Patents

Literature

47results about How to "Relieve contraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ferric phosphate battery adopting compound conductive agent and manufacturing method thereof

InactiveCN102683712AIncreased capacity and magnificationImprove conductivity stabilityFinal product manufactureCell electrodesIonPolyvinylidene fluoride

The invention discloses a manufacturing method for a lithium ferric phosphate battery adopting a compound conductive agent. The manufacturing method comprises the following steps of: dissolving anode binder polyvinylidene fluoride in N-methyl pyrrolidone and stirring, thereby obtaining anode glue; adding a carbon nano-tube / conductive polymer compound material into the anode glue and scattering; adding anode active matter LiFePO4 and stirring, thereby obtaining anode slurry; uniformly coating the anode slurry on two surfaces of an aluminum foil, drying, and then rolling and slicing, thereby obtaining anode plates; uniformly mixing cathode active matter graphite, the carbon nano-tube / conductive polymer compound material, a cathode binder and de-ionized water, thereby obtaining cathode slurry; uniformly coating the cathode slurry on two surfaces of a copper foil, drying, and then rolling and slicing, thereby obtaining cathode slices; coiling, flatly pressing and banding, and then drying for 8 hours in vacuum at 65 DEG C; filling electrolyte into a dried battery; and forming an end product of the lithium ferric phosphate battery after filling the electrolyte. According to the manufacturing method provided by the invention, the capacity, multiplying power, circulation and safety property of the battery are greatly improved.

Owner:ZHEJIANG ZHENLONG BATTERY

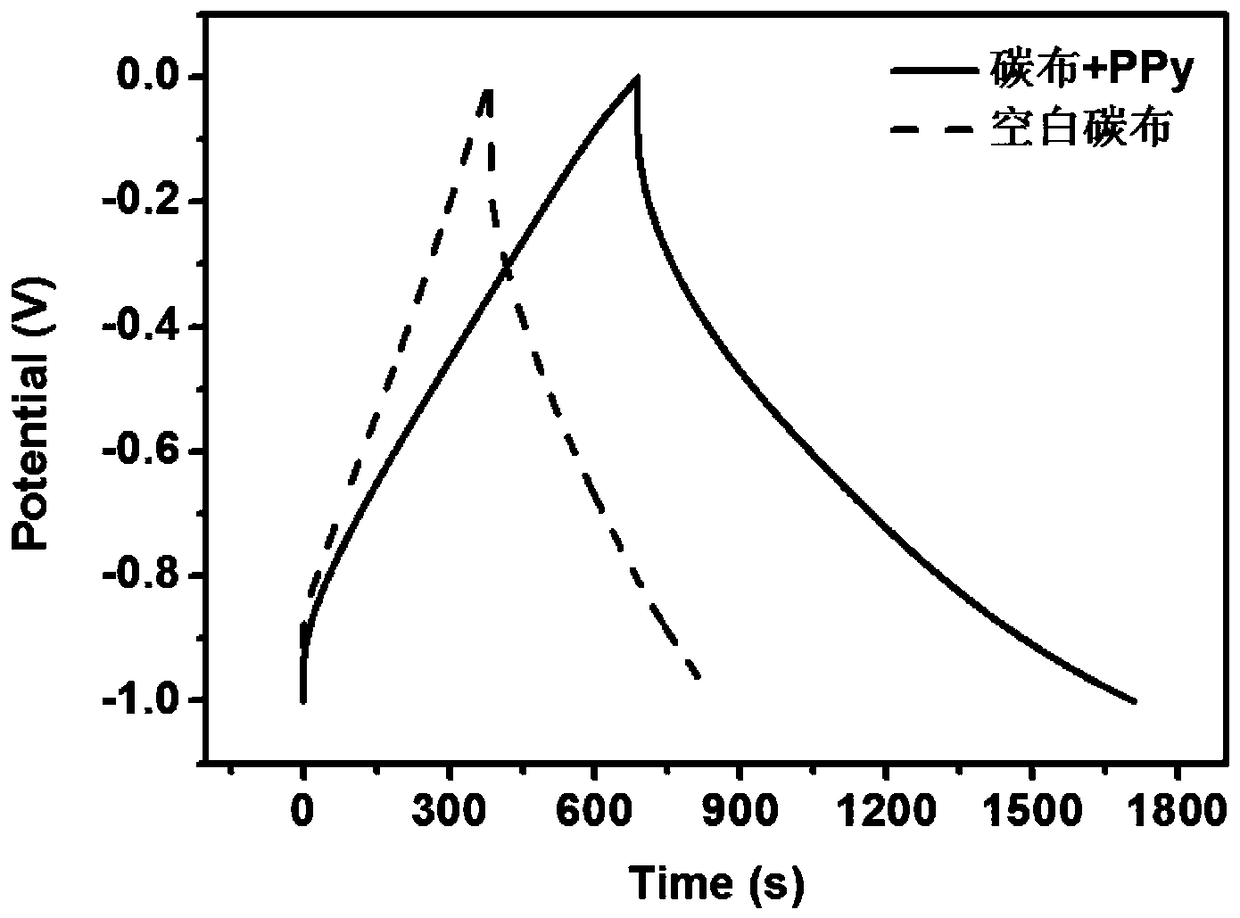

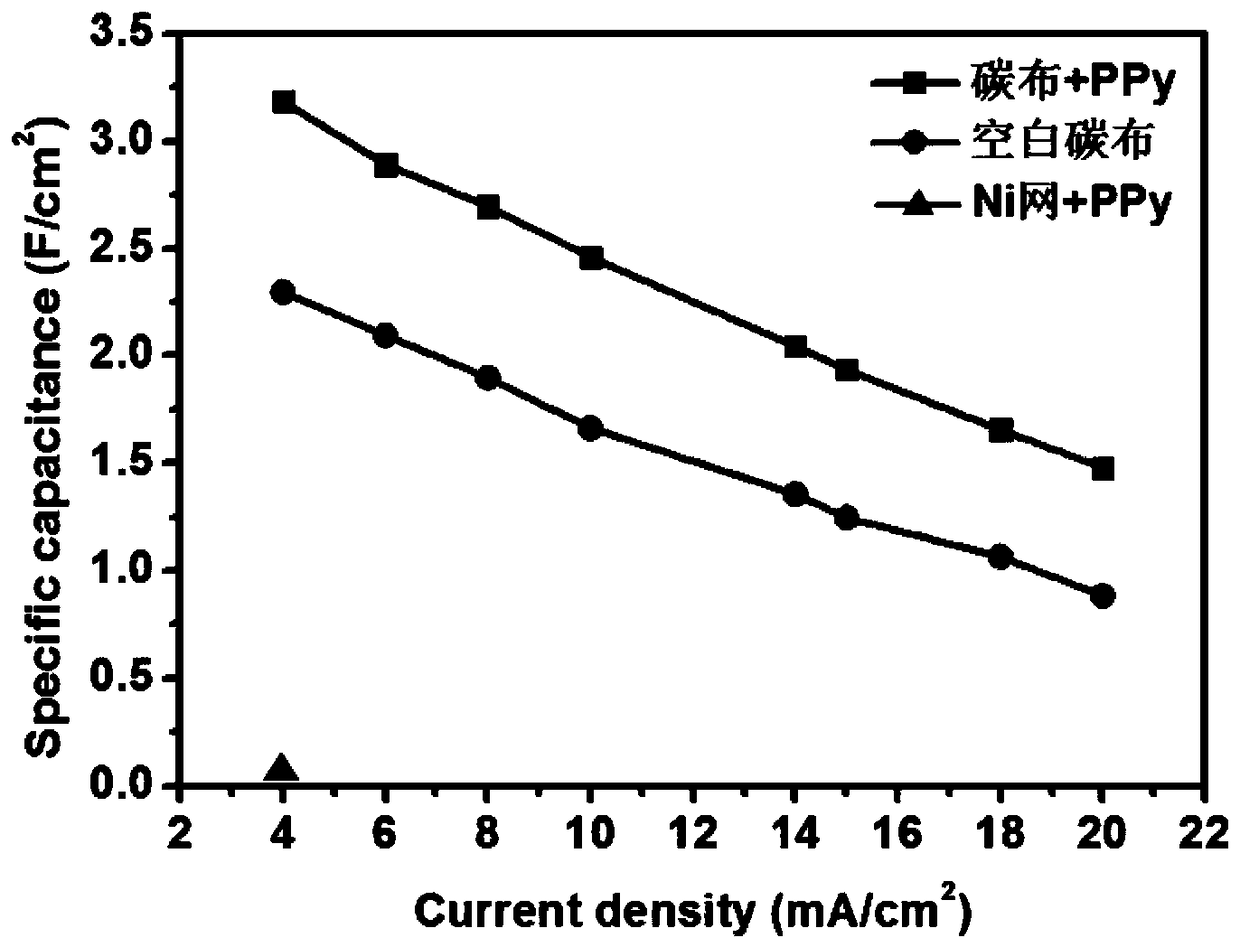

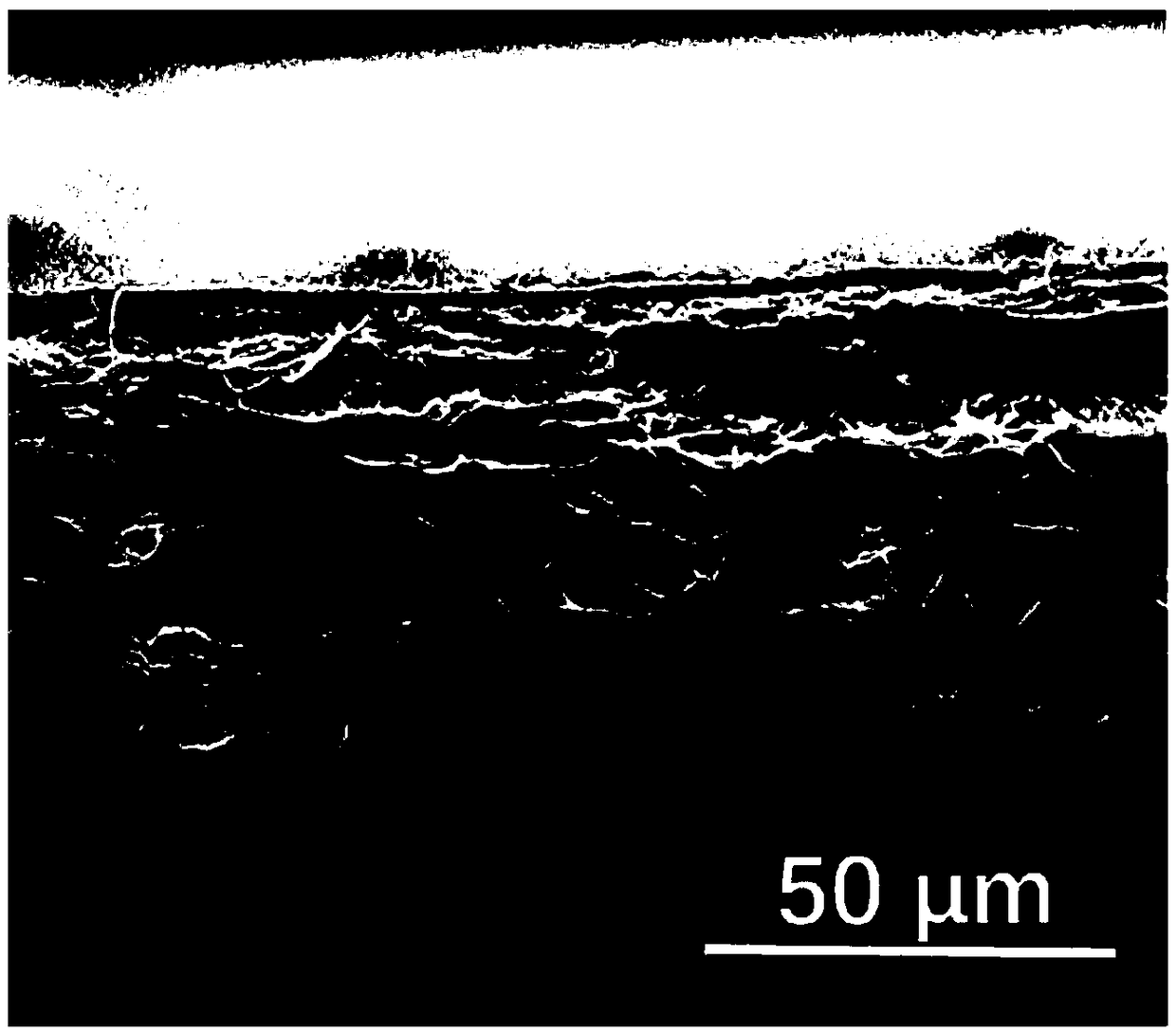

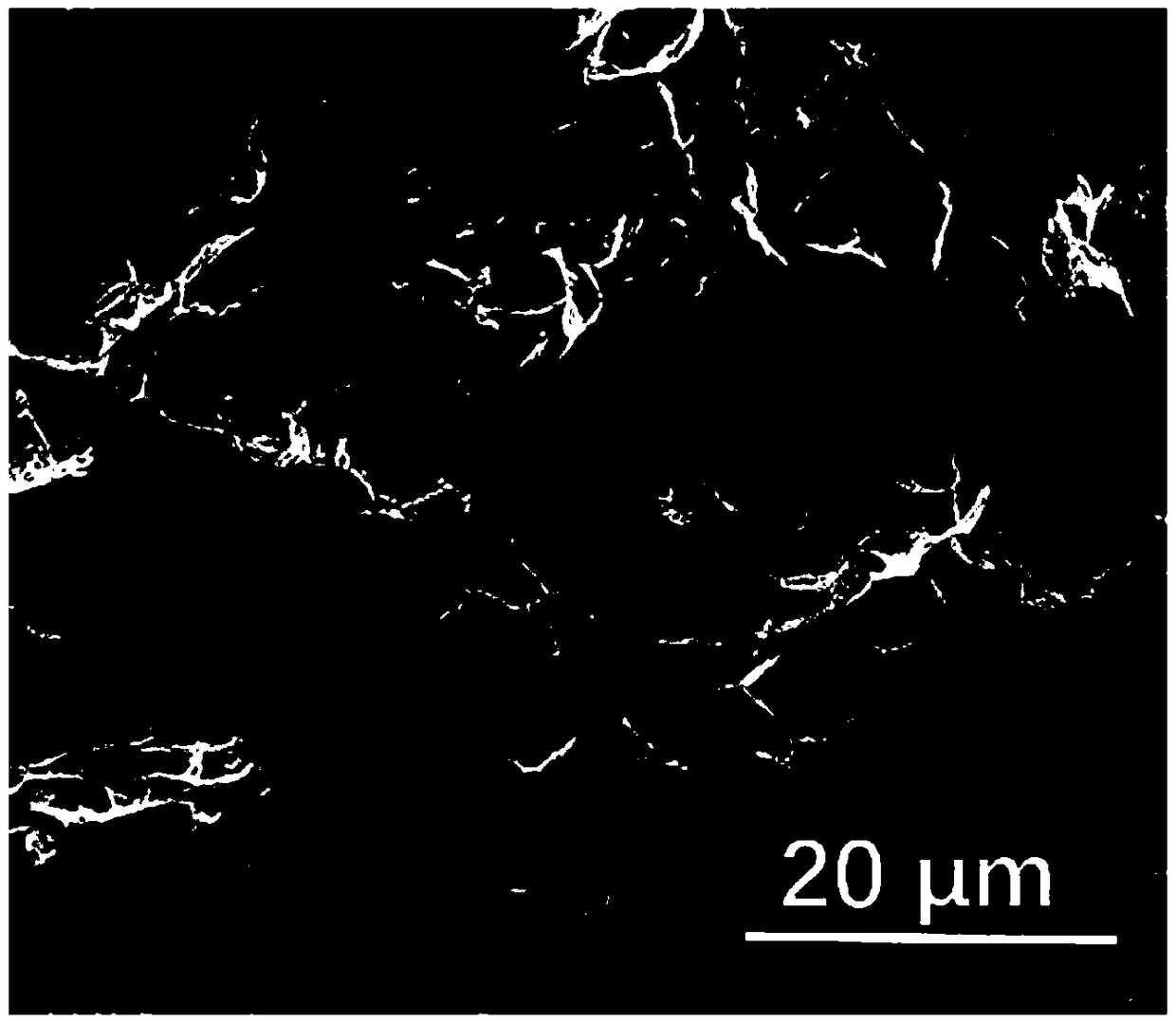

Manufacturing method for polypyrrole/conductive carbon cloth combined electrode, and application thereof

ActiveCN108447696AIncrease capacityImprove cycle stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitancePolypyrrole

The invention discloses a manufacturing method for a polypyrrole / conductive carbon cloth combined electrode, and application thereof on a supercapacitor. A potentiostatic method is used, a solution containing pyrrole monomer and sodium perchlorate (NaClO4) is used as an electrolyte, a polypyrrole thin film is deposited on the surface of a carbon cloth, and the thin film shows a sheet structure. In1 M KOH electrolyte, electrochemical performance evaluation is performed on the polypyrrole / carbon cloth in -1-0 V potential window range. Compared with performance of a blank carbon cloth and polypyrrole (polypyrrole / Ni) which is loaded on a base of foamed nickel, maximum area specific capacitance of the blank carbon cloth and the polypyrrole / Ni combined electrode is 2.29 F / cm<2>, after 1000 times of circulation, capacity retention ratio is 69.56%, and maximum capacity of polypyrrole / Ni is just 0.064 F / cm<2>. After the polypyrrole is combined with the carbon cloth, maximum specific capacitance can reach 3.18 F / cm<2>, and after 1000 times of circulation, capacity retention ratio reaches up to 96.35%, obviously superior to that of the blank carbon cloth and the polypyrrole / Ni.

