Patents

Literature

126 results about "Vanadium pentoxide dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vanadium dust. Related Pages. Synonyms & Trade Names Divanadium pentoxide dust, Vanadic anhydride dust, Vanadium oxide dust, Vanadium pentaoxide dust CAS No. 1314-62-1 RTECS No. YW2450000. DOT ID & Guide. 2862 151. Formula. V₂O₅ ...

Vanadium redox battery electrolyte

InactiveUS20040241552A1Loss in Coulombic efficiencyEvolution of hydrogen is thereby avoidedTantalum compoundsRegenerative fuel cellsVanadium redox batterySlurry

The present invention relates generally to the production of a vanadium electrolyte, including a mixture of trivalent and tetravalent vanadium ions in a sulphuric acid solution, by the reactive dissolution of vanadium trioxide and vanadium pentoxide powders, the surface area and particle size characteristics being controlled for complete reaction to produce the desired ratio of V(III) to V(IV) ions in the solution. The solution may be suitable for direct use in the vanadium redox battery, or the solution can provide an electrolyte concentrate or slurry which can be reconstituted by the addition of water or sulphuric acid prior to use in the vanadium redox battery.

Owner:UNISEARCH LTD

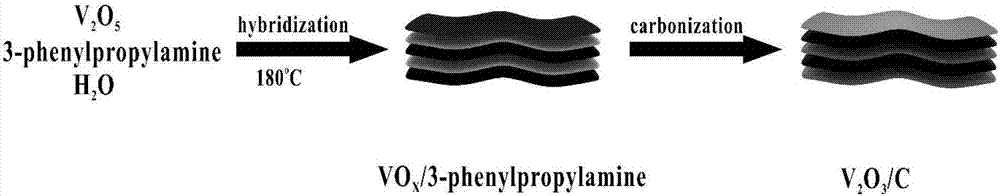

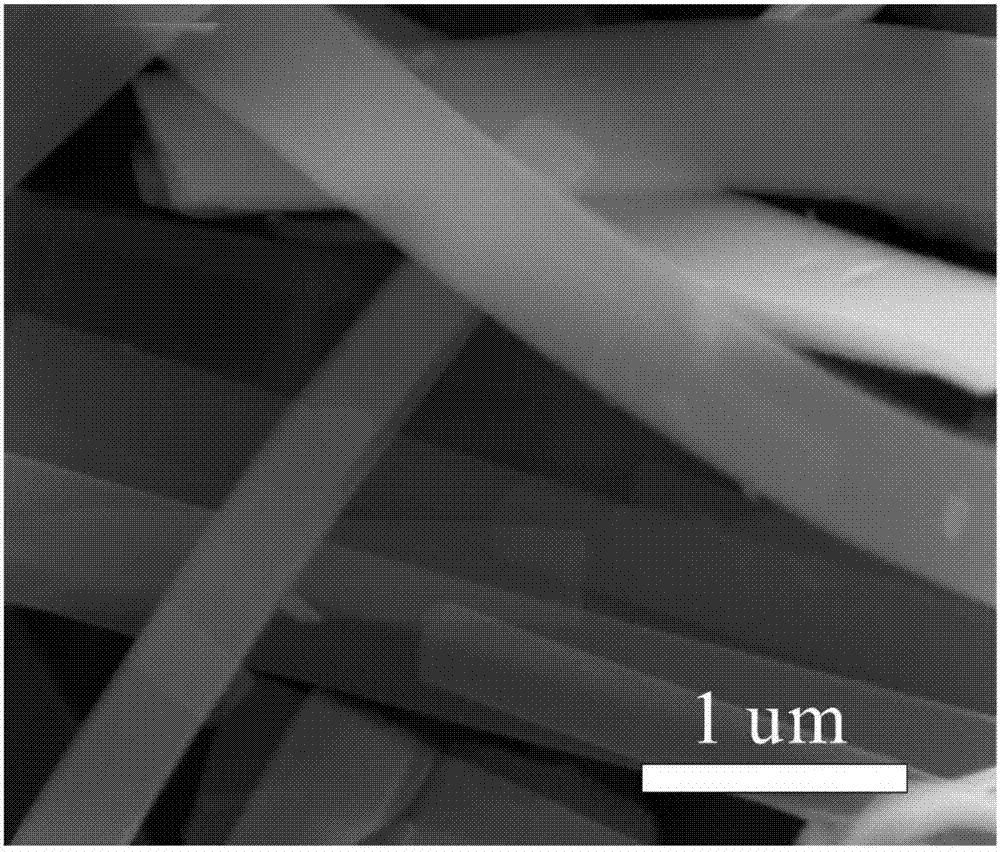

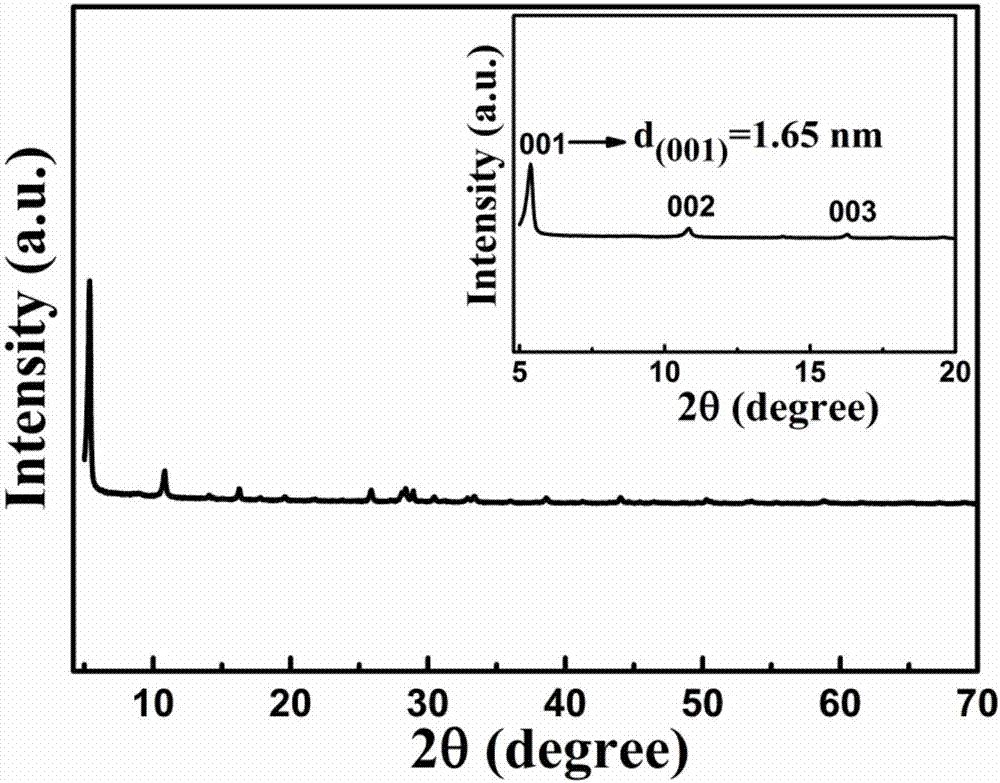

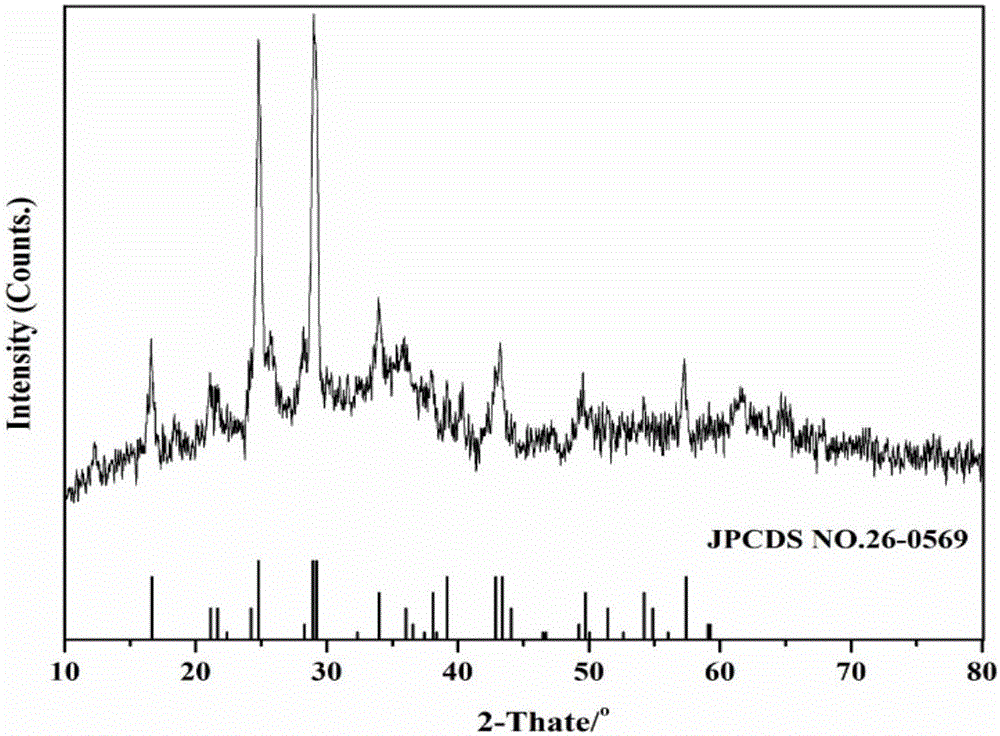

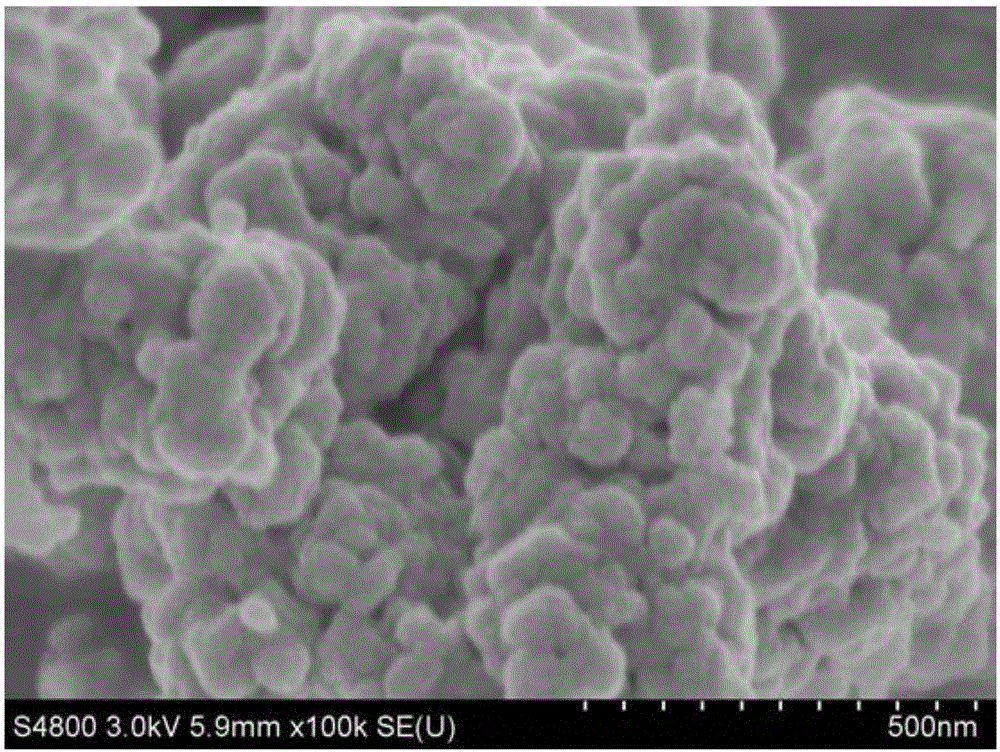

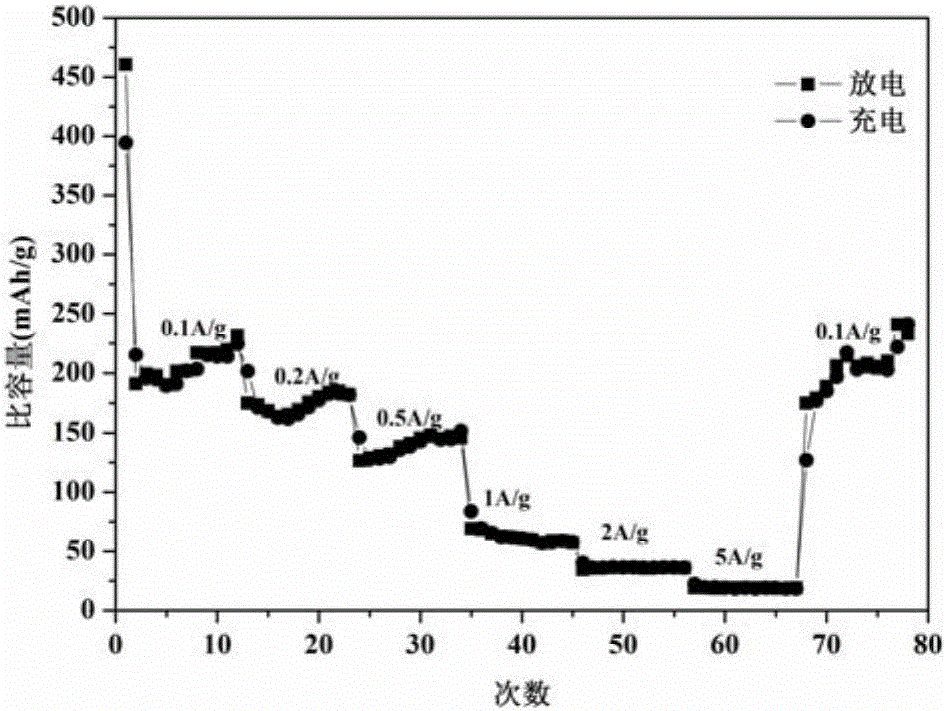

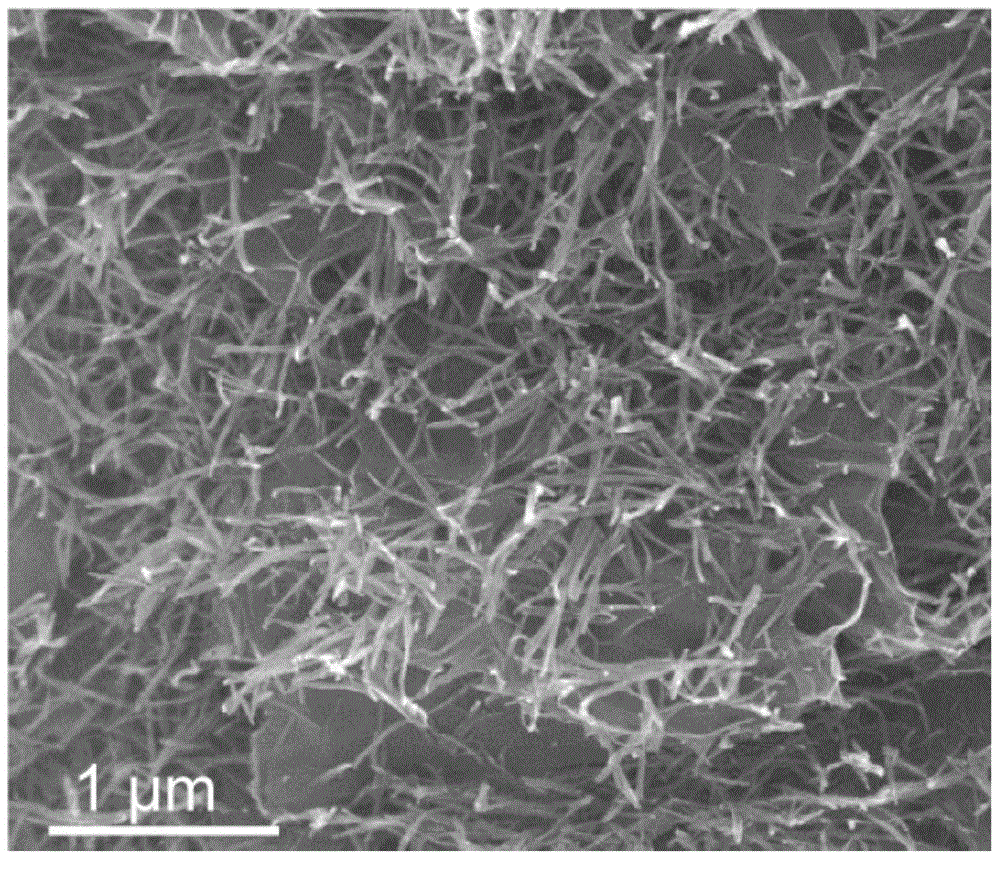

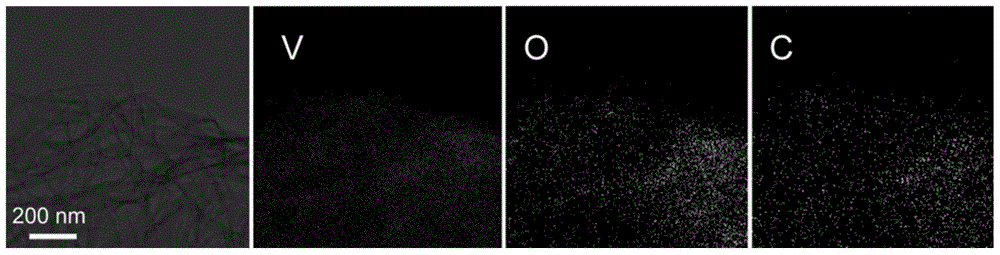

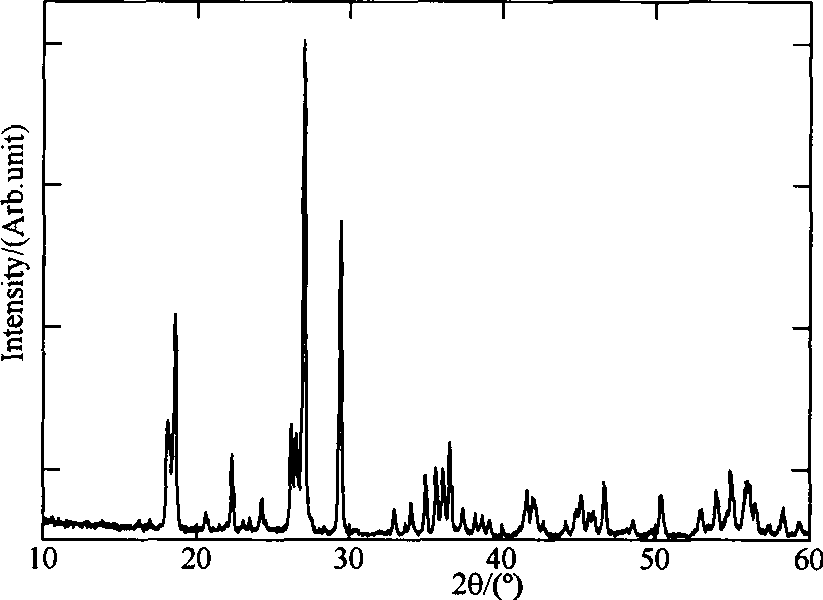

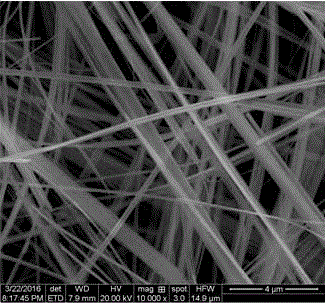

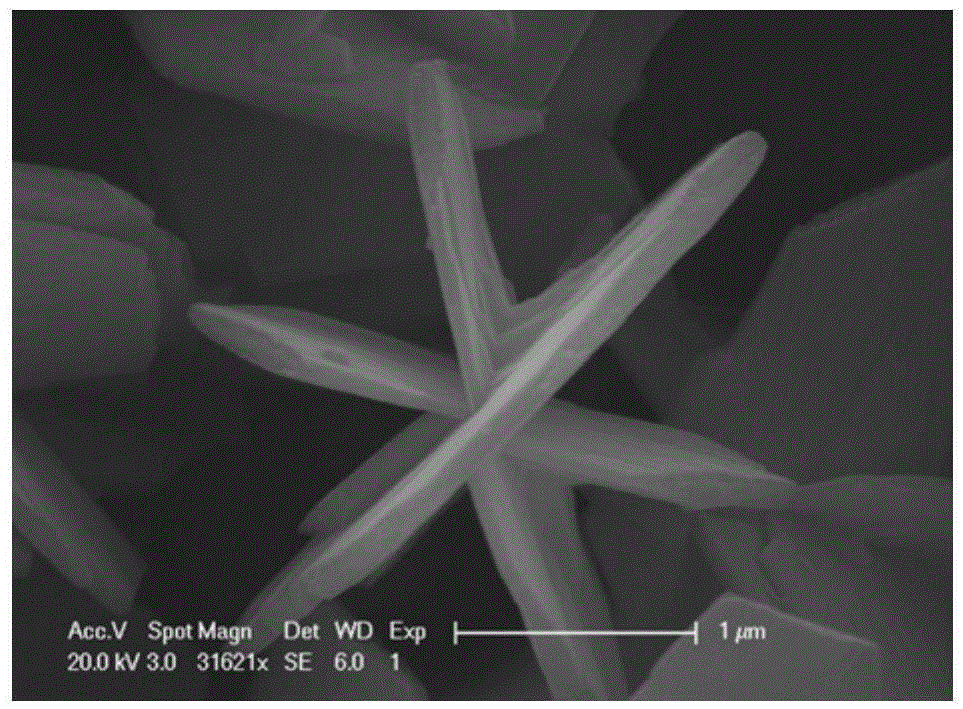

Carbon intercalation layer V2O3 nanometer material and preparation method and application thereof

ActiveCN106935860AAlleviate volume changesImprove cycle stabilityCell electrodesCarbon layerCarbonization

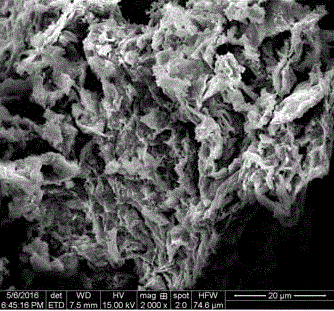

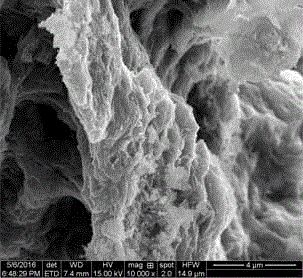

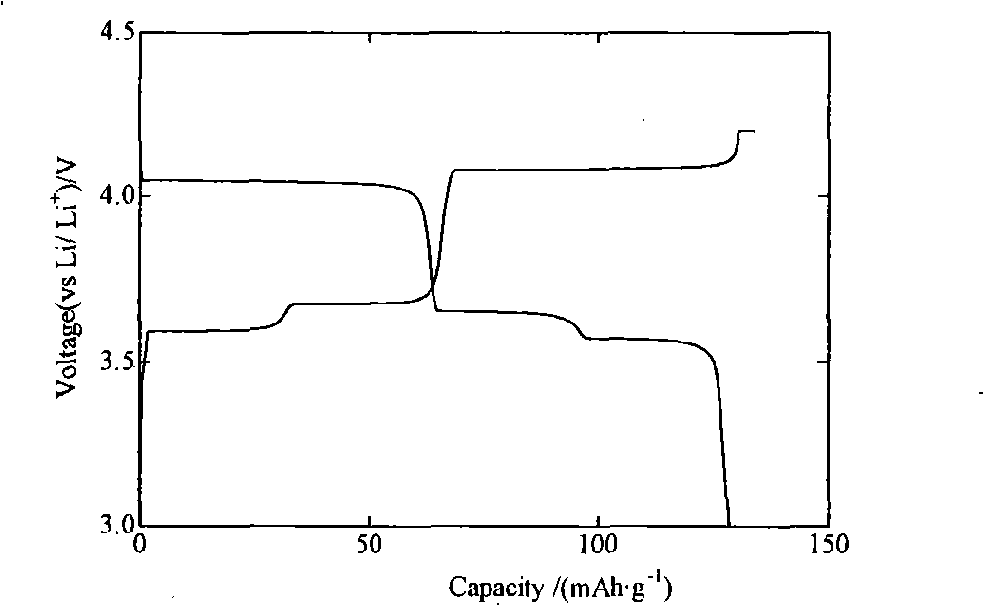

The invention discloses a preparation method and application of a carbon intercalation layer V2O3 nanometer material. The preparation method comprises the following steps of (1) adding vanadium pentoxide powder into an organic amine liquid, and uniformly stirring and mixing the powder; (2) transferring a mixed liquid to a reaction kettle for hydrothermal reaction; and (3) placing the obtained hybrid precursor in a furnace after drying, introducing an inert gas for carbonization to obtain a V2O3 / C hybrid nanometer material. The V2O3 / C hybrid nanometer material prepared by the method is uniform in morphology, and a carbon layer can be effectively dispersed in a nanometer substrate in the material. When the material is applied to a lithium ion battery or sodium ion battery negative electrode, the rate performance of a metal oxide used as an electrode material can be greatly improved, the volume energy density of the battery is improved, and the material has relatively large application prospect.

