Formula and preparation method for low-shrinkage artificial inorganic stone

A low-shrinkage, inorganic technology, applied in the formulation of low-shrinkage artificial inorganic stone and its preparation field, can solve the problems of inorganic stone cracking and affect the appearance and durability of inorganic stone materials, so as to alleviate shrinkage, reduce the risk of cracking, and reduce the risk of cracking. The effect of shrinkage properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

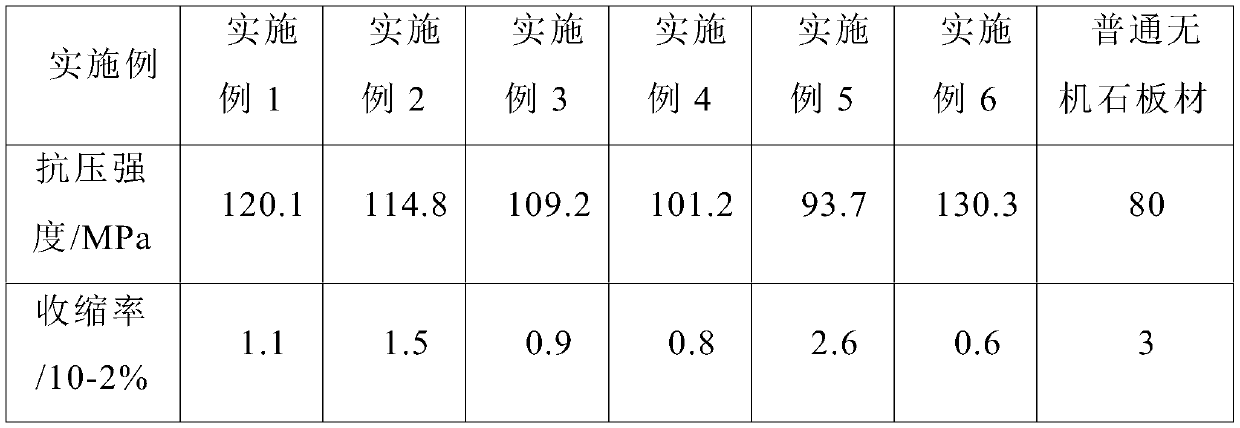

Examples

Embodiment 1

[0032] Add 50 parts of quartz sand, 40 parts of cement, 2 parts of fly ash, 2 parts of internal curing agent and 6 parts of expansion agent into the mixer, stir for 45 seconds, then add 1 part of shrinkage reducing agent and 1.5 parts of water reducing agent into the measured water glue Mixing water with a ratio of 0.20, after stirring evenly, add to the mixer and continue stirring for 450s;

[0033] Spread the stirred material evenly in the mold with a paving thickness of 2.7cm, and then vacuumize the material;

[0034] Put the material after vacuum treatment into the steam curing equipment, remove the mold after the curing, and obtain the inorganic stone blank, and then place the inorganic stone blank in a 5% shrinkage reducing agent solution for curing for 4 days;

[0035] Finally, the inorganic stone rough after soaking and curing is ground, polished, and cut to obtain finished products.

Embodiment 2

[0037] Add 50 parts of quartz sand, 38 parts of cement, 4 parts of fly ash, 1.5 parts of internal curing agent and 8 parts of expansion agent into the mixer, stir for 45 seconds, then add 1.5 parts of shrinkage reducing agent and 2 parts of water reducing agent into the measured water glue Mixing water with a ratio of 0.22, after stirring evenly, add to the mixer and continue stirring for 450s;

[0038] Spread the stirred material evenly in the mold with a paving thickness of 2.7cm, and then vacuumize the material;

[0039] Put the material after vacuum treatment into the steam curing equipment, remove the mold after the curing, and obtain the inorganic stone blank, and then place the inorganic stone blank in a 5% shrinkage reducing agent solution for curing for 4 days;

[0040] Finally, the inorganic stone rough after soaking and curing is ground, polished, and cut to obtain finished products.

Embodiment 3

[0042] Add 50 parts of quartz sand, 36 parts of cement, 6 parts of fly ash, 2 parts of internal curing agent and 10 parts of expansion agent into the mixer, stir for 45 seconds, then add 2 parts of shrinkage reducing agent and 2 parts of water reducing agent into the measured water glue Mixing water with a ratio of 0.18, after stirring evenly, add to the mixer and continue stirring for 450s;

[0043] Spread the stirred material evenly in the mold with a paving thickness of 2.7cm, and then vacuumize the material;

[0044] Put the material after vacuum treatment into the steam curing equipment, remove the mold after the curing, and obtain the inorganic stone blank, and then place the inorganic stone blank in a 5% shrinkage reducing agent solution for curing for 4 days;

[0045] Finally, the inorganic stone rough after soaking and curing is ground, polished, and cut to obtain finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com