Owner:CHINA THREE GORGES UNIV

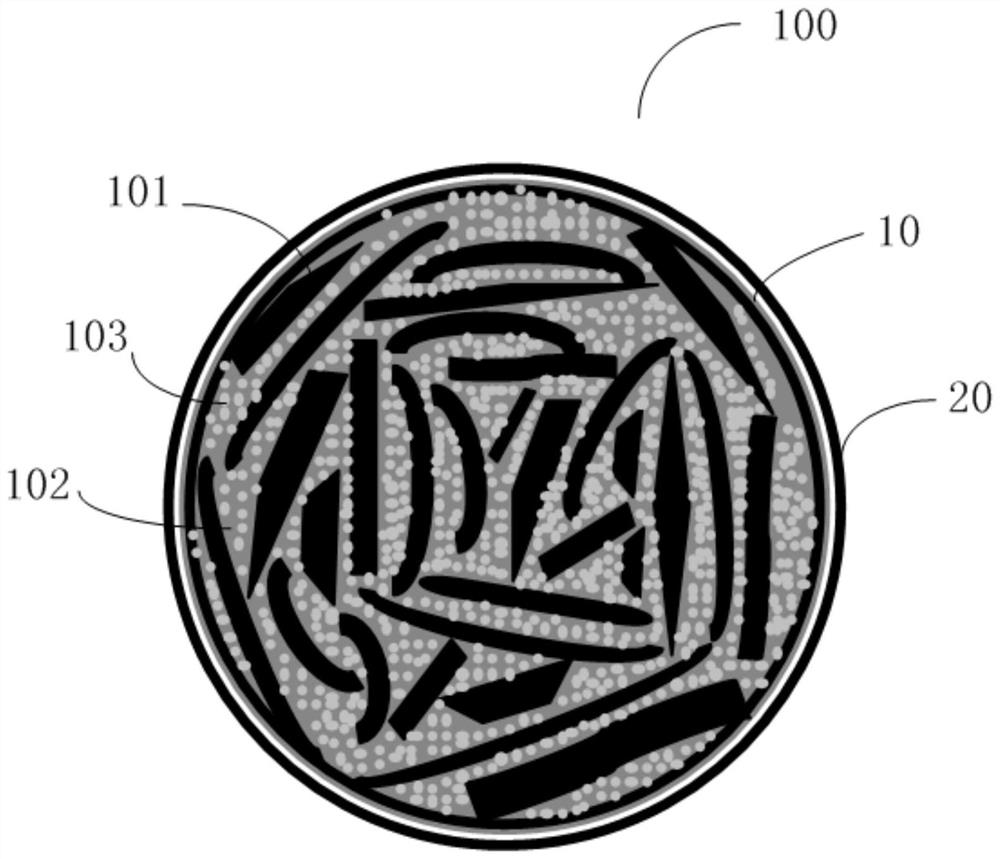

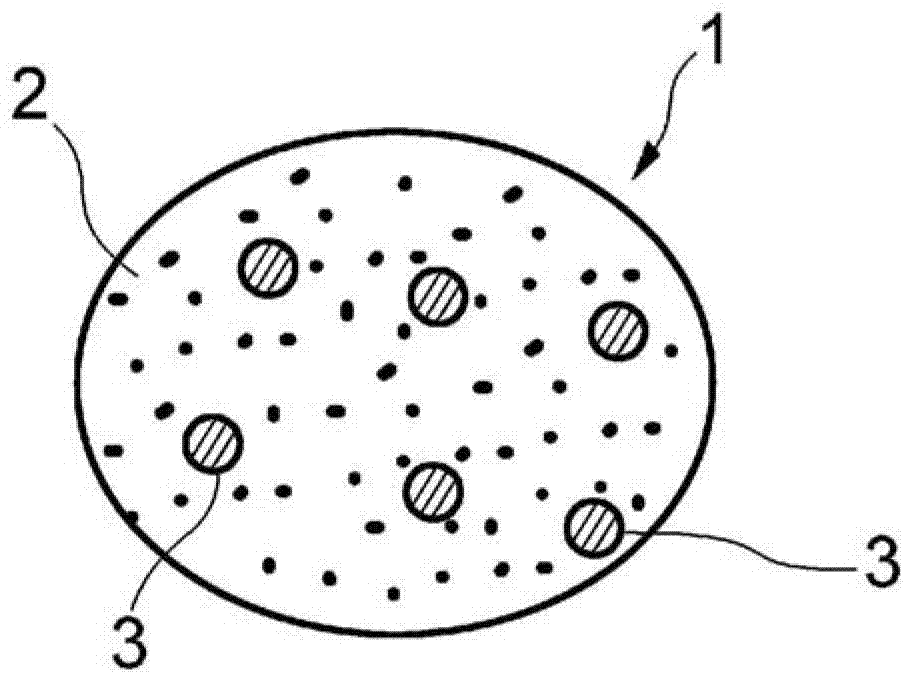

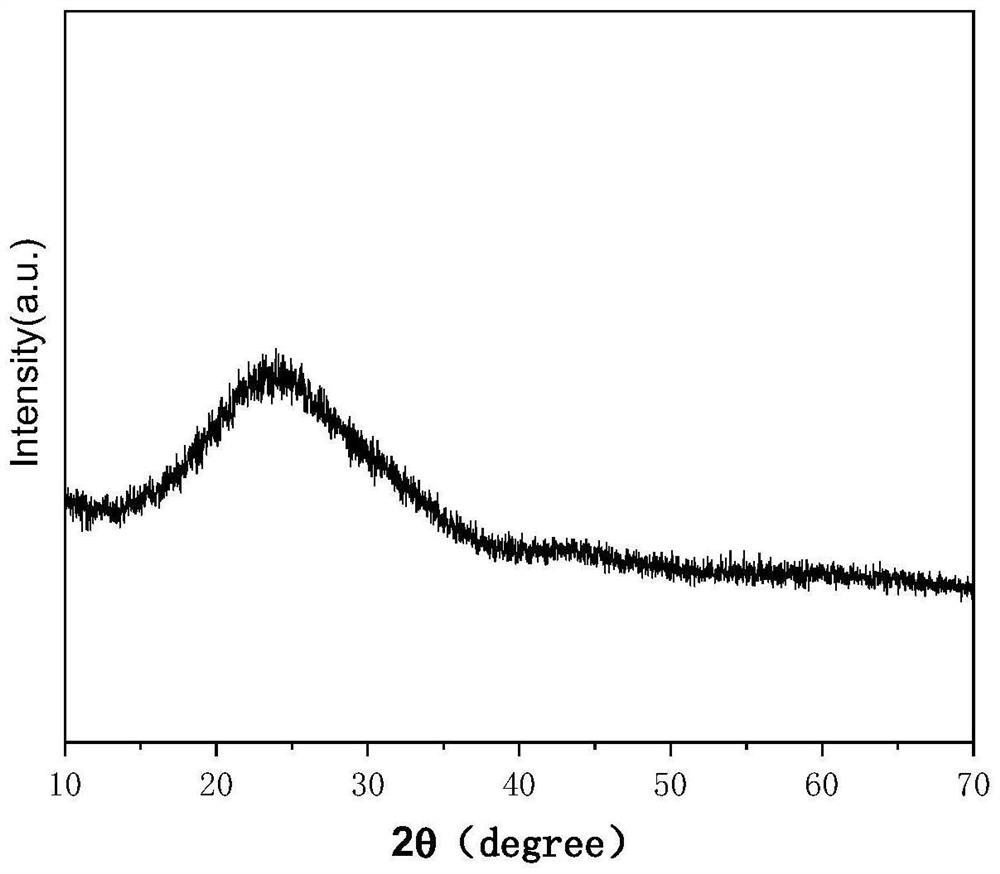

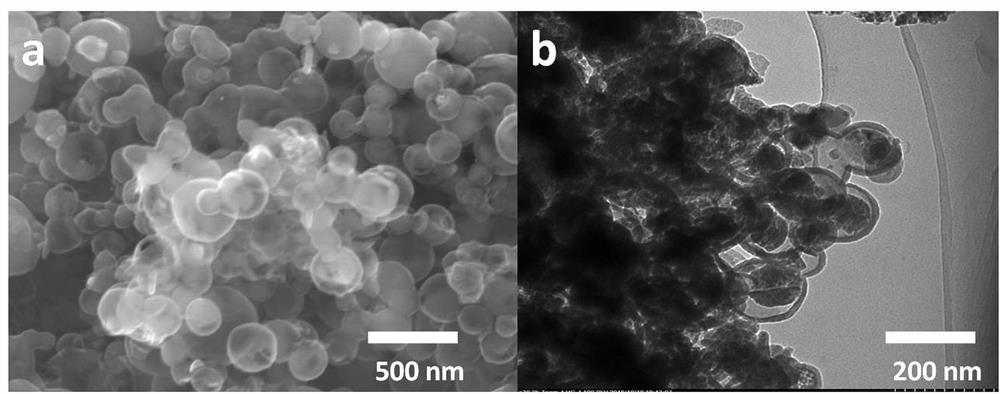

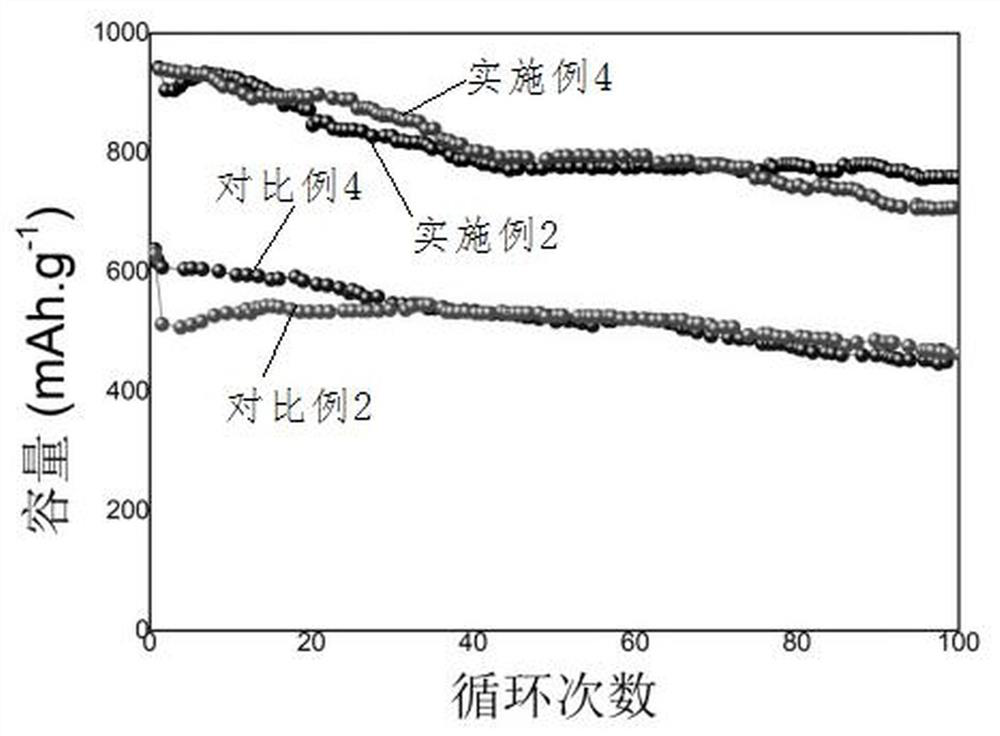

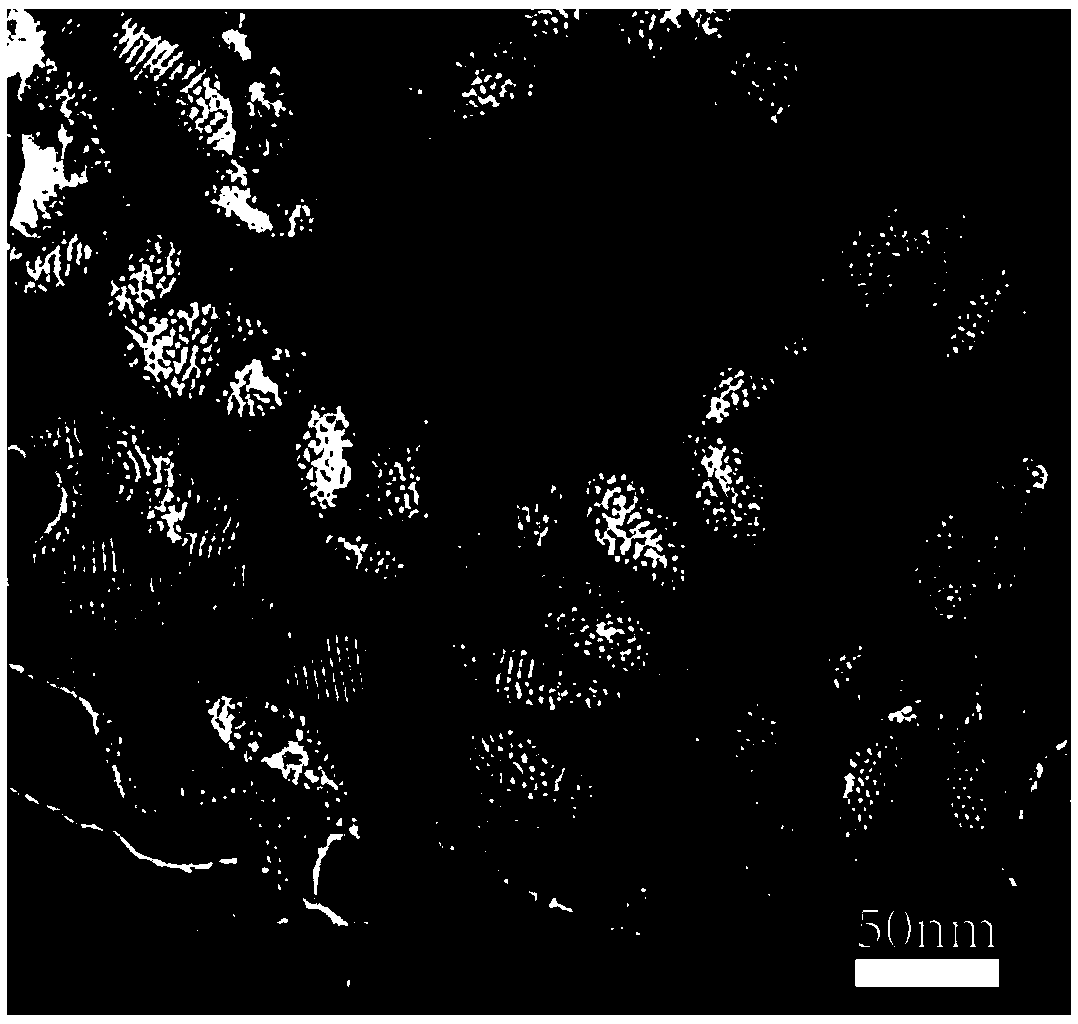

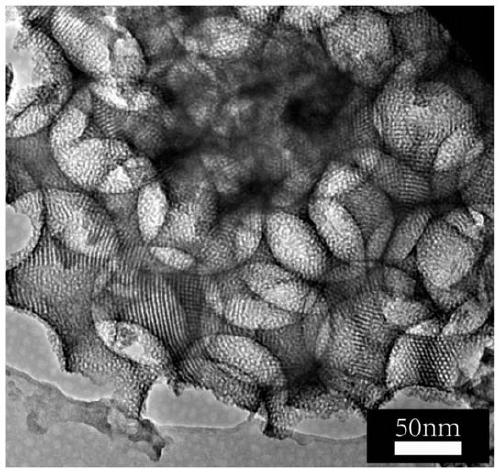

Silicon@carbon-graphene-based flexible composite material and preparation method thereof and lithium battery

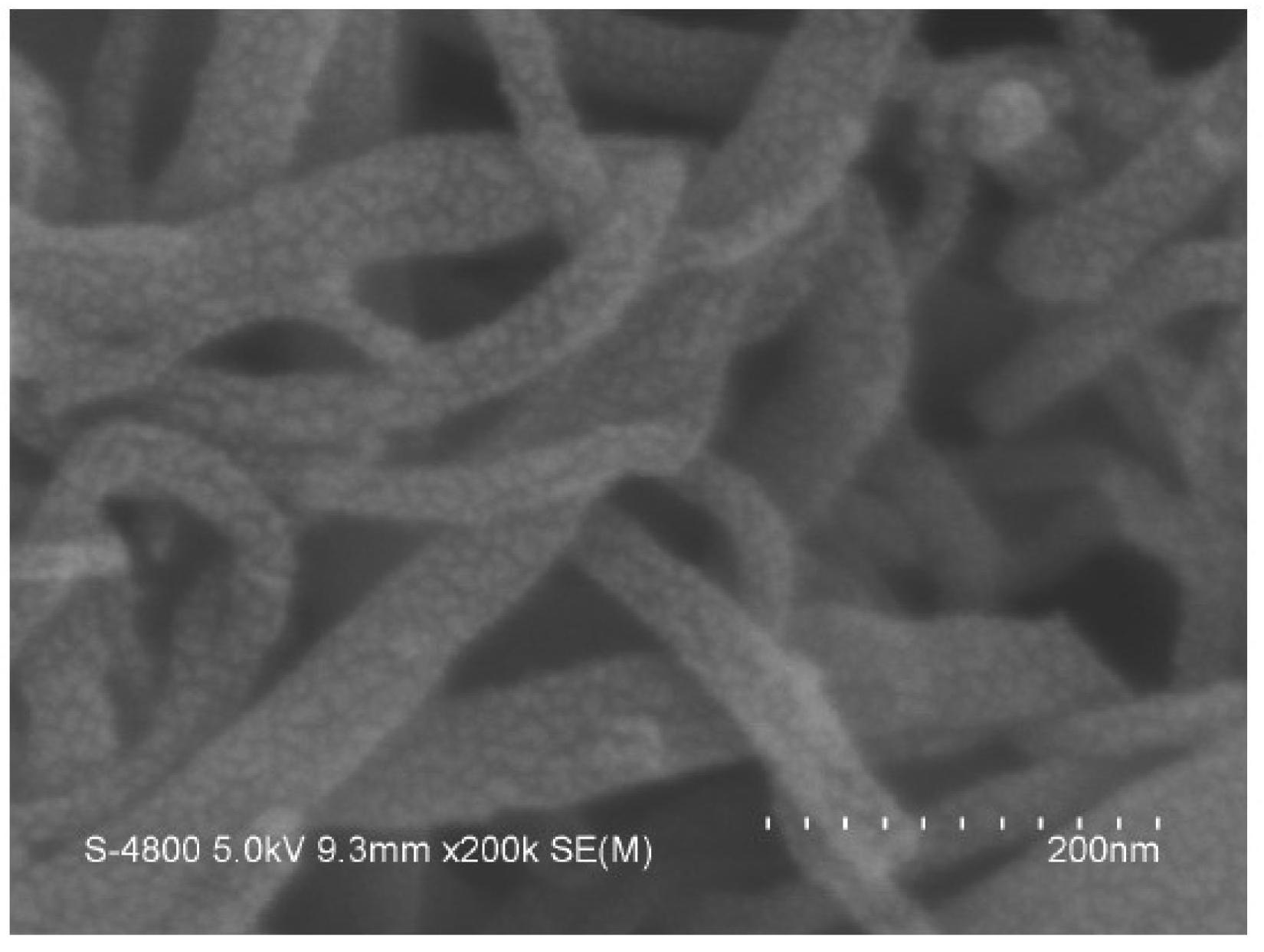

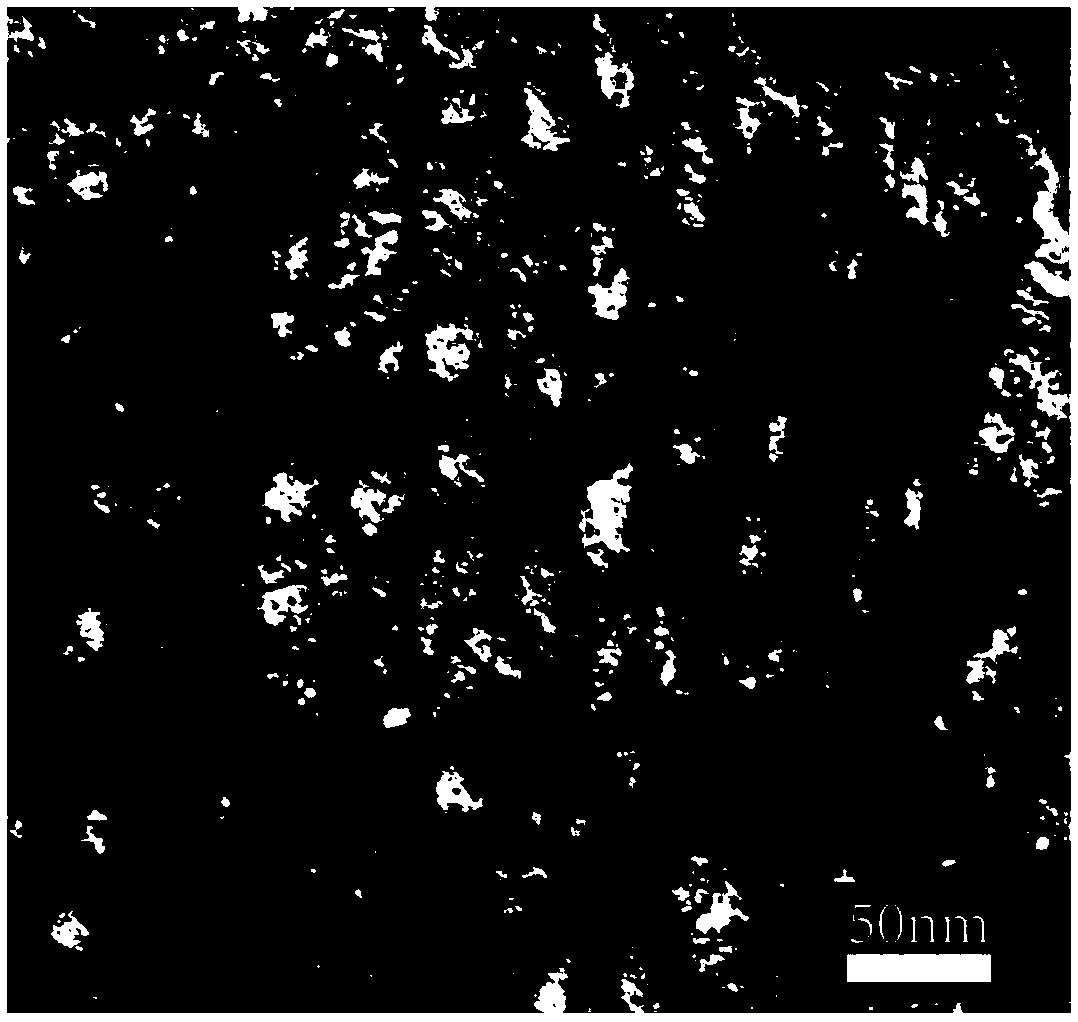

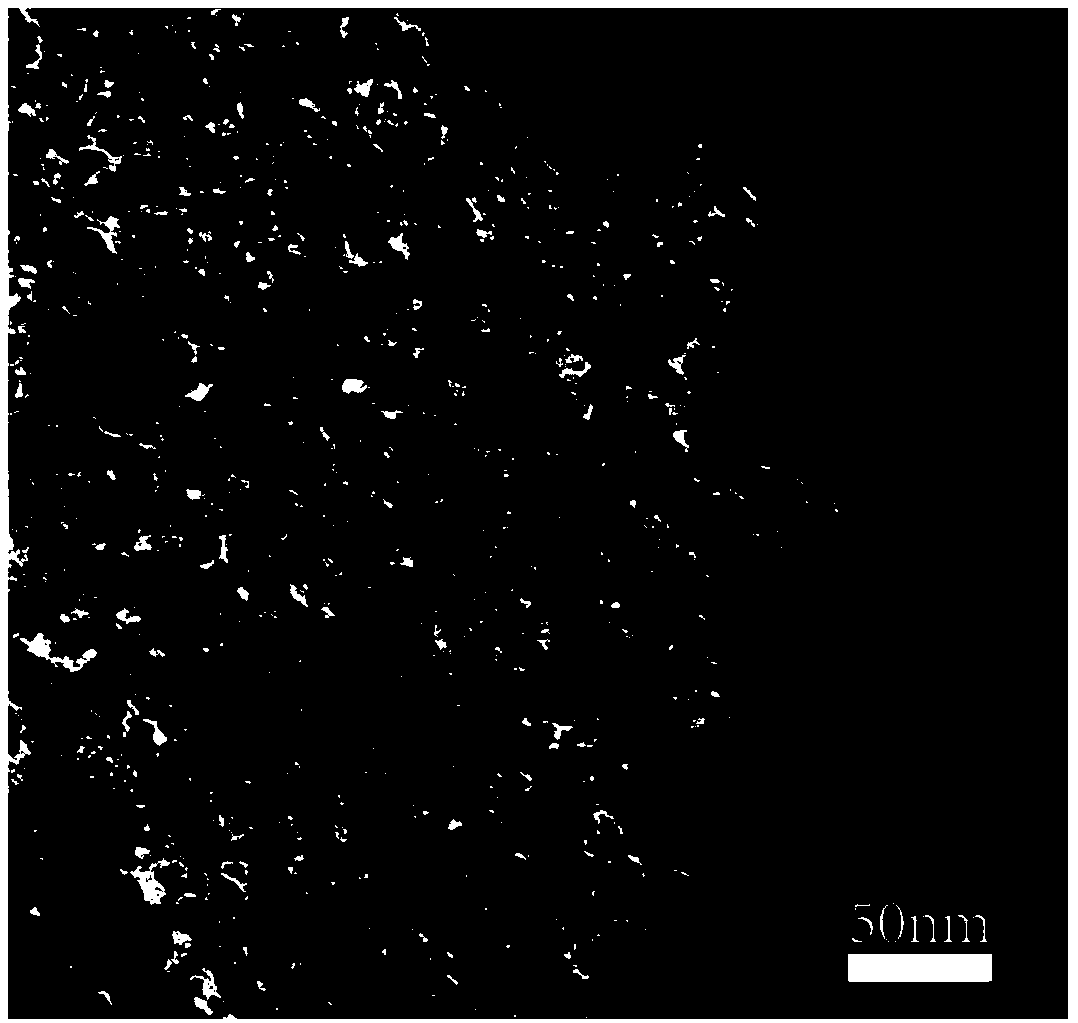

ActiveCN108807842ARelieve contractionImprove electronic conductivitySecondary cellsNon-aqueous electrolyte accumulator electrodesCarbon layerCyclic process