Owner:HUAZHONG UNIV OF SCI & TECH

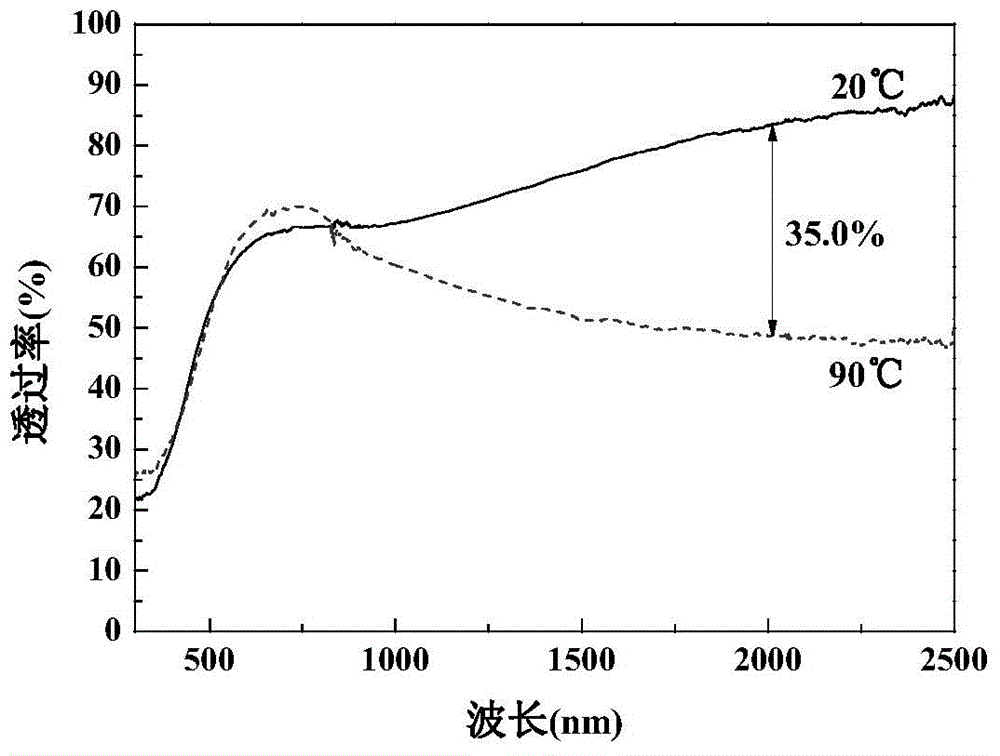

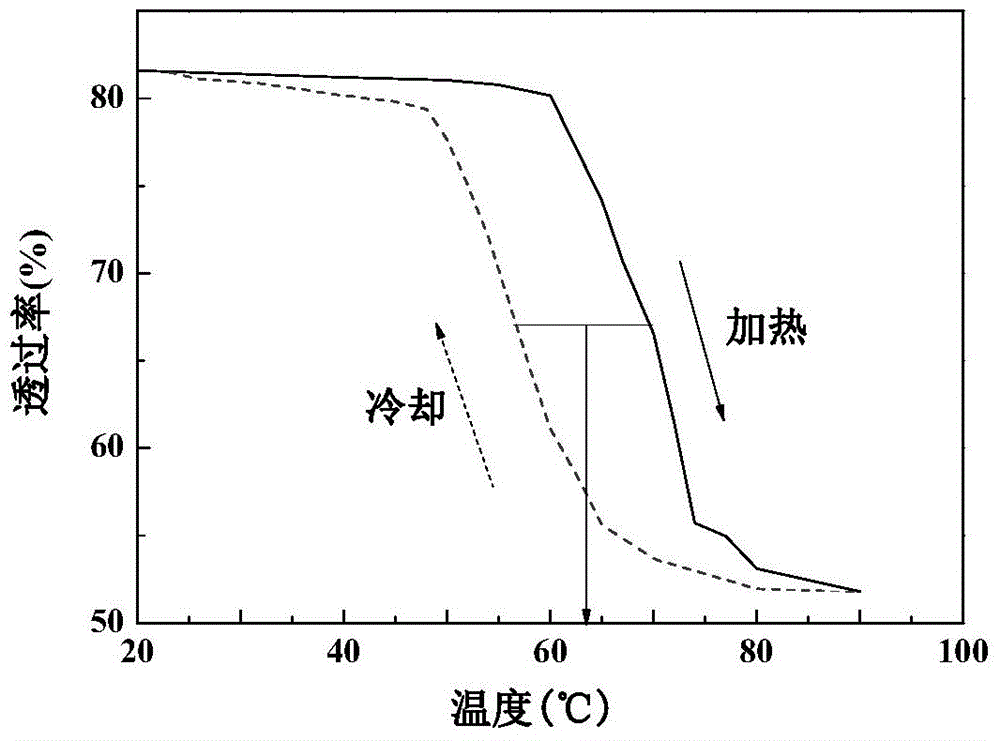

Vanadium dioxide intelligent temperature control film and preparation method thereof

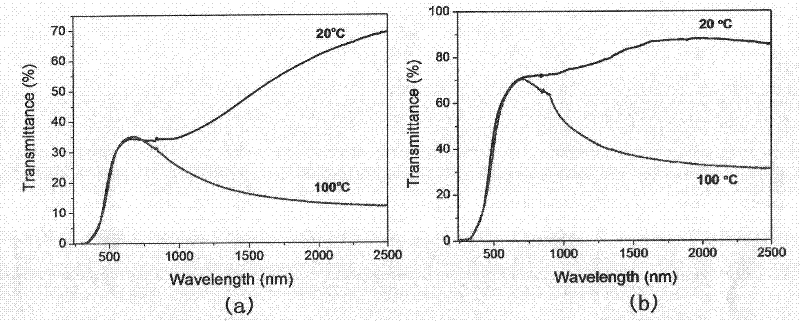

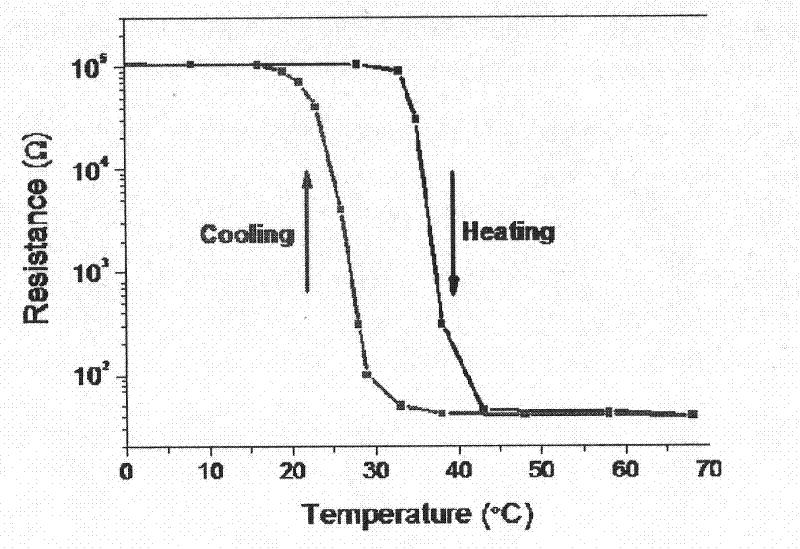

The invention relates to a vanadium dioxide intelligent temperature control film and a preparation method thereof. The preparation method comprises the following steps of: uniformly dispersing and dissolving vanadic oxide powder in an organic solvent with weak reductibility by adopting a wet chemical solution method; adding PVP (Polyvinyl Pyrrolidone) or PEG (polyethylene glycol) and a metal salt to prepare a doped VOx film (x is more than 2.0 and less than 2.5); and performing thermal treatment to form a doped porous hypovanadic oxide (VO2) film. In a better embodiment, the preparation method comprises the following steps of: adding polyvinyl pyrrolidone and a wolfram salt into a system consisting of vanadic oxide powder, benzyl alcohol and isopropyl alcohol to prepare a wolfram-doped VOx film; and annealing in hydrogen / argon atmosphere at the temperature 410 DEG C for 3 hours to prepare a wolfram-doped porous VO2 film, wherein the metal-insulator phase-transition temperature of the wolfram-doped porous VO2 film can be adjusted between 30 DEG C and 68 DEG C according to doping amount of wolfram, the penetration rate of a visible light region is 70 percent, the difference between the penetration rate before phase transition and the penetration rate after phase transition at the position of which the wavelength is 2,500 nanometers is 62 percent, 3-4 orders of magnitude of specific resistance is changed, and higher practical value is achieved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

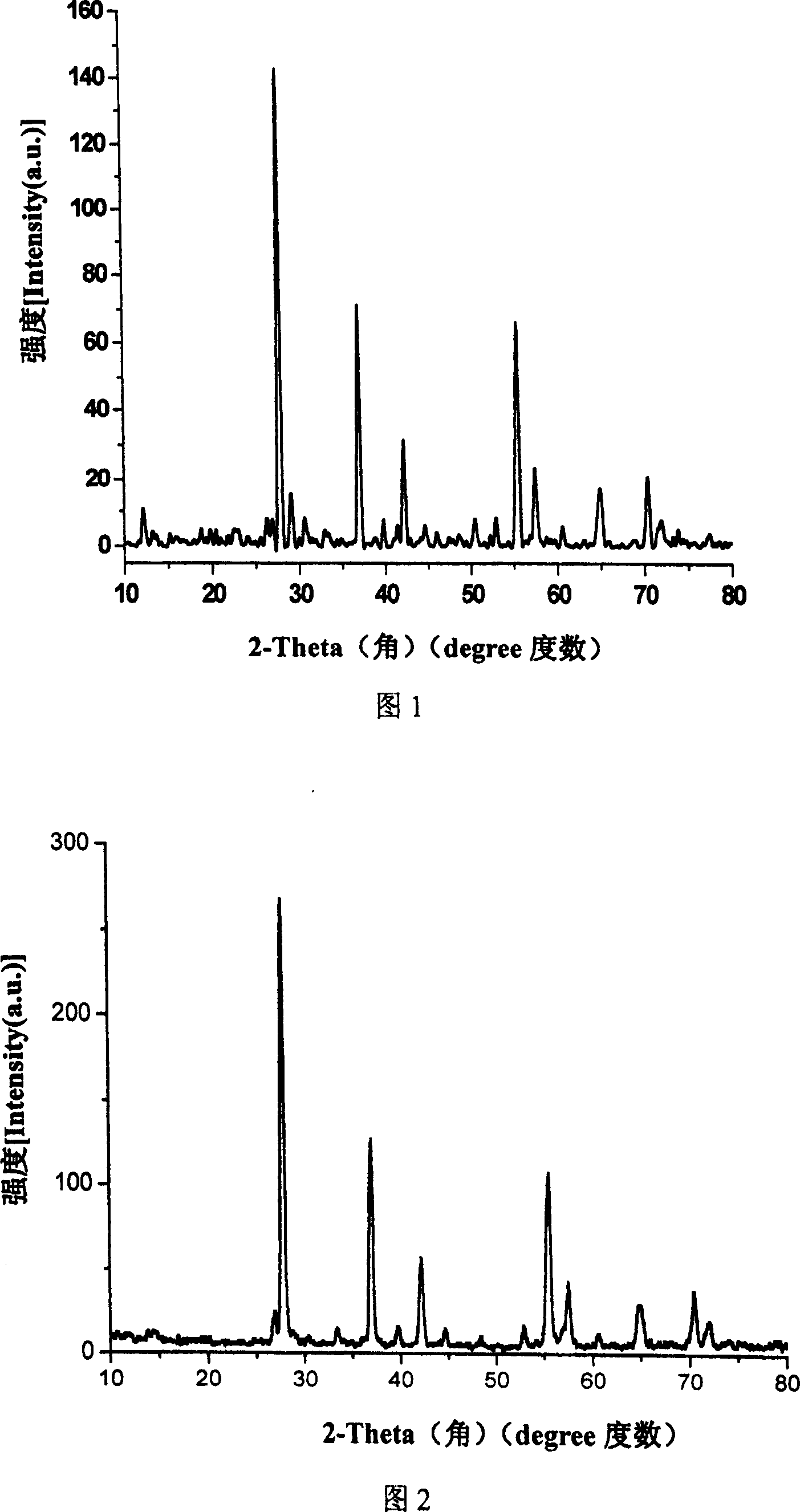

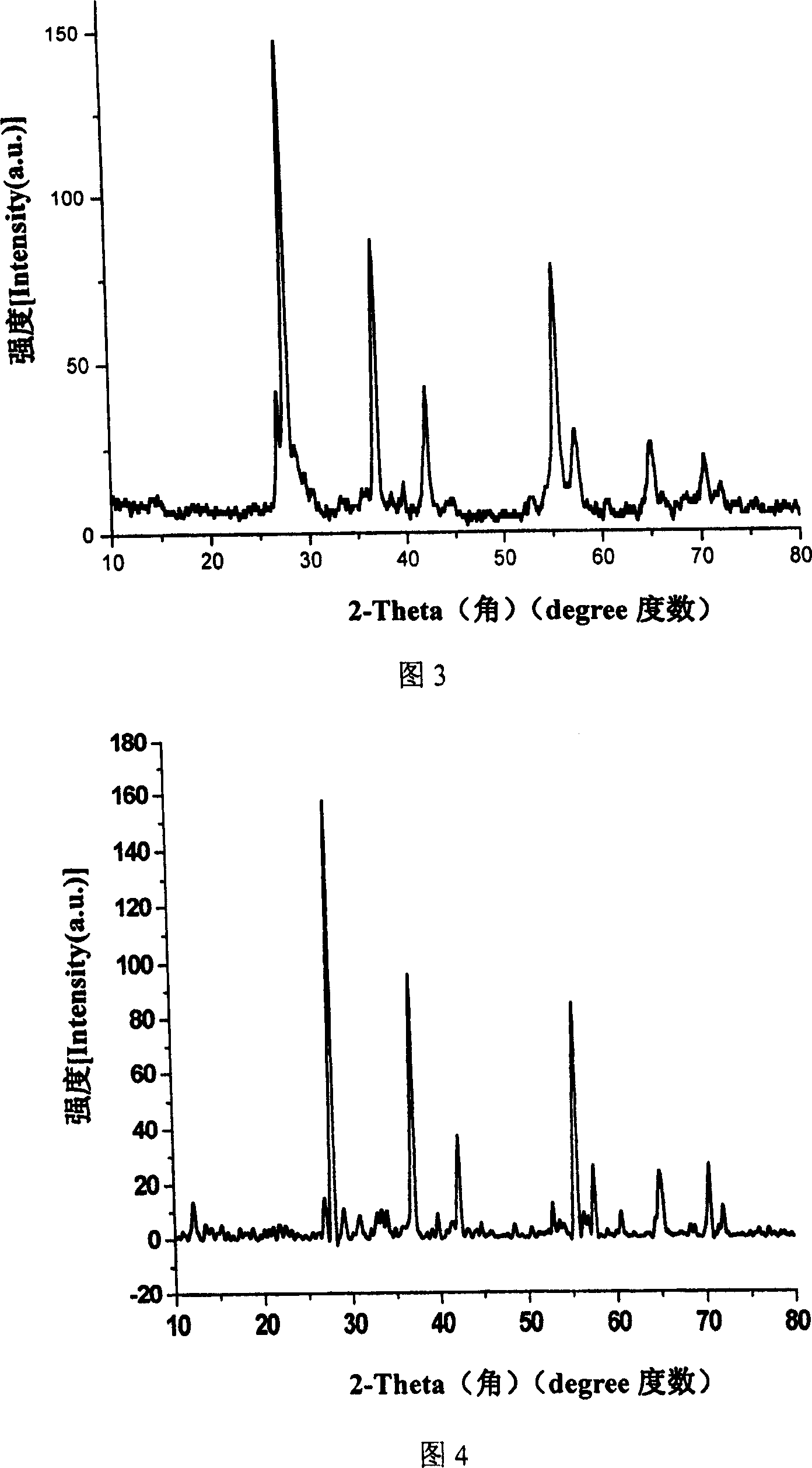

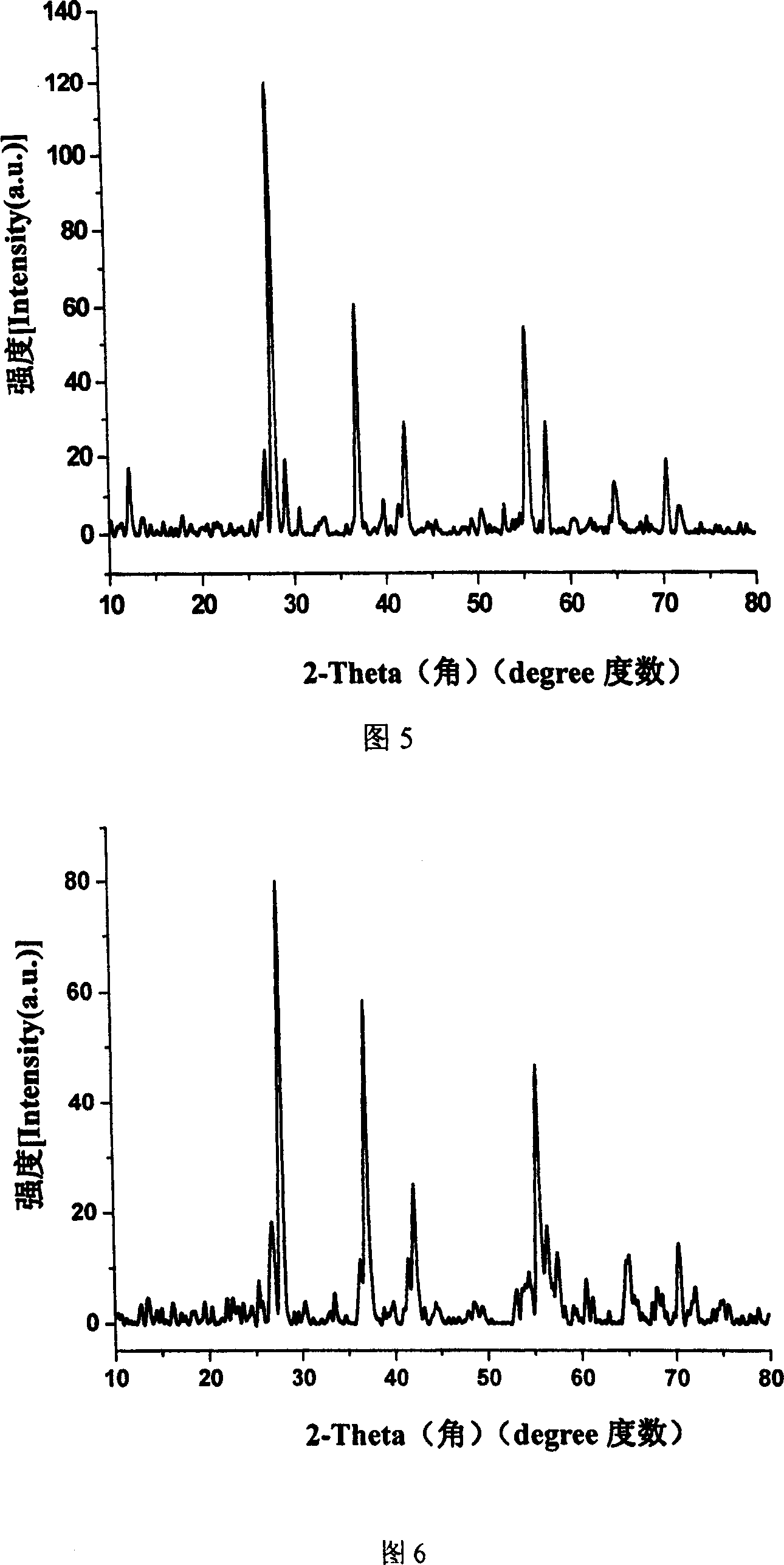

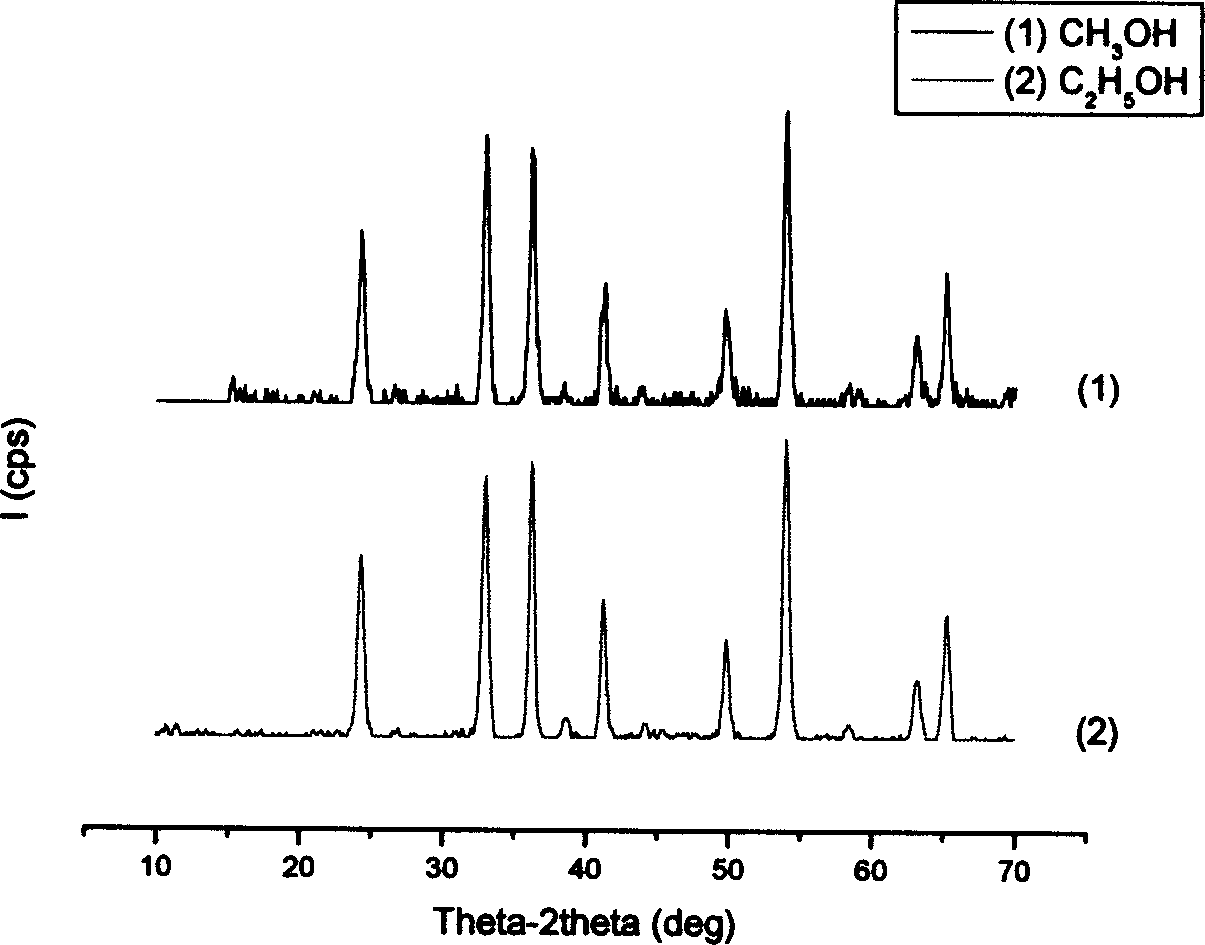

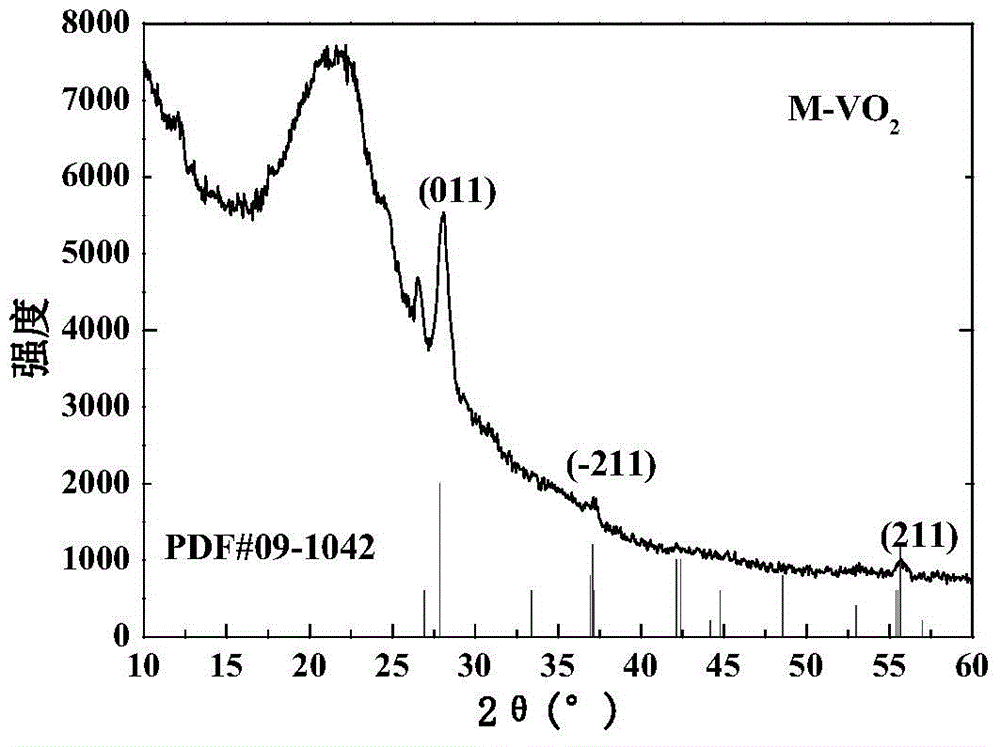

Preparing process for vanadium dioxide powder

The vanadium dioxide powder preparing process includes dispersing vanadium pentoxide powder material in sufficient or solvent, heating to 140-190 deg.c at 0.05-10 MPa in a reactor and maintaining for 2-24 hr, naturally cooling, washing with deionized water and anhydrous alcohol, and vacuum drying to obtain vanadium dioxide powder. The vanadium dioxide powder may be further calcined at 300-800 deg.c in protecting inert gas for 1-12 hr to obtain crystallized vanadium dioxide. The present invention has the features of simple material, low cost, low reaction temperature, less environment pollution, etc.

Owner:张家港楚人新材料科技有限公司

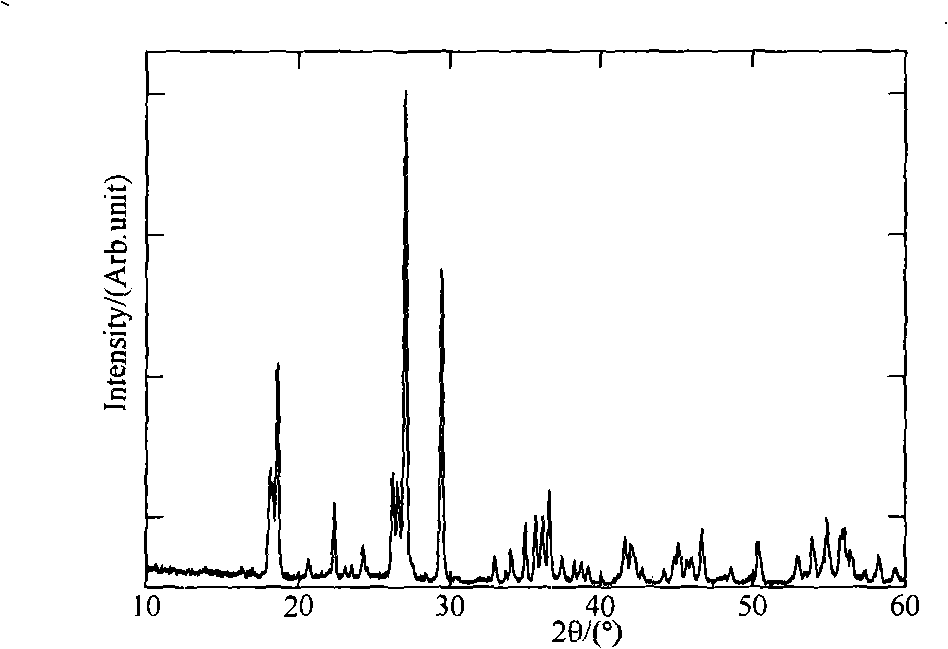

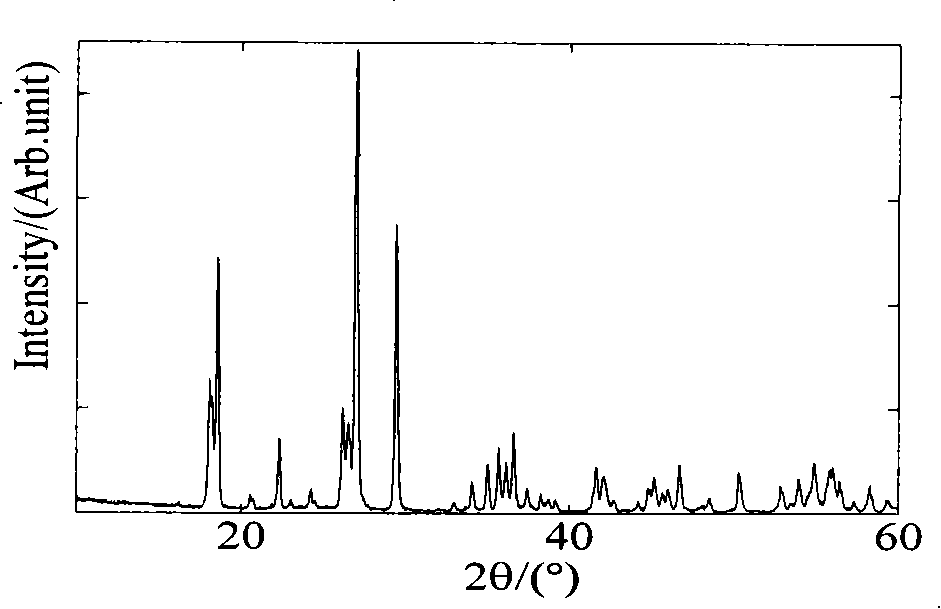

Process for preparing crystal vanadium trioxide

A process for preparing crystalline V2O3 includes such steps as dispersing V2O5 powder in proper organic solvent, adding to high-pressure tubular reactor, reacting at a certain temp under a certain pressure, and removing solvent.

Owner:WUHAN UNIV

Method for preparing lithium ion battery anode material vanadium lithium fluophosphate by one-step solid phase reaction

InactiveCN101320808ASolve easy oxidationImprove charge and discharge performanceElectrode manufacturing processesChemical/physical/physico-chemical processesLithiumOrganic acid

The invention discloses a method for producing fluorophoshoric acid vanadium lithium of lithium iron battery positive pole material at low temperature by one-step solid phase reaction, comprising the step of: uniformly blending vanadic oxide powders, phosphate, organic acid, lithium salts with villaumite to sinter for 3 to 12 hours under the protection of inert gases, consequently the final product LiVPO4F is obtained after cooling; the invention is simple and convenient in usage, easy in control and low in cost, and simplifies the synthesis process and promotes the discharge and charge performance and circulation performance of samples.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

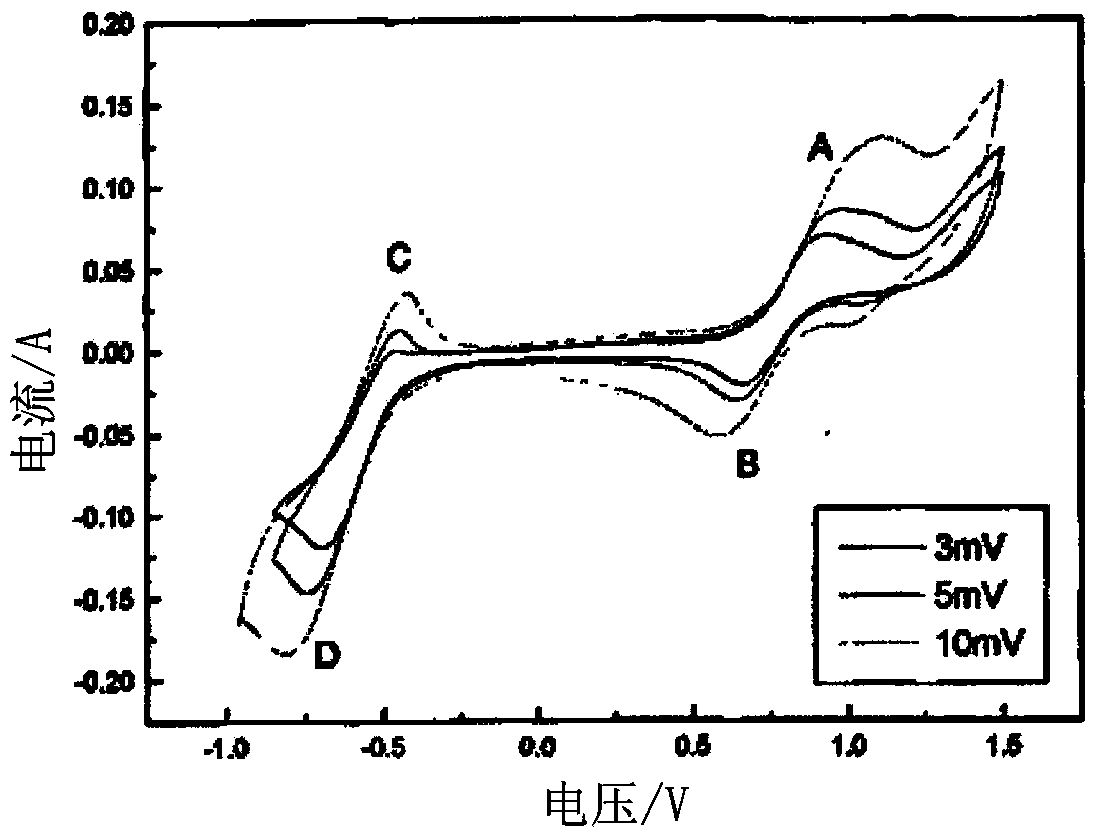

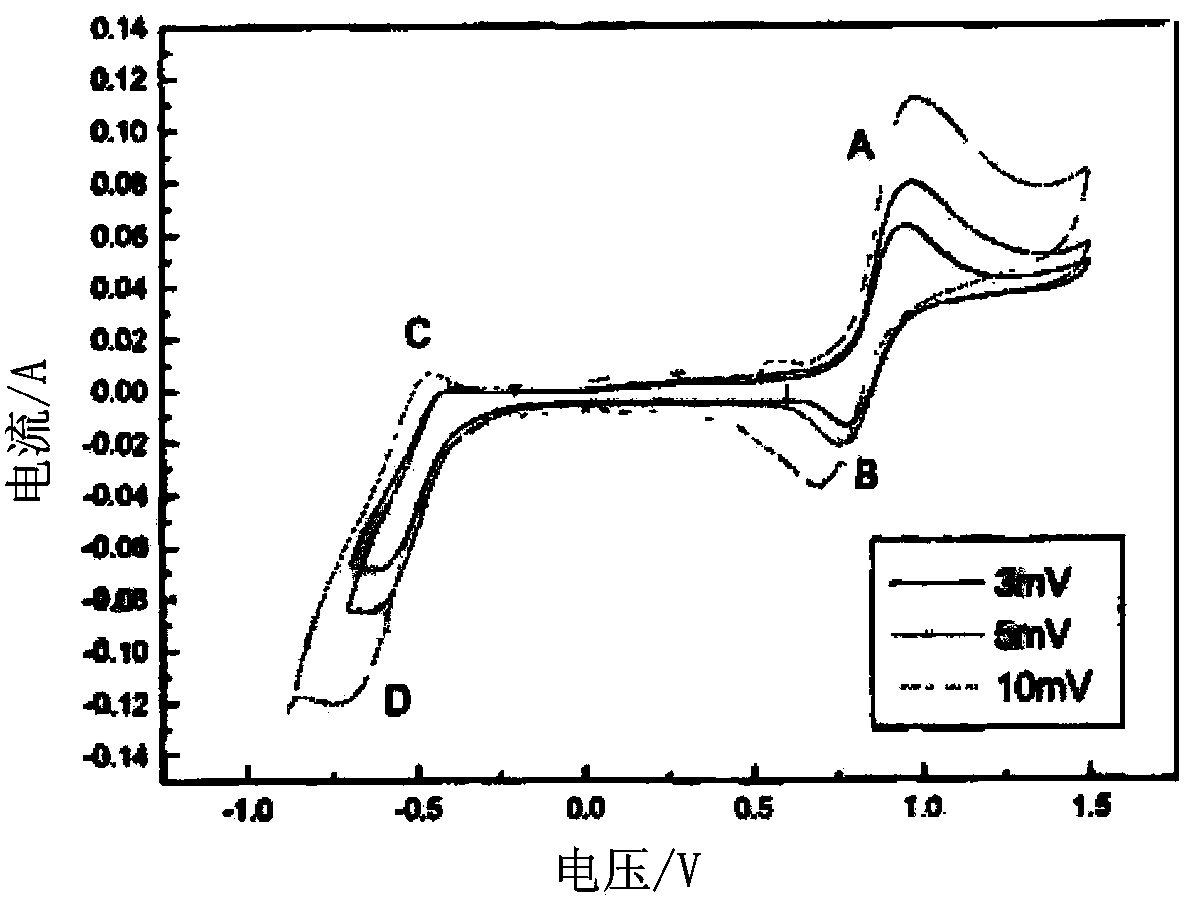

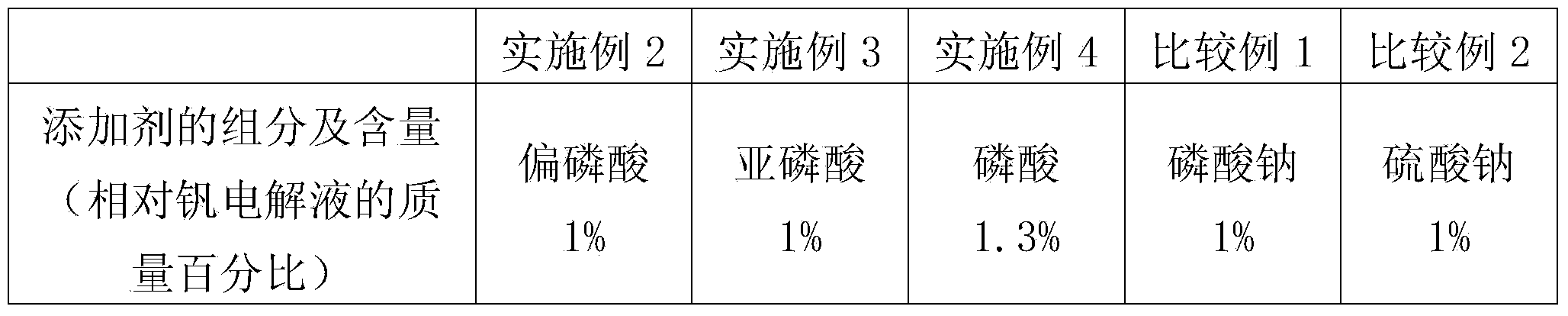

Preparation method of vanadium electrolyte

InactiveCN103490086AImprove solubilityIncrease profitRegenerative fuel cellsElectrolysisPhysical chemistry

The invention relates to a preparation method of a vanadium electrolyte, which comprises the following steps: dissolving vanadium pentoxide powder in a concentrated sulfuric acid for activation, adding into deionized water, dissolving and filtering to obtain a pentavalent vanadium ion solution; carrying out electrolysis by using the pentavalent vanadium ion solution as a negative electrode electrolyte solution and a sulfuric acid solution as a positive electrode electrolyte solution to obtain a vanadium ion electrolyte in which the mol ratio of trivalent vanadium to tetravalent vanadium is 1:1, wherein the molar weights of the sulfuric acid in the positive electrode electrolyte solution and the sulfuric acid in the negative electrode electrolyte solution are equal; and adding an additive into the vanadium ion electrolyte, and dissolving to obtain the vanadium electrolyte, wherein the additive comprises a phosphorous compound, and the mass percent of the compound in the vanadium electrolyte is 0.5-1.5%. The preparation method provided by the invention does not influence the service life of the vanadium battery and electrolyte on the premise of enhancing the concentration and stability of the electrolyte.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Preparation method of copper vanadate for lithium-ion battery cathode material

Owner:SHAANXI UNIV OF SCI & TECH

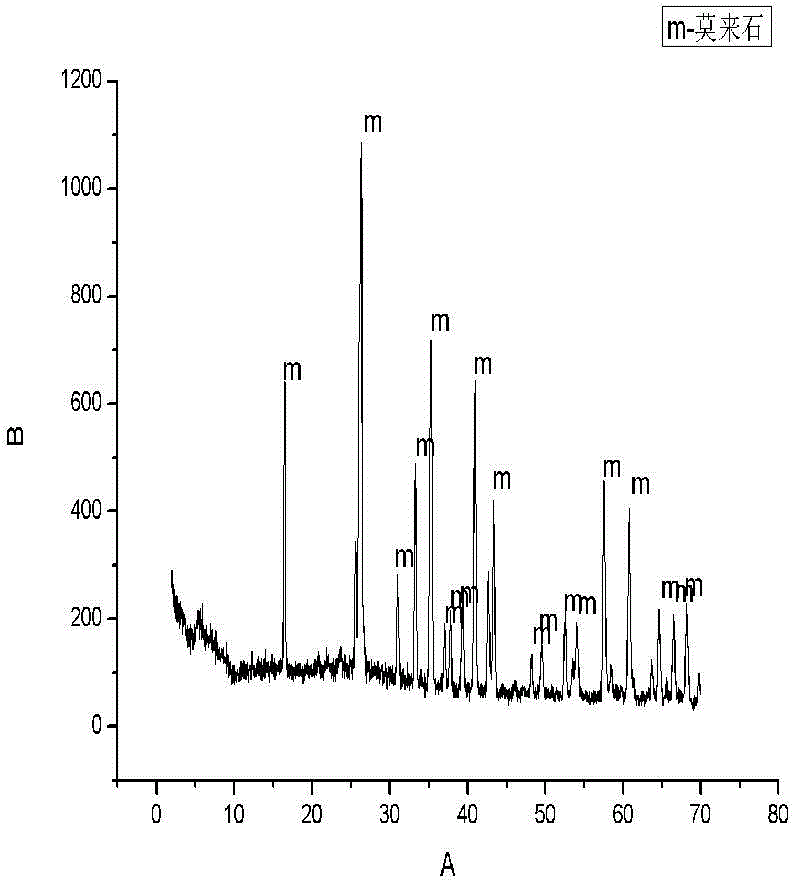

Preparation method of acicular mullite porous ceramic block material with superhigh amount of porosity

The present invention discloses a preparation method of mullite porous ceramic with cluster-like whisker structure. The method is as below: dispersing aluminum hydroxide, silica, aluminum fluoride and vanadium pentoxide powder in a polyvinyl alcohol (PVA) aqueous solution; mixing evenly and freezing in a mold; separating PVA and water; crosslinking a PVA molecular chain, and curing the ceramic powder by the PVA molecular chain and ice; and then freeze-drying, batching and sintering to obtain the mullite porous ceramic with in-situ grown whiskers, porosity of 50%-90%, and compressive strength of 2-15 MPa. The present invention can be applied to the fields of muffler noise reduction, catalyst carrier and gas-solid separation.

