Automatic continuous thymol crystallization system and method

A technology of thymol and crystallization system, which is applied in the field of automatic continuous crystallization system of thymol, can solve the problems of low automation, low production efficiency, and large floor area, so as to improve the applicable range of the process, reduce labor costs, and simplify equipment The effect of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1 A thymol automatic continuous crystallization system

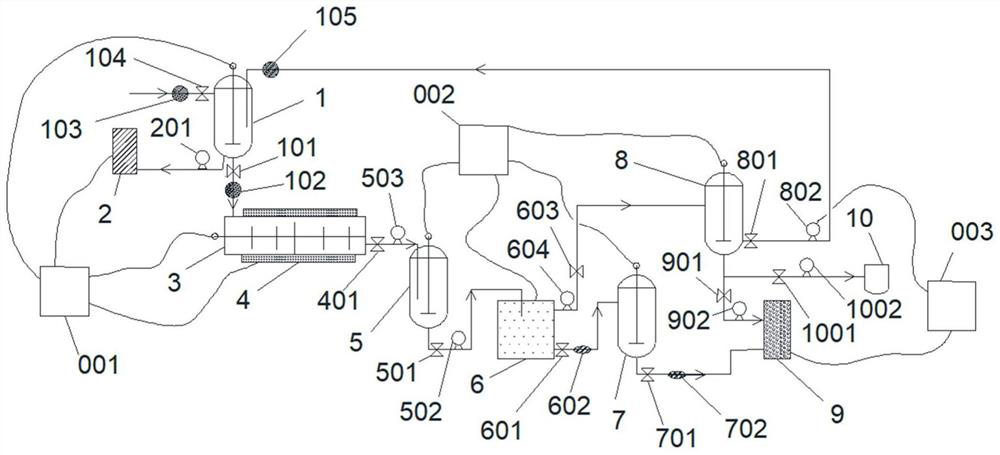

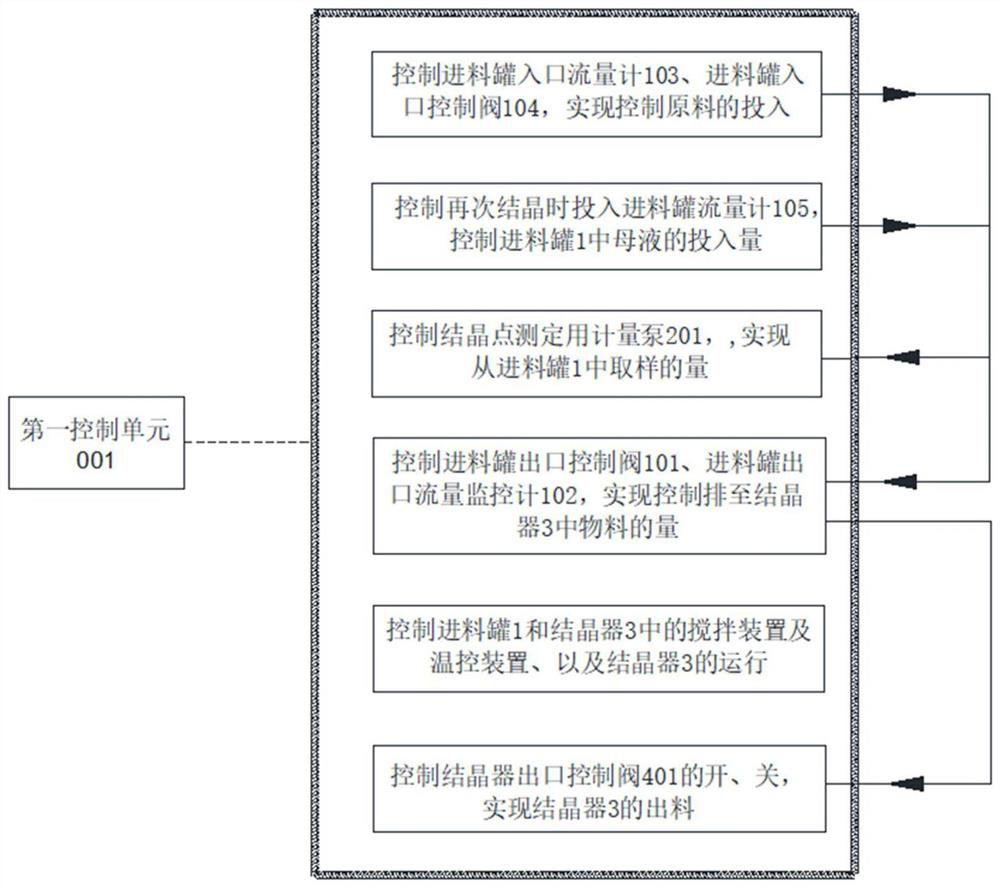

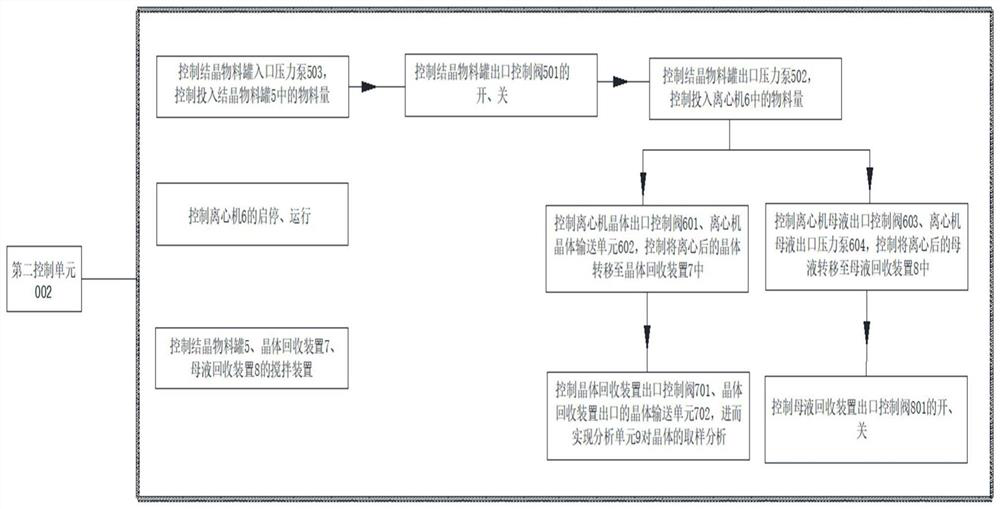

[0057] An automatic continuous crystallization system of thymol, such as figure 1 As shown, including feeding tank 1, crystallizer 3, material tank 5 after crystallization, centrifuge 6, crystal recovery device 7, mother liquor recovery device 8, thymol content analysis unit 9 and waste liquid recovery tank 10, feeding tank 1 The outlet of the crystallizer is connected to the inlet of the crystallization point measuring unit 2 and the crystallizer 3, the outlet of the crystallizer 3 is connected to the inlet of the material tank 5 after crystallization, the outlet of the material tank 5 after crystallization is connected to the inlet of the centrifuge 6, and the outlet of the centrifuge 6 is connected to the crystal. Recovery device 7 and mother liquor recovery device 8, the outlet of crystal recovery device 7 is connected to thymol content analysis unit 9, and the outlet of mother liquor recovery device 8...

Embodiment 2

[0093] Example 2 Automatic continuous crystallization method of thymol

[0094] The method of this example is carried out in the automatic continuous crystallization system of thymol described in Example 1.

[0095] The crystallizing point measuring unit 2 is specifically an automatic crystallizing point measuring instrument, and the thymol content analysis unit 9 can specifically use a gas chromatograph, using a common measurement and analysis method, and the specific analysis and measurement process will not be repeated.

[0096] The first control unit 001 controls the feed tank inlet flowmeter 103 to start, the feed tank inlet control valve 104 to open, and the thymol raw material to be separated and purified with a purity of 98.7w% and 95v% ethanol, according to the mass ratio of thymol to ethanol. The ratio of 10:1 is put into the feed tank 1, the temperature of the feed tank 1 is controlled at 45-50 ° C, and the thymol automatic continuous crystallization system is start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com