The invention provides a silicon@carbon-graphene-based flexible composite material and a preparation method thereof and a lithium battery. The flexible composite material is prepared from graphene nanosheets and silicon@carbon particles inlaid in the graphene nanosheets, wherein the graphene nanosheets are irregularly arranged and served as a basic skeleton of the flexible composite material; thesilicon@carbon particles take a silicon particle as a core and comprise a double-carbon layer coating the surface of the silicon particle. The method comprises the following steps: adding silicon intoa solution with oxidability, washing and drying; then adding polydiallyl dimethyl ammonium chloride, stirring and drying; mixing with graphene oxide, and regulating pH; performing suction filtrationto form a film; performing freeze drying on the film; sintering to obtain the flexible composite material. With the double-carbon layer structure on the silicon surface, the flexible composite material provided by the invention can remarkably relieve the volume expansion and contraction of silicon in a cyclic process, and thus improves the electronic conductivity of the silicon particle; moreover,bending of the material can be realized, and the flexible composite material has excellent electrochemical performance.

Owner:四川天诺聚能新能源开发有限公司

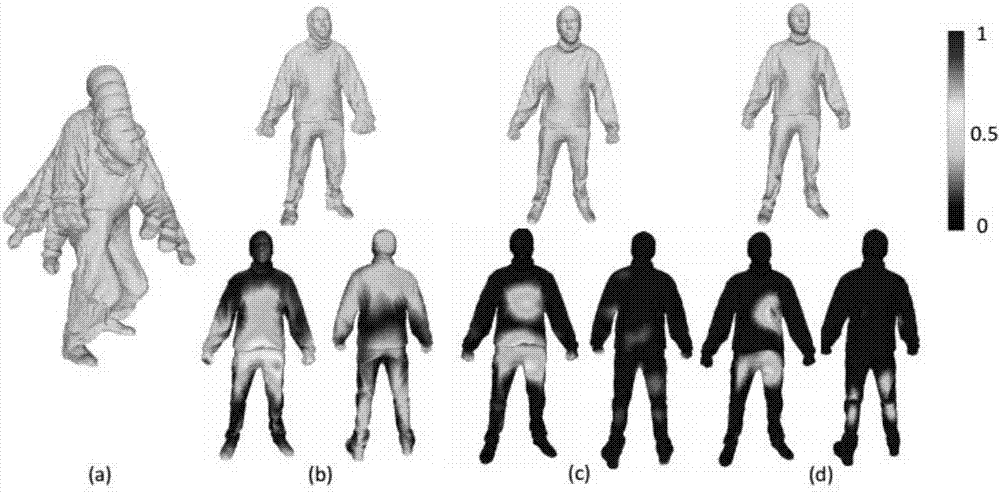

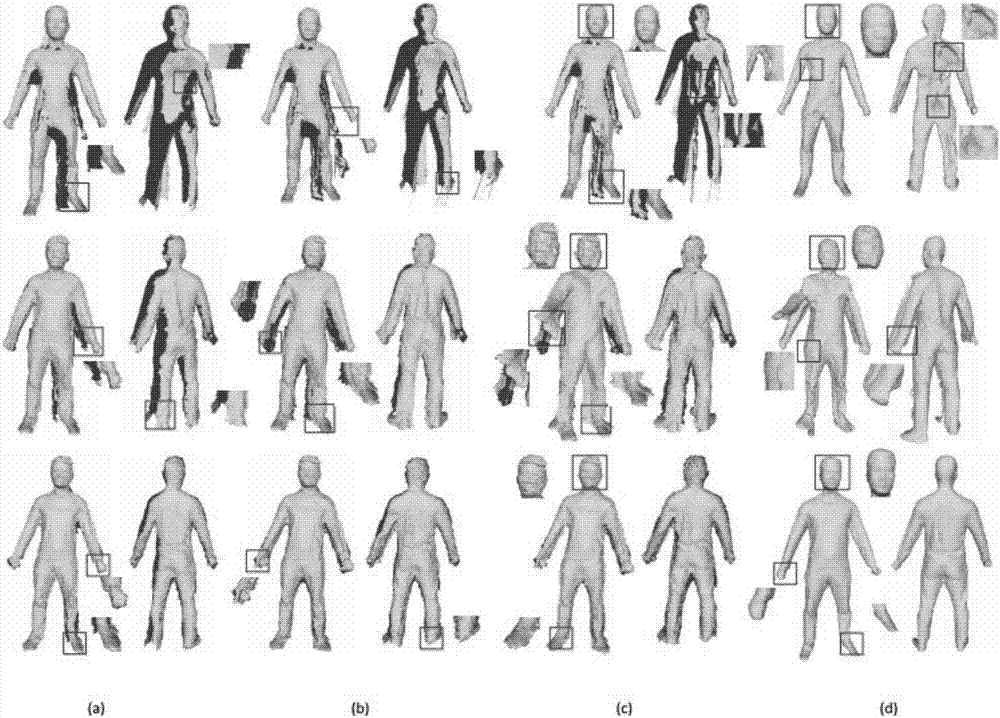

Global non-rigid registration and reconstruction method of deformable object

ActiveCN106934824AAvoiding Loop Detection ProblemsAlleviate the problem of error accumulationImage analysisGeometric image transformationView modelReconstruction method

The invention belongs to the field of computer application, three-dimensional reconstruction and registration, and aims to process the deformation of large action of a three-dimensional target object. The technical scheme employed by the invention is that according to a global non-rigid registration and reconstruction method of a deformable object, n view models are assumed and are denoted by U1, U2 to Un. For any model p, Up={u[1], u[2],***, u[N]} , N is the number of points of the model p, u[i]=(x[i],y[i],z[i],1 ) is the homogeneous coordinates of a point u[i], for pair of adjacent models Up and U(p+1), for a last model Un, an adjacent model is U1, the initial mapping relation (shown in specification) among the models is found by humans or solving a corresponding relation algorithm, namely a corresponding point, then the non-rigid transformation Xp among the models is solved, Xp={X[1],X[2], ***, X[N]}, and X[i] is a 3*4 transformation matrix. The method is mainly applied to an occasion of processing the deformation of the large action of a three-dimensional target object.

Owner:深圳市凌云视迅科技有限责任公司

Method for preparing boron-nitrogen co-doped carbon aerogel

ActiveCN107651662ALarge specific surface areaImproves ablation resistanceNanotechnologyNano-carbonFreeze-dryingSolvent

A method for preparing boron-nitrogen co-doped carbon aerogel is disclosed. According to the method, graphene, phenols, aldehydes, a catalyst, boron, amine and a solvent are used as a reaction system,and through reaction crosslinking solidification, organogel is then obtained; the organogel is dried at normal pressure to obtain organic aerogel; and finally, the organic aerogel is carbonized in inert atmosphere to obtain graphene crosslinked boron-nitrogen co-doped carbon aerogel. By the preparation technology, a complex preparation technology of a conventional supercritical or freeze drying method is avoided, and a carbon aerogel material which meets different performance requirements can be prepared by regulating addition amount of B and N elements. In addition, the method of the invention has simple process, has low equipment requirements, is environmentally friendly, can be applied in the fields of energy storage materials, lithium ion batteries, super-capacitors, electro-adsorption materials and the like, and also can realize industrial production of carbon aerogel.

Owner:BEIJING UNIV OF CHEM TECH

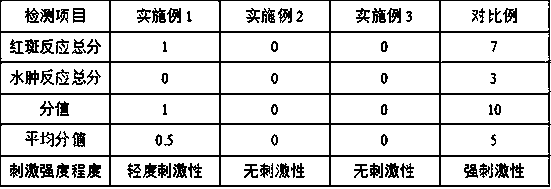

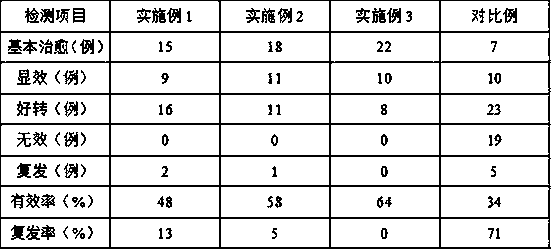

Asthma moxibustion and preparation method thereof

InactiveCN110420311ARelieve contractionIrritation reliefDevices for heating/cooling reflex pointsHydroxy compound active ingredientsArteriolar VasoconstrictionDamages tissue

The invention discloses asthma moxibustion and a preparation method thereof. The asthma moxibustion comprises a heat-generating bag, and an ointment paste, the ointment paste comprises an ointment bagand an ointment body, and the ointment body is prepared from the following components in parts by weight: 10-15 parts of sinapis alba, 10-15 parts of herba asari, 10-15 parts of ginger juice, 20-25 parts of kansui root, 10-14 parts of rhizoma corydalis, 5-10 parts of folium artemisiae argyi, 4-6 parts of pubescent holly root, 4-6 parts of Chinese pyrola herb, 20-40 parts of glycerinum, and 5-10 parts of water. The heat-generating bag can locally heat the affected area, expand capillaries, speed up blood circulation and tissue metabolism, and relieve symptoms of non-breathing; a coupling agentis used for efficiently and evenly absorbing energy by the skin and tissue, and the coupling agent has the functions of coupling, conduction and penetration; the skin and subcutaneous tissue are affected, the molecular movement in cells is intensified, metabolism is accelerated, and damaged tissue is repaired; and according to the scheme, the ointment bag can inhibit vasoconstriction and relieveasthma symptoms.

Owner:刘敏

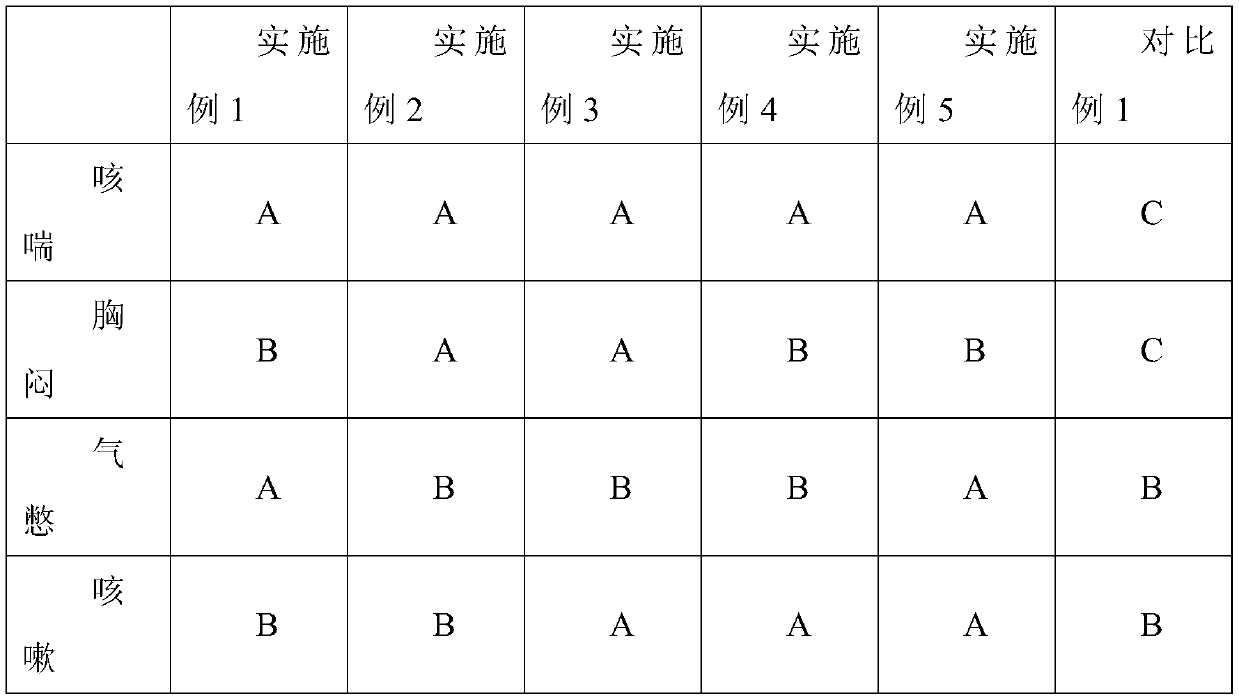

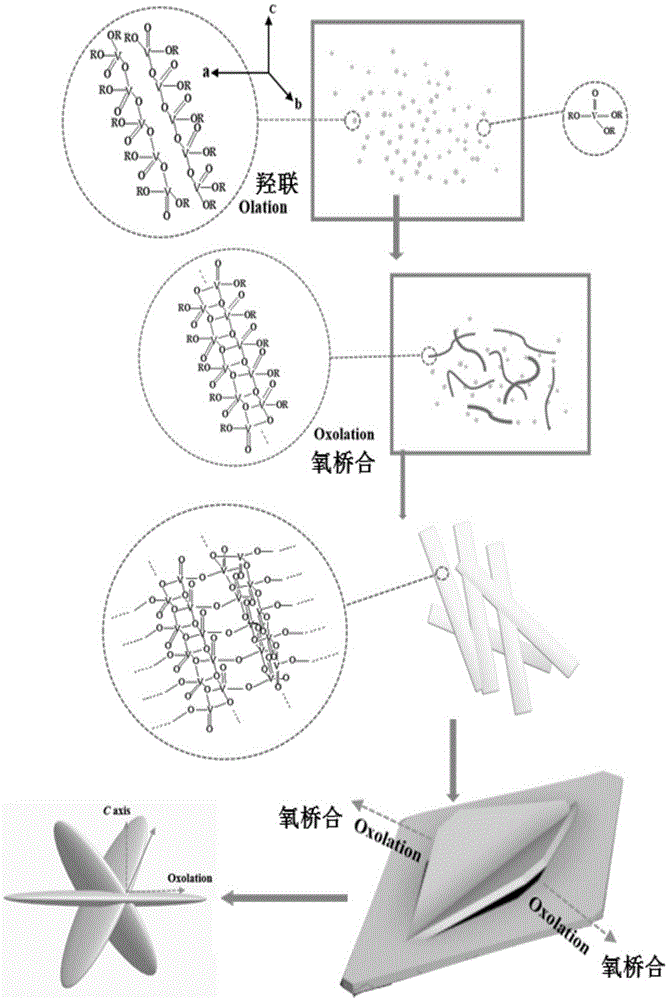

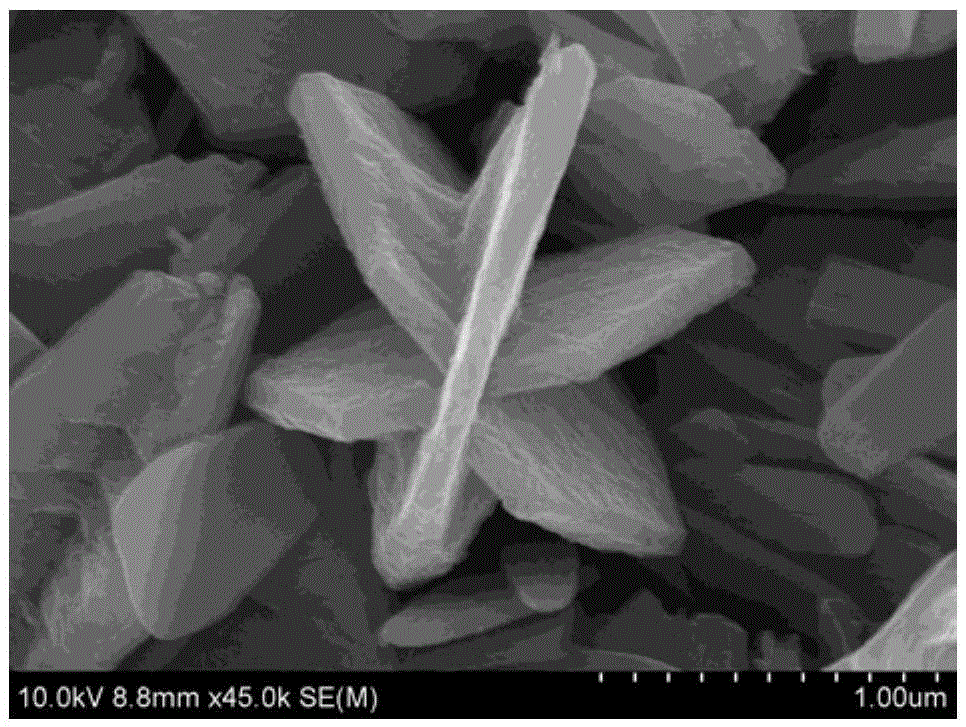

Hexagonal vanadium pentoxide nano-material as well as preparation method and application thereof

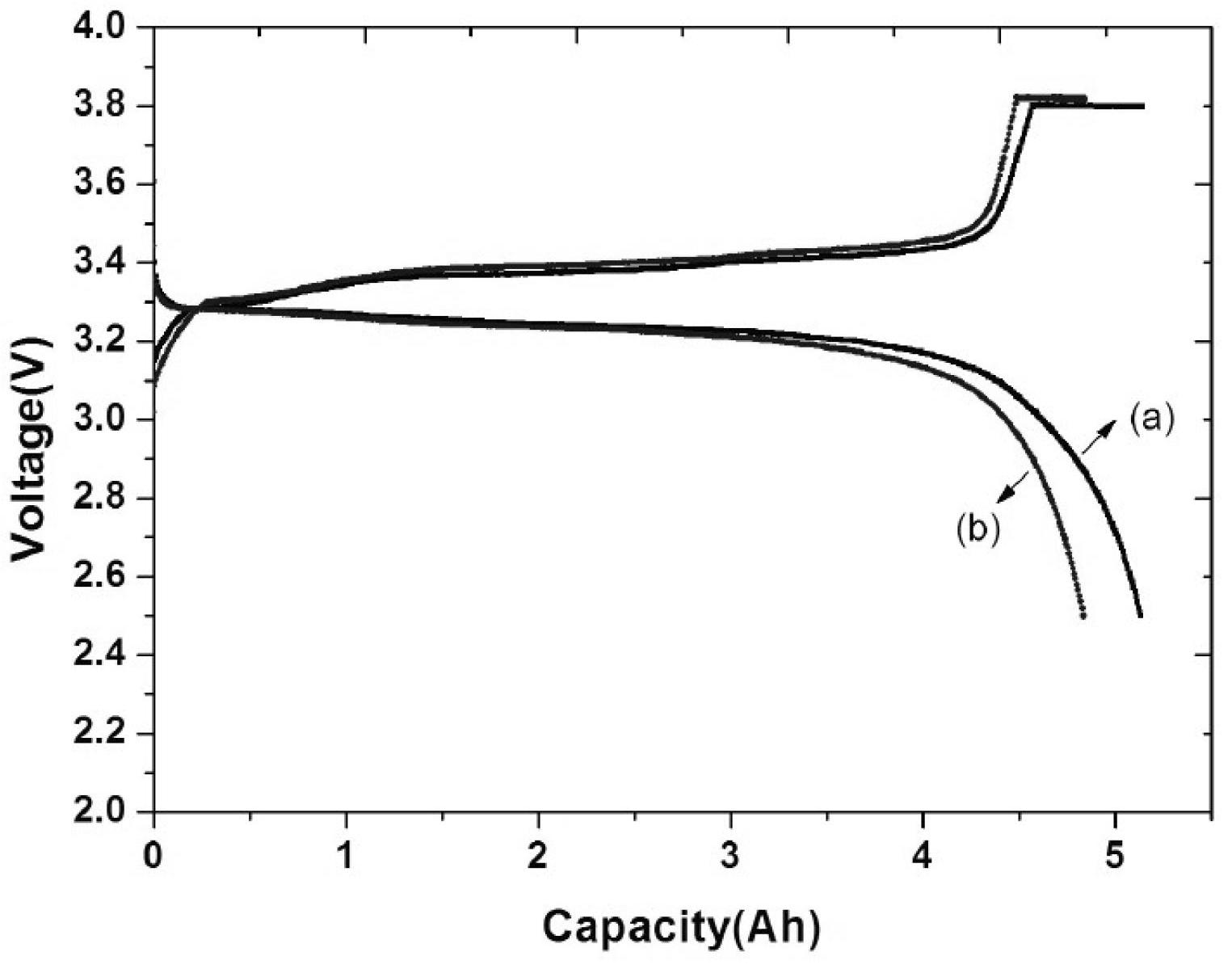

ActiveCN105384191AShorten the diffusion distanceIncrease contact areaCell electrodesNanotechnologyDistillationVanadium oxide

The present invention relates to a hexagonal vanadium pentoxide nano-material as well as a preparation method and an application thereof. The vanadium pentoxide nano-material is hexagonal, and the thickness of each angle is about 100-300 nm. The preparation method comprises the following steps: using vanadium pentoxide powder, benzyl alcohol, and isopropanol as raw materials, preparing vanadium oxide collosol through reflux condensation and distillation concentration, mixing the collosol, ethanol and deionized water to obtain a vanadium pentoxide nano-material through a hydrothermal reaction and post sintering treatment. The prepared vanadium pentoxide nano-material is extremely suitable for an anode material of lithium-ion batteries. Compared with the prior art, the nano-material has the advantages of simple process, low manufacturing costs and excellent electrochemical performance and the like.

Owner:TONGJI UNIV

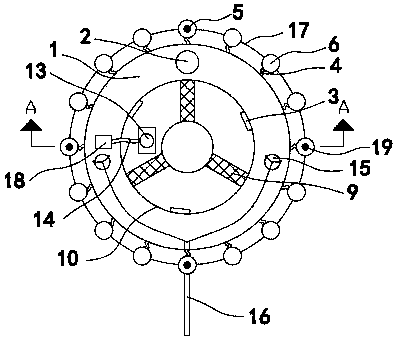

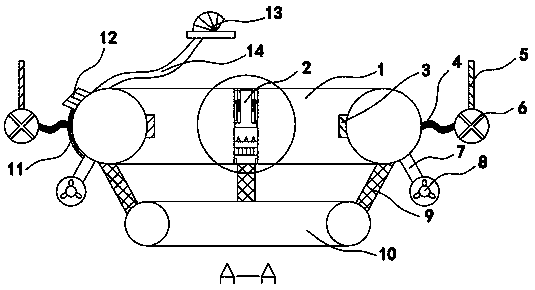

Multifunctional life buoy

InactiveCN109515647APlay the role of cushioning and shock absorptionRelieve contractionPropulsion power plantsLife-savingEngineeringBuoy

The invention discloses a multifunctional life buoy, and belongs to the technical field of a life rescue device. The multifunctional life buoy comprises a life buoy body, wherein the lower side of thelife buoy body is communicated with one end of a ventilation pipe; the other end of the ventilation pipe is connected with an air cushion; the outer ring of the life buoy body is connected with a circle of floating ball; a pressing device is arranged inside the life buoy body; the height of the pressing device is identical to the height of the life buoy body after the inflation; the upper surfaceof the life buoy body is provided with a base; the base is connected with a protection cap through a metal hose. The life buoy has the advantages that the occupied space is small; through chemical bag reaction, automatic inflation is realized; the uncomfortable symptoms of people can be relieved; the precious time can be won for the use by the self and the recue on others in emergency.

Owner:ZHEJIANG OCEAN UNIV

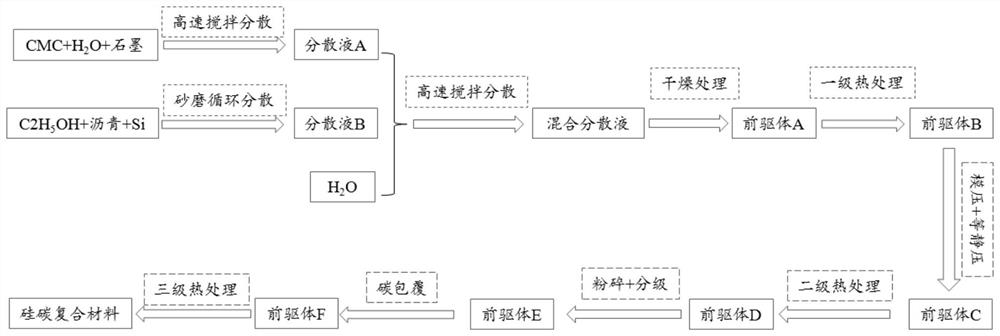

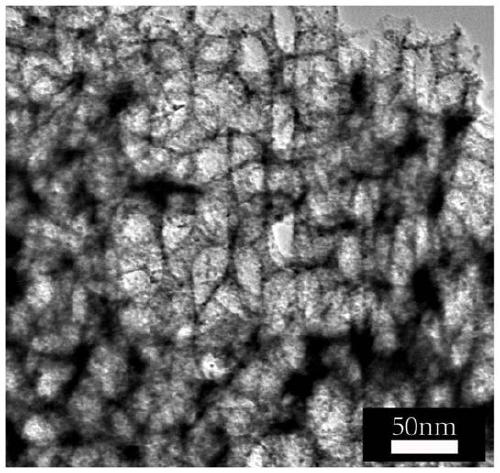

Silicon-carbon composite material, preparation method thereof and lithium ion battery

ActiveCN112310363AImprove structural stabilityIncrease energy densitySecondary cellsNegative electrodesCarbon compositesCarbon layer

The embodiment of the invention provides a silicon-carbon composite material, which comprises an inner core and a carbon layer coated on the surface of the inner core, wherein the inner core comprisesa graphite skeleton, amorphous carbon filled in the graphite skeleton structure, and a silicon material uniformly distributed in the amorphous carbon, the silicon-carbon composite material only has apore structure with a pore diameter of less than or equal to 50nm inside, and a pore structure with the pore diameter of greater than 50nm does not exist. The silicon-carbon composite material is small in internal pore size, the contact area of the silicon material and electrolyte can be effectively reduced, side reactions are reduced, and the service life of a battery is prolonged; and meanwhile, the silicon material is uniformly dispersed around the graphite skeleton without agglomeration, so that the volume expansion and shrinkage of the silicon material can be effectively relieved by thegraphite skeleton, and the structural stability and energy density of the composite material are improved. The embodiment of the invention also provides a preparation method of the silicon-carbon composite material and a lithium ion battery containing the silicon-carbon composite material.

Owner:HUAWEI TECH CO LTD

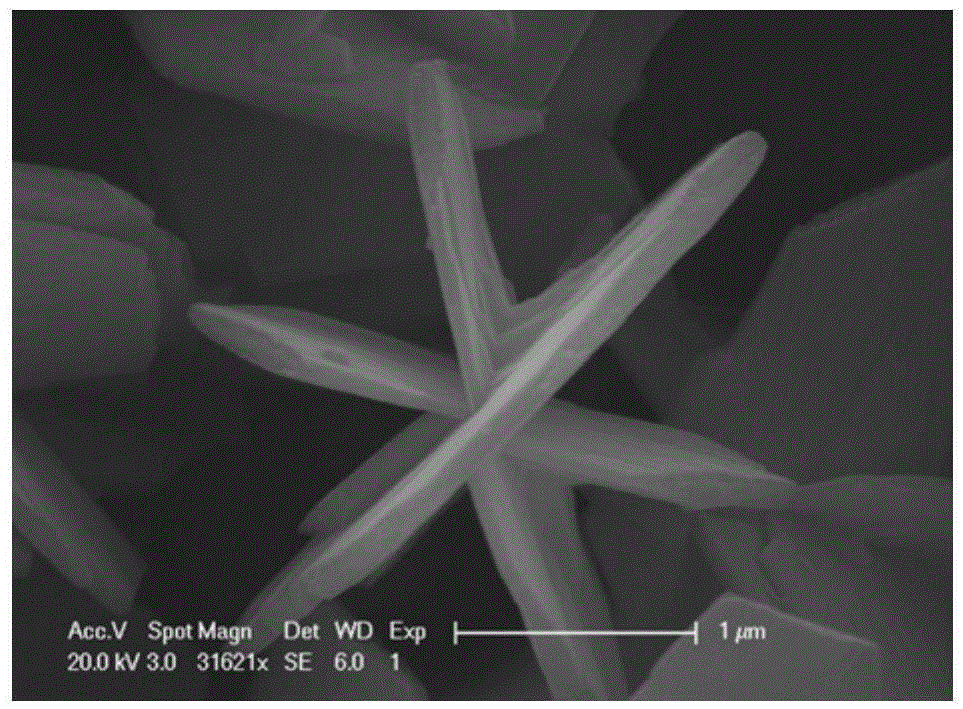

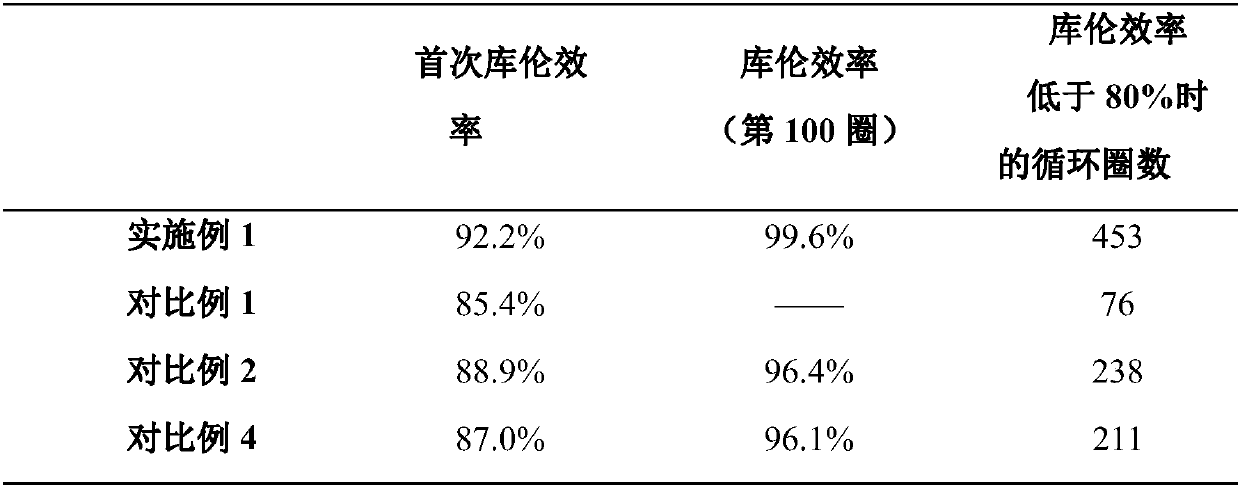

Nitrogen-doped composite planar metal lithium anode, preparation and application of nitrogen-doped composite planar metal lithium anode in lithium metal battery

ActiveCN110875467ARelieve swellingRelieve contractionMaterial nanotechnologyElectrode collector coatingMetallic lithiumLithium metal

The invention discloses preparation and application of a nitrogen-doped composite planar metal lithium anode. The nitrogen-doped composite planar metal lithium anode is composed of a flat plate current collector, nitrogen-doped hollow carbon nanocages, adhesive active layers and metal lithium, wherein the nitrogen-doped hollow carbon nanocages and the adhesive active layers uniformly cover two sides of the planar metal current collector, and metal lithium exists in the nitrogen-doped hollow carbon nanocages. The nitrogen-doped composite planar metal lithium anode has the advantages that the existence of the hollow carbon nanocages with high specific surface area effectively reduces the overpotential in during the nucleation and deposition of lithium metal, and the doping of nitrogen atomsprovides uniform nucleation and deposition sites, so that the lithium metal intends to grow into the hollow carbon nanocages, thereby achieving uniform deposition and dissolution in the continuous cycle process of the lithium metal. In addition, the ultrathin carbon wall effectively prevents the interface reaction from happening, and the cycle life of the lithium metal battery is greatly prolonged.

Owner:CENT SOUTH UNIV

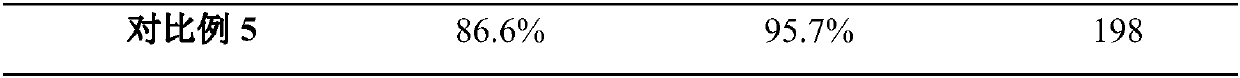

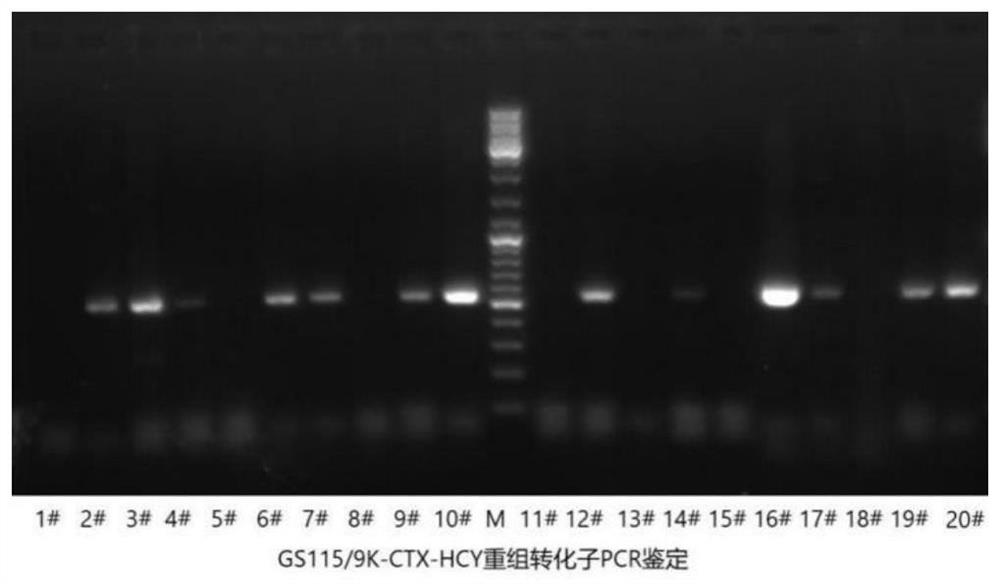

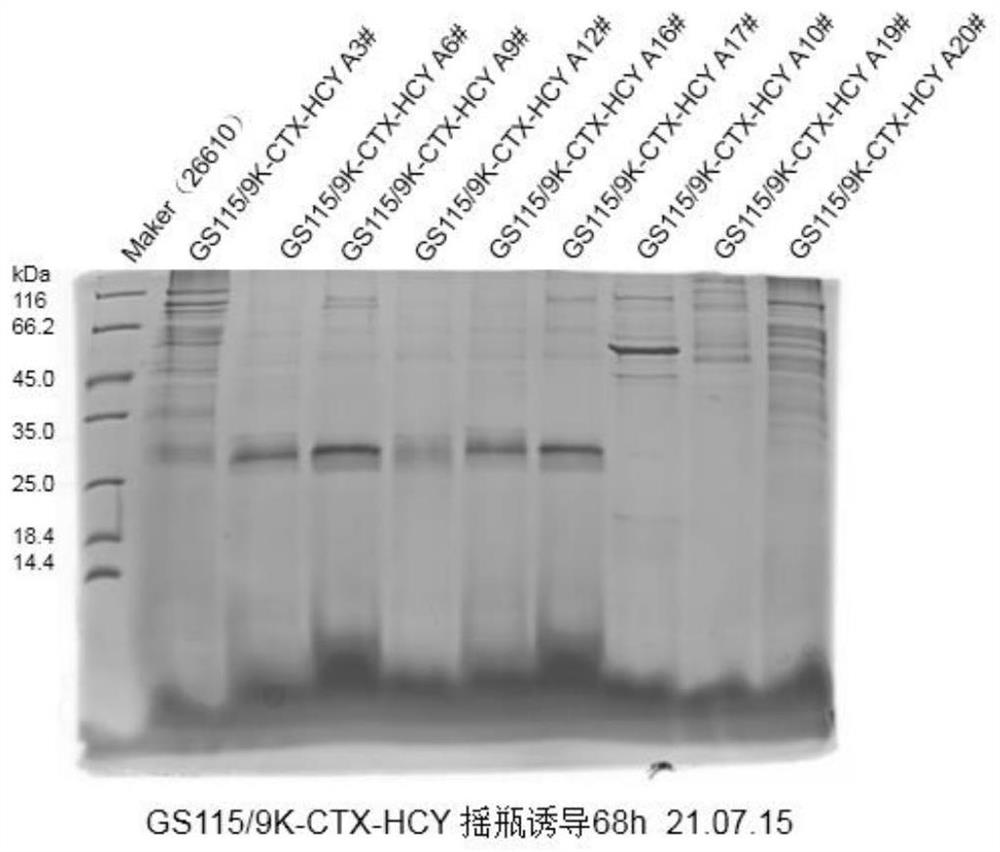

Conotoxin and collagen fusion protein as well as preparation method and application thereof

PendingCN114106202ALow cytotoxicityPromote transdermal absorptionCosmetic preparationsConnective tissue peptidesConotoxinCollagenan

The invention discloses conotoxin and collagen fusion protein as well as a preparation method and application thereof, and relates to the technical field of biological genes. The amino acid sequence of the fusion protein is as shown in SEQ. ID. No.5. The fusion protein disclosed by the invention is proved to be capable of effectively reducing the cytotoxicity of the conotoxin and improving the biological safety of raw materials on the premise of not influencing the effect of the conotoxin by collagen fusion; meanwhile, transdermal peptide is added during molecular design, the wrinkle removing and moisturizing capacities are verified by efficacy, and it is proved that the transdermal absorption capacity of fusion protein can be effectively improved by adding the transdermal peptide, and transdermal absorption of conotoxin is promoted.

Owner:西安德诺海思医疗科技有限公司

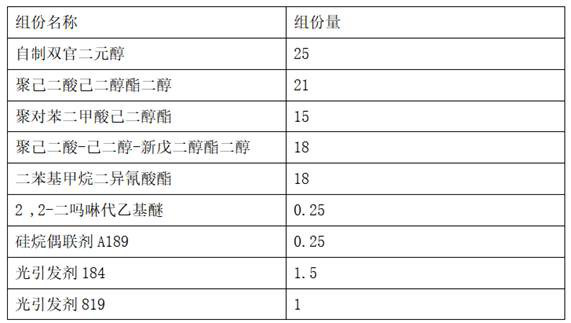

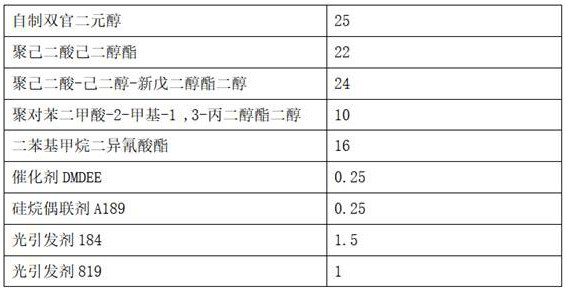

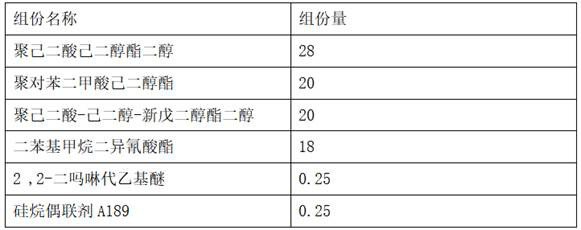

Quick-positioning low-shrinkage UV moisture dual-curing polyurethane hot melt adhesive and preparation method thereof

ActiveCN114774066AGood flexibilityRelieve contractionPolyureas/polyurethane adhesivesPhotovoltaic energy generationPolyesterPolymer science

The invention provides a fast-positioning low-shrinkage UV moisture dual-curing polyurethane hot melt adhesive and a preparation method thereof, and relates to the field of adhesives, flexible polyurethane modified dihydric alcohol with acrylate double bonds is prepared, the double bonds capable of being subjected to free radical photopolymerization are introduced into a polyurethane prepolymer, and UV illumination is carried out to obtain the fast-positioning low-shrinkage UV moisture dual-curing polyurethane hot melt adhesive. The prepolymer side chain with double bonds can be subjected to free radical photopolymerization to form a certain degree of crosslinking, so that the cohesion of the colloid is rapidly improved, the rapid positioning effect is achieved, and the main chain segment reaches the final strength through later moisture curing. In addition, the polyurethane modified polyether glycol is good in molecular chain flexibility and high in molecular adjustable degree, the flexible long chain can relieve shrinkage caused by colloidal crystallization formed by main chain crystalline polyester polyol, the cohesion strength of the colloid is guaranteed, the impact resistance of the colloid is improved, and the polyurethane modified polyether glycol has a great application prospect in the aspect of intelligent wearing.

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

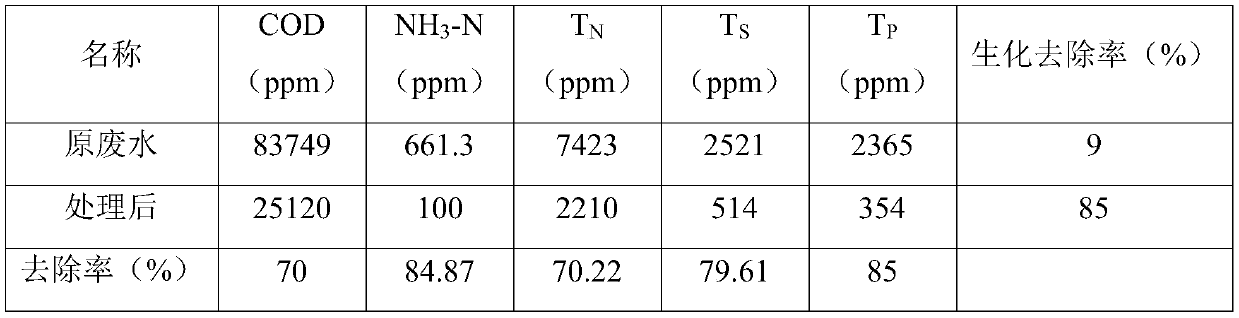

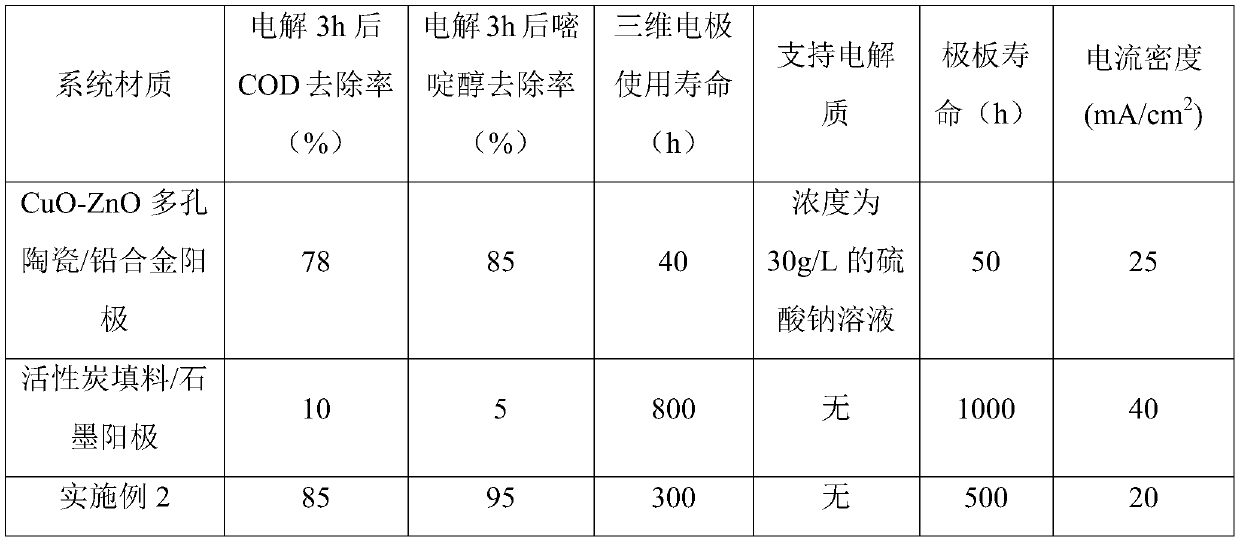

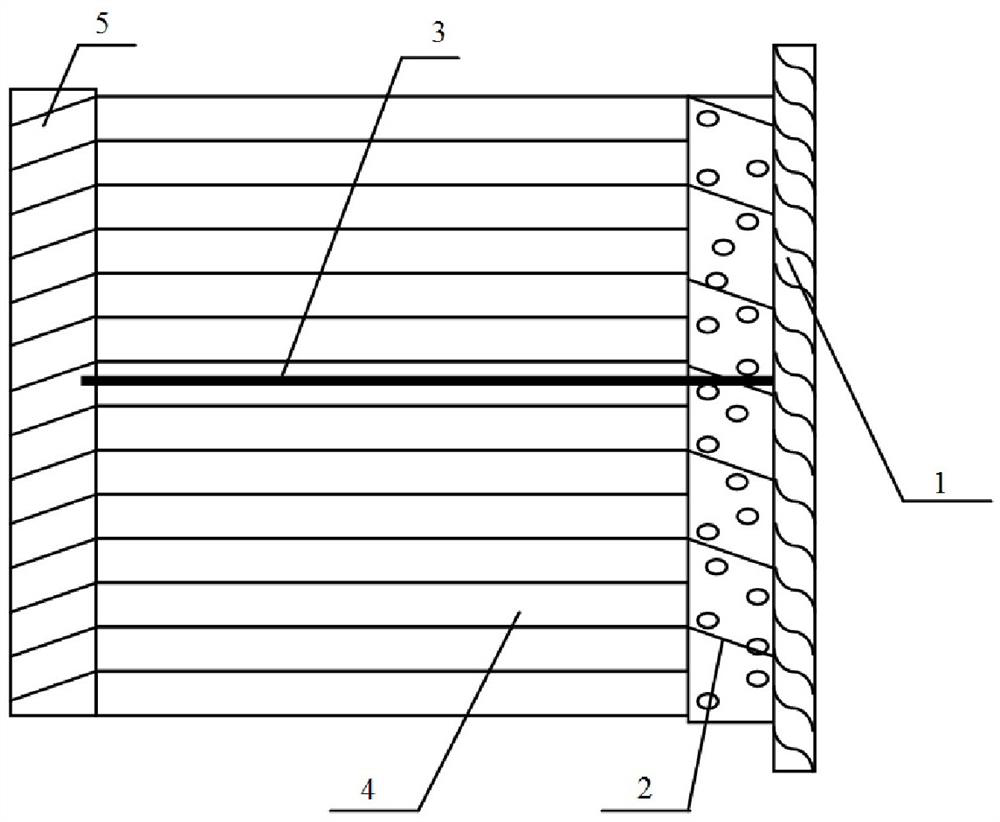

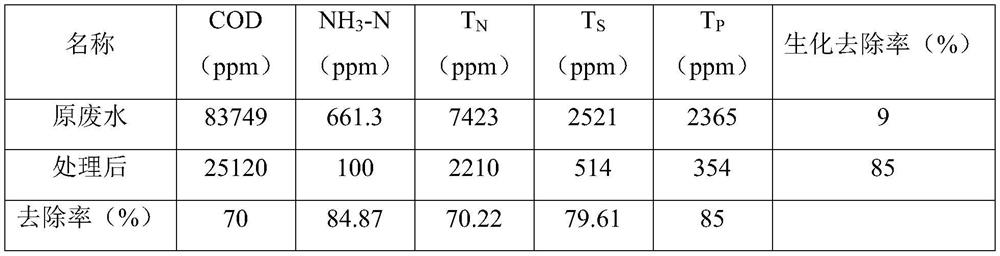

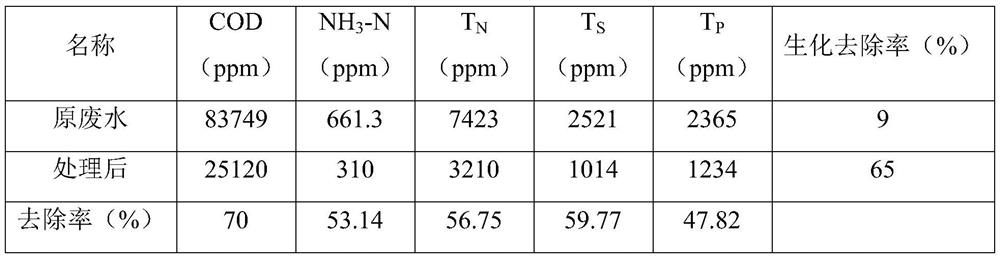

Electrocatalytic oxidation filler, preparation method thereof and three-dimensional electrocatalytic oxidation device

ActiveCN110734114AHigh catalytic activityImprove conductivityWater treatment parameter controlNature of treatment waterSupporting electrolyteClay minerals

The invention discloses an electrocatalytic oxidation filler, a preparation method thereof and a three-dimensional electrocatalytic oxidation device. The electrocatalytic oxidation filler is preparedby mixing a mixture of clay minerals and a curing agent and a mixed solution of Cu < 2 + > / Mn < 2 + > and roasting. The three-dimensional electrocatalytic oxidation device comprises an anode, a cathode and an electrocatalytic oxidation filler filled between the anode and the cathode. The electrocatalytic oxidation filler provided by the invention has the advantages of good conductivity, low energyconsumption, high stability, strong catalytic activity, no need of supporting electrolyte and the like, is widely applied to treatment of industrial wastewater as a filler of a three-dimensional electrocatalytic oxidation device, can realize effective removal of organic pollutants in the wastewater, and has relatively high use value and relatively good application prospect. The preparation methodof the filler has the advantages of being simple in process, convenient to operate, easy to control, low in raw material cost, low in energy consumption, short in consumed time, environmentally friendly and the like, is suitable for continuous large-scale batch production, facilitates industrial utilization and shows a good application prospect.

Owner:湖南海利常德农药化工有限公司

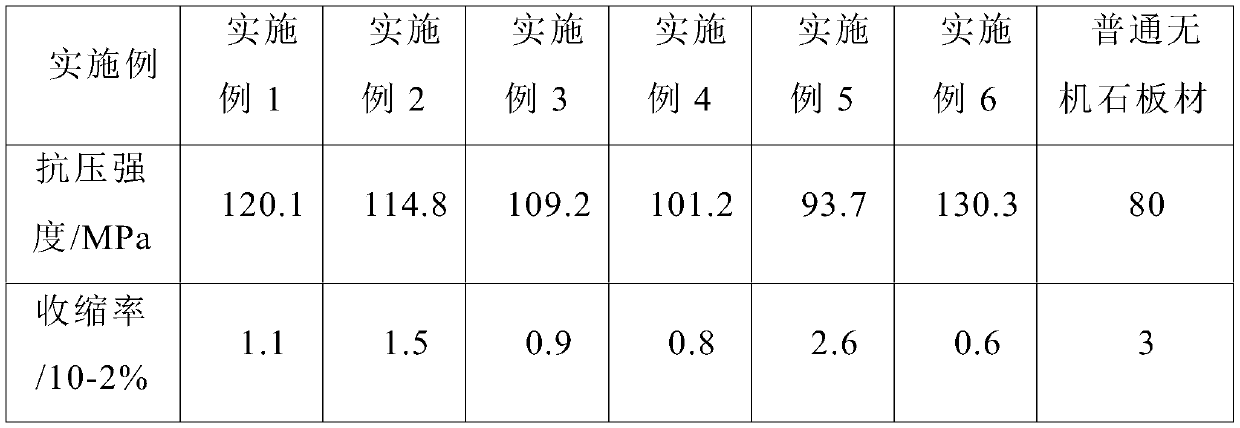

Formula and preparation method for low-shrinkage artificial inorganic stone

The invention discloses a formula and preparation method for low-shrinkage artificial inorganic stone. The inorganic stone comprises the following components in parts by weight: 20-40 parts of an inorganic cementing material, 2-10 parts of an inorganic mineral admixture, 30-80 parts of quartz sand, 6-15 parts of an expanding agent, 1-5 parts of a shrinkage reducing agent, 0.5-4 parts of a water reducing agent, 1-3 parts of an internal curing agent and 1-5 parts of chopped fibers. By adding various raw materials, the shrinkage of the inorganic stone is reduced, so the risk of cracking is lowered; the expanding agent undergoes a chemical reaction in the hydration process to generate a hydration product, so volume expansion is generated and compensates for the shrinkage of the inorganic stone; the shrinkage reducing agent reduces the surface tension of a mesoporous solution in the inorganic stone, so tension on a capillary pore wall in water loss process is reduced, and the shrinkage of the inorganic stone is reduced; the internal curing agent is added, so water required by the cement in hydration process is supplemented and self-shrinkage in water migration process is reduced; and the breaking strength of the inorganic stone is improved through the chopped fibers, so the low shrinkage performance of the artificial inorganic stone is achieved, and the artificial inorganic stone issuitable for being widely used and popularized.

Owner:四川力达建材科技有限公司

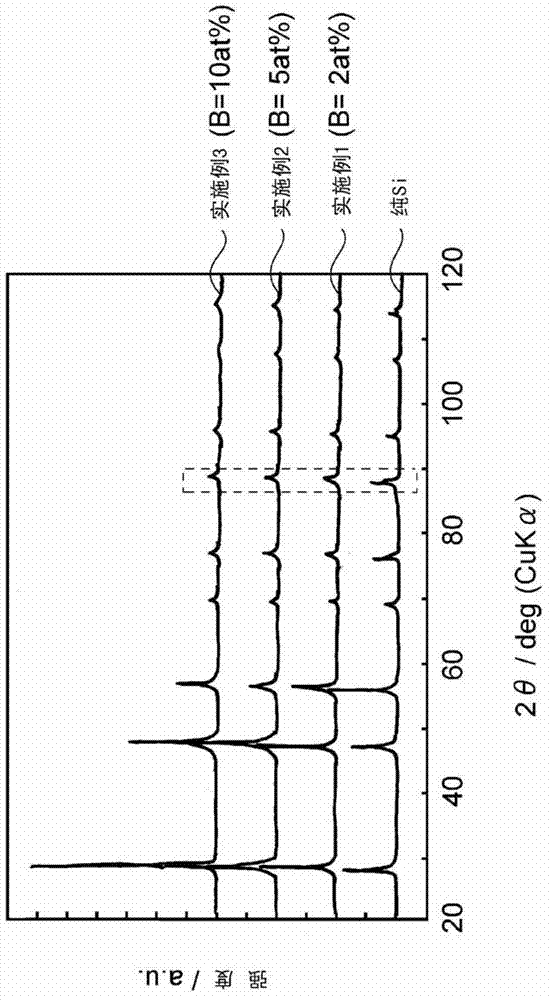

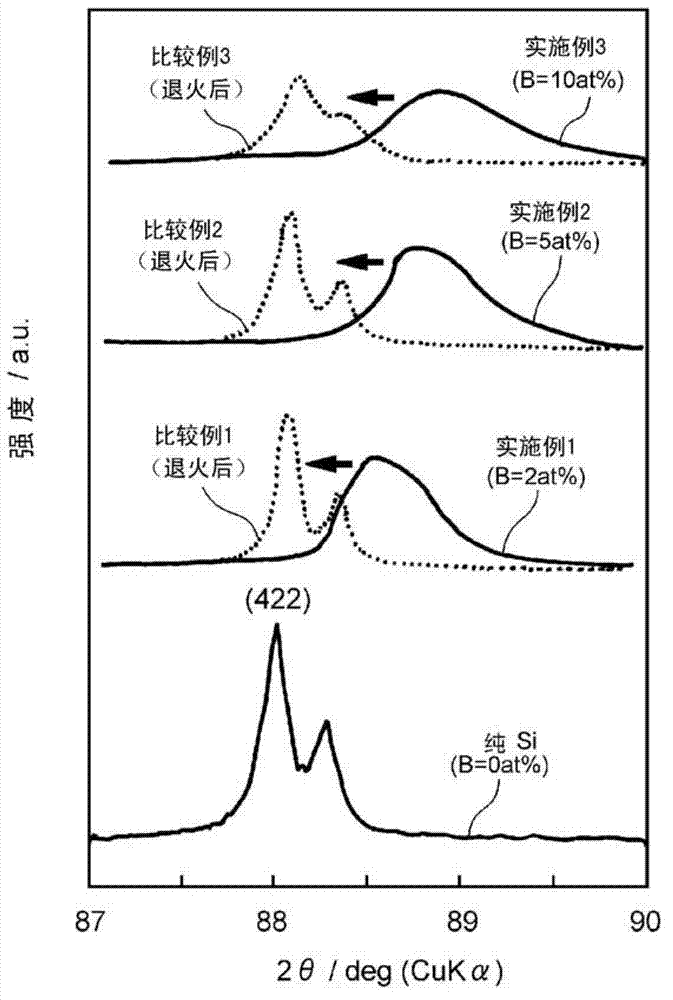

Negative electrode active material for nonaqueous electrolyte secondary battery

ActiveCN102782907ARelieve swellingImprove electronic conductivityCell electrodesLi-accumulatorsSolid solutionSilicon

A negative electrode active material for a nonaqueous electrolyte secondary battery, comprising a silicon solid solution in which one or more members selected from among a semimetal element or a metal element of group 3, a semimetal element or a metal element of group 4 (excluding silicon) and a nonmetal or semimetal element of group 5 are solid-solubilized in silicon. Relative to the position of the diffraction peak in XRD assignable to face (422) of silicon, the position of the diffraction peak in XRD of said solid solution, which corresponds to the aforesaid peak, shifts by 0.1-1 DEG toward the low angle or high angle side. The lattice distortion of said solid solution measured by XRD is 0.01-1%.