Owner:HAINAN UNIVERSITY

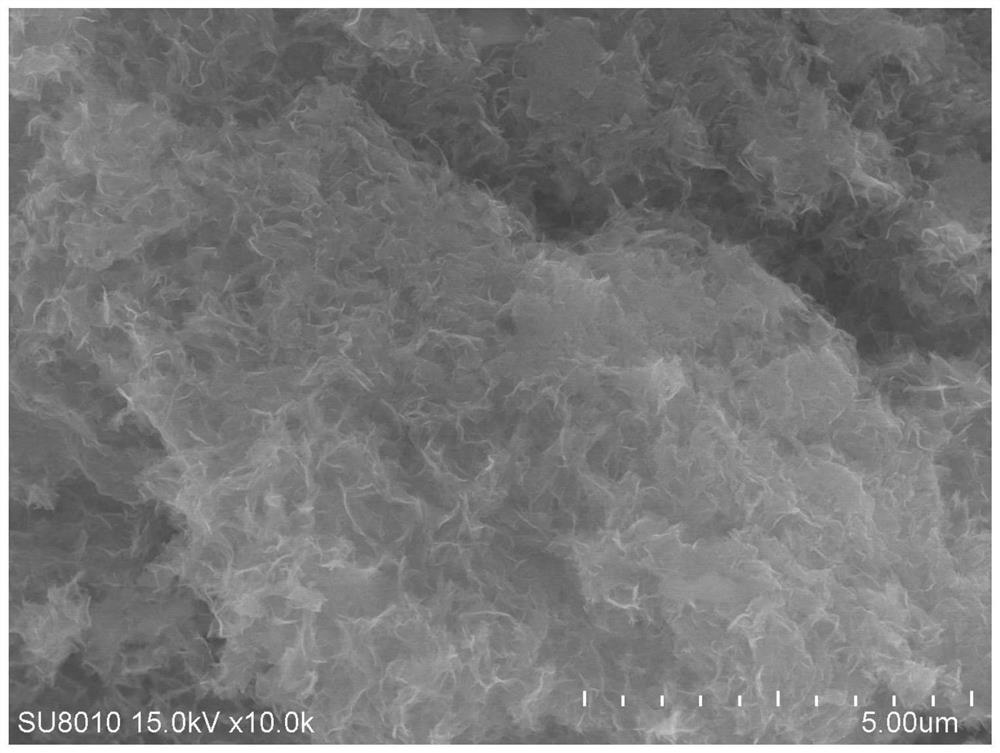

Method for preparing vanadium pentoxide/graphene composite aerogel material

ActiveCN104437277AReduce weightLarge specific surface areaAerogel preparationColloidal chemistry detailsSolventBENZYL ALCOHOL/WATER

The invention relates to a method for preparing a vanadium pentoxide / graphene composite aerogel material. The method comprises the following steps: firstly, evenly mixing vanadium pentoxide powder, benzyl alcohol and isopropyl alcohol, refluxing, condensing, and filtering to obtain vanadium pentoxide sol; evaporating and concentrating to obtain concentrated vanadium pentoxide sol; adding an aqueous dispersion of graphene oxide and a catalyst to the concentrated vanadium pentoxide gel; stirring and ageing, so as to obtain vanadium pentoxide / graphene composite wet gel; carrying out solvent replacement in replaced solvent; drying to obtain vanadium pentoxide / graphene composite aerogel; and carrying out thermal treatment, so as to obtain the vanadium pentoxide / graphene composite aerogel. Compared with the prior art, the method disclosed by the invention is simple and easy to achieve; and meanwhile, inorganic vanadium pentoxide powder is adopted as the raw material, so that the cost is relatively low; and popularization and application are facilitated; meanwhile, a metallic oxide is evenly compounded with graphene through in-situ growth; and a new way is provided for the preparation of metallic oxide / graphene composite aerogel.

Owner:TONGJI UNIV

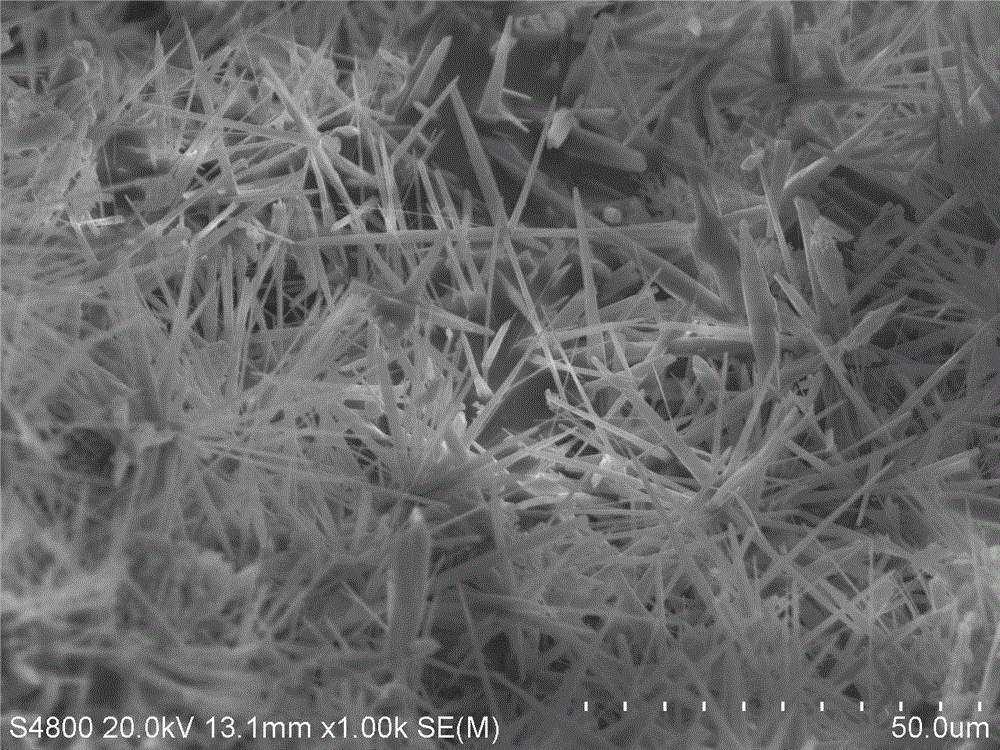

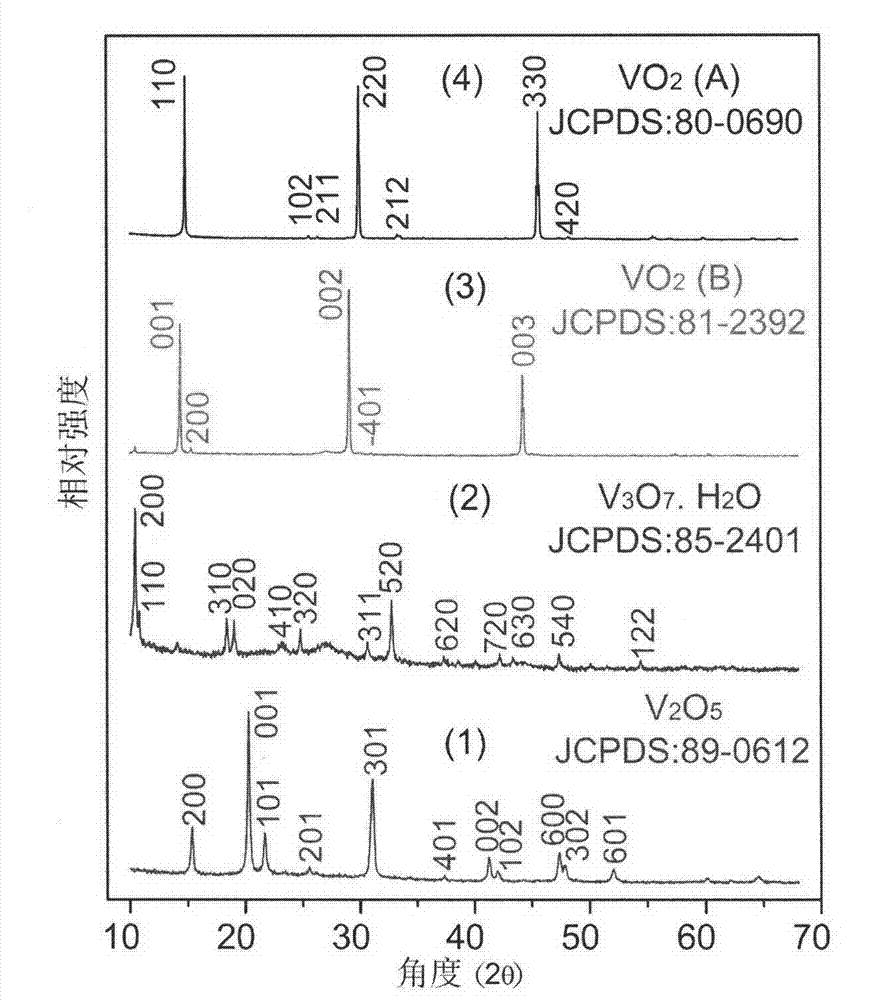

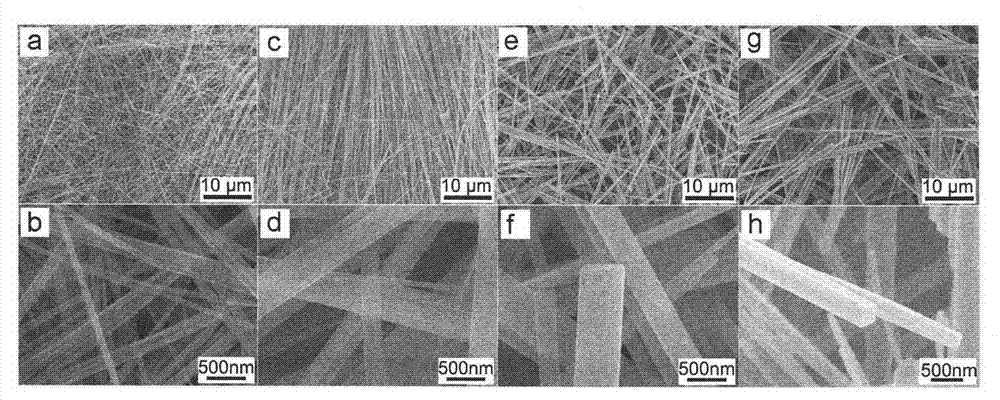

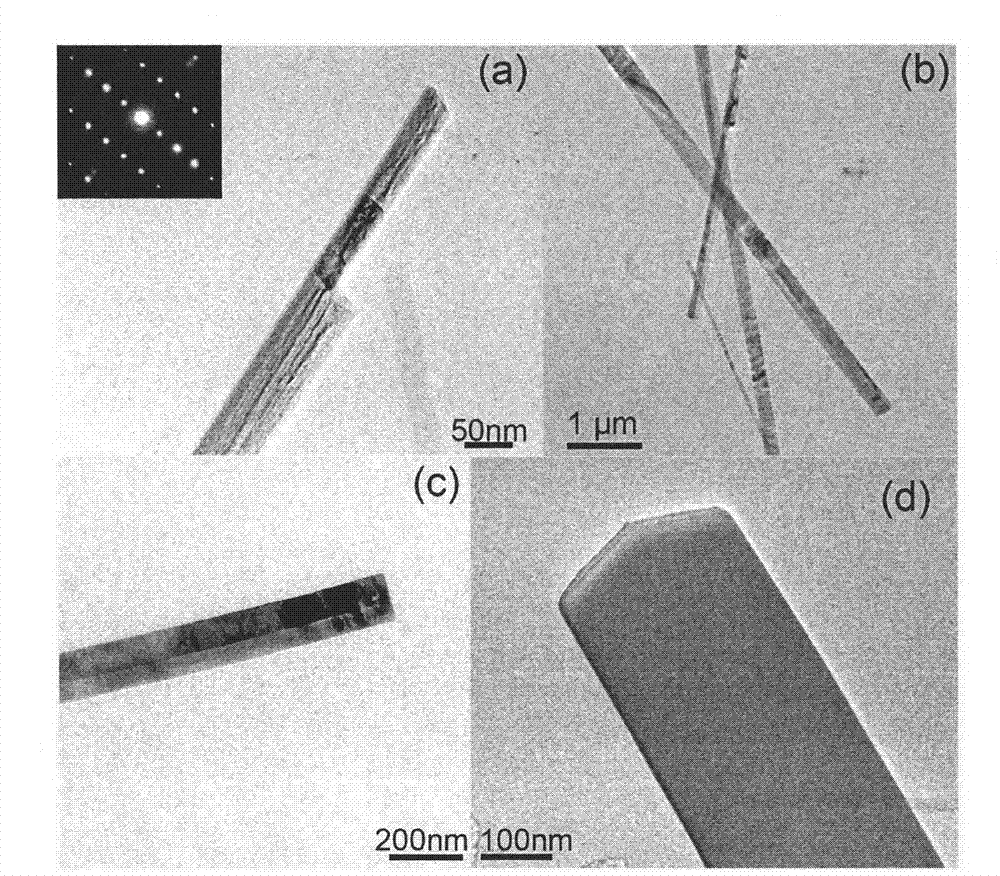

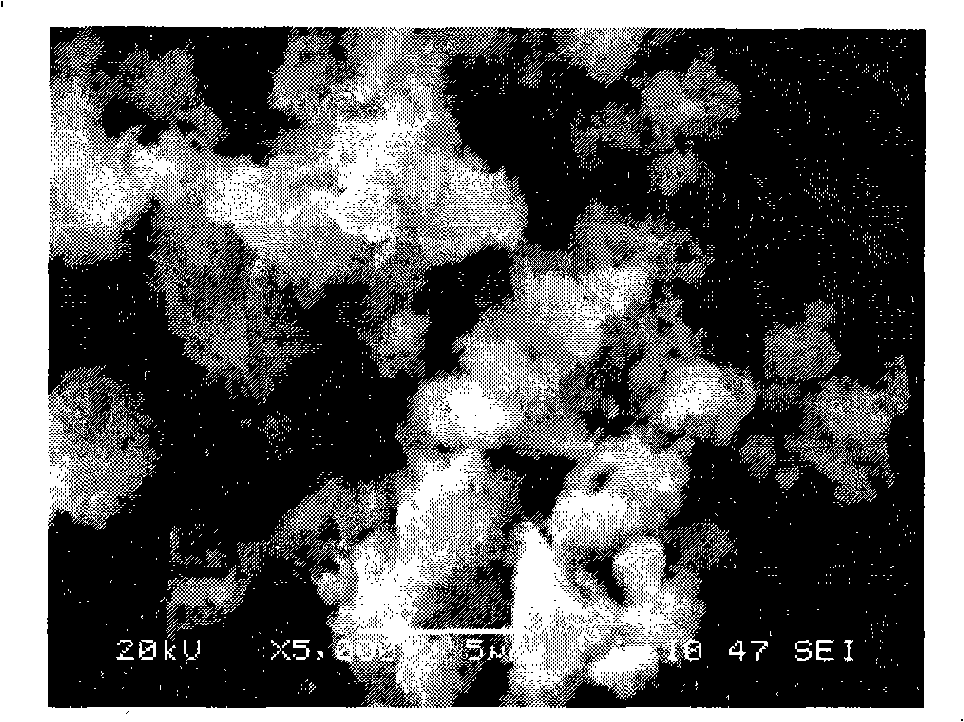

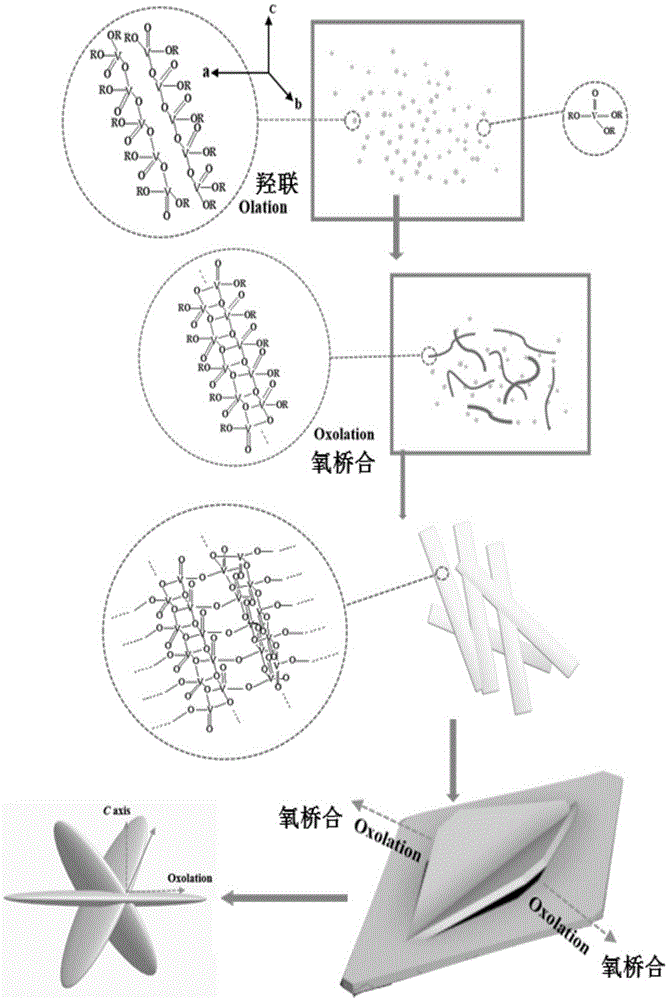

Nano vanadium oxide and preparation method thereof

InactiveCN103241773AGood dispersionEasy to useNanotechnologyVanadium oxidesVanadium dioxidePolyethylene glycol

The invention discloses a nano vanadium oxide and a preparation method thereof. The vanadium oxide is ribbon-shaped nano vanadium pentoxide of which the length, width and thickness are respectively 1-10mm, 30-200mm and 5-40nm, or nano vanadium oxide hydrate of which the length, width and thickness are respectively no more than 1mm, 80-480nm and 10-50nm, or nano B-phase vanadium dioxide of which the length, width and thickness are respectively 130-170mu m, 180-560nm and 20-50nm, or nano A-phase vanadium dioxide of which the length, width and thickness are respectively 80-120mu m, 0.5-5mu m and 200-450nm. The method comprises the following steps: melting vanadium pentoxide powder, and immersing in a quenching medium while stirring, thus obtaining vanadium pentoxide collosol; and performing hydrothermal reaction on the vanadium pentoxide collosol in a closed state to obtain the nano vanadium pentoxide, or adding polyethyleneglycol into the vanadium pentoxide collosol, and performing hydrothermal reaction in a closed state for different time periods to respectively obtain the nano vanadium oxide hydrate or the nano B-phase vanadium dioxide or the nano A-phase vanadium dioxide. The invention can be used in lithium ion batteries and super capacitors.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

