Hexagonal vanadium pentoxide nano-material as well as preparation method and application thereof

A technology of vanadium pentoxide and nanomaterials, which is applied in the field of electrochemistry, can solve the problems of complex reaction process and high cost of reaction raw materials, and achieve the effects of simple preparation process, good cycle stability and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

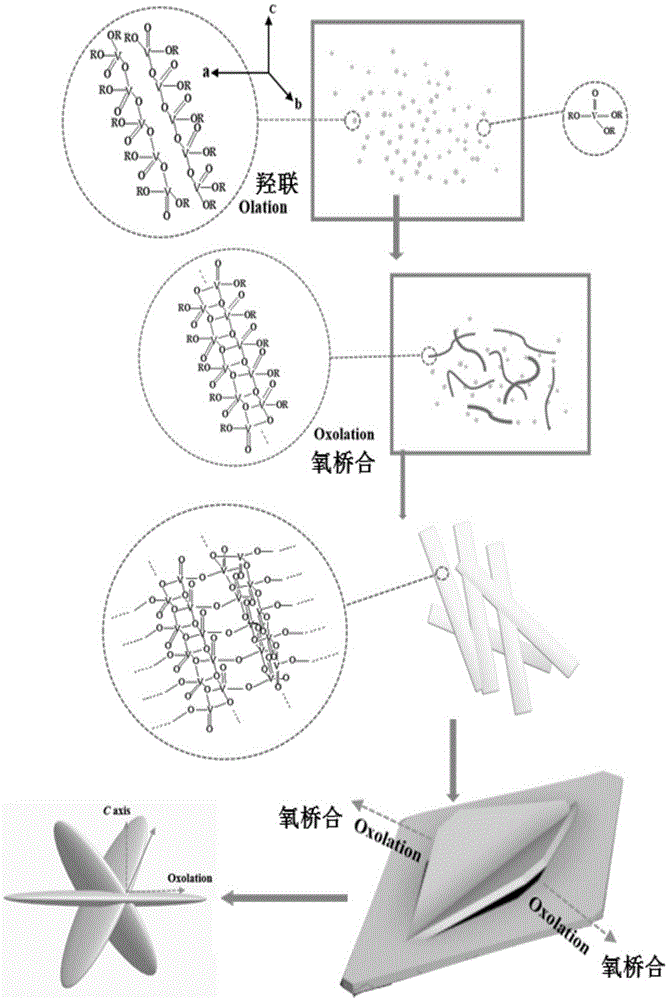

Method used

Image

Examples

Embodiment 1

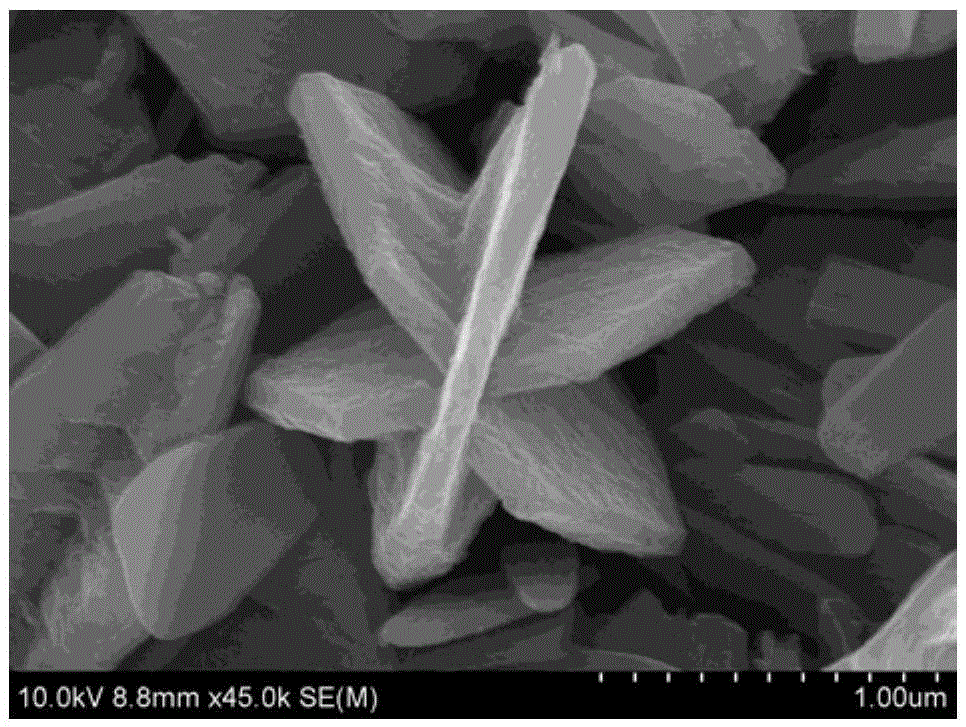

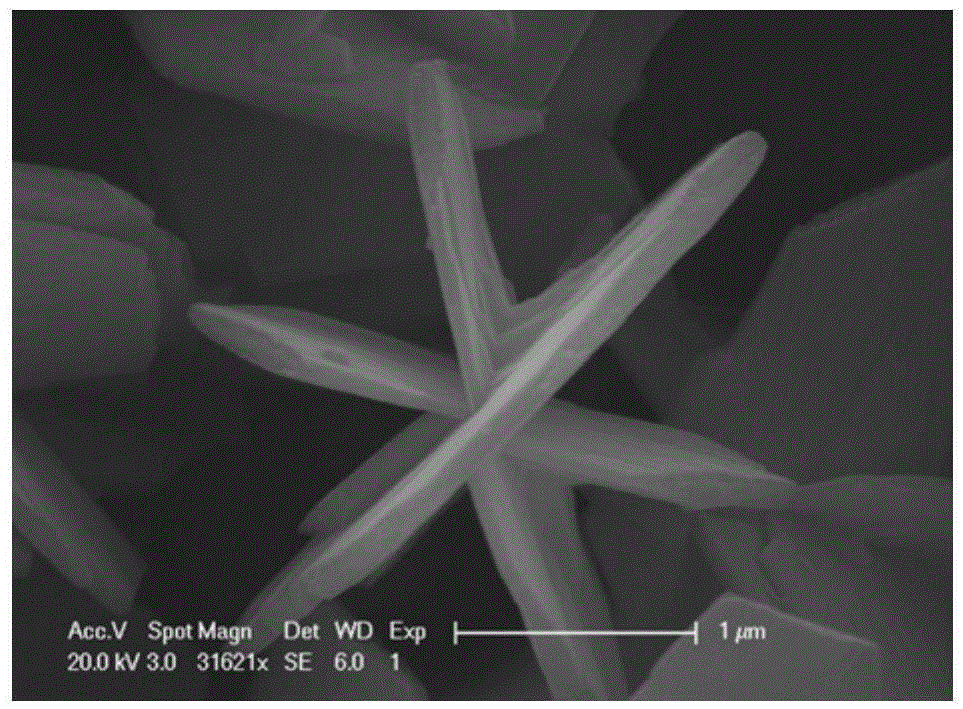

[0034] Stir and mix 32g of vanadium pentoxide powder, 72ml of benzyl alcohol and 530ml of isopropanol (molar ratio: 1:4:40), reflux and condense at 95°C for 4 hours, remove unreacted vanadium pentoxide powder by filtration, and obtain oxidized Vanadium sol. The obtained vanadium oxide sol was concentrated by distillation at 95° C. to 1 / 3 of the original volume to obtain concentrated vanadium oxide sol. Mix and stir 15ml of concentrated vanadium oxide sol and 2ml of ethanol evenly, then add 30ml of deionized water and keep stirring to obtain a red-black viscous solution. After stirring for half an hour, transfer the viscous solution into a 50ml hydrothermal kettle, and place it in a 180°C oven for hydrothermal reaction for 7 days. After naturally cooling to room temperature, filter and rinse with deionized water and absolute ethanol several times. A black deposit was obtained. The obtained black deposit is heat-treated at 350° C. in air for 1 hour to obtain vanadium pentoxide...

Embodiment 2