Owner:MITSUI MINING & SMELTING CO LTD

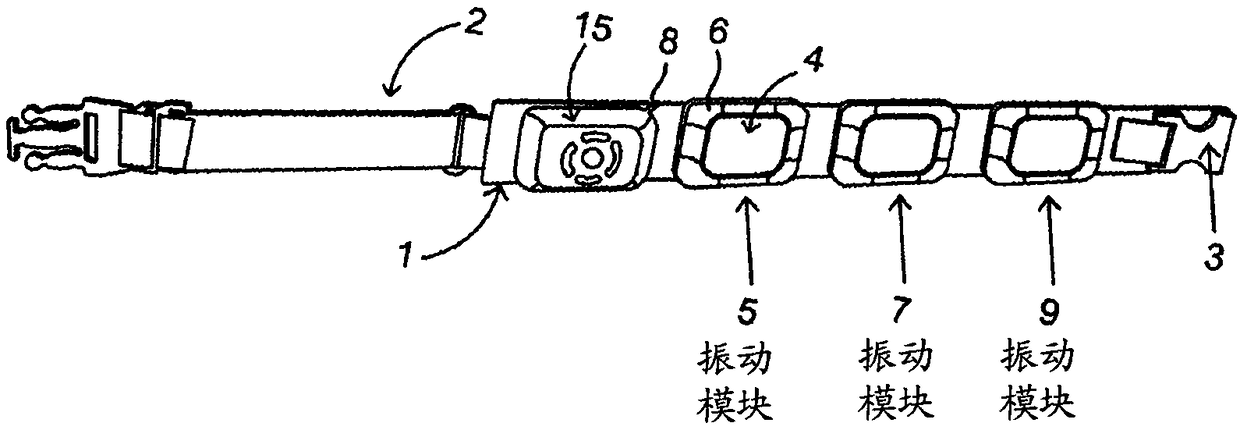

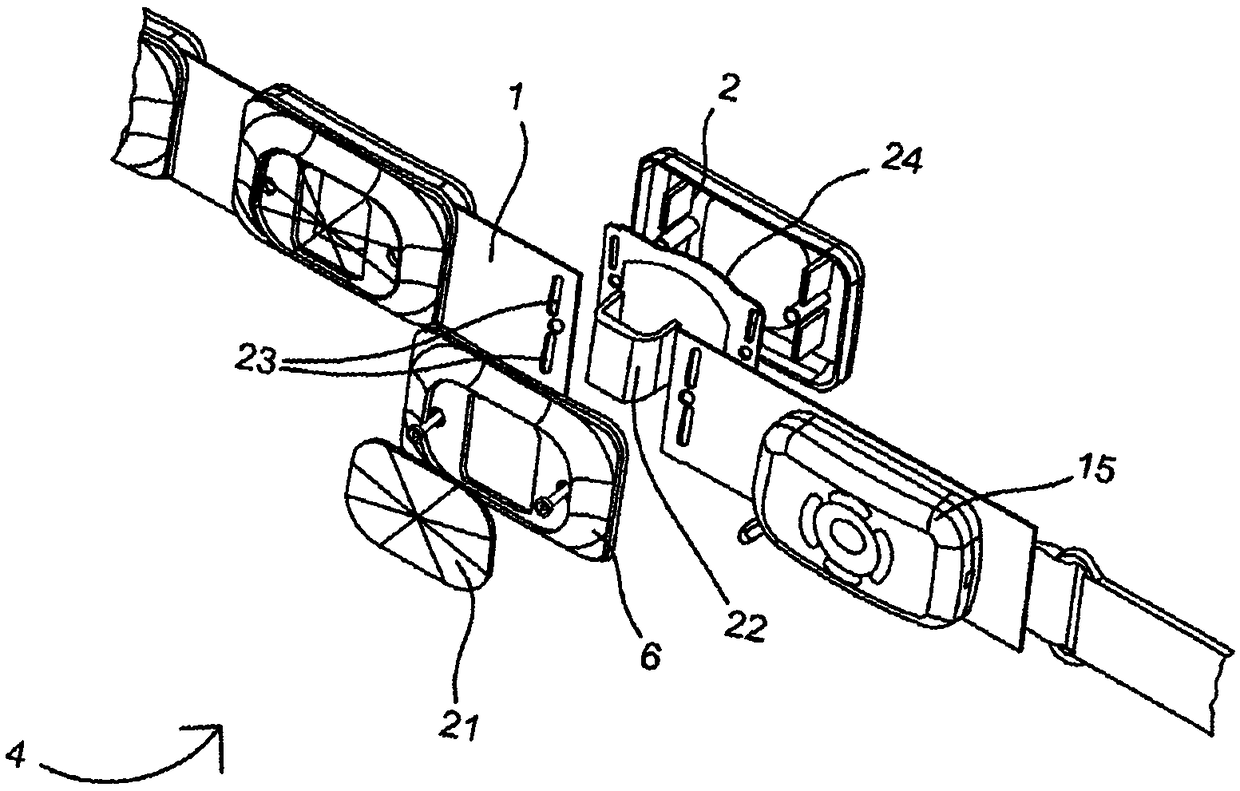

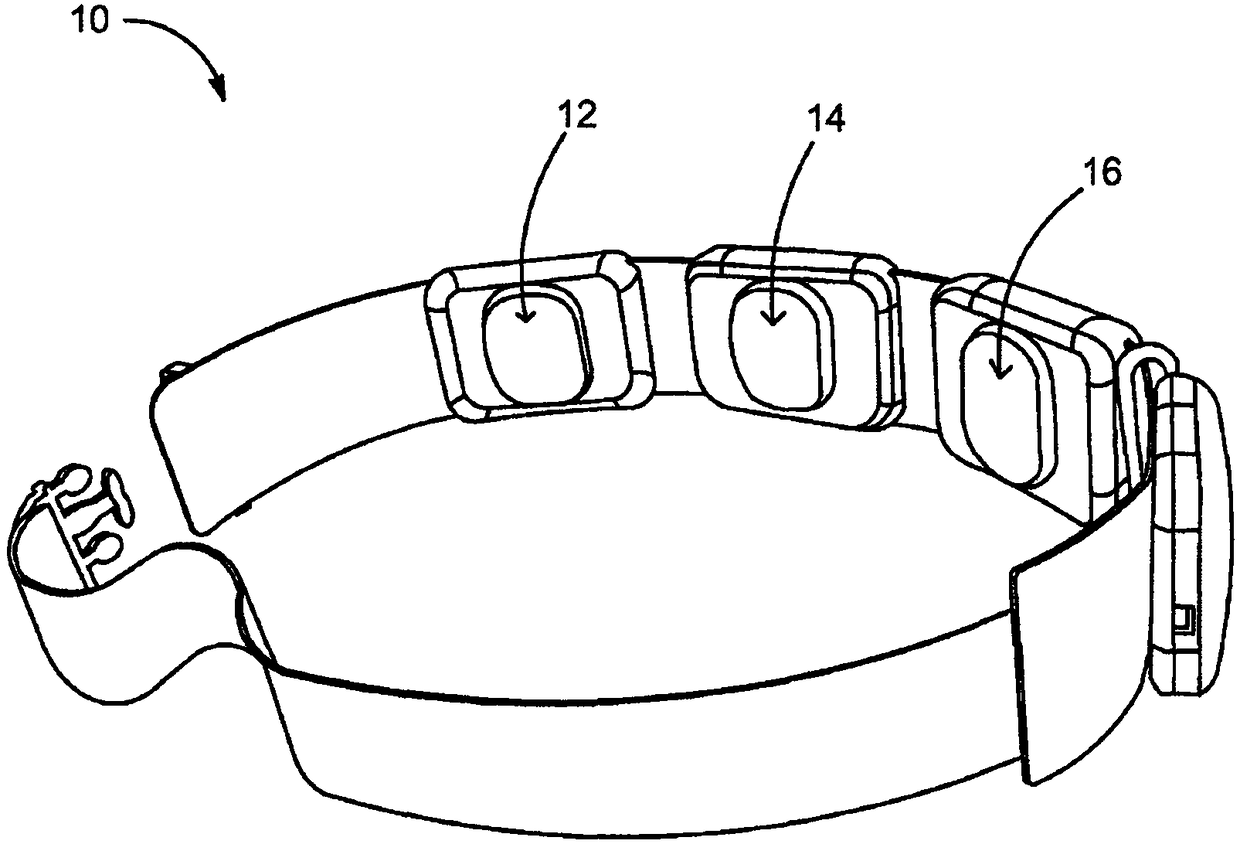

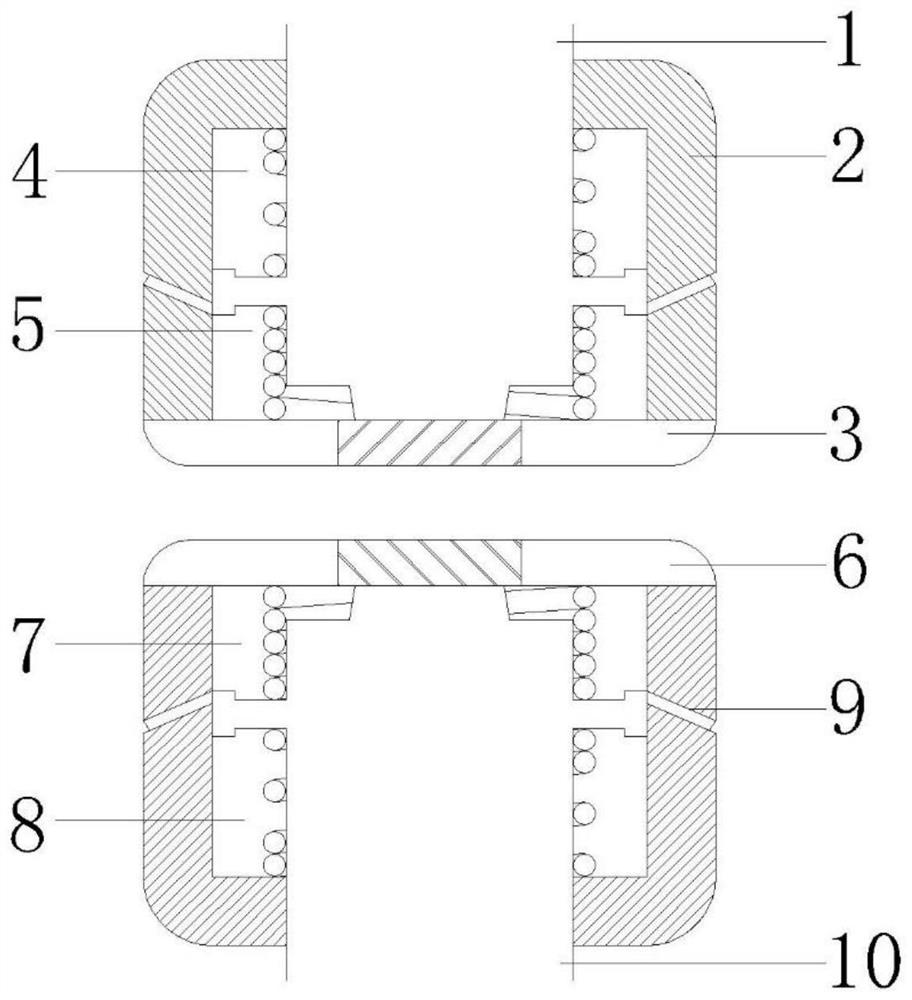

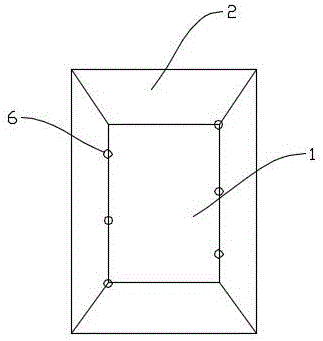

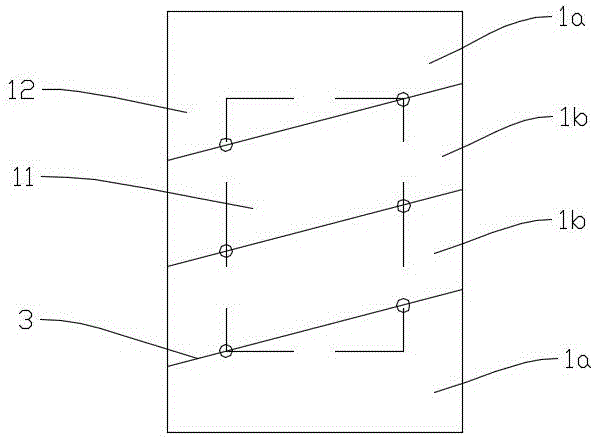

Stimulating device

ActiveCN109414369AIncrease mobilityEasy to relaxMassage combsMassage beltsPhysical medicine and rehabilitationElectric machinery

The invention discloses a stimulation device comprising: a belt (10) containing at least two vibration modules (5, 7, 9), wherein each of the at least two vibration modules (5, 7, 9) comprises: a pod(4) with a casing (6, 26) and a vibration pad (24) arranged within the casing (6, 26), and a vibration motor (20) with a flywheel (28) within the casing (6, 26), a control panel (15) operating said vibration motors (20) of the at least two vibration modules (5, 7, 9); wherein the vibration motor (20) is mounted to the vibration pad (24) via at least one elastic motor housing (22). The invention further discloses the use of such a device for treating hypoventilation and respiratory depression and a method of treating hypoventilation and respiratory depression by fastening a belt (10) to the abdomen of a user and operating the belt (10), wherein the at least two vibration modules are externally applied to an abdominal region of a user to stimulate the diaphragm, to enhance pulmonary function.

Owner:萨蒂纳医疗有限责任公司

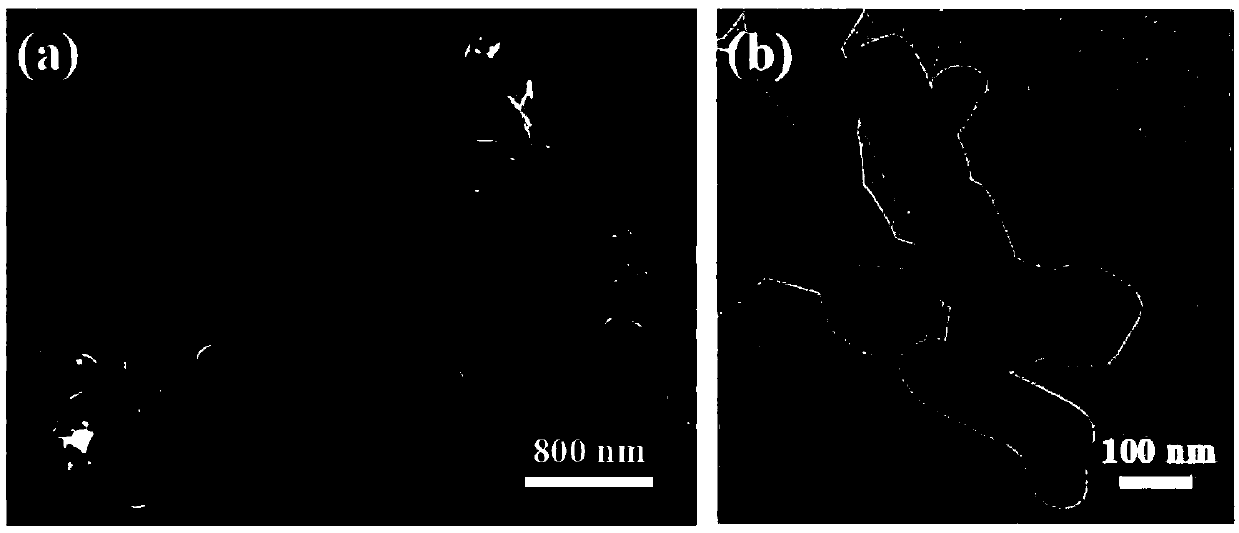

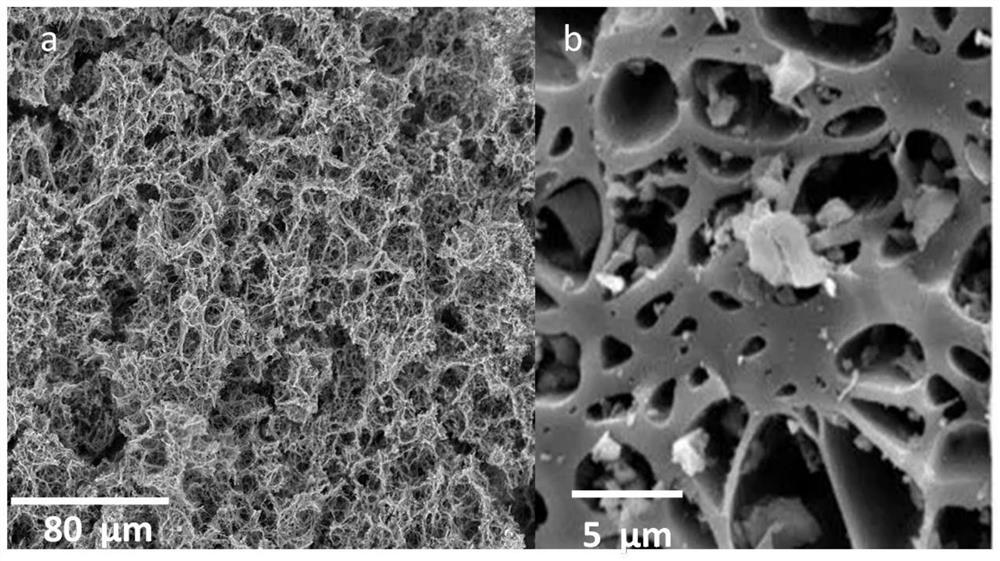

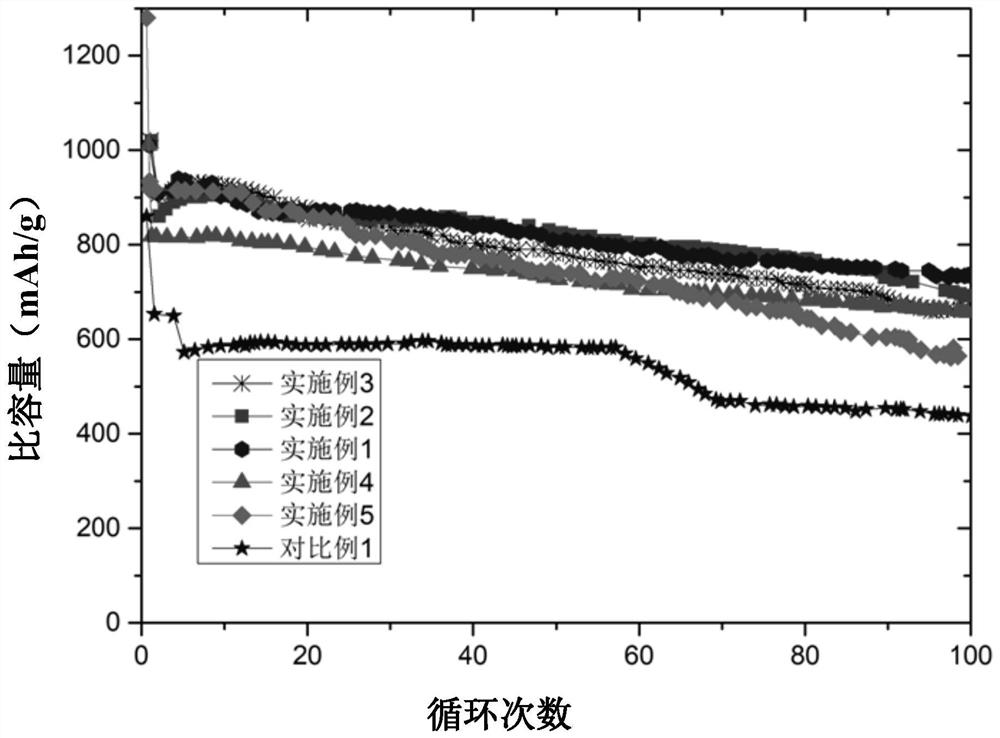

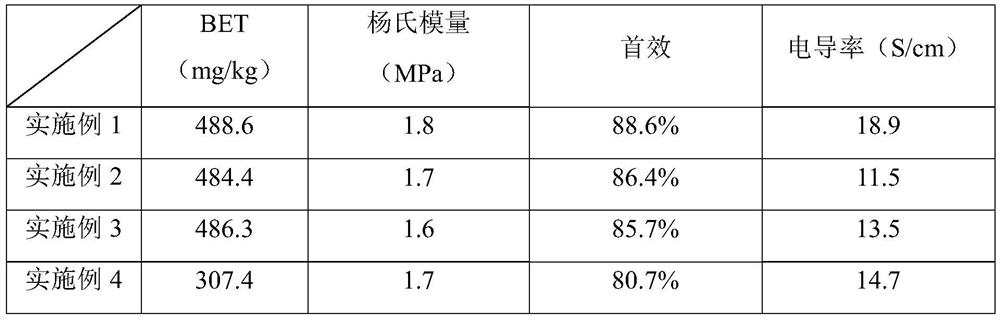

Preparation method of composite nano silicon negative electrode material based on conductive carbon aerogel and product thereof

ActiveCN112635731AImprove mechanical propertiesRelieve contractionCell electrodesSecondary cells servicing/maintenanceNano siliconFiber

The invention discloses a preparation method of a composite nano silicon negative electrode material based on conductive carbon aerogel and a product thereof, and the preparation method comprises the following steps of: (1) dissolving pretreated waste biomass and a fiber additive in an aqueous solution of an alkaline substance together, and performing stirring to obtain reticular solid gel; (2) drying the reticular solid gel, and performing screening to obtain a carbon aerogel precursor; (3) taking a gaseous silicon source and the carbon aerogel precursor as raw materials, and carrying out a chemical vapor deposition process to prepare a compound of carbon aerogel and nano silicon; and (4) blending the compound of the carbon aerogel and the nano silicon with a carbon source, and conducting heating and carbonizing to obtain the composite nano silicon negative electrode material based on the conductive carbon aerogel. According to the preparation method disclosed by the invention, the waste biomass is used as the raw material, the cost is low, the prepared negative electrode material is high in strength and good in conductivity, and the assembled battery has a relatively high first effect.

