Silicon@carbon-graphene-based flexible composite material and preparation method thereof and lithium battery

A composite material and vinyl flexible technology, applied in the direction of battery electrodes, secondary batteries, non-aqueous electrolyte battery electrodes, etc., can solve problems such as stress concentration, limited bonding strength, and material separation from each other, so as to alleviate volume expansion and contraction, The effect of improving electronic conductivity and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

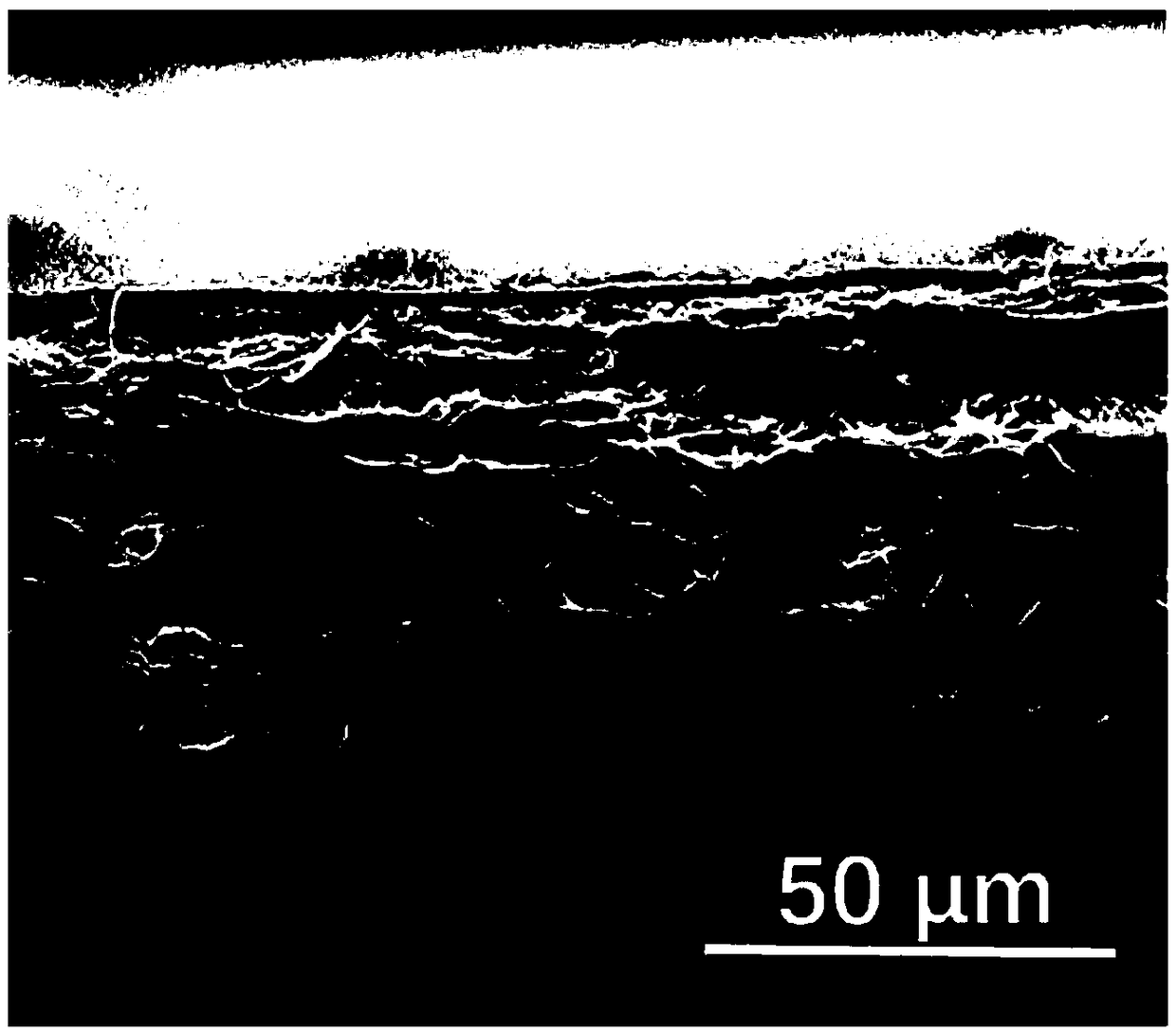

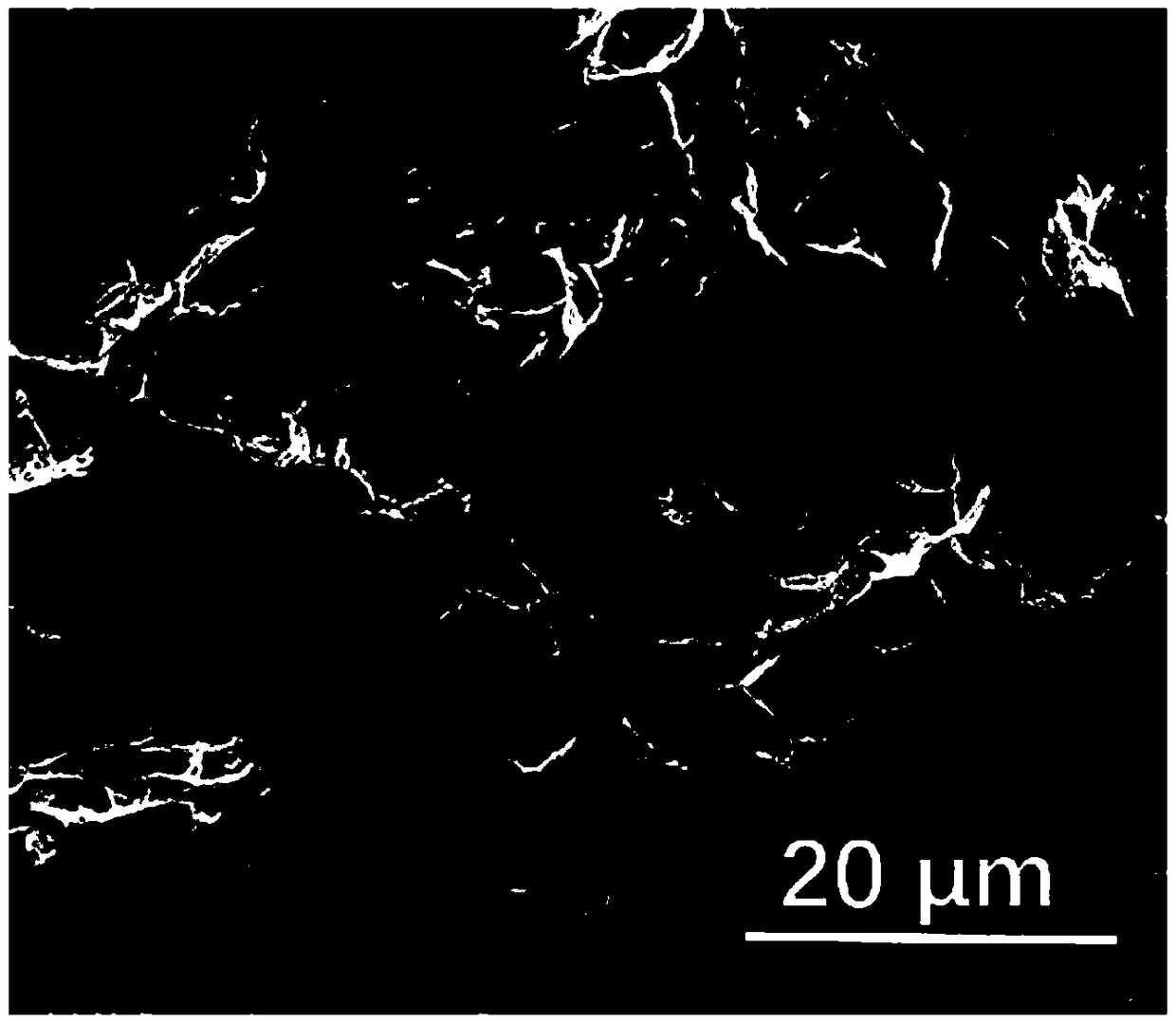

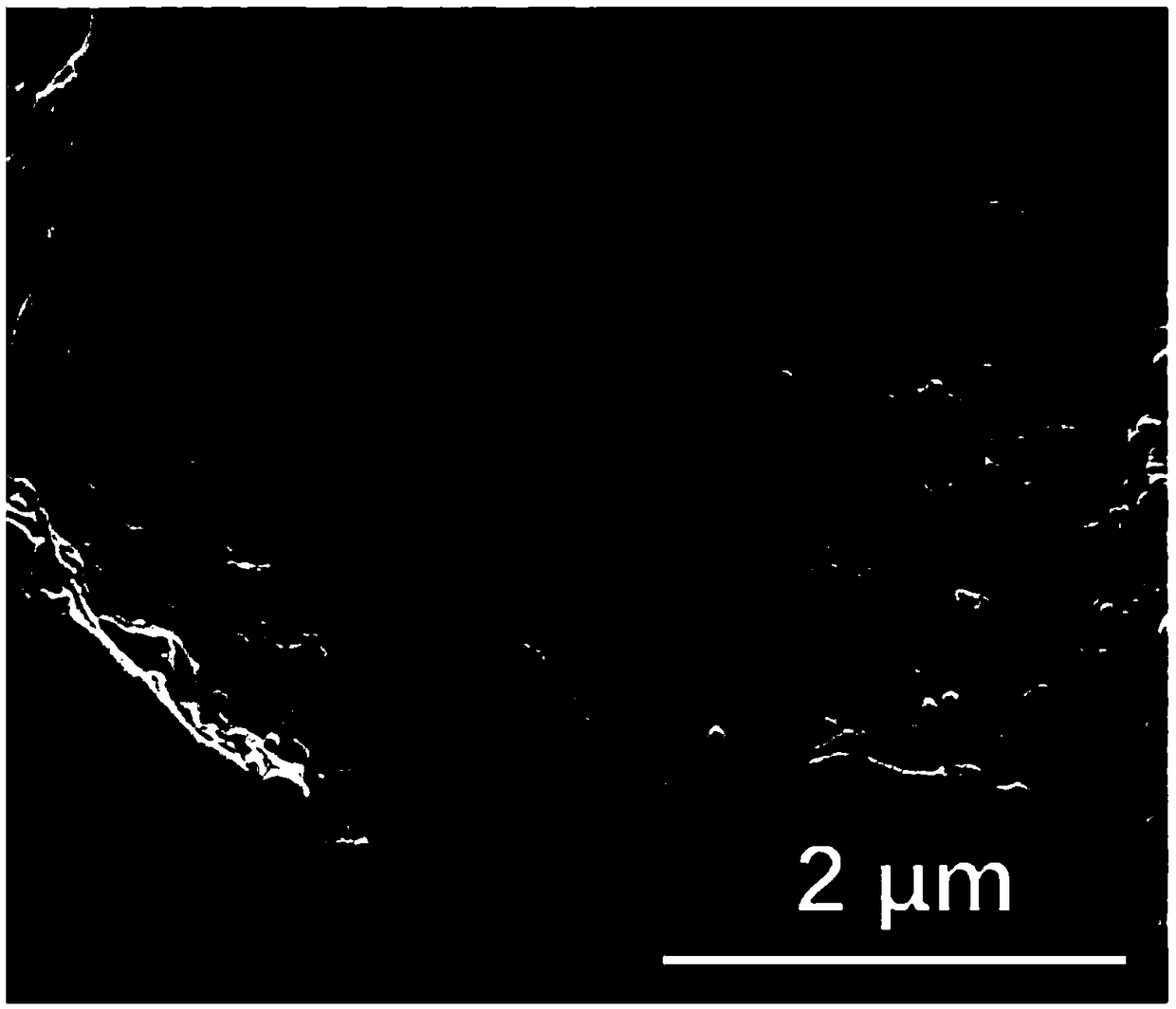

[0046] Another aspect of the present invention provides a method for preparing a silicon@carbon-graphene-based flexible composite material. In an exemplary embodiment of the method for preparing a silicon@carbon-graphene-based flexible composite material of the present invention, the Shown preparation methods may include:

[0047] S01, modify the surface of silicon particles to realize the electrostatic self-assembly of silicon particles and graphene oxide.

[0048] In this example, first, an oxidizing solution is prepared. Then add the silicon particles into the prepared oxidizing solution, wash and dry to obtain the dried silicon particles. adding the dried silicon particles into deionized water to form a solution, adding polydiallyldimethylammonium chloride (PDDA), stirring, and drying to obtain modified silicon particles. Finally, after the modified silicon particles are mixed with graphene oