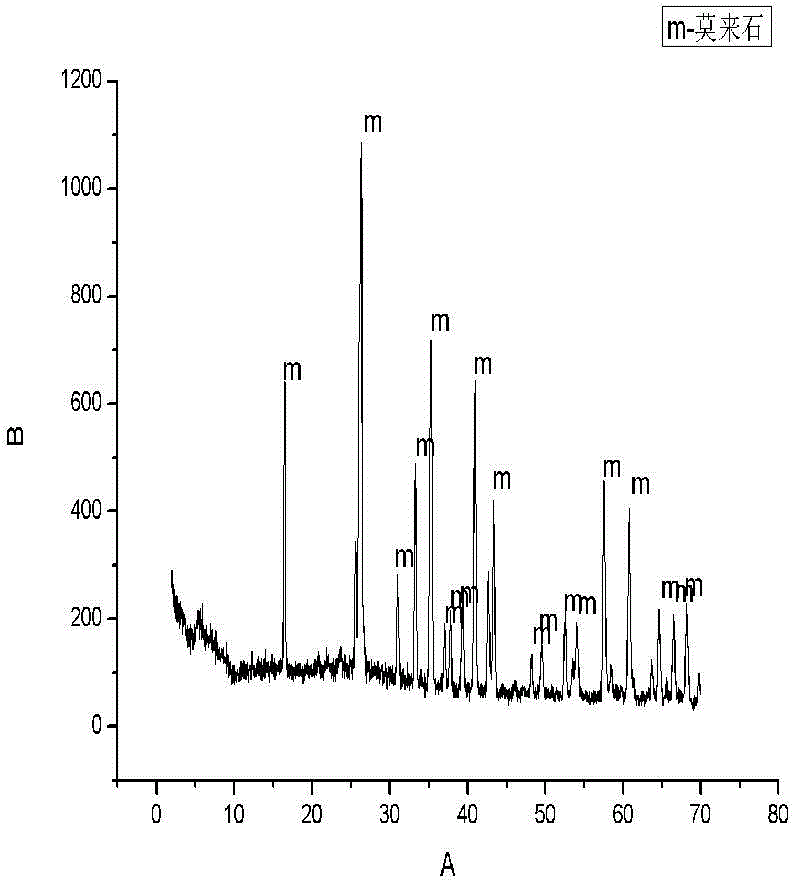

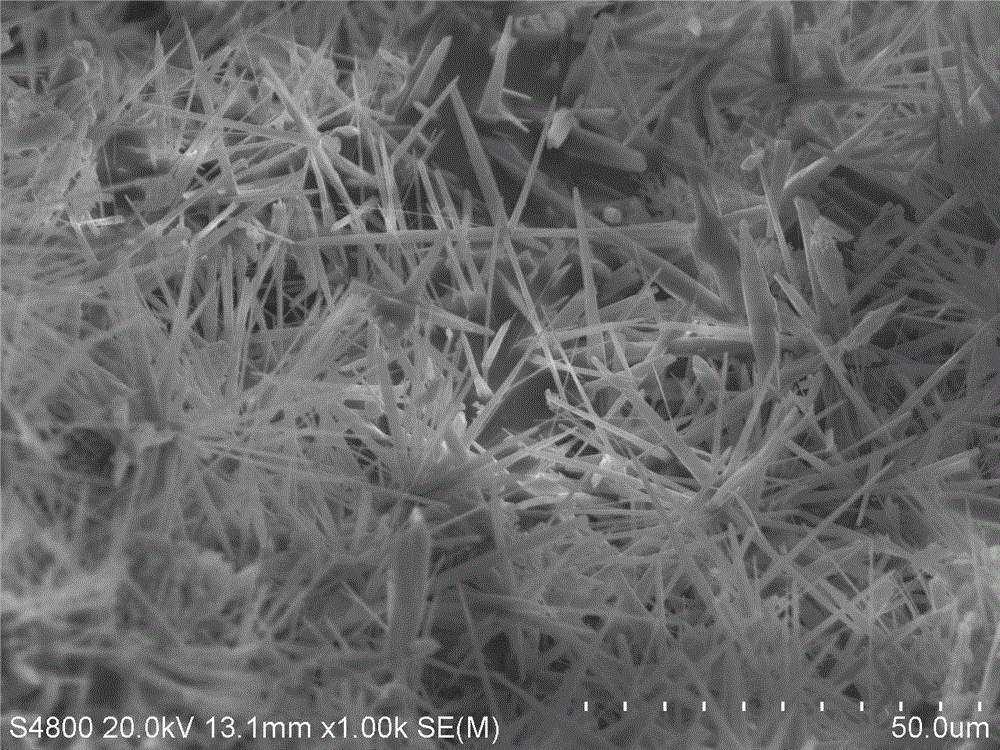

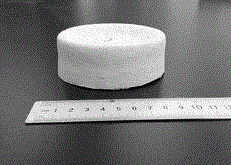

Preparation method of acicular mullite porous ceramic block material with superhigh amount of porosity

A technology of acicular mullite and porous ceramics, applied in the field of porous ceramics, can solve the problems of no room for whiskers to grow, difficult to disperse whiskers, and difficult to grow in situ, etc., to achieve good strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add ceramic powder with a solid content of 50% (volume fraction) to 50ml of an aqueous solution containing 10wt% PVA, wherein the mass ratio of aluminum hydroxide, silicon dioxide, aluminum fluoride and vanadium pentoxide is 77:20:1.5 :1.5. The obtained mixture was stirred with a magnetic stirrer at room temperature for 10 min, and then ultrasonically dispersed at room temperature for 3 min, then boiled and concentrated to 10 ml to obtain a ceramic slurry. Pour the ceramic slurry into a cylindrical mold in batches (the bottom of the mold is made of pure copper, and the wall is made of polytetrafluoroethylene), and then refrigerated at -18°C for 10 minutes before demoulding. The demolded samples were further frozen for 1 hour, and then transferred to a freeze dryer at 1.0 Pa and freeze-dried at -50°C for 24 hours to remove moisture. The ceramic green body after dehydration was moved to a high-temperature tubular electric furnace, heated to 300°C at a rate of 10°C / min in...

Embodiment 2

[0026] Add ceramic powder with a solid content of 50% (volume fraction) to 50ml of an aqueous solution containing 7wt%PVA, wherein the mass ratio of aluminum hydroxide, silicon dioxide, aluminum fluoride and vanadium pentoxide is 76:19:3 :2. The obtained mixture was stirred with a magnetic stirrer at room temperature for 5 minutes, then ultrasonically dispersed at room temperature for 3 minutes, and then left to stand for 24 hours to obtain a ceramic slurry. Pour the ceramic slurry into a cylindrical mold in batches (the bottom of the mold is made of pure copper, and the wall is made of polytetrafluoroethylene), and then freeze at -60°C for 10 minutes before demoulding. The demolded samples were further frozen for 2 hours, and then transferred to a freeze dryer at 1.0 Pa, and freeze-dried at -50°C for 24 hours to remove moisture. The dehydrated ceramic green body was moved to a tube furnace, heated to 800°C at a rate of 5°C / min in an air atmosphere, kept for 2 hours, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com