Owner:云南锂宸新材料科技有限公司

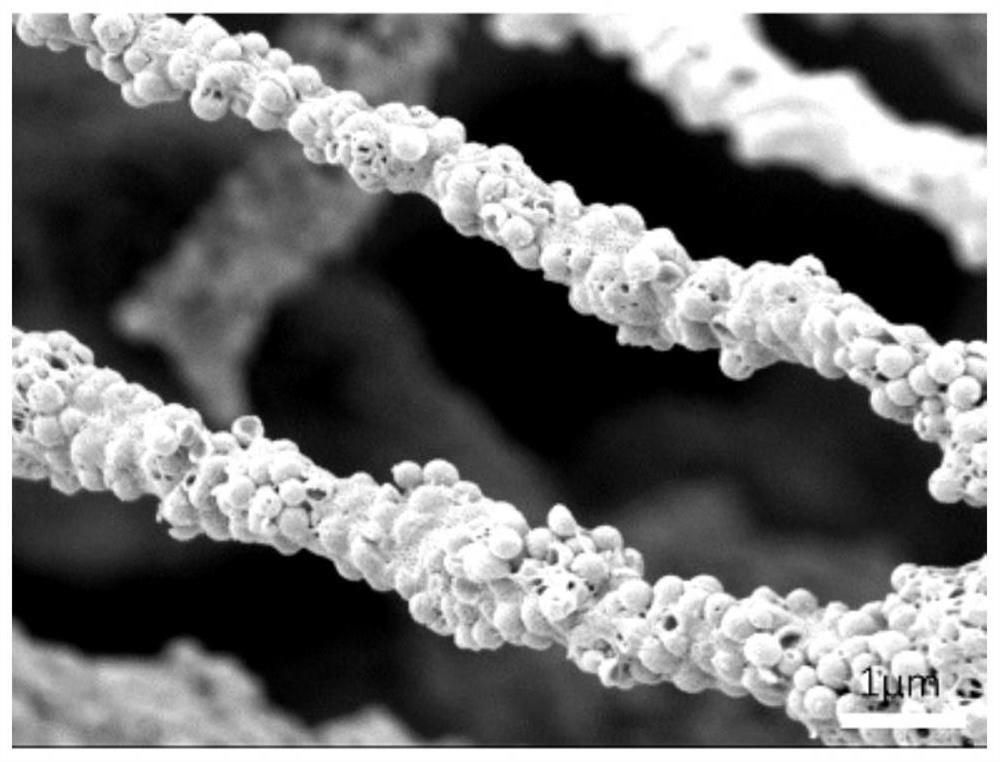

Preparation method of flexible spinning hollow carbon self-supporting electrode

PendingCN114388788AHigh controllability of operation stepsIncrease transfer rateCell electrodesElectrospinningElectrically conductive

The invention discloses a preparation method of a flexible spinning hollow carbon self-supporting electrode, which comprises the following steps: carbonizing phenolic resin at high temperature to obtain solid carbon spheres, etching with hydrofluoric acid to obtain hollow carbon spheres, uniformly mixing the hollow carbon spheres with polyacrylonitrile, obtaining a flexible spinning composite material through an electrostatic spinning technology, and finally, preparing the flexible spinning hollow carbon self-supporting electrode. The flexible spinning composite material is subjected to pre-oxidation and high-temperature carbonization to obtain the flexible self-supporting electrode. The prepared flexible spinning composite material is mainly formed by compounding hollow carbon spheres and polyacrylonitrile, the pore size distribution and the specific surface area of the flexible spinning composite material can be effectively changed by controlling the proportion of the hollow carbon spheres, and then the electrochemical performance of the flexible spinning composite material is regulated and controlled; meanwhile, polyacrylonitrile can provide a good three-dimensional flexible conductive framework after high-temperature carbonization, so that the conductivity is improved, the cycling stability of the self-supporting electrode is improved, and the volume expansion and shrinkage performance of the self-supporting electrode in the ion transmission process is relieved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

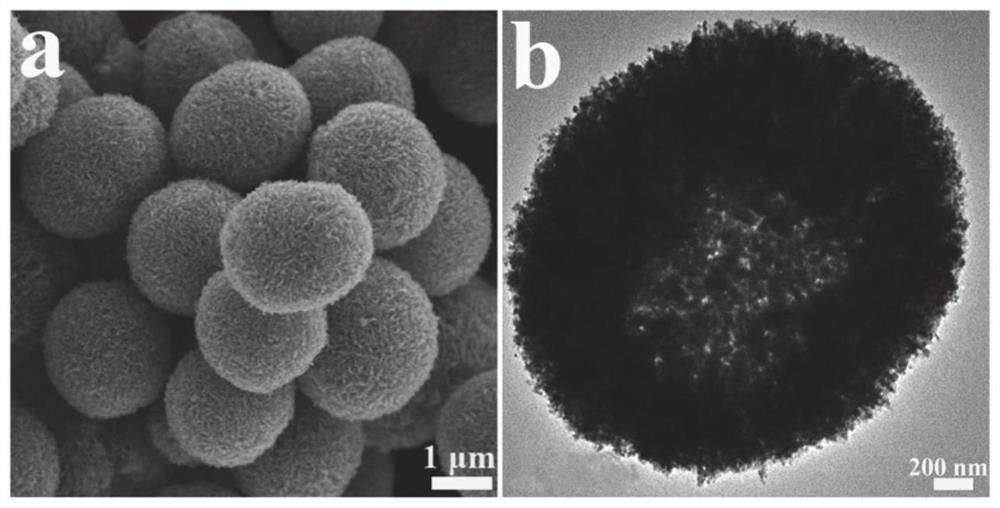

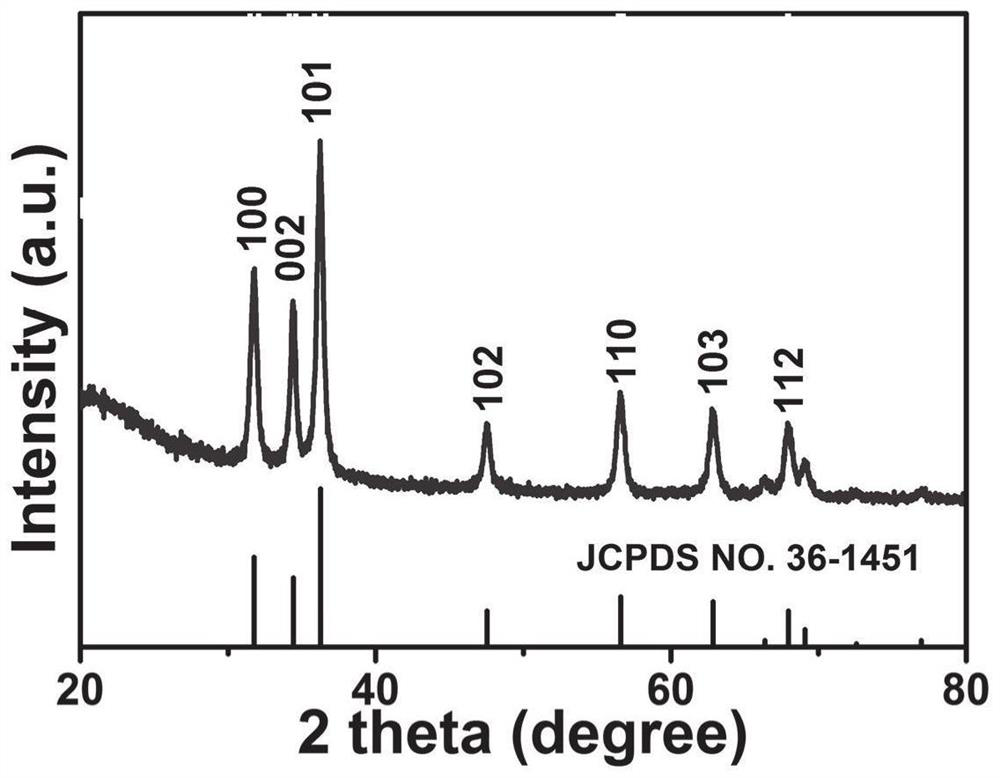

Zinc oxide microsphere, electrode and preparation method thereof

ActiveCN113135586AEasy to prepareIncrease contact areaZinc oxides/hydroxidesCell electrodesGlyceric acidElectrical battery

The invention discloses a zinc oxide microsphere, an electrode and a preparation method thereof, and the preparation method of the zinc oxide microsphere comprises the following steps: 1) preparing a mixed solution; 2) reacting the mixed solution to prepare zinc-based glycerate; and 3) calcining the zinc-based glycerate to prepare zinc oxide microspheres. The zinc oxide microspheres which are controllable in size, controllable in internal structure and uniform in size are prepared through a simple solvothermal method by utilizing the reaction of the zinc salt, the glycerol and the isopropanol which are low in price. When the zinc oxide microsphere is used as a lithium ion battery negative electrode material, an electrochemical test result shows that the zinc oxide microsphere has high specific discharge capacity and excellent cycle performance. According to the method, expansion and shrinkage of zinc oxide in the charging and discharging process are effectively relieved, the problem of capacity fading caused by the volume effect can be effectively solved, and good cycle performance is achieved.

Owner:INNER MONGOLIA UNIVERSITY

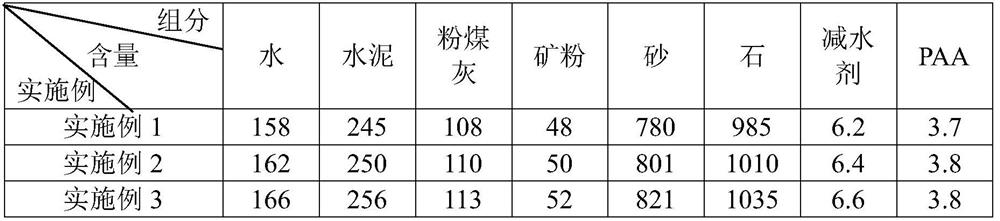

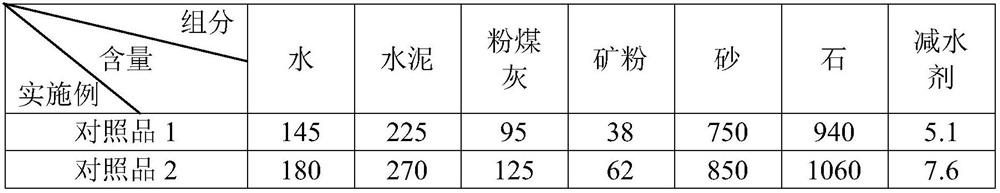

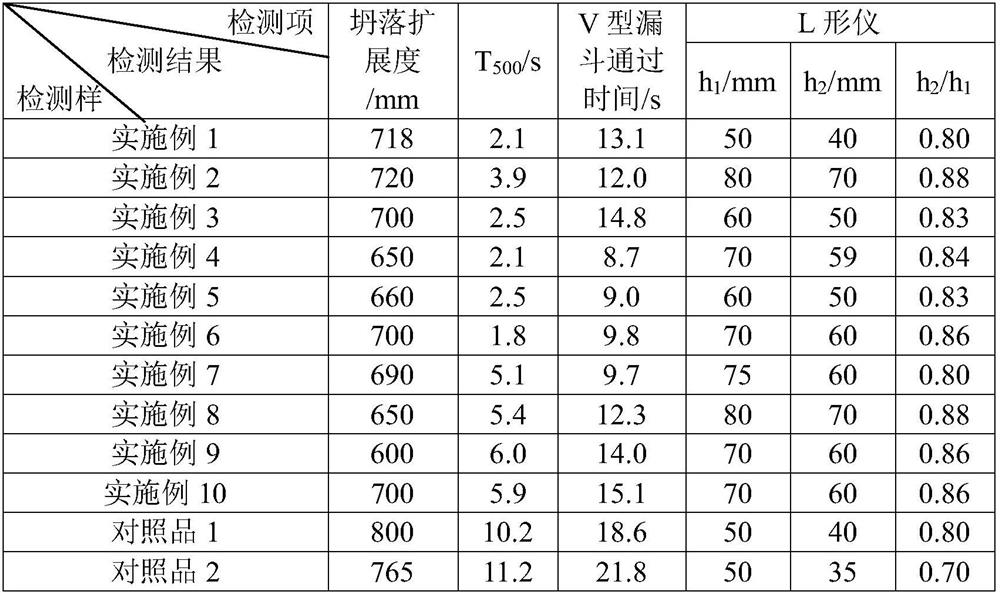

A kind of self-compacting concrete and preparation method thereof

Owner:北京城建银龙混凝土有限公司

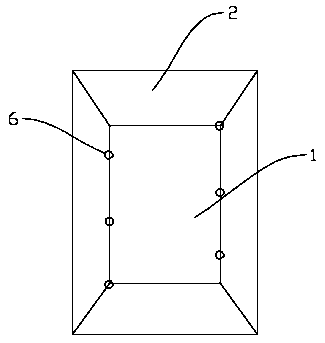

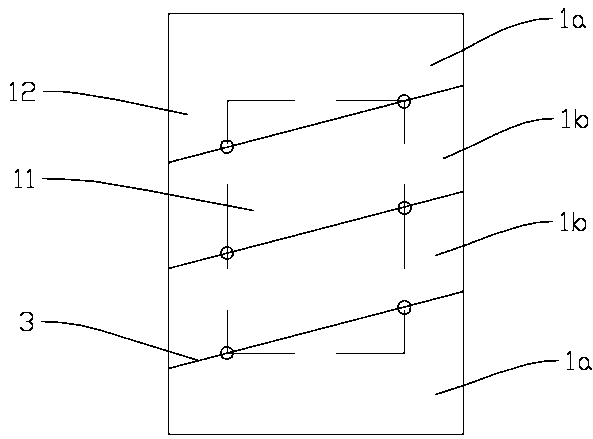

wooden door leaf

The invention discloses a wooden door leaf, which comprises a pool plate and a side frame. The pool plate is spliced by a plurality of auxiliary plates, and the auxiliary plate includes a base plate in the shape of a right-angled trapezoid and a group plate in the shape of a parallelogram. The base plate and the set plate are spliced into a rectangular pool plate, the base plate and the set plate or the set plate and the set plate are connected to form a splicing seam, and the base plate and the set plate or the set plate and the set plate on the upper and lower sides of the splicing seam A drying tank is set between the panels, the drying tank is hidden inside the pool plate, and a desiccant is arranged in the drying tank; the splicing seam is arranged obliquely, and the first and last ends of the splicing seam are arranged There is a threaded hole, the threaded hole runs through to the drying tank, the threaded hole is arranged on both sides of the drying tank, a metal ring is arranged in the threaded hole, and a plug is arranged in the metal ring. The wooden door leaf provided by the invention has the characteristics of good moisture-proof effect, small deformation and long service life.

Owner:浙江林昌木业有限公司

Steel ladle furnace lining

In order to solve the problems that a steel ladle is large in weight, short in service life, frequent in maintenance and the like, the invention provides a steel ladle furnace lining which mainly comprises a heat preservation layer, a permanent layer and a working layer which are sequentially distributed from outside to inside. An anchoring part is further fixedly connected to the inner wall of a steel ladle shell, one end of the anchoring part is fixedly connected with the steel ladle, the other end of the anchoring part sequentially penetrates through the heat preservation layer and the permanent layer to be located in the working layer, the heat preservation layer is made of a composite silicate heat preservation material, and the working layer is made of a ceramic fiber high-temperature fireproof coating. The overall structure is light in weight, the heat preservation effect is good, thermal shock resistance is achieved, erosion resistance is achieved, and maintaining is easy.

Owner:山东民烨耐火纤维有限公司

A kind of nitrogen self-doping carbon-coated silicon oxide negative electrode material, preparation method and application thereof

ActiveCN112331852BHigh theoretical specific capacityImprove stabilityNegative electrodesSecondary cellsCarbon coatingSilicon oxide

The invention discloses a nitrogen self-doping carbon-coated silicon oxide negative electrode material and its preparation method and application. The preparation method of the nitrogen self-doping carbon-coated silicon oxide negative electrode material first passes trimethylbenzene in an alcohol aqueous solution The block copolymer is combined with dopamine or acrylate monomer, and then the pH is adjusted so that the dopamine / acrylate monomer self-polymerizes on the outer layer of trimethylbenzene, and the block copolymer is used as a buffer layer, and then the block is removed by alcohol washing Copolymer and trimethylbenzene, and then form a nitrogen self-doped carbon coating layer by high-temperature carbonization, and then put silicon dioxide into the coating layer in the form of a salt solution, and then obtain a nitrogen self-doped carbon coating layer by magnesia thermal reduction reaction Coated silicon negative electrode material, which has high theoretical specific capacity and good cycle stability, and has a certain degree of stretching elasticity, and can alleviate the volume expansion and contraction caused by silicon oxide when deintercalating lithium, effectively overcoming the silicon volume. Loss and chalking results from expansion and contraction.

Owner:云南锂宸新材料科技有限公司

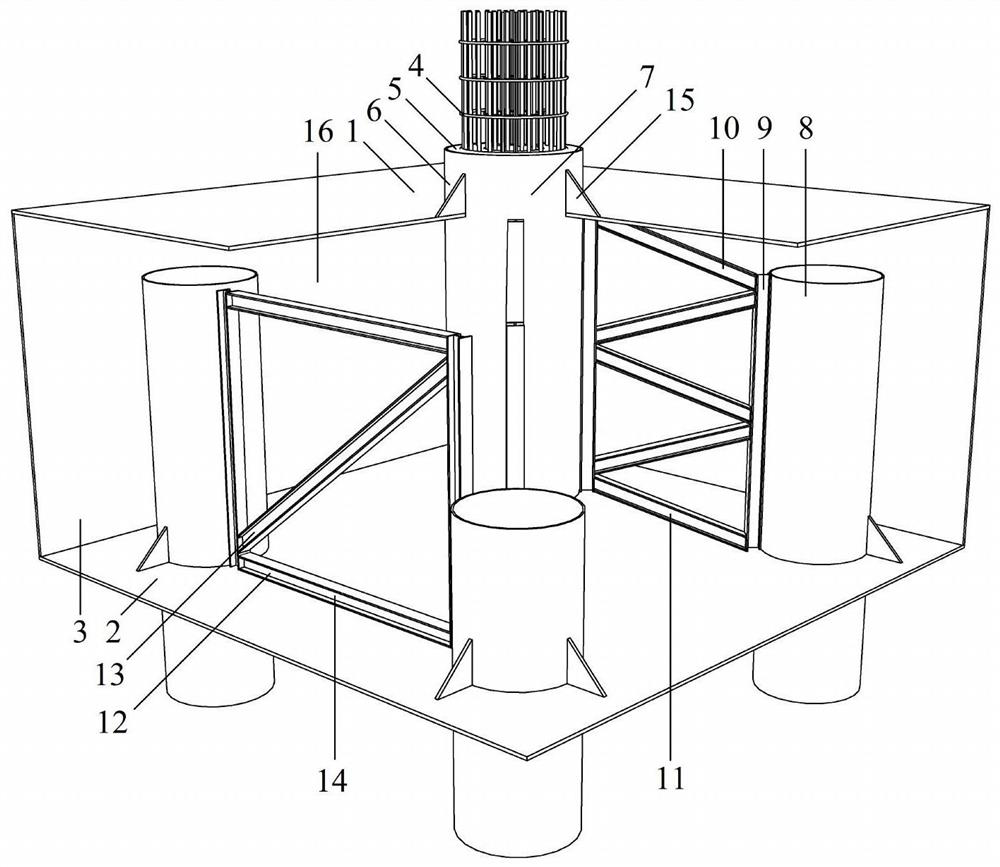

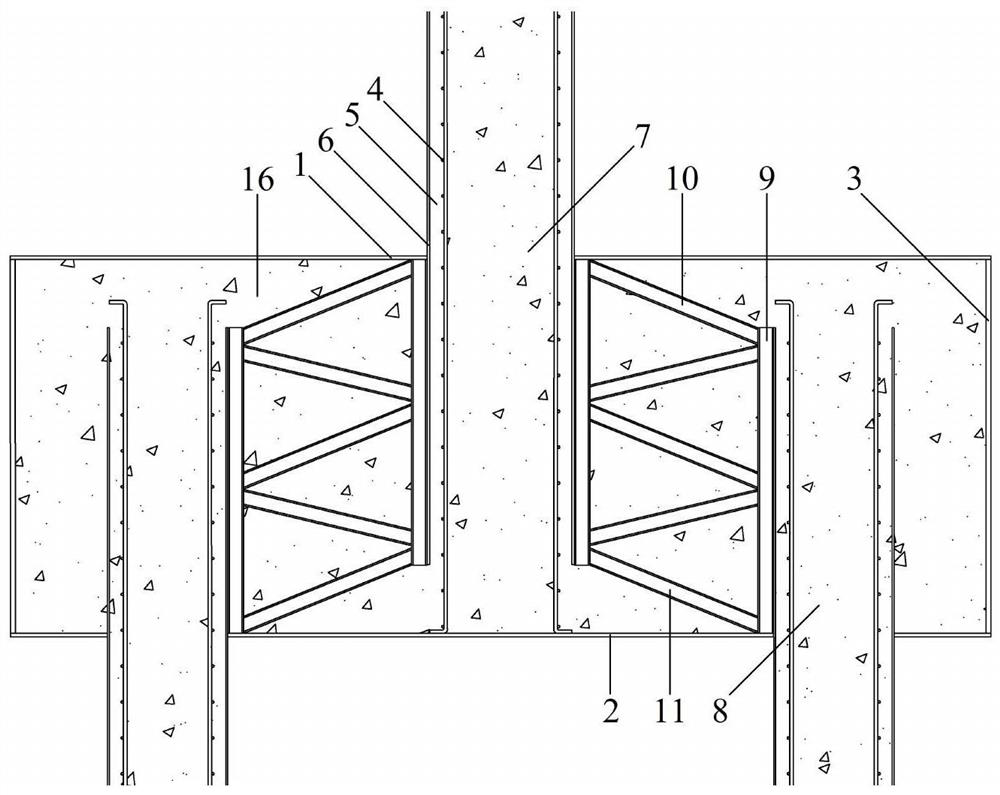

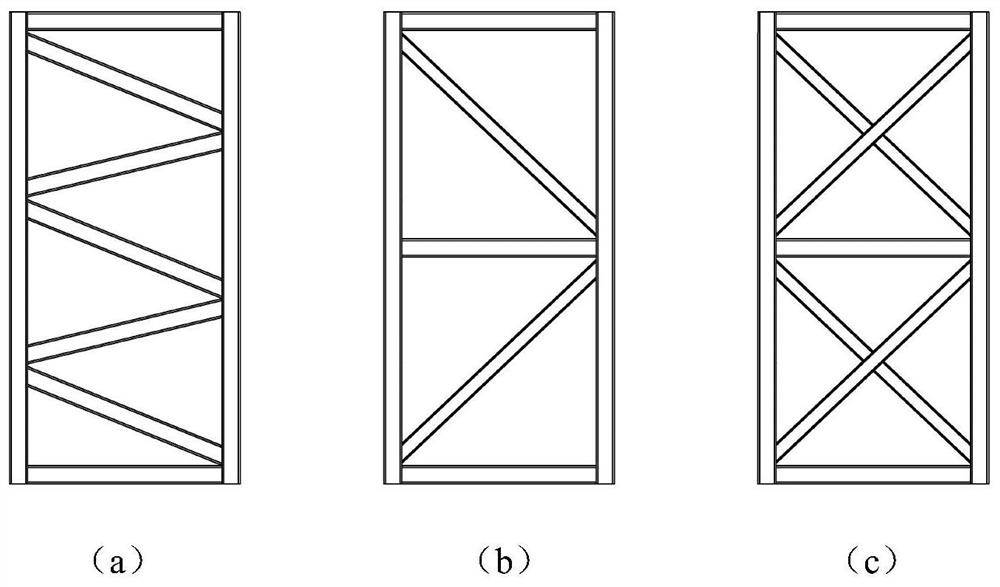

Steel-solid waste concrete combined bearing platform with composite structure and construction method thereof

ActiveCN113833005AImprove bearing capacityIncrease stiffnessBulkheads/pilesCrack resistanceArchitectural engineering

The invention provides a steel-solid waste concrete combined bearing platform with a composite structure and a construction method thereof. According to the steel-solid waste concrete combined bearing platform with the composite structure and the construction method thereof, six steel plates are adopted to form a closed box body, so that the tensile strength and the crack resistance of the outermost layer of the bearing platform are improved, and the bearing capacity and the rigidity of the bearing platform are greatly improved; a shear-resistant truss is arranged between a column foot and a pile body, and effective transmission of concentrated loads is achieved through the multiple pieces of profile steel arranged in the inclined direction; and stress coordination trusses are arranged between the adjacent concrete-filled steel tube piles to enhance the overall coordination between the concrete-filled steel tube piles, the shear-resistant trusses and the stress coordination trusses greatly increase the interface bonding degree of the steel tubes and the bearing platform, reinforcing connecting plates are arranged at the joints of the steel tubes and the steel plates to increase the connecting degree of the steel tubes and the steel plates, and the integrity of the whole combined bearing platform is greatly improved. Solid waste concrete with the solid waste replacement rate lower than 30% is adopted in the bearing platform box body, the adverse effect caused by shrinkage of mass concrete can be relieved, and the demonstration effect on engineering application and popularization of the solid waste concrete is achieved.

Owner:HARBIN INST OF TECH

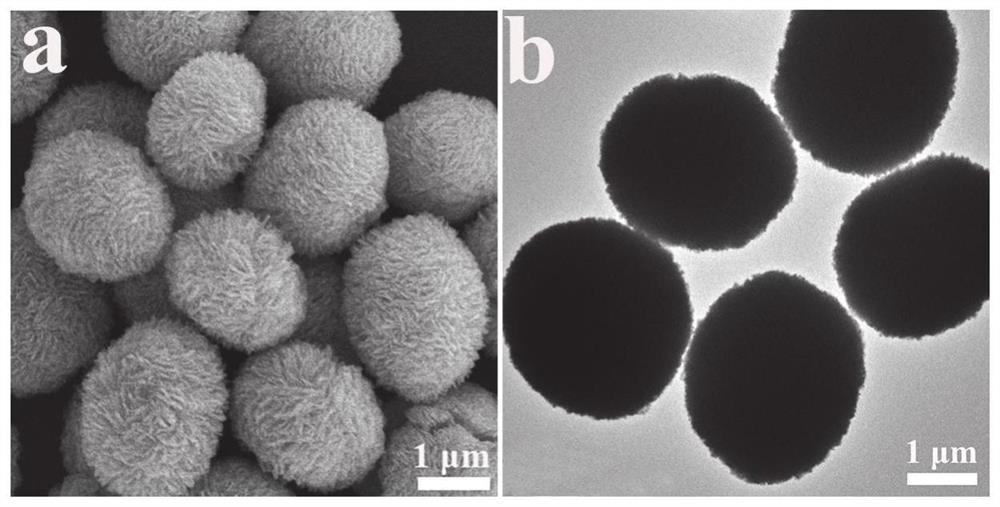

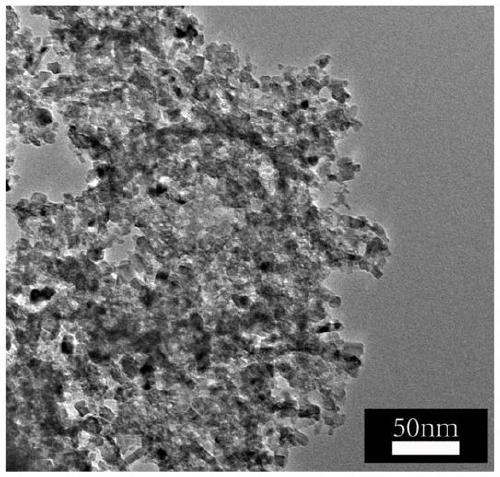

A TiO2 and CuO composite porous material for a supercapacitor and a preparation method thereof

ActiveCN109148162AOrdered pore structureOrdered mesoporous structureHybrid capacitor electrodesHybrid/EDL manufactureMicrosphereCopper(II) oxide

The invention provides a TiO2 and CuO composite porous material for a supercapacitor and a preparation method thereof, belonging to the technical field of electrode materials. The composite porous material has an ordered porous structure, and as the electrode material of the supercapacitor, can effectively reduce the expansion and contraction generated in the charging and discharging process, andkeep the structure stable. The preparation method of the composite porous material comprises the following steps: placing a slide in an ethanol solution of polystyrene microspheres, evaporating ethanol to form a polystyrene film by self-assembly; P123 is stirred and dissolved in ethanol, isopropyl titanate and hydrochloric acid are added, titanium tetrachloride is added dropwise, and cupric chloride dihydrate is added to obtain composite precursor solution of titanium dioxide and cupric oxide; The glass slide loaded with polystyrene film was inserted into the composite precursor solution obliquely, and the ethanol was evaporated to induce the self-assembly of the composite precursor on the polystyrene film. TiO2 and CuO composite porous materials were obtained by calcination in muffle furnace.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

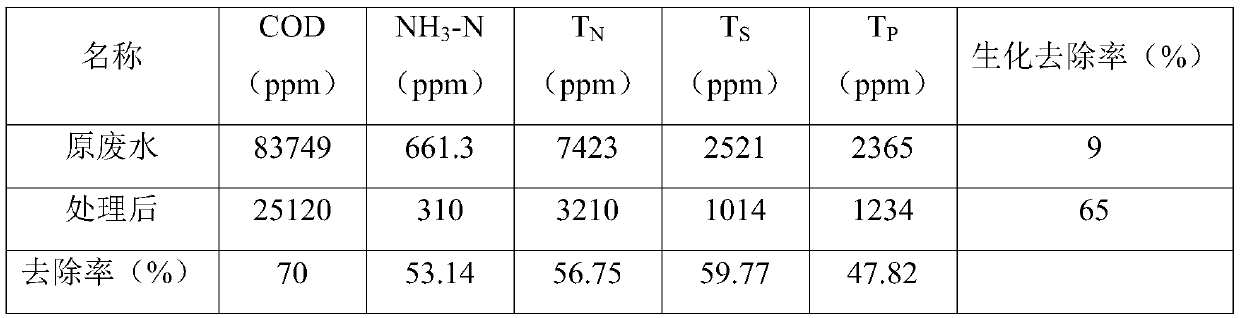

Electrocatalytic oxidation filler and its preparation method, three-dimensional electrocatalytic oxidation device

ActiveCN110734114BHigh catalytic activityImprove conductivityWater treatment parameter controlNature of treatment waterSupporting electrolyteIndustrial waste water

The invention discloses an electrocatalytic oxidation filler, a preparation method thereof, and a three-dimensional electrocatalytic oxidation device. The electrocatalytic oxidation filler is a mixture of clay minerals and a curing agent, Cu 2+ / Mn 2+ The mixed solutions are mixed and then roasted. The three-dimensional electrocatalytic oxidation device comprises an anode, a cathode and an electrocatalytic oxidation filler filled between them. The electrocatalytic oxidation filler of the present invention has the advantages of good conductivity, low energy consumption, high stability, strong catalytic activity, and no need for supporting electrolytes. As a filler for a three-dimensional electrocatalytic oxidation device, it is widely used to treat industrial wastewater, and can realize The effective removal of organic pollutants has high use value and good application prospects. The preparation method of the filler of the present invention has the advantages of simple process, convenient operation, easy control, low raw material cost, less energy consumption, short time consumption, green environmental protection, etc., is suitable for continuous large-scale batch production, is convenient for industrial utilization, and shows good application prospect.

Owner:湖南海利常德农药化工有限公司

Preparation method of eye drops

InactiveCN107753633AStrong antibacterialRelieves eye inflammationSenses disorderAntipyreticAnti-inflammatoryChemistry

The invention relates to the field of pharmaceuticals and particularly relates to a preparation method of eye drops. The preparation method comprises the following step: soaking raw material pedicularis verticillata in a sodium chloride isotonic solution for treatment, wherein when the osmotic pressure of the sodium chloride solution is equal to that of cells of pedicularis verticillata, the osmotic pressures inside and outside the cells are balanced, matter exchange is avoided, and component loss is avoided; the active components are fully extracted, a phenylpropanoid glycoside compound is extracted therefrom, so that on one hand, the eye drops have relatively strong antibacterial and anti-inflammatory activities, achieve the effect of transcriptional activation of tissue inflammation genes, and are capable of alleviating inflammation of eyes; on the other hand, the eye drops also contain antioxidant active matters for alleviating fatigue, so that muscle contraction caused by fatiguecan be alleviated, and the eye drops play roles of preventing fatigue and protecting eyeballs.

Owner:李竑靓

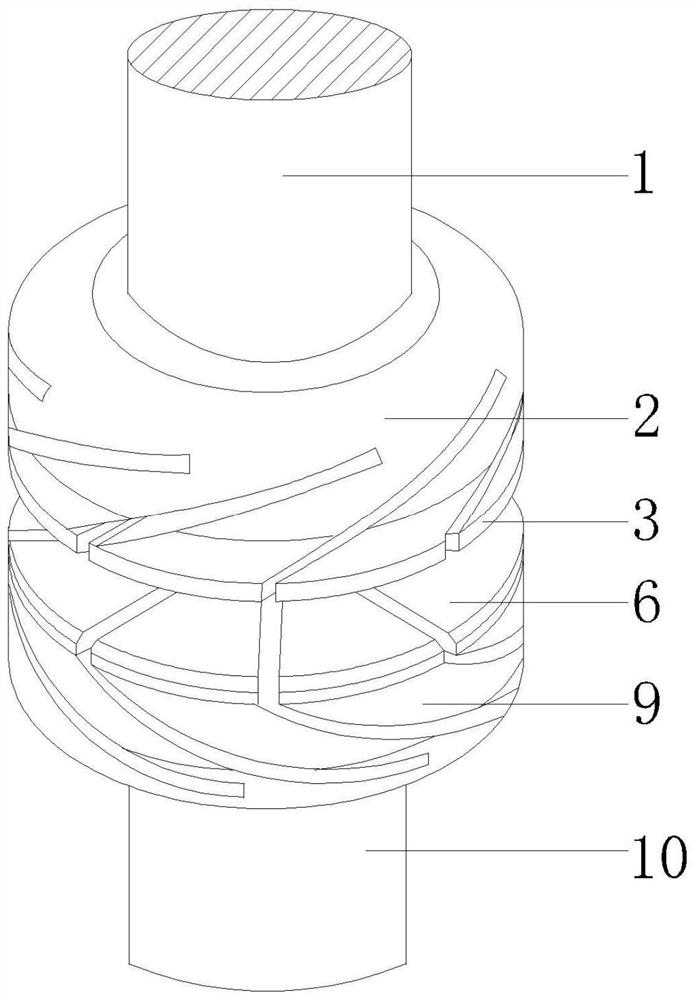

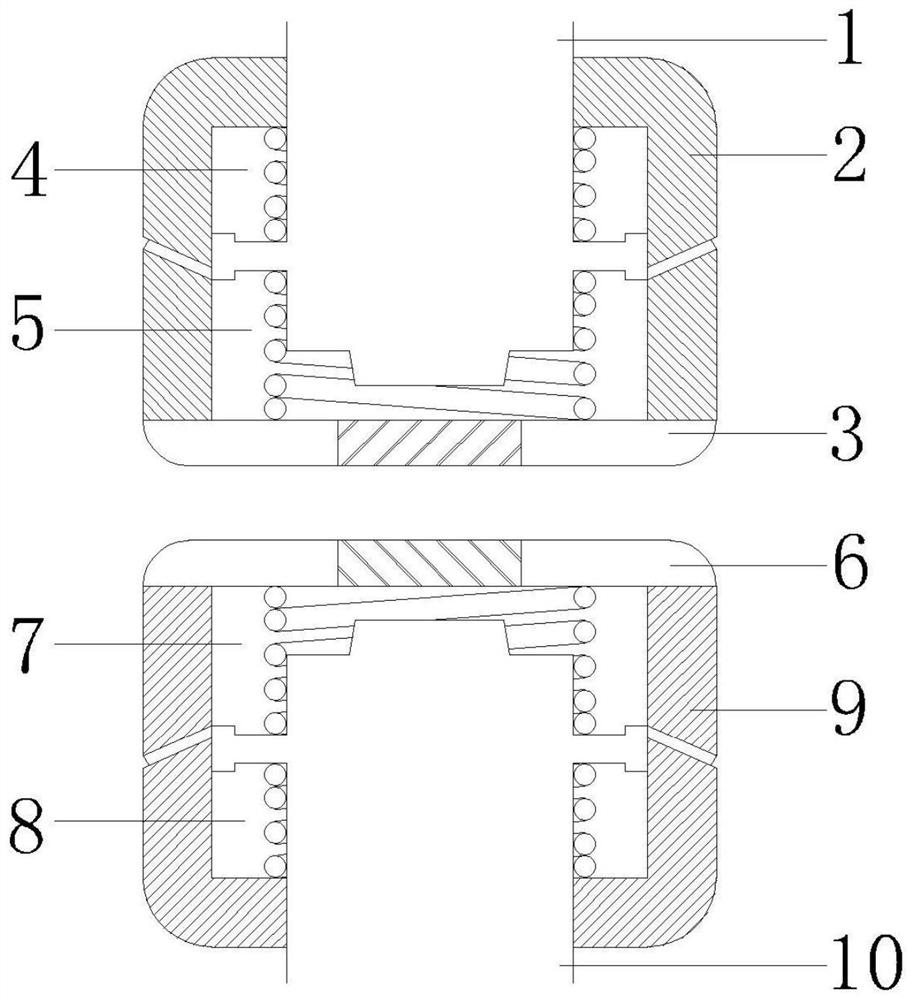

A kind of vacuum arc extinguishing chamber contact

ActiveCN113745044BReduce temperature riseReduce ablationHigh-tension/heavy-dress switchesAir-break switchesTemperature resistanceBreaking capacity

The invention provides a vacuum arc extinguishing chamber contact, which includes an anode side contact piece, a cathode side contact piece, an anode side conductive rod, a cathode side conductive rod, an anode side cup holder, anode side spring No. No. 1 spring, No. 1 spring on the cathode side, and No. 2 spring on the cathode side. The invention adopts a spring with high temperature resistance, high strength and high elastic coefficient to achieve the effect of buffering and shock absorption, which is beneficial to the huge impact when the contact is opened and improves the overall mechanical strength. At the same time, springs are used to cleverly design the conversion between the normal working structure of the contact and the structure during breaking. During normal operation, the conductive rod contacts the contact piece, and the cross-sectional area through which the current flows increases, which is beneficial to reducing the temperature rise. Extend contact life. The rotation direction of the spring is clockwise (from the anode to the cathode), and the current during interruption can be used to generate a magnetic field, which strengthens the longitudinal magnetic field twice, alleviates arc contraction and is beneficial to arc extinguishing. The use of springs can effectively control the pressure between the dynamic and static contacts to achieve an effective balance between the increase in contact resistance due to too small pressure and the deformation caused by excessive pressure. The number of slots in the contact piece is increased, which further suppresses eddy currents and reduces residual magnetism. Compared with traditional cup-shaped longitudinal magnetic contacts, the vacuum arc extinguishing chamber contacts provided by the present invention have smaller temperature rise during rated operation, larger longitudinal magnetic field during breaking, higher breaking success rate, strong impact resistance, and small residual magnetism. It helps to further improve the breaking capacity of vacuum circuit breakers.

Owner:SICHUAN UNIV

Wooden door leaf

The invention discloses a wooden door leaf which comprises a pool plate and an edge purlin. The pool plate is formed by splicing a plurality of subplates. Each subplate comprises base plates in a right trapezoid shape and assembly plates in a parallelogram shape, and the base plates and the assembly plates are spliced into the rectangular pool plate. Splicing seams are formed at the junctions between the base plates and the assembly plates or between the assembly plates. Drying grooves are formed between the base plates and the assembly plates or between the assembly plates on the upper side and the lower side of the splicing seams. The drying grooves are hidden in the pool plate. Drying agents are arranged in the drying grooves. The splicing seams are arranged obliquely. Threaded holes are formed in the head end and the tail end of each splicing seam. The threaded holes lead to the drying grooves. The threaded holes are formed in the two sides of the drying grooves. Metal rings are arranged in the threaded holes. Plug columns are arranged in the metal rings. The wooden door leaf provided by the invention has the characteristics of being good in damp-proof effect, small in deformation and long in service life.

Owner:浙江林昌木业有限公司

A tio for supercapacitors 2 Composite porous material with cuo and preparation method thereof

ActiveCN109148162BRelieve swellingRelieve contractionHybrid capacitor electrodesHybrid/EDL manufactureTitanium chlorideMicrosphere

The invention provides a TiO2 and CuO composite porous material for a supercapacitor and a preparation method thereof, belonging to the technical field of electrode materials. The composite porous material has an ordered porous structure, and as the electrode material of the supercapacitor, can effectively reduce the expansion and contraction generated in the charging and discharging process, andkeep the structure stable. The preparation method of the composite porous material comprises the following steps: placing a slide in an ethanol solution of polystyrene microspheres, evaporating ethanol to form a polystyrene film by self-assembly; P123 is stirred and dissolved in ethanol, isopropyl titanate and hydrochloric acid are added, titanium tetrachloride is added dropwise, and cupric chloride dihydrate is added to obtain composite precursor solution of titanium dioxide and cupric oxide; The glass slide loaded with polystyrene film was inserted into the composite precursor solution obliquely, and the ethanol was evaporated to induce the self-assembly of the composite precursor on the polystyrene film. TiO2 and CuO composite porous materials were obtained by calcination in muffle furnace.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com