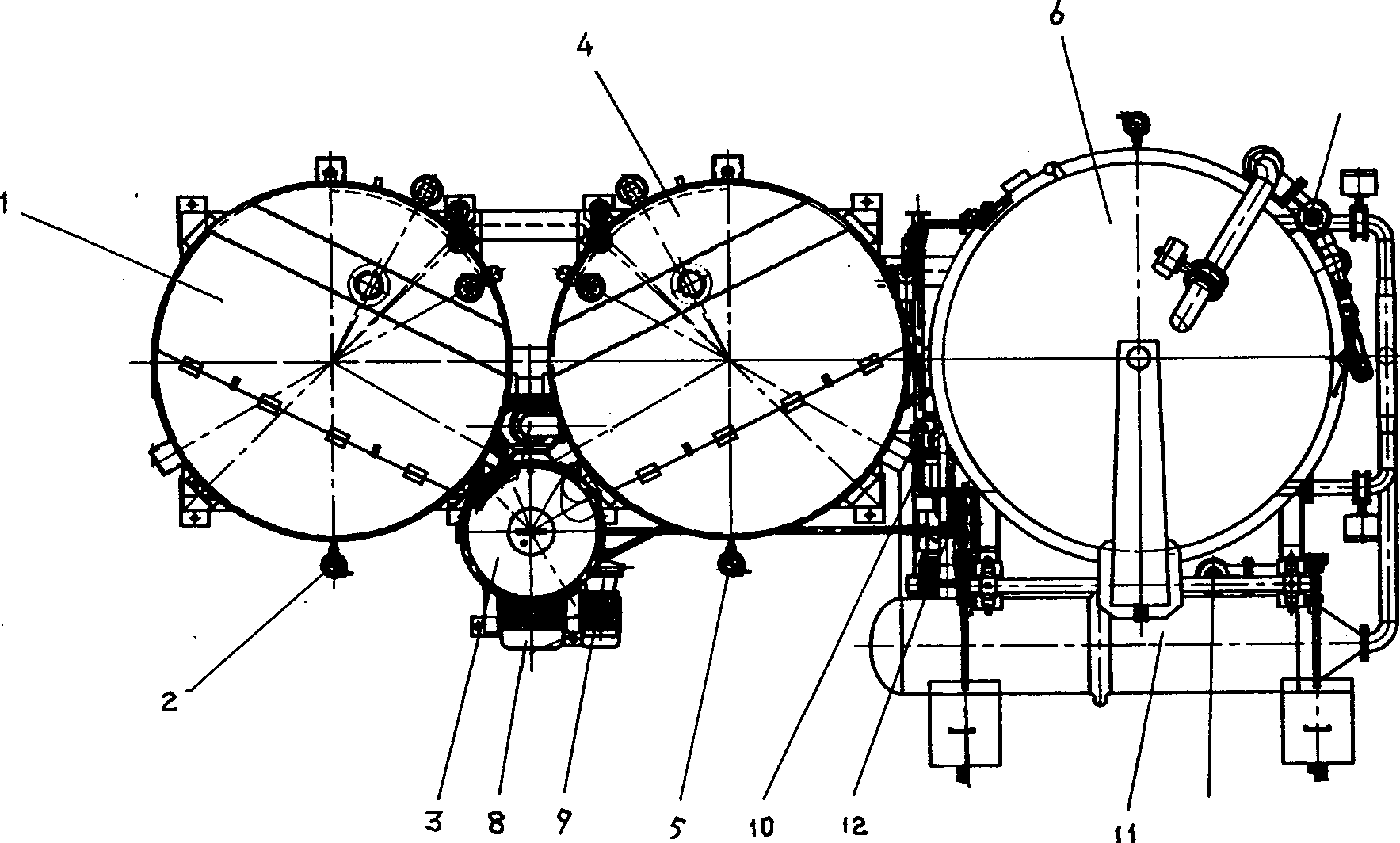

[0013] Such as figure 1 with figure 2 As shown, this silk high-temperature refining machine includes a master training cylinder, a heat exchanger 11 and a main circulation pump 10 . The master training cylinder is a high-temperature refining cylinder 6, a quantitative barrel 3, two reserve cylinders 1, 4, an injection pump 9, and a reserve cylinder pump 8. Among the figure, 2 and 5 are the water gauge of the preparatory tank, and 12 is a thermometer. figure 1 The double dotted line in is the position when the cylinder head is open.