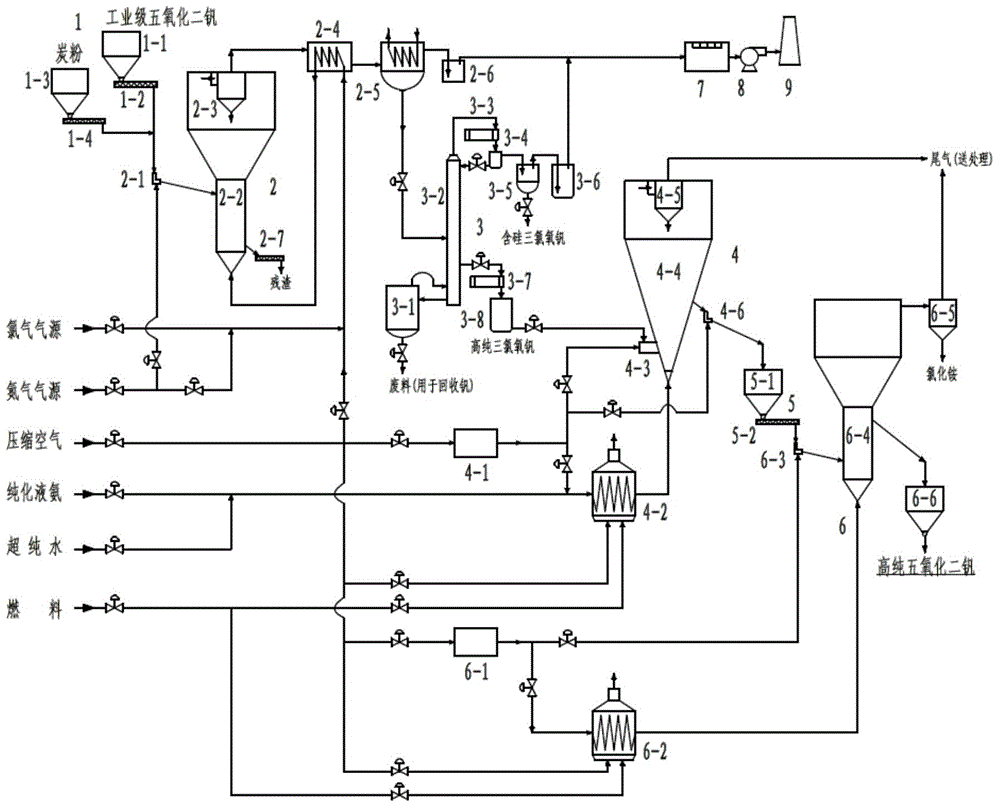

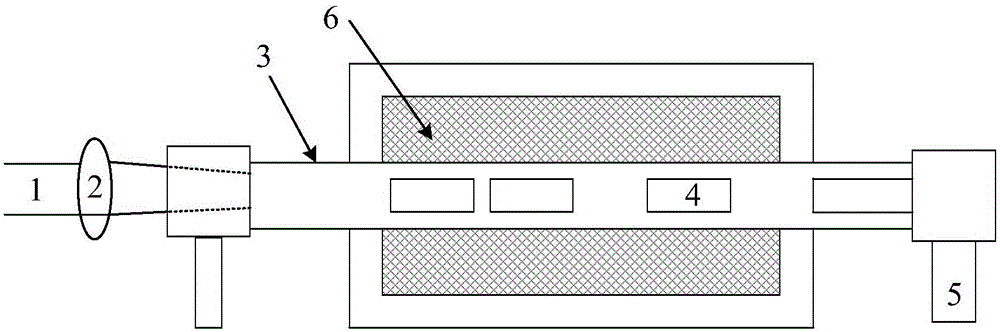

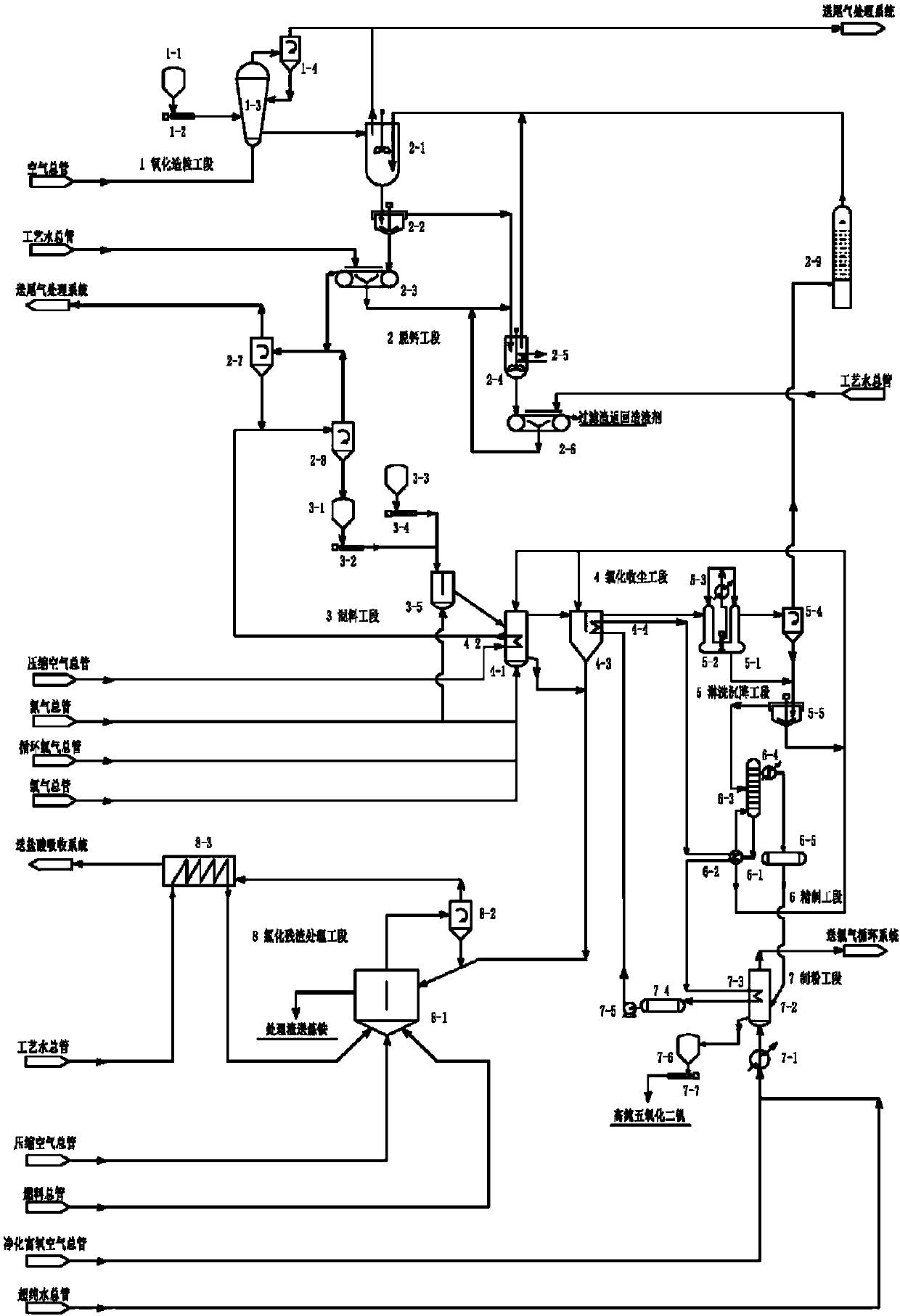

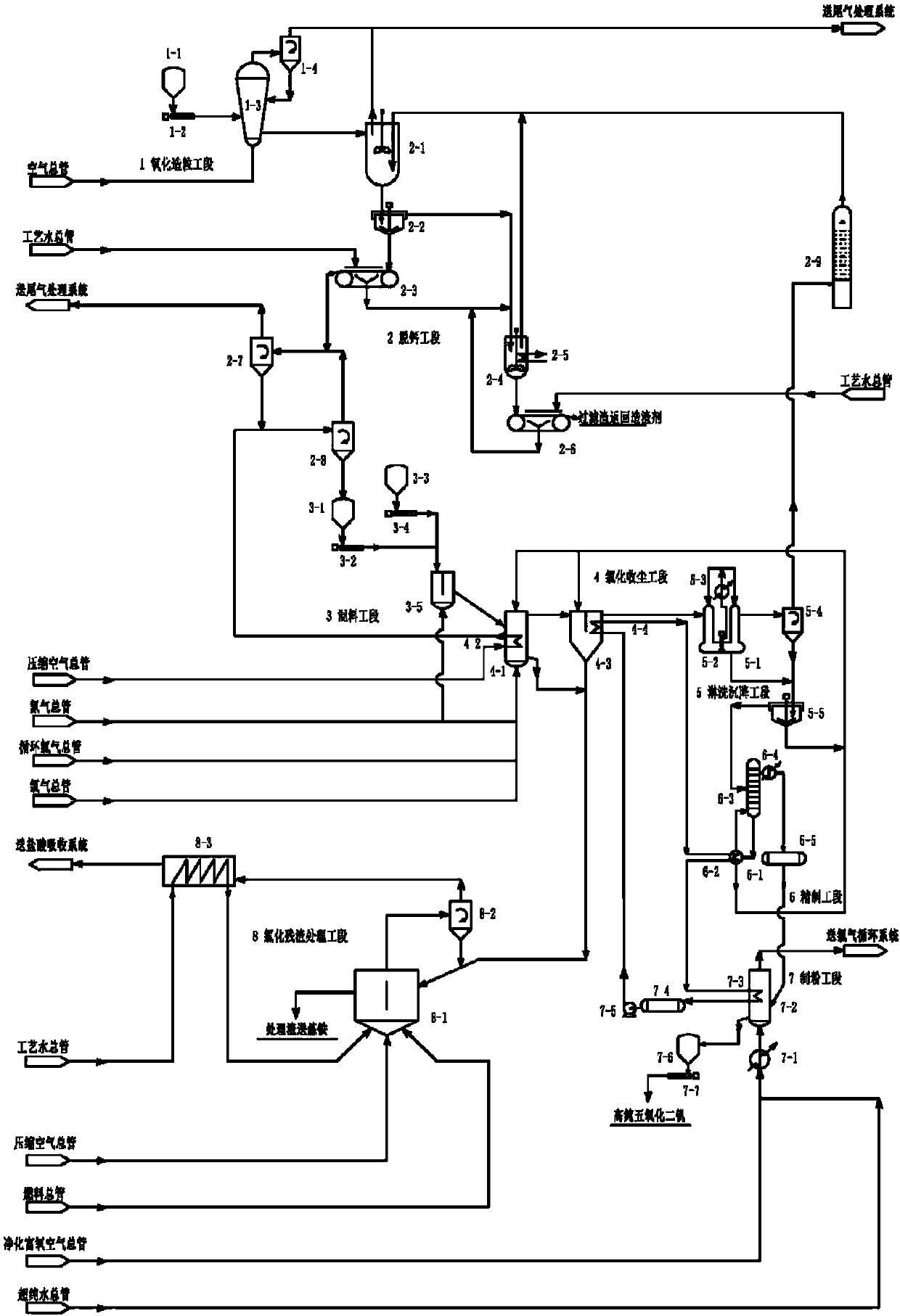

System and method for purifying and producing high-purity vanadium pentoxide powder

ActiveCN105984896AAchieve warm-upUniform temperature distributionNitrogen compoundsTransportation and packagingDistillationCalcination

The invention discloses a system and method for purifying and producing high-purity vanadium pentoxide powder, belonging to the fields of chemical engineering and materials. According to the invention, fluidizing low-temperature chlorination is used for converting industrial-grade vanadium pentoxide into vanadium oxytrichloride; through heat exchange between fluidization gas and chlorination flue gas, chlorination gas is preheated; a proper amount of air is added to allow a part of coke powder to combust, thus providing a balanced supply of heat during the process of chlorination, improving chlorination efficiency, and ensuring good selectivity of low-temperature chlorination; and the vanadium oxytrichloride is subjected to fluidized-vapor-phase ammoniation after distillation and purification and further to fluidized calcination to produce a high-purity vanadium pentoxide product. The system and method have the advantages that raw materials are good in adaptability, only a small amount of ammonia-nitrogen wastewater is discharged, low energy consumption in production and low cost in operation are realized, product quality is stable, etc.; and the system and method are applicable to large-scale industrial production of high-purity vanadium pentoxide having a purity of 4N or higher and have good economic benefits and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

