Preparation method of flexible spinning hollow carbon self-supporting electrode

A self-supporting electrode, hollow carbon technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of affecting the electrochemical performance of electrode materials, inability to fold, bulky and other problems, achieve good metal ion adsorption and storage capacity, improve electricity. The effect of high controllability of chemical reaction kinetics and operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

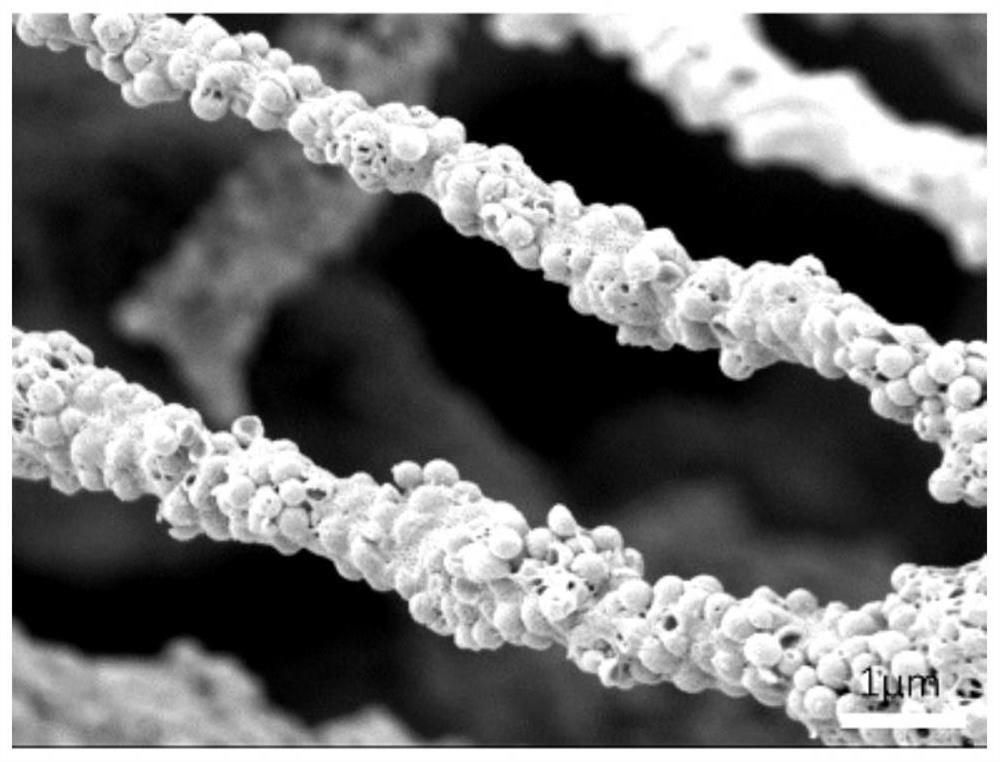

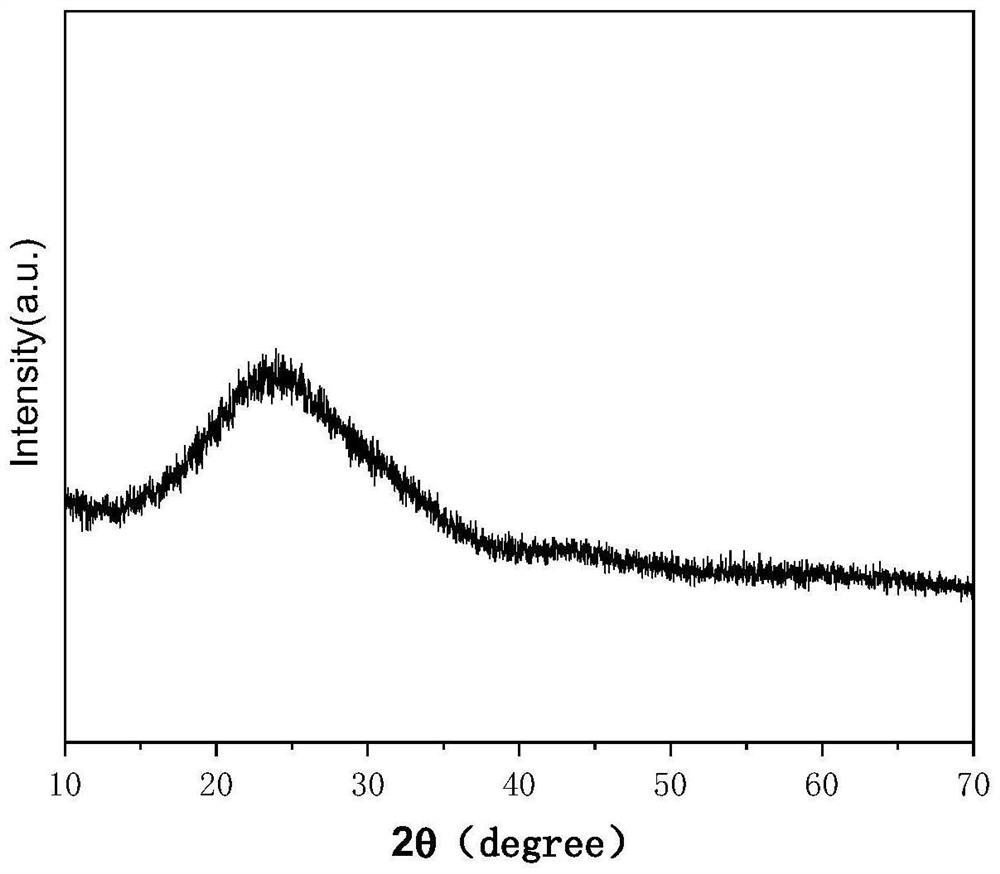

[0024] A method for preparing a flexible spinning hollow carbon self-supporting electrode, specifically comprising the following steps:

[0025] (1), add 1.6g resorcinol and 2.24ml formaldehyde solution into the mixed solution of 280ml ethanol and 40ml water and stir, the stirring temperature is 30°C, the stirring time is 24h, the stirring speed is 500r / min, after stirring The obtained phenolic resin was centrifuged and washed three times with ethanol and water respectively, and then dried in an ordinary oven at 80°C for 24 hours to obtain a yellow solid powder, which was transferred to a tube furnace and heated to 800 °C under the protection of argon gas. ℃, the heating rate is 5°C / min, and the holding time is 2h, a black solid powder is obtained, and after the black solid powder is etched by hydrofluoric acid (HF) with a mass fraction of 10%, hollow carbon spheres are obtained;

[0026] (2), weigh 0.2835g hollow carbon spheres and 0.567g polyacrylonitrile respectively and jo...

Embodiment 2

[0030] A method for preparing a flexible spinning hollow carbon self-supporting electrode, specifically comprising the following steps:

[0031] (1), add 1.6g resorcinol and 2.24ml formaldehyde solution into the mixed solution of 280ml ethanol and 40ml water and stir, the stirring temperature is 30°C, the stirring time is 24h, the stirring speed is 500r / min, after stirring The obtained phenolic resin was centrifuged and washed three times with ethanol and water respectively, and then dried in an ordinary oven at 80°C for 24 hours to obtain a yellow solid powder, which was transferred to a tube furnace and heated to 800 °C under the protection of argon gas. ℃, the heating rate is 5°C / min, and the holding time is 2h, a black solid powder is obtained, and after the black solid powder is etched by hydrofluoric acid (HF) with a mass fraction of 10%, hollow carbon spheres are obtained;

[0032] (2), weigh 0.1134g hollow carbon spheres and 0.567g polyacrylonitrile respectively and jo...

Embodiment 3

[0035] A method for preparing a flexible spinning hollow carbon self-supporting electrode, specifically comprising the following steps:

[0036] (1), add 1.6g resorcinol and 2.24ml formaldehyde solution into the mixed solution of 280ml ethanol and 40ml water and stir, the stirring temperature is 30°C, the stirring time is 24h, the stirring speed is 500r / min, after stirring The obtained phenolic resin was centrifuged and washed three times with ethanol and water, and then dried in a common oven at 80°C for 24 hours to obtain a yellow solid powder, which was transferred to a tube furnace and heated to 800 °C under the protection of argon gas. ℃, the heating rate is 5°C / min, and the holding time is 2h, a black solid powder is obtained, and after the black solid powder is etched by hydrofluoric acid (HF) with a mass fraction of 10%, hollow carbon spheres are obtained;

[0037] (2), weigh 0.063g hollow carbon spheres and 0.567g polyacrylonitrile respectively and join in the DMF sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com