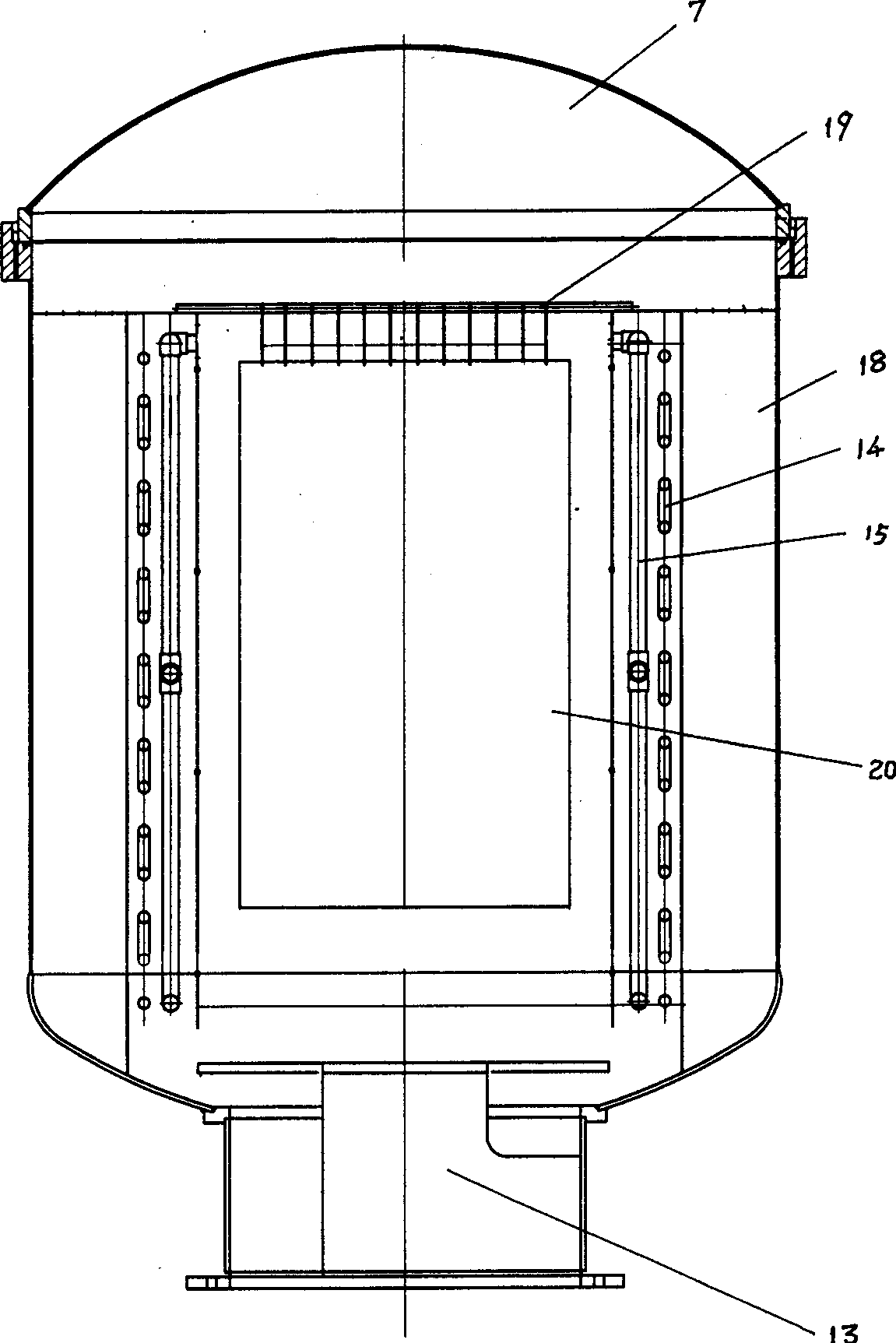

[0014] Such as image 3 with Figure 4 As shown, the refining cylinder 6 includes a vertical cylindrical cylinder body 18, a cylinder cover 7, and a silk hanging device 19. In the cylinder body, near the inner wall, a hot water inlet pipe 15 is also distributed, and a liquid inlet and outlet 13 is arranged at the bottom of the cylinder. image 3 20 of them are silk materials for hanging. Some steam heating pipes 14 can also be installed nea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com