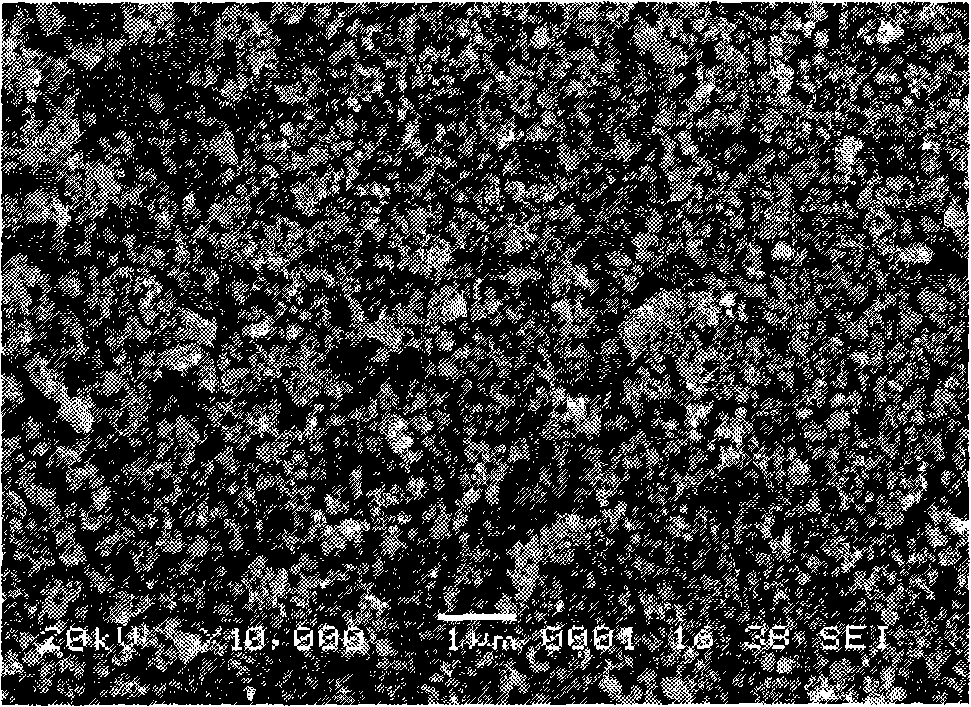

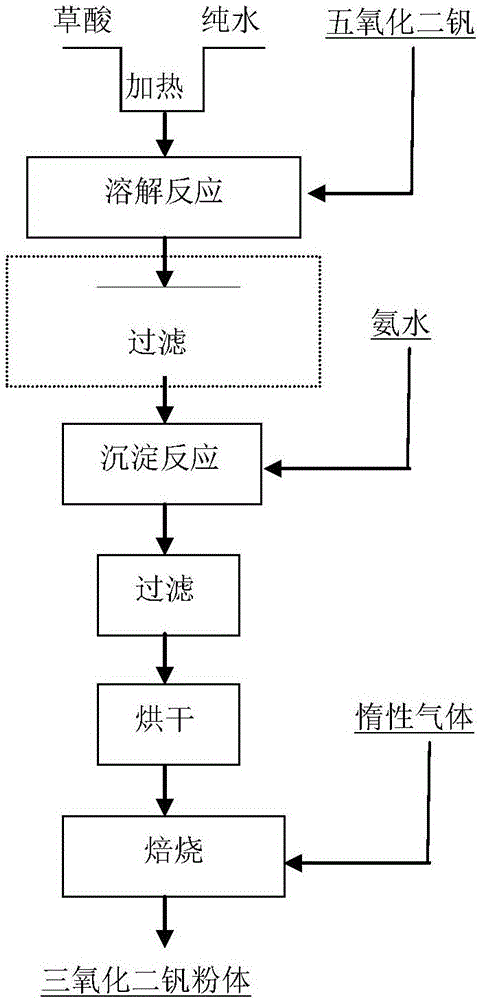

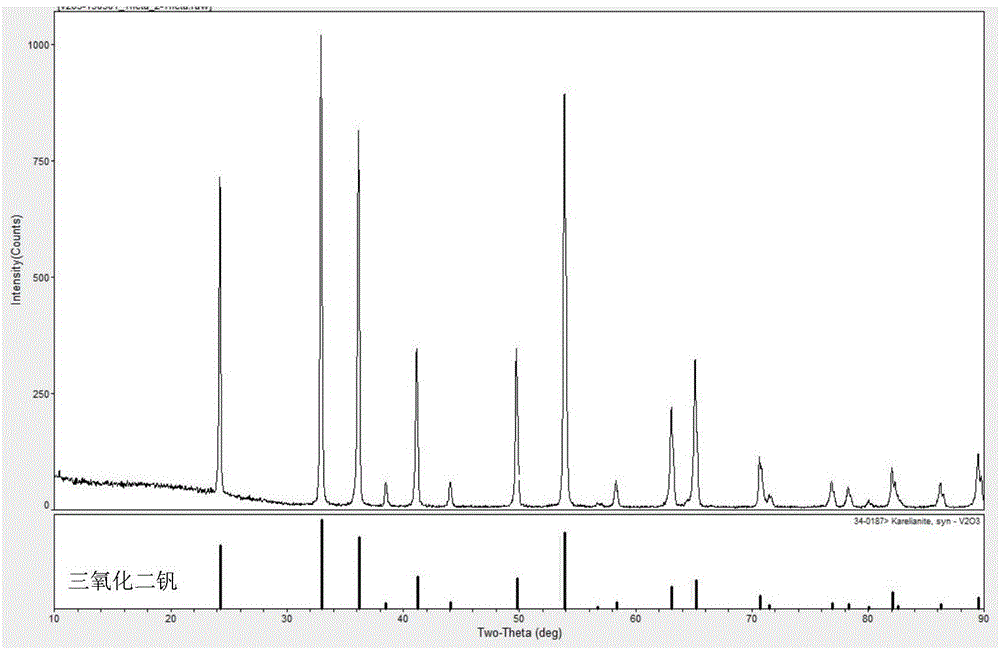

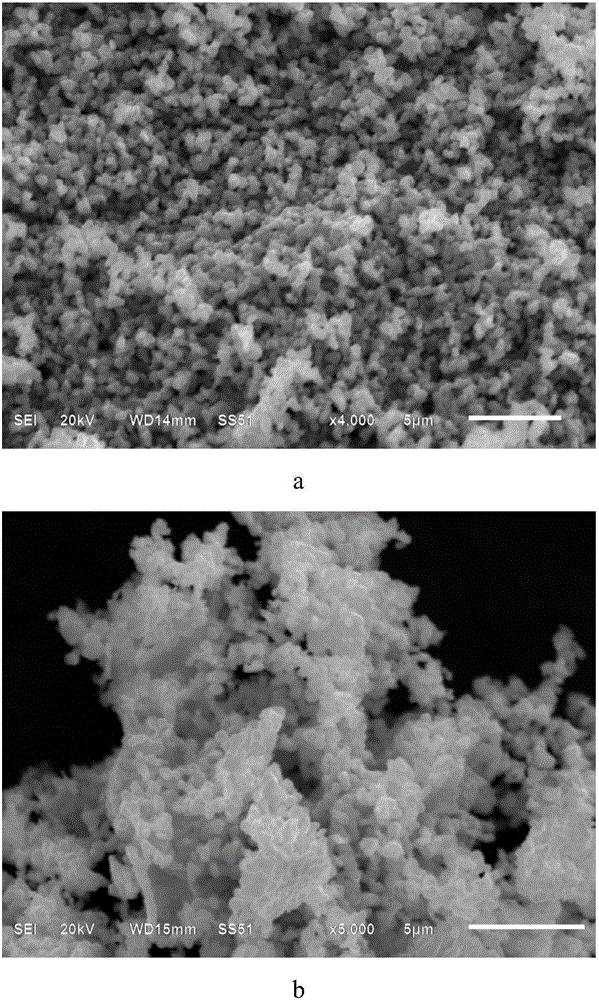

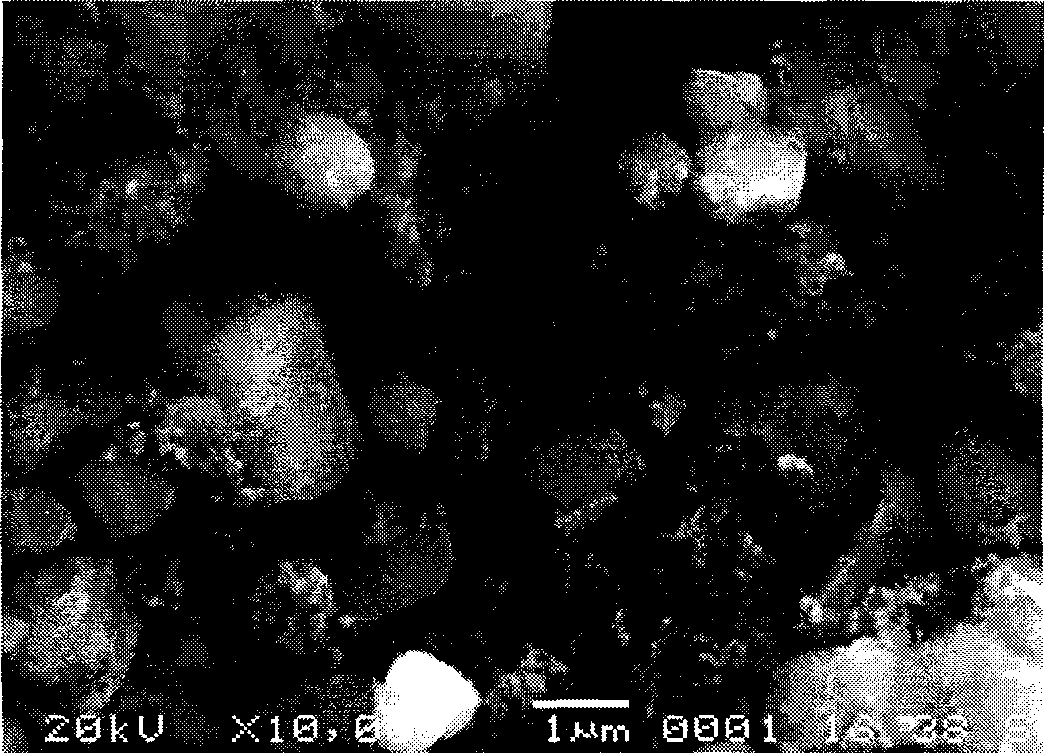

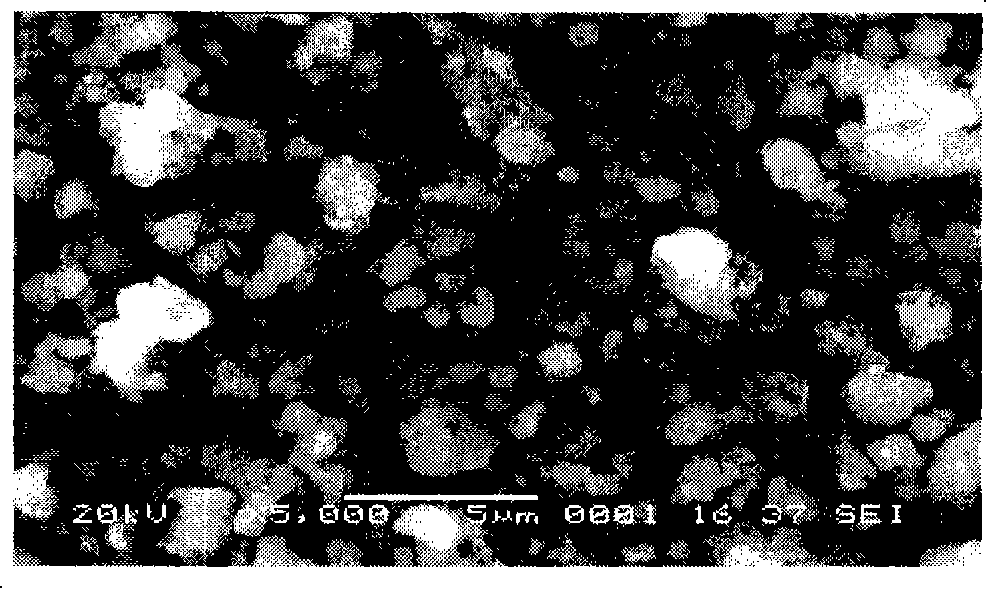

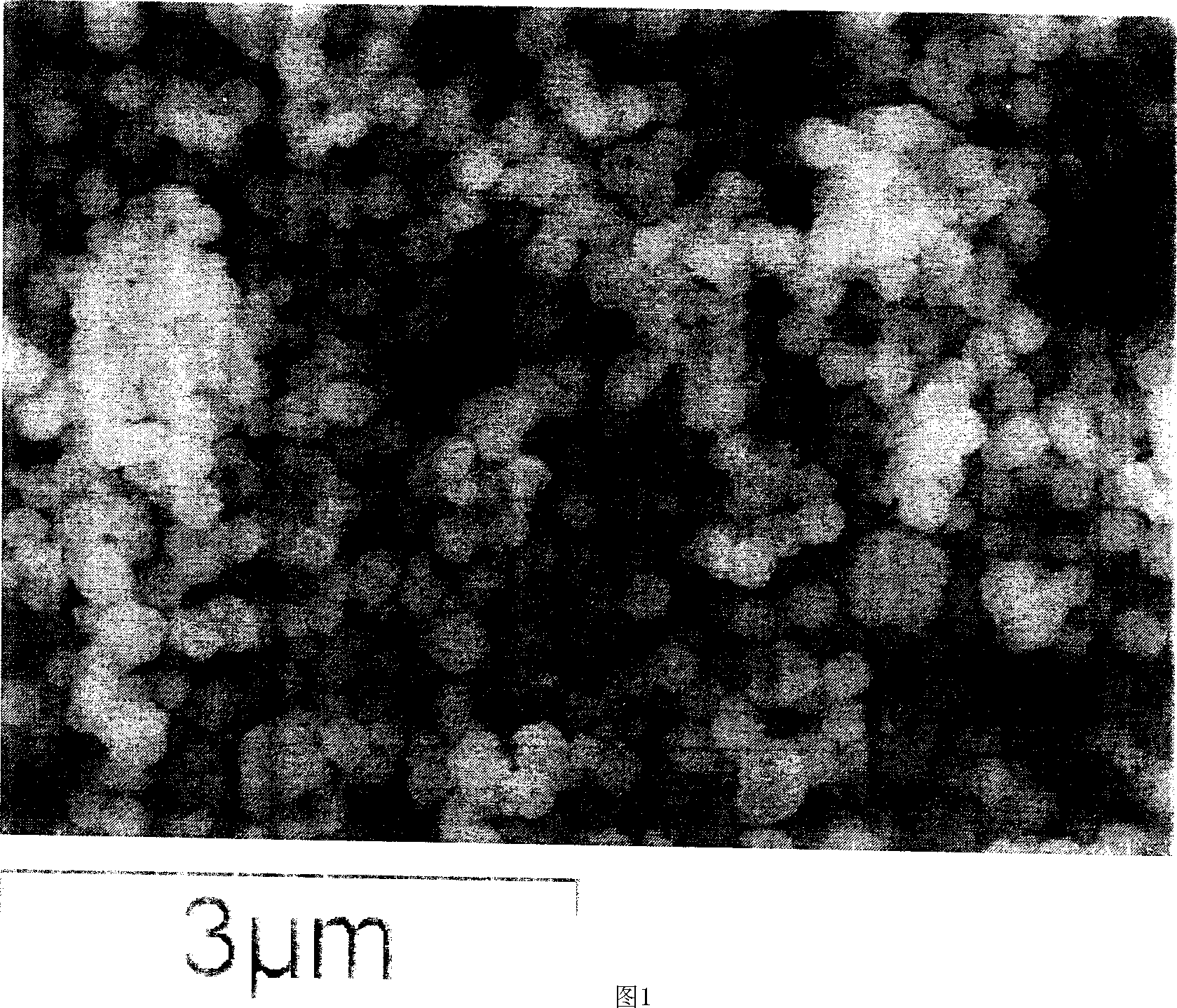

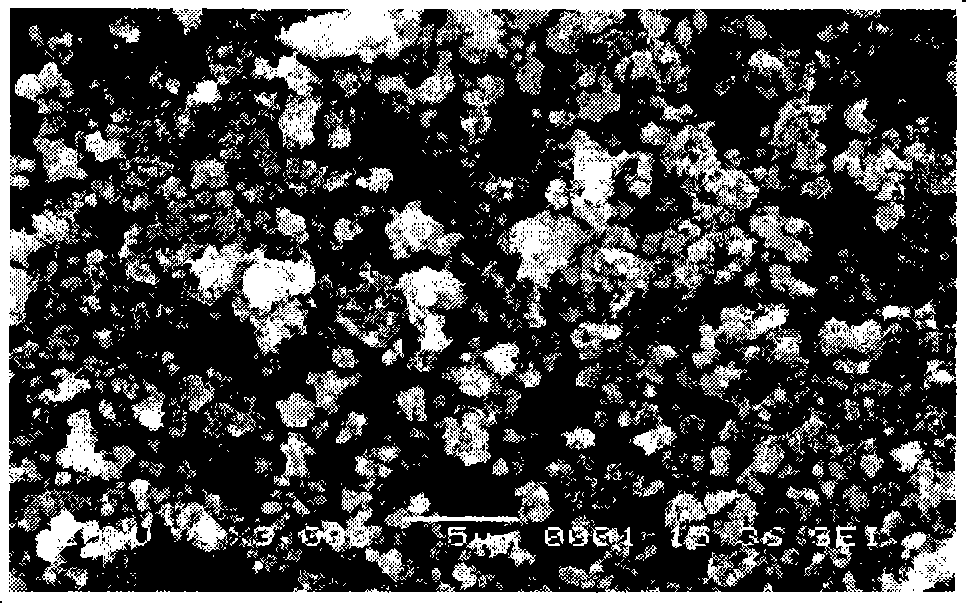

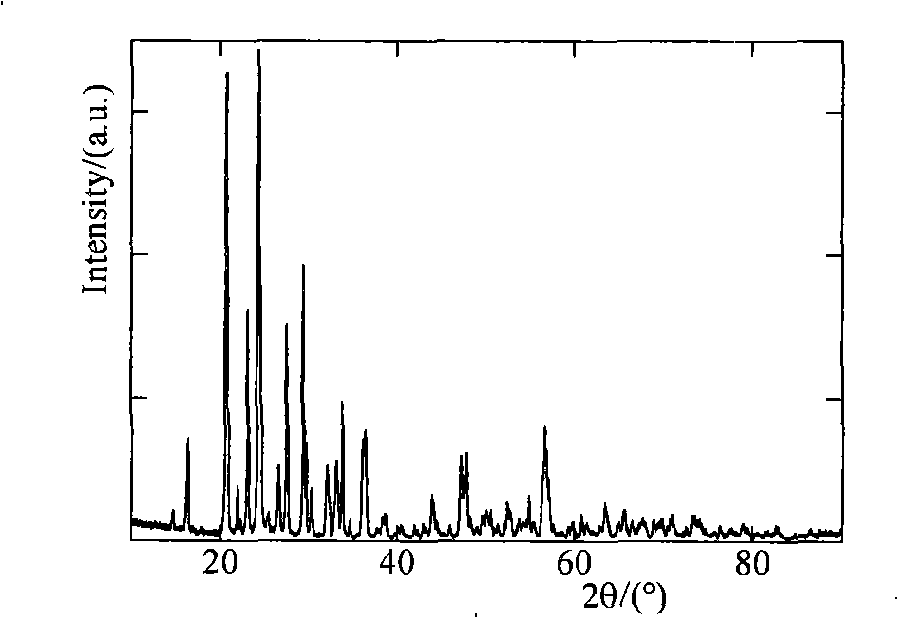

Preparation method of submicron-level vanadium trioxide powder

The invention relates to a preparation method of submicron-level vanadium trioxide powder. The preparation method comprises 1, preparing an oxalic acid solution, 2, heating the oxalic acid solution, adding vanadium pentoxide powder into the oxalic acid solution, and carrying out a stirring reaction process until complete dissolution to obtain a vanadyl oxalate solution, 3, slowly adding ammonium hydroxide into the vanadyl oxalate solution and carrying out stirring for a reaction to obtain precipitates, 4, filtering the precipitates and carrying out drying to obtain a high-activity precursor and 5, roasting the high-activity precursor in an inert atmosphere to obtain submicron-level vanadium trioxide powder. The submicron-level vanadium trioxide powder has high product purity and a single phase, contains submicron-level spherical particles with the uniform sizes less than 1 microns and high particle surface activity and is conducive to further processing and use. The preparation method has simple processes, can be operated easily, has a low cost, is free of hydrogen or other reducing atmospheres, has high safety and a low three waste treating capacity and can be easily industrialized.

Owner:有研资源环境技术研究院(北京)有限公司

A method of producing lithium ion battery positive pole material fluorine Lithium Vanadium Phosphate by microwave rapid reaction

InactiveCN101445230ASolve easy oxidationImprove charge and discharge performanceCell electrodesPhosphorus compoundsOrganic acidNoble gas

The present invention discloses a method of producing lithium ion battery positive pole material fluorine Lithium Vanadium Phosphate by microwave rapid reaction. First evenly mix vanadic oxide powder, phosphates, organic acid, lithium salt and villaumite in molar ratio 0. 95-1.1:1.9-2.1:0.95-1.1:1. 9-2.1:1.9-2.1 respectively. Then sinter the mixture in a microwave reactor for 10 to 40 minutes in 450 EDG C to 750 EDG C under noble gas protection, and get completed product LiVPO4F after cooling. The invention is simple and convenient, easy controlled and cost low which simplifies the synthesizing process and improves charge-discharge performance and circulates performance of sample.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

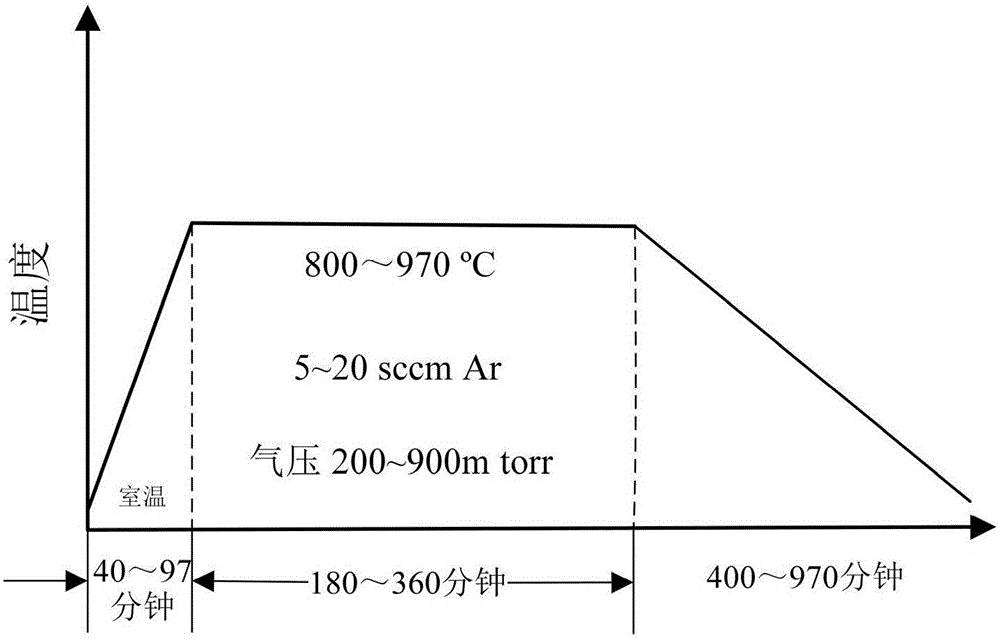

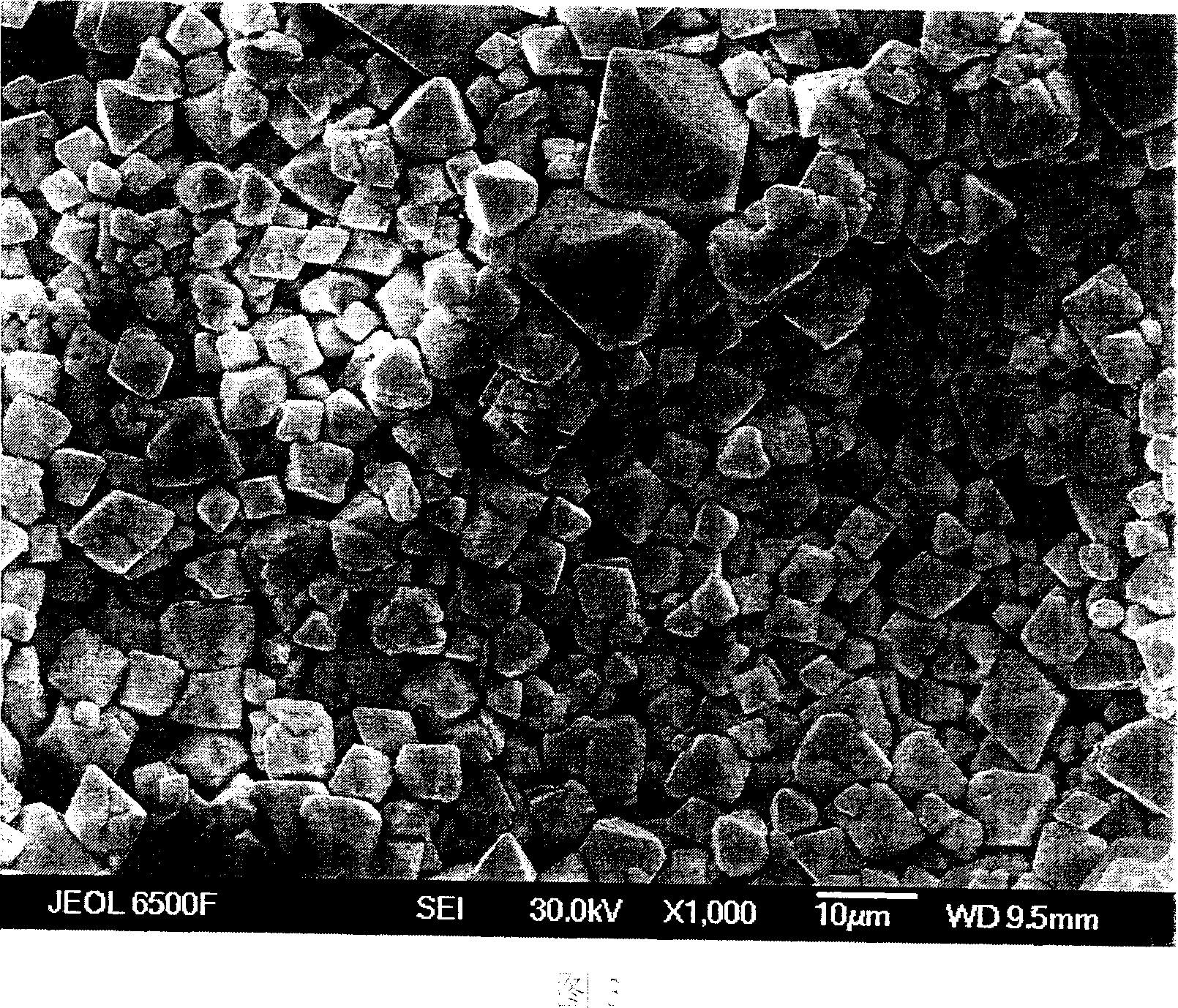

Method for growing large-area mono-crystal vanadium dioxide thin film by utilizing tubular furnace

ActiveCN106637404AObvious abrupt change in resistanceHigh film forming ratePolycrystalline material growthFrom solid stateVanadium dioxideSingle crystal

The invention discloses a method for growing a large-area mono-crystal vanadium dioxide thin film by utilizing a tubular furnace. The thin film grows on an experiment substrate with a certain thickness of SiO2 / Si, Si3N4 / Si, silicon, quartz, sapphires and the like by adopting a gas-solid manner. A growth surface of the experiment substrate is subjected to strict polishing treatment, and a reaction source vanadium pentaoxide powder is uniformly put at the bottom of a quartz boat; the experiment substrate is put into the quartz boat and the growth surface of the substrate is put downward. The large-area mono-crystal vanadium dioxide thin film is prepared through controlling a temperature rising speed, temperature, air pressure, gas flow size and reaction time in a vacuum environment of the tubular furnace. Compared with a common vanadium dioxide thin film, the large-area mono-crystal vanadium dioxide thin film prepared by the method has more excellent performances, the process is simple and the film forming quality is high; after the prepared mono-crystal vanadium dioxide thin film is subjected to insulator-metal phase change, the changing amplitude of the electrical conductivity reaches 4 to 5 orders of magnitude; the mono-crystal vanadium dioxide thin film is a mono-crystal material thin film and has wide application prospects in photo-electric, infrared and gas sensing aspects and the like.

Owner:EAST CHINA UNIV OF TECH

Method for preparing vanadium pentoxide by utilizing invalid vanadium battery positive pole electrolyte

ActiveCN106395902AHigh purityEnable recyclingRegenerative fuel cellsVanadium oxidesEvaporationElectrolyte

The invention provides a method for preparing vanadium pentoxide by utilizing invalid vanadium battery positive pole electrolyte. The method comprises the following steps that the invalid vanadium battery positive pole electrolyte is led into a vanadium battery positive pole, charging pre-oxidation is performed to obtain electrolyte of pentavalent vanadium ions; evaporation and concentration are conducted on the electrolyte of pentavalent vanadium ions, and then standing is performed to form mixed liquid containing a pentavalent vanadium precipitate; the mixed liquid is filtered, and a filter cake is dried and grinded to obtain vanadium pentoxide powder. By the adoption of the method, recycle of vanadium electrolyte is achieved, and the produced vanadium pentoxide is high in purity and can be continuously used for preparing electrolyte and other purposes or used as a catalyst.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

Method for low temperature preparing lithium ion battery positive pole material fluorophosphoric acid vanadium lithium

InactiveCN101252188ASolve easy oxidationImprove charge and discharge performanceElectrode manufacturing processesPhosphateLithium-ion battery

The invention discloses a method for preparing anode material vanadium lithium fluoroalkylphosphate of a lithium -ion cell at low temperature, comprising the steps of: (1) heating vanadic oxide powder to six hundred to nine hundred DEG C; allowing to melt at a constant temperature for one to four hours and pouring into a container with water rapidly to form a brown-red solution; letting the solution stand for four to sixteen hours to form wet gel V2O5.nH2O; washing the wet gel, removing most of moisture, keeping drying for four to sixteen hours in a vacuum ambient of seventy to one hundred DEG C and grinding to obtain vanadic oxide powder. (2) Mixing the vanadic oxide powder obtained through the preparation method with Lithium, villiaumite, phosphates and acetylene black evenly at mol ratio of one to two to two to two to two point four, sintering for five to twenty hours at temperature between four hundred and seven hundred DEG C under the protection of an inert gas and cooling to obtain a finished product of LiVPO4F. The preparation method is easy and simple, easy to control and low in cost, reduces sintering temperature and improves the charging and discharging performance and cycle performance of samples.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

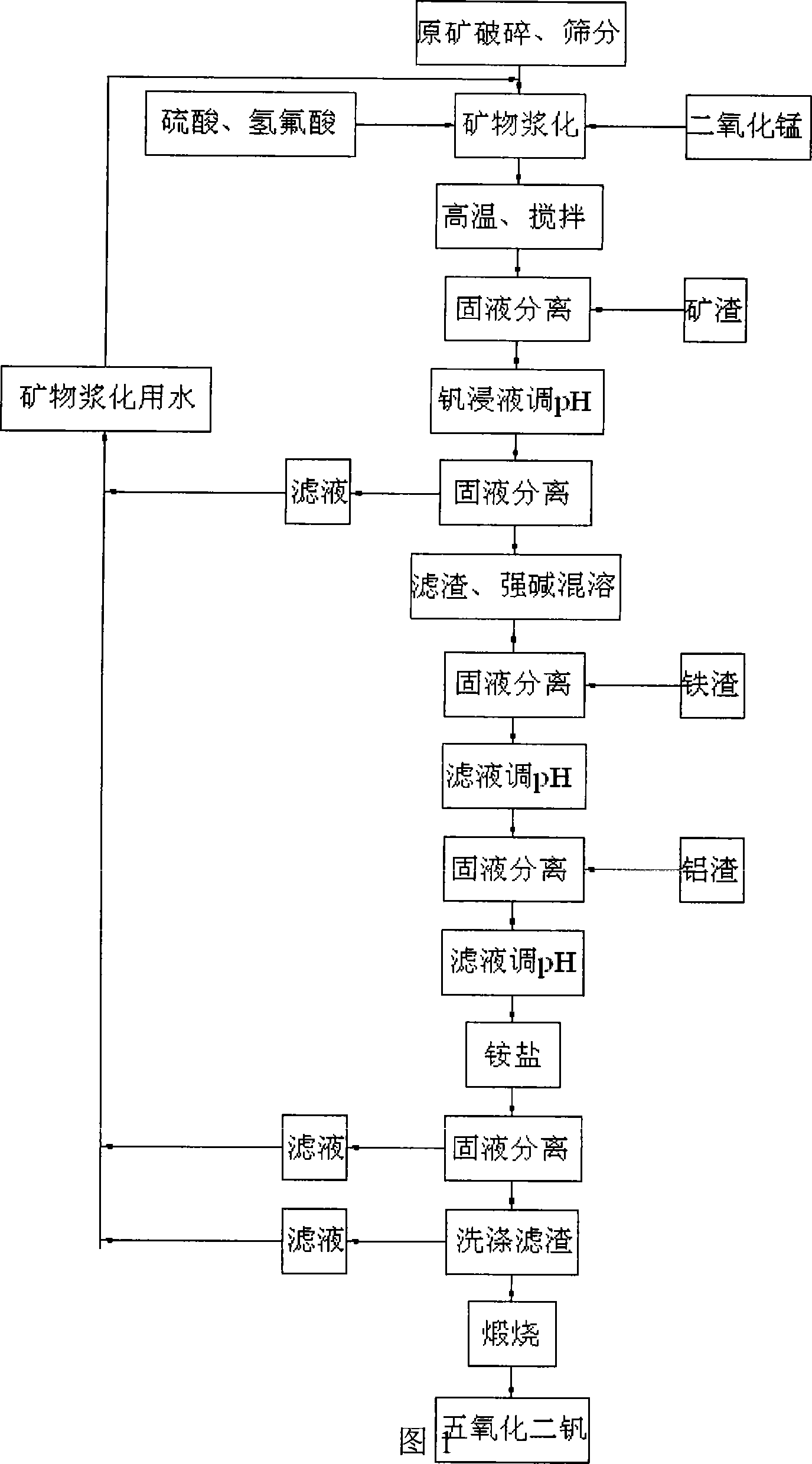

Alum extracting technique for clay ore by wet method

InactiveCN101215646AImprove use valueShort processVanadium oxidesProcess efficiency improvementFluohydric acidAmmonium metavanadate

The invention relates to a wet process vanadium extraction technology of clay ore, providing a valuable metal technology for extracting vanadium by wet process from vanadium clay ore, which belongs to the non-ferrous metal metallurgical technology field. The invention is characterized in that disintegrating clay ore, proceeding thermostatic mixing acid leaching reaction as adding sulfuric acid, fluohydric acid and oxidation agent under certain liquid solid volumetric ratio, separating solid and liquid, removing out iron and aluminum and recycling to utilize after leaching solution being treated by multistep pH value regulation and alkali deposition solubilization reaction, depositing vanadium by ammonium salt after purified vanadium being regulated pH value, filtering, drying and calcining ammonium metavanadate which is prepared to obtain vanadium pentoxide powder. The invention directly leaches clay ore mixing with acid, has high acid leaching rate, lower energy consumption, short technical process, easy operation and control, low productive cost, environment-friendly and safety, realizes zero discharge in the production process, has no waste gas generation, and recycles waste water and valuable metal, and the recycle rate of vanadium reaches 70-75%, purity of vanadium pentoxide of the product is larger than 99%.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of oxygen-producing photocatalyst of composite oxides

InactiveCN101007271AReduce adverse effectsSimple processMetal/metal-oxides/metal-hydroxide catalystsOxygen preparationUltraviolet lightsAmmonium metavanadate

A preparation method of oxide photochemical catalyst prepared by composite oxide belongs to visible light catalysis field. The preparation process is: it dissolves bismuth nitrate containing crystal water into 2-2.5M nitrate, the mass concentration of bismuth nitrate is 7.4%--29.5%; dissolves metavanadate ammonium into 40-50DEG C hot water, the mass concentration of metavanadate ammonium is 1.8%-7.1%; mixes said two solution and adds surface activator into it, stirs it uniformly and adjusts it with aqua forties until the pH is 0-2; heats it in press-still and maintains temperature of 190-260DEG C, the reaction time is 30-50 hours; then cools it and sucks it, washes repeatedly with deionized water until the solution is colorless and clear, dries it. The preparation precess avoids using acute-toxic vanadic anhydride powder and precipitant, and no acute-toxic intermediate product is generated; the active of oxygen prepared by ultraviolet light and using the oxide photochemical catalyst can reach 40-90umol / h and the active of oxygen catalyzed by visible light is 70-355umol / h.

