Cold disinfection method for cip center control system of milk product production line

A central control system and cold disinfection technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of long manual control of the CIP system, poor coordination of the CIP cleaning process, and poor disinfection effect Stability and other issues, to achieve the effect of excellent flushing effect, shortened working time and waiting time, and reduced waiting time and disinfection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

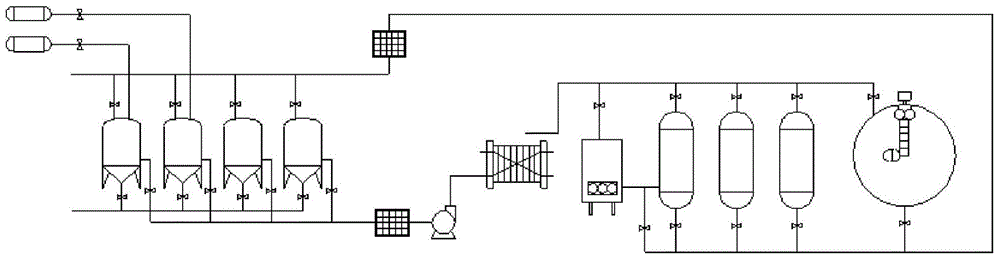

[0031] Such as figure 1 The production line of the CIP central control system shown is subjected to cold disinfection according to the following steps: (1) Turn on the CIP central control system to clean and disinfect the production line: first rinse with clean water for 3 minutes. Then circulate with hot alkaline detergent at 75°C for 15 minutes, and rinse with water for 5 minutes after the cycle of hot alkaline detergent is completed. Then circulate the acid solution at 70°C for 15 minutes, and rinse with warm water at 50-55°C for 5 minutes after the acid solution cycle is completed. (2) Empty the acid solution in the pickling tank in the CIP central control system, and input 500ppm peracetic acid cold disinfectant. (3) Adjust the temperature of the pickling program to room temperature through the CIP central control system without additional heat treatment; set the rinse time of the pickling program to 15 minutes. Then, turn on the CIP central control system to implement...

Embodiment 2

[0034] The cold disinfection of the pasteurized pure milk production line is as follows: (1) Turn on the CIP central control system to perform original cleaning on the production line: first, rinse with water for 5 minutes, then stop the clean water rinse in the CIP central control, and use 75°C with a concentration of 0.8%~ 1.2% sodium hydroxide solution circulates as alkaline detergent for 10-15 minutes. After the cycle of alkaline detergent is completed, rinse with water for 3 to 5 minutes, then circulate with dilute nitric acid with a concentration of 0.8% to 1.0% at 65 to 70°C for 10 to 15 minutes, and after the cycle of acid solution is completed, rinse with hot water at 90°C for 3 to 5 minutes 5min. (2) Transfer the acid solution in the pickling tank in the CIP central control system to an idle tank for storage, and then input 500ppm peracetic acid solution as a cold disinfectant. (3) Set the flushing degree of the pickling tank in the CIP system through the CIP centra...

Embodiment 3

[0036] Similar to Example 2, only a filter is set on the solution output pipeline of the CIP system, and a filter screen with a pore size of 0.21 to 0.75 microns is arranged in the filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com