[0041] Stir and mix 32g of vanadium pentoxide powder, 72ml of benzyl alcohol and 530ml of isopropanol (molar ratio: 1:4:40), reflux and condense at 95°C for 4 hours, remove unreacted vanadium pentoxide powder by filtration, and obtain oxidized Vanadium sol. The obtained vanadium oxide sol was concentrated by distillation at 95° C. to 1 / 3 of the original volume to obtain concentrated vanadium oxide sol. The prepared 15ml of concentrated vanadium oxide sol was not mixed with the ethanol solution, and 30ml of deionized water was directly added to the 15ml of concentrated vanadium oxide sol and continuously stirred to obtain a red-black viscous solution. After stirring for half an hour, transfer the viscous solution into a 50ml hydrothermal kettle, and place it in a 180°C oven for hydrothermal reaction for 7 days. After naturally cooling to room temperature, filter and rinse with deionized water and absolute ethanol several times. A black deposit was obtained. The obtained black...

Embodiment 3

[0044] Stir and mix 30g of vanadium pentoxide powder, 17.5ml of benzyl alcohol and 500ml of isopropanol (the molar ratio is 1:1:40), reflux and condense at 90°C for 4h, and remove unreacted vanadium pentoxide powder by filtration to obtain Vanadium oxide sol. The obtained vanadium oxide sol was concentrated by distillation at 95°C to 1 / 2 of the original volume to obtain concentrated vanadium oxide sol. Mix and stir 15ml of concentrated vanadium oxide sol and 1ml of ethanol evenly, then add 30ml of deionized water and keep stirring to obtain a red-black viscous solution. After stirring for half an hour, transfer the viscous solution into a 50ml hydrothermal kettle, and place it in a 200°C oven for hydrothermal reaction for 7 days. After naturally cooling to room temperature, filter it, and rinse it several times with deionized water and absolute ethanol. A black deposit was obtained. The obtained black deposit was heat-treated in air at 300° C. for 2 hours to obtain vanadium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com