Owner:BEIJING UNIV OF TECH

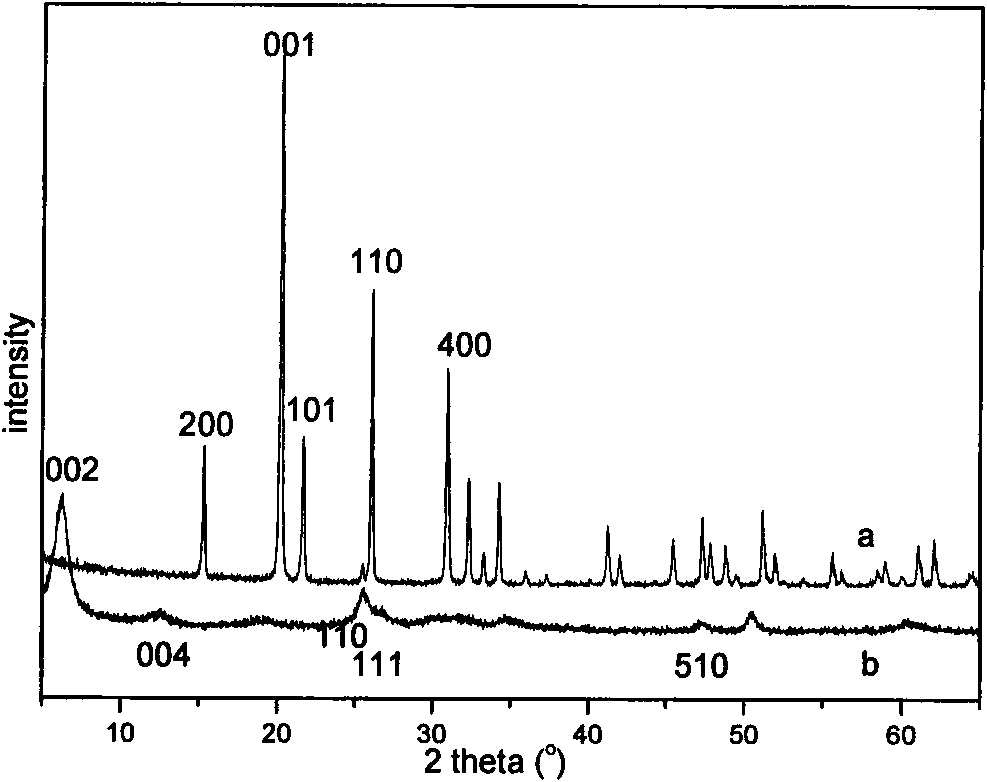

Inorganic sol-gel preparation method of vanadium dioxide film

InactiveCN105198231AExcellent optical control performanceAvoid cumbersomeVanadium oxidesVanadium dioxideMaterials science

The invention belongs to the technical field of material chemistry and relates to an inorganic sol-gel preparation method of a vanadium dioxide film. The inorganic sol-gel preparation method comprises 1, dissolving vanadium powder or vanadic anhydride powder in hydrogen peroxide, carrying out stirring, carrying out standing, and carrying out room temperature preservation to obtain pentavalent vanadium sol, and 2, coating a substrate with the sol obtained by the step 1 and carrying out weak-reduction one-step annealing in an inert gas protective atmosphere to obtain the vanadium dioxide film. The one-step annealing method solves the problem that the existing pentavalent vanadium sol film preparation method needs hydrogen pre-reduction and a complicated two-step annealing process or harsh conditions of high-vacuum and high-temperature thermal decomposition, has an annealing temperature in a common glass bearing range, has low requirements on an annealing furnace and further reduces a cost. The vanadium dioxide film has excellent optical regulation and control performances, the highest visible light transmittance rate of 70%, the highest infrared adjusting performance of 60% and a wide application prospect in the field of a photoelectric functional material.

Owner:WUHAN UNIV OF TECH

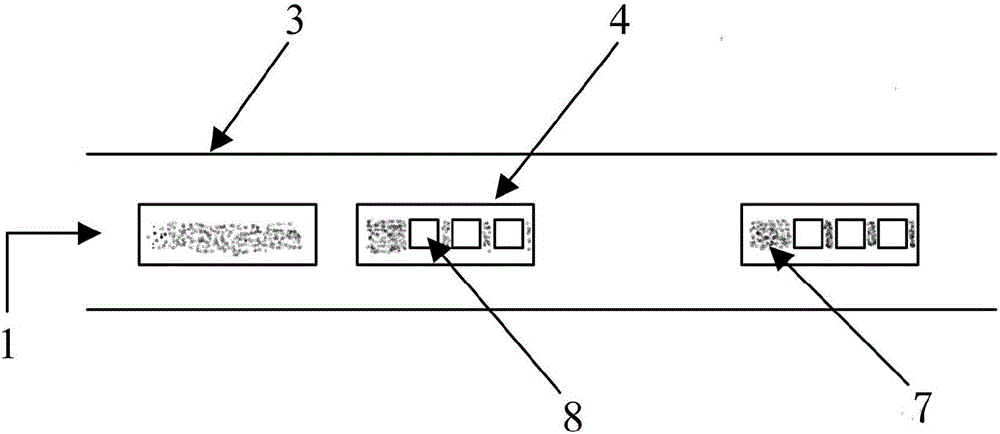

Method for rapid preparation of vanadium-nitrogen alloy

The invention discloses a method for rapid preparation of a vanadium-nitrogen alloy. The method comprises the following steps: S1, preparing ingredients: weighing and taking a vanadium pentoxide powder, a graphite powder, a sodium silicate aqueous solution and an iron powder for standby application; S2, pretreating: mixing evenly the above raw materials, pressing into oblate spheroids, and drying; S3, feeding: placing the dried oblate-spheroid material on a graphite material basket, sending into a vacuum furnace by a transfer device, sealing the vacuum furnace, and starting a vacuum pump; S4, carrying out vacuum nitridation sintering: allowing the temperature in the furnace to reach 1400-1500 DEG C in 5 hours, then stopping the vacuum pump, carrying out deep carbonation and nitridation reaction, and continuously filling nitrogen during the reaction; and S5, discharging: after vacuum treatment, continuing to fill the nitrogen, cutting off power, cooling the vacuum furnace, when the temperature is dropped to 190-210 DEG C, stopping supplying nitrogen, opening the furnace, and taking out the graphite material basket. The method has the advantages of simple operation, low production cost, accurate process control, fast preparation, low energy consumption, and stable product production; and the vanadium-nitrogen alloy prepared by the method is high in nitrogen content and low in impurity content.

Owner:SICHUAN ZHANXIANG SPECIAL ALLOY TECH

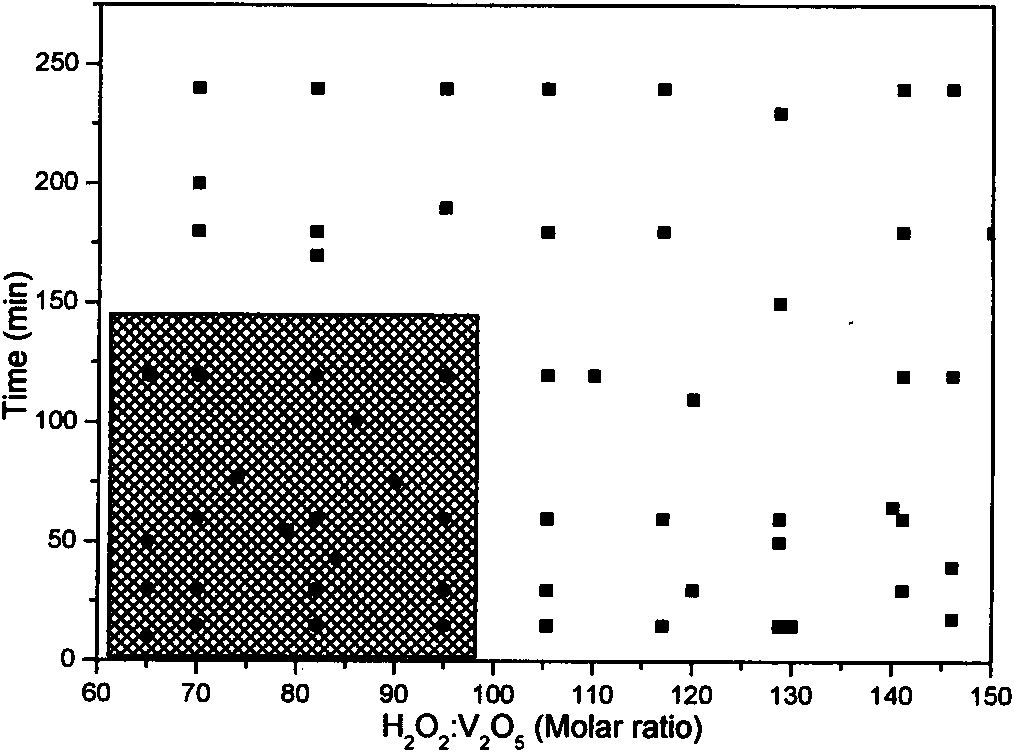

Method for preparing novel nano-material V10O24.12H2O

The invention discloses a method for preparing a novel nano-material V10O24.12H2O. The method takes industrial vanadium pentoxide powders and peroxide as main raw materials, uses a sol-gel method, combines with a solvent replacement process and prepares a nano-porous material at normal pressures. The method comprises the following steps of: using the V2O5 powders and the peroxide to prepare the sol by a sol-gel method; sealing and storing the sol till gel is formed; ageing the gel and carrying out solvent replacing and drying at normal pressure. The method has the advantages of cheap and easily obtained raw materials, simple reaction process, moderate reaction conditions, etc. The method well makes up the shortcomings of preparing the V10O24.12H2O by the hydrolysis method and fusing method of organic vanadic salts, and leads the preparation of the material to tend to mature.

Owner:TONGJI UNIV

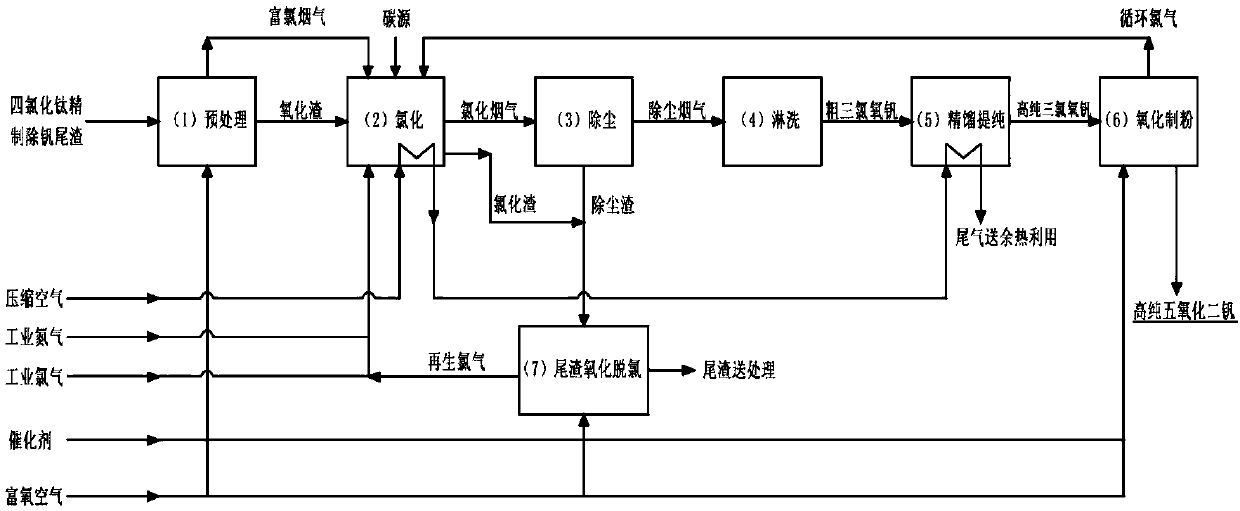

Method for producing high-purity vanadium pentoxide through titanium tetrachloride refined vanadium-removed tailings

The invention discloses a method for producing high-purity vanadium pentoxide through titanium tetrachloride refined vanadium-removed tailings. The method includes the seven processes: pre-treatment (1), chlorination (2), dust removal (3), drip washing (4), distillation purification (5), oxidation powdering (6) and tailing oxidation dechlorination (7). According to the method, in the pre-treatmentprocess, the titanium tetrachloride refined vanadium-removed tailings are subjected to oxidation dechlorination to obtain corresponding oxidized slag and circulating chlorine gas; in the process of feeding the oxidized slag into chlorination, selective chlorination of vanadium oxide is achieved, and chlorinated flue gas and chlorinated slag are obtained; the chlorinated flue gas is subjected to the processes of dust removal, drip washing and distillation purification, and high-purity vanadium oxytrichloride is obtained; and high-purity vanadium pentoxide powder is obtained from the high-purity vanadium oxytrichloride under action of oxygen-rich air and a catalyst. The method is suitable for treatment of the vanadium-removed tailings, and has the advantages of high raw material adaptability, good selectivity, low reaction temperature, chlorine gas recycling, energy saving and consumption reduction, environmental friendliness, high product additional value and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for low temperature preparing lithium ion battery positive pole material phosphoric acid vanadium lithium

InactiveCN101252187ASolve easy oxidationImprove charge and discharge performanceElectrode manufacturing processesPhosphorus compoundsPhosphatePhosphoric acid

The invention discloses a method for preparing anode material vanadium lithium phosphate of a lithium-ion cell at low temperature, comprising the steps of: (1) heating vanadic oxide powder to six hundred to nine hundred DEG C; allowing to melt at a constant temperature for one to four hours and pouring into a container with water rapidly to form a brown-red solution; letting the solution stand for four to sixteen hours to form wet gel V2O5.nH2O; washing the wet gel, removing most of moisture, keeping drying for four to sixteen hours in a vacuum ambient of seventy to one hundred DEG C and grinding to obtain vanadic oxide powder. (2) Mixing the vanadic oxide powder obtained through the preparation method with lithium, phosphates and acetylene black evenly at mol ratio of one to three to three to three point six, sintering for ten to forty hours at temperature between four hundred to seven hundred DEG C under the protection of an inert gas and cooling to obtain a finished product of Li3V2 (PO4)3.The preparation method solves the problem that vanadium ion is easy to be oxidized, reduces sintering temperature and cost, improves the charging and discharging performance and cycle performance of samples.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Method for producing vanadium pentoxide by microwave calcinations of ammonium metavanadate

InactiveCN101811734AWell mixedEliminate premixing processVanadium oxidesAmmonium metavanadateCalcination

The invention discloses a method for producing vanadium pentoxide by microwave calcinations of ammonium metavanadate. The ammonium metavanadate and vanadium pentoxide powder are packed in a microwave reactor after drying respectively, wherein the weight of the vanadium pentoxide is 10 to 50 percent of the total weight; the microwave frequency is 2.45GHz; the power is 0 to 80kW; the calcining temperature is between 50 and 550DEG C; the time is 5 to 30 minutes; and the purity of the calcined products is 98.5 weight percent.

Owner:KUNMING UNIV OF SCI & TECH

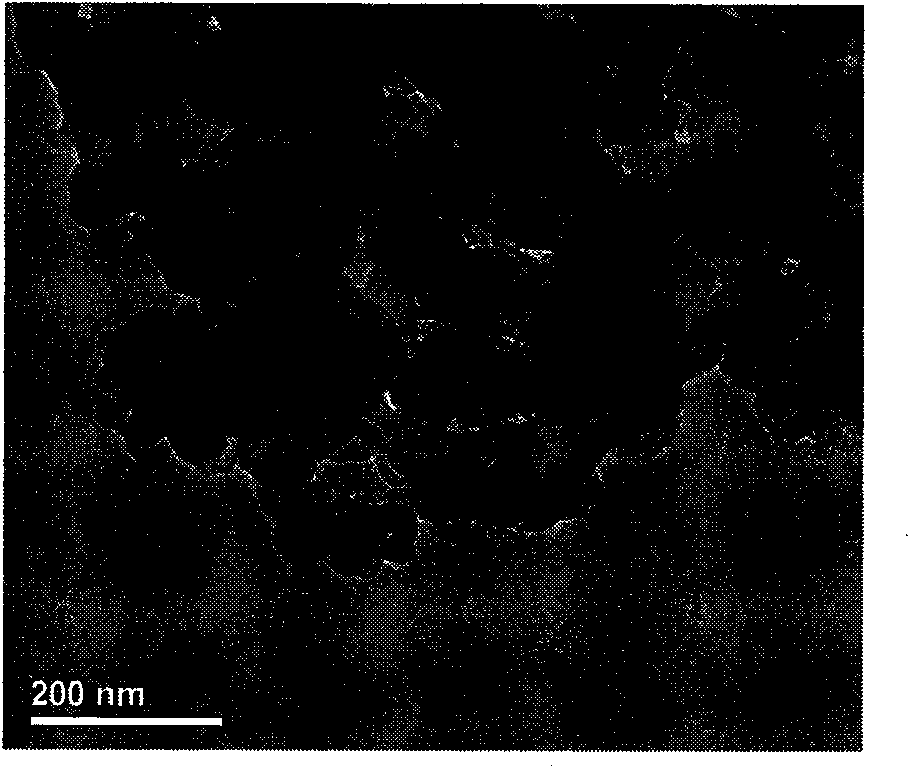

Preparation method of CoV2O6 sheets

InactiveCN106241891ALarge specific surface areaImprove product qualityNanotechnologyCobalt compoundsMaterials preparationNitrate

The invention mainly discloses a preparation method of CoV2O6 sheets, and belongs to the technical field of inorganic advanced nano material preparation. The preparation method comprises following steps: a certain amount of vanadium pentoxide powder and H2O2 are mixed and stirred, distilled water is added, an obtained mixture is delivered into an autoclave for hydrothermal reaction, and V2O5 strips are obtained via washing and drying; a certain amount of cobalt nitrate is dispersed in distilled water, the V2O5 strips are added with stirring, an obtained solution is stirred for a certain period of time, and is subjected to centrifugation, washing, and drying, and an obtained product is delivered into a muffle furnace for sintering for a certain period of time so as to obtain the CoV2O6 sheets. The preparation method is simple; yield is high; cost is relatively low; the obtained nano materials are thin sheets; the specific surface area is large; and product quality is excellent.

Owner:UNIV OF JINAN

Method for producing lithium ion battery anode material vanadium lithium phosphate by sol-gel method

InactiveCN101315979ASolve easy oxidationImprove charge and discharge performanceElectrode manufacturing processesPhosphorus compoundsOrganic acidPhosphate

The invention discloses a method for preparing lithium ion battery anode material vanadium lithium phosphoric acid by a sol-gel method. The method of the invention comprises the following steps: the vanadium pentoxide powder is heated to 600-900 DEG C and the temperature is kept for 1-4 hours till the power is melted; the melted powder is rapidly dumped into a container with water to form a brownish red solution; subsequently, lithium salt, phosphate and organic acid are added into the solution; the solution is uniformly mixed and then sintered for 5-20 hours under the protection of inert gas so as to form a finished product LI3V2(PO4)3 after being cooled. The method of the invention solves the problem that the vanadium ion is easy to be oxidated, the sintering temperature and the cost are reduced, and the charging and discharging performance and the circulation performance of the samples are improved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

System and method for producing powdery vanadium by using chlorination process

ActiveCN109835951AImprove chlorination selectivityAchieve separationDispersed particle separationEnergy inputGas phaseCatalytic oxidation

The present invention discloses a system and a method for producing powdery vanadium by using a chlorination process. According to the present invention, through fluidized bed oxidative granulation treatment, the mineral phase reforming and the mineral particle growth of the vanadium residue are achieved; through calcium fixing treatment with carbon dioxide, the decalcification of the vanadium residue is achieved; the vanadium in the vanadium residue is converted into gaseous vanadium oxytrichloride through selective chlorination, and most of impurities such as iron, manganese, phosphorus, titanium, silicon and the like are remained in the chlorinated residue so as to effectively separate vanadium and other impurities; the gaseous vanadium oxytrichloride is sequentially subjected to dust removal, leaching, settlement, rectification purification, catalytic oxidation and other processes to prepare the high-purity vanadium pentoxide powder (powdery vanadium); the chlorinated residue is subjected to gas phase hydrolysis dechlorination treatment, and the dechlorination residue returns to iron making; and with the system and the method, the clean comprehensive utilization of vanadium residue is achieved while the sensible heat of the high temperature flue gas of the chlorination furnace is effectively utilized so as to achieve the purposes of energy saving and consumption reduction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

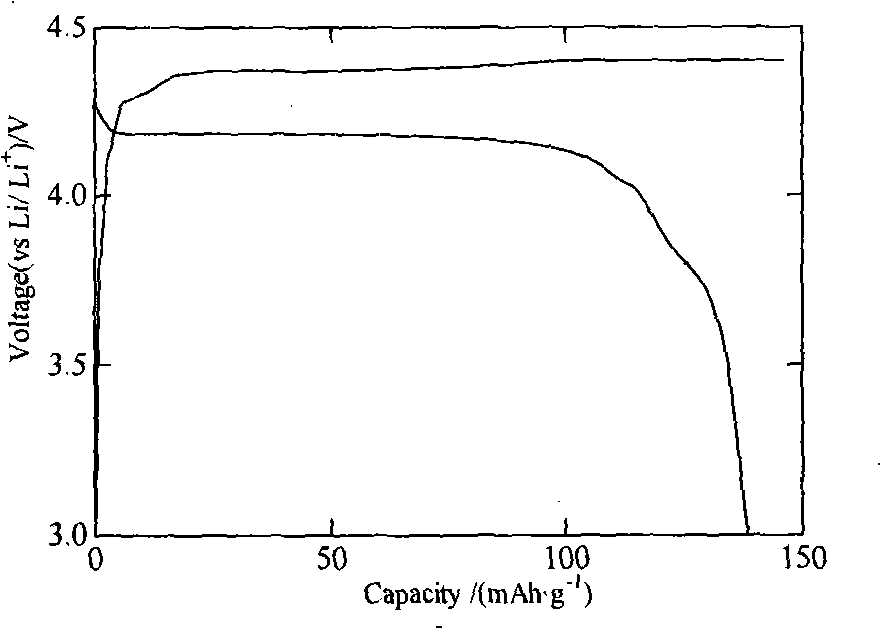

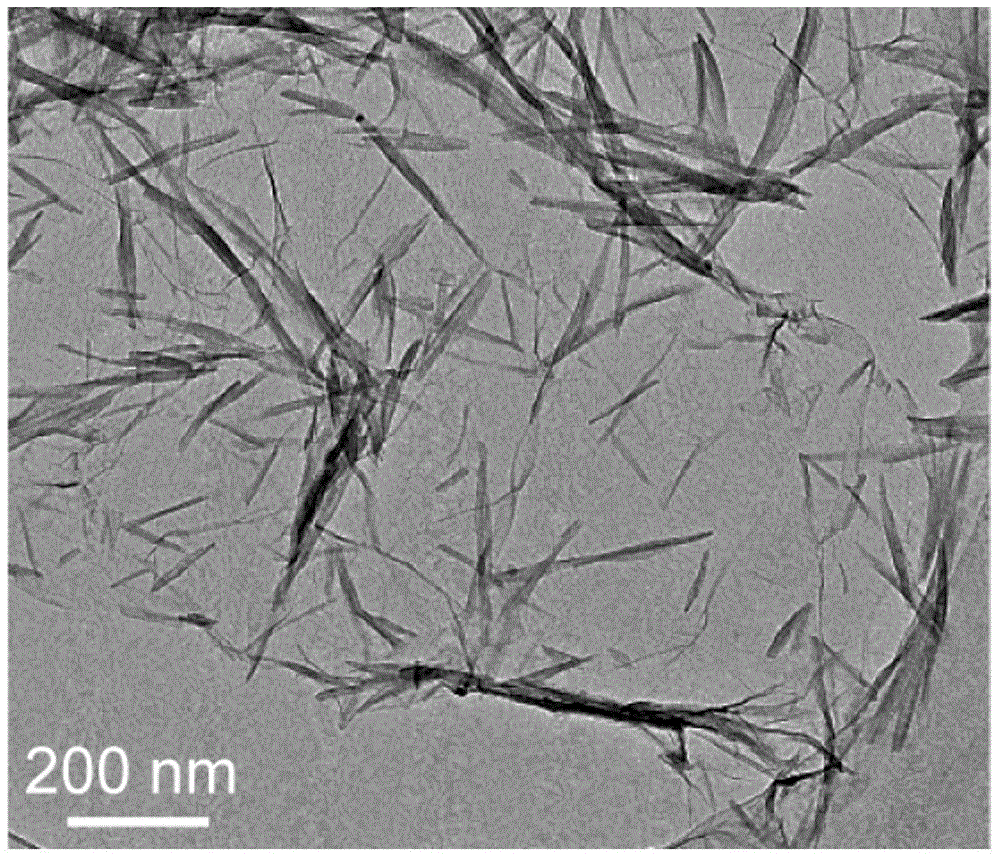

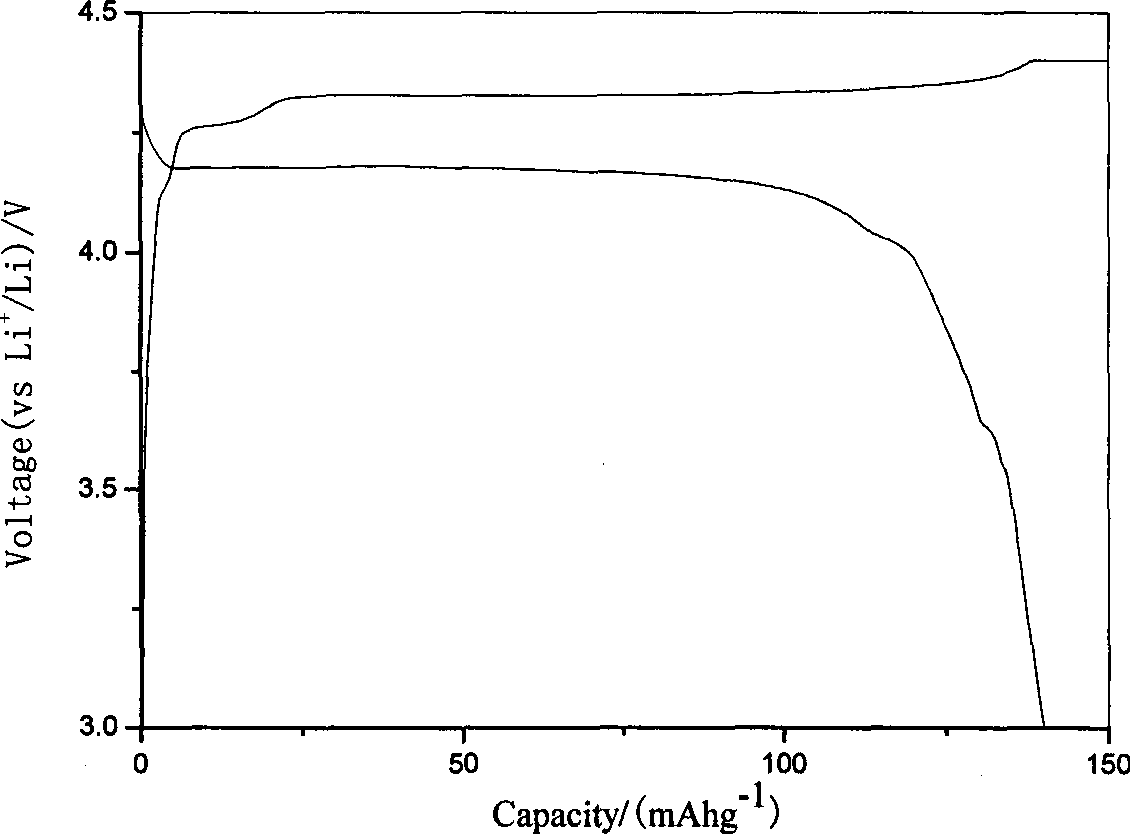

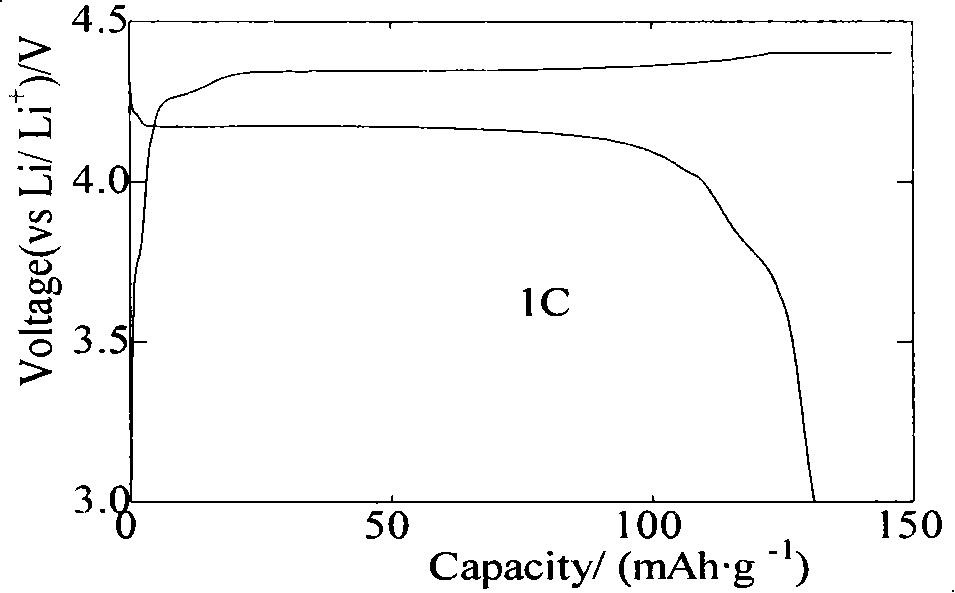

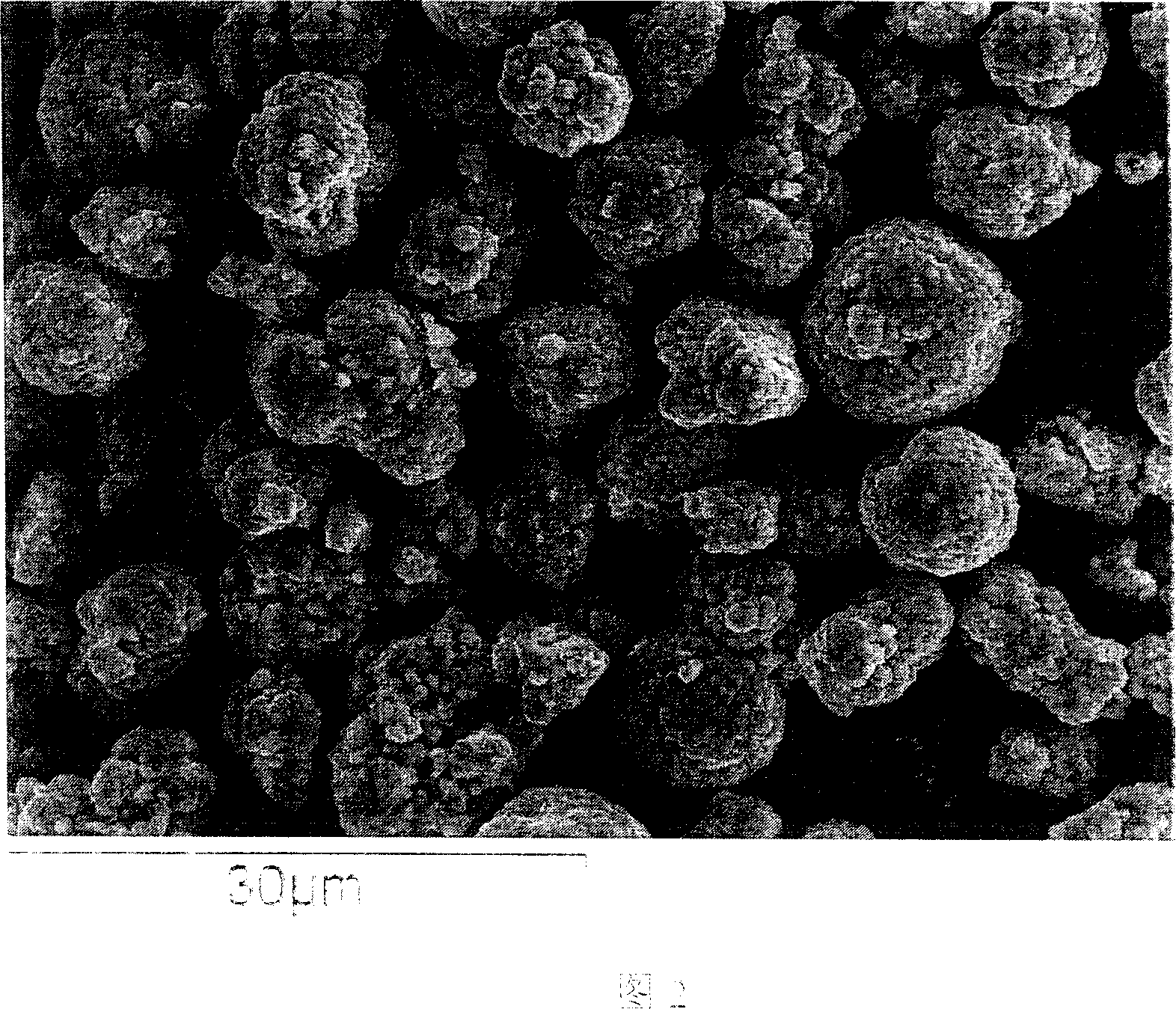

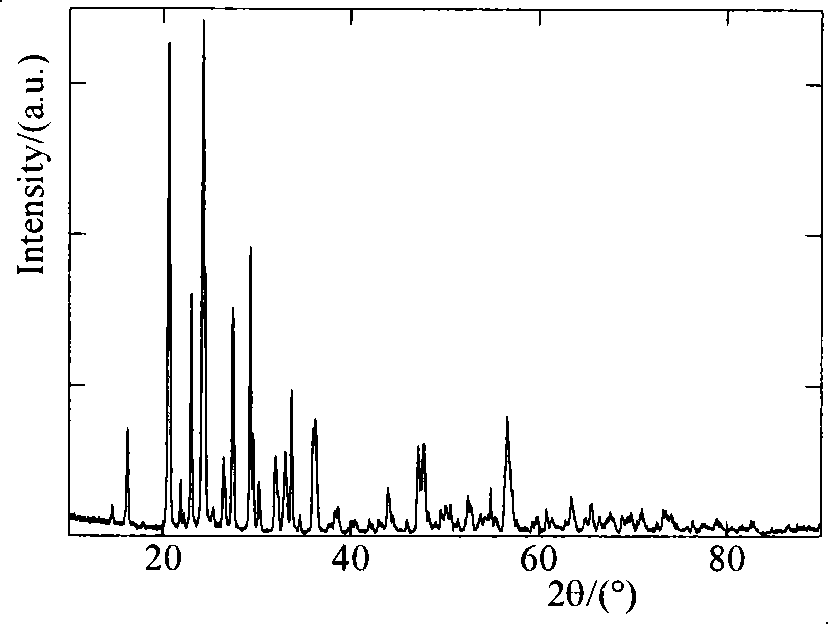

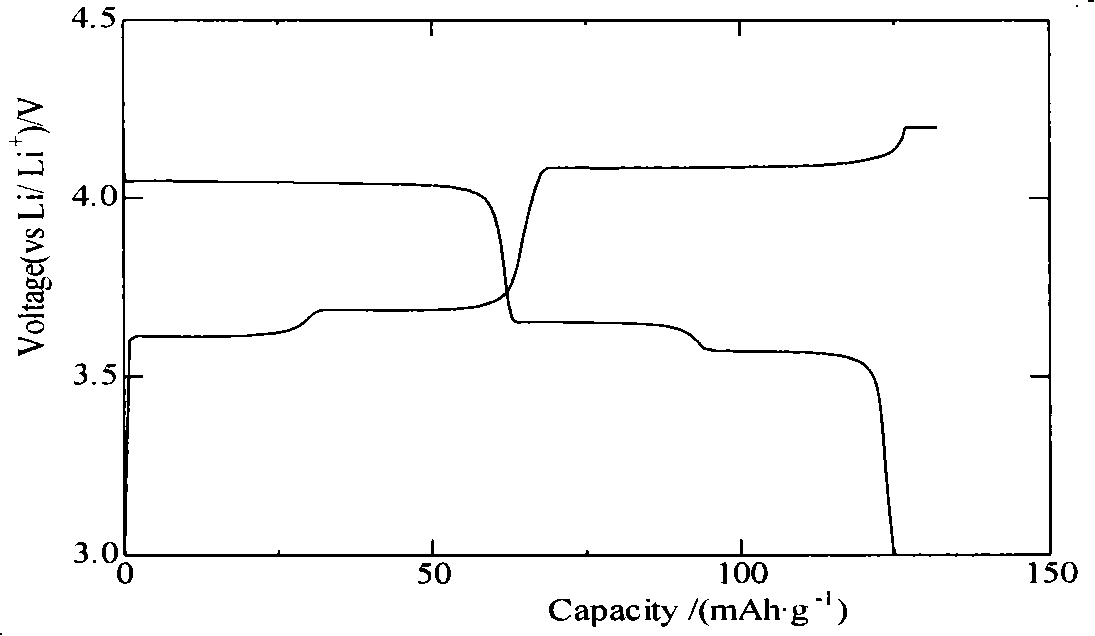

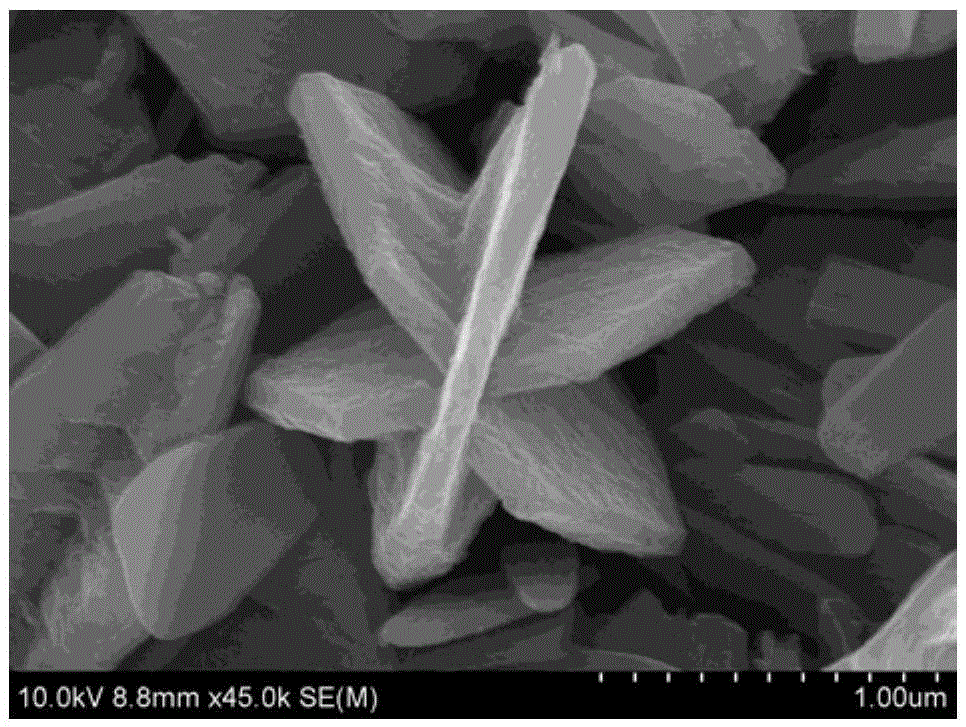

Hexagonal vanadium pentoxide nano-material as well as preparation method and application thereof

ActiveCN105384191AShorten the diffusion distanceIncrease contact areaCell electrodesNanotechnologyDistillationVanadium oxide

The present invention relates to a hexagonal vanadium pentoxide nano-material as well as a preparation method and an application thereof. The vanadium pentoxide nano-material is hexagonal, and the thickness of each angle is about 100-300 nm. The preparation method comprises the following steps: using vanadium pentoxide powder, benzyl alcohol, and isopropanol as raw materials, preparing vanadium oxide collosol through reflux condensation and distillation concentration, mixing the collosol, ethanol and deionized water to obtain a vanadium pentoxide nano-material through a hydrothermal reaction and post sintering treatment. The prepared vanadium pentoxide nano-material is extremely suitable for an anode material of lithium-ion batteries. Compared with the prior art, the nano-material has the advantages of simple process, low manufacturing costs and excellent electrochemical performance and the like.

Owner:TONGJI UNIV

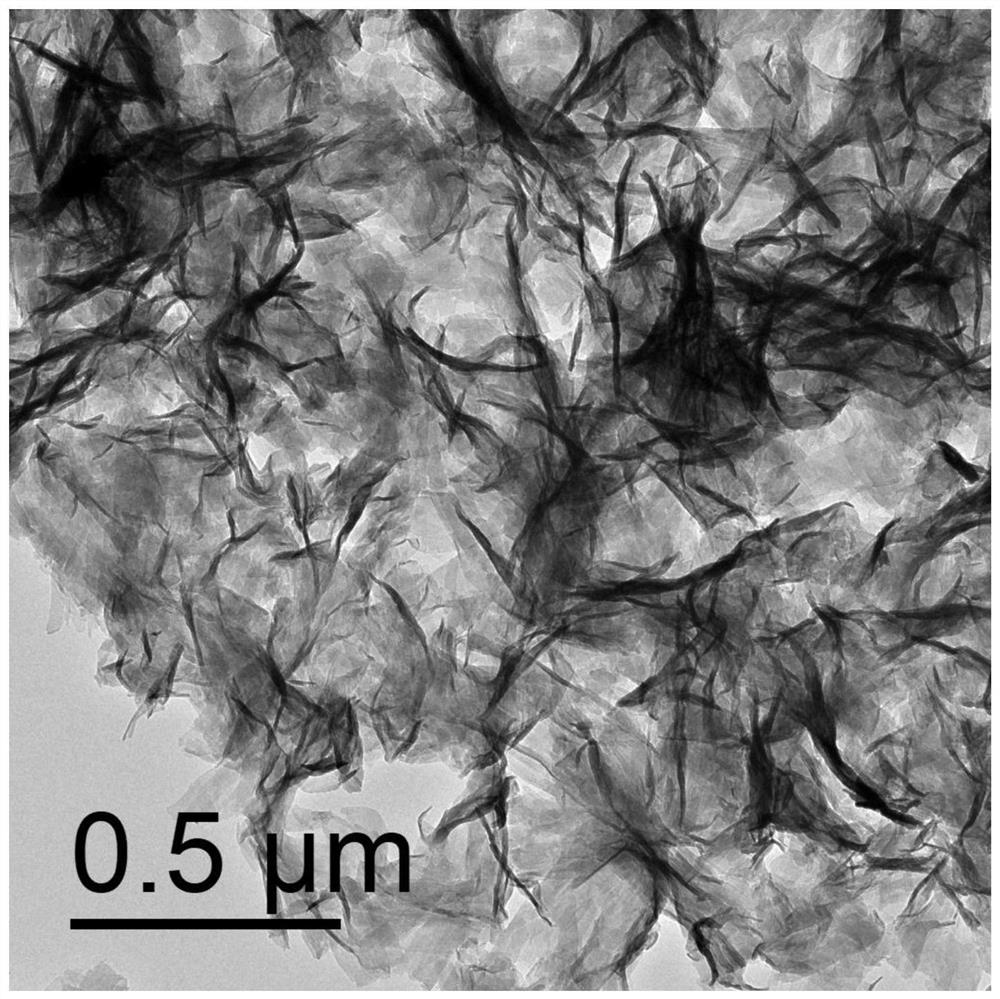

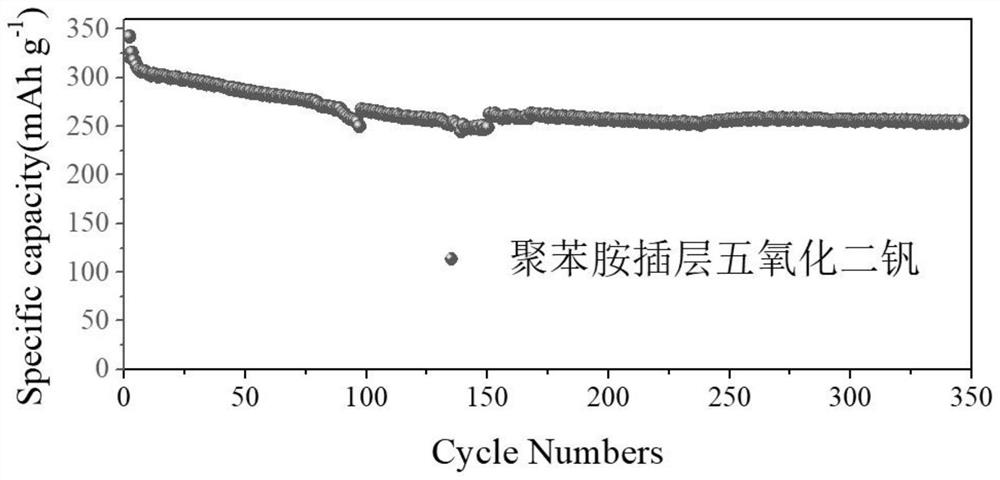

Polyaniline in-situ polymerization intercalated vanadium pentoxide and preparation method and application thereof

PendingCN111847510AHigh specific capacityImprove cycle stabilityHybrid capacitor electrodesCell electrodesIn situ polymerizationAniline

The invention belongs to the technical field of electrode materials, and provides a preparation method of polyaniline in-situ polymerization intercalated vanadium pentoxide. The preparation method comprises the following steps of: mixing vanadium pentoxide powder, water and hydrogen peroxide to obtain a solution a; mixing an aniline monomer with water, and adjusting the pH value with an acid solution to obtain a solution b; and mixing the solution a and the solution b, and reacting to obtain polyaniline in-situ polymerization intercalated vanadium pentoxide. Vanadium pentoxide powder is used as a vanadium source, aniline monomer in-situ polymerization is used as intercalation molecules, and hydrogen peroxide is used as a cosolvent to prepare polyaniline in-situ polymerization intercalatedvanadium pentoxide with high specific capacity, excellent cycling stability and excellent rate capability. The first specific discharge capacities of the electrode material disclosed by the inventionare respectively 330-390mAh. g <-1> and 120-180mAh. g <-1> under the current densities of 1A. g <-1 > and 5A. g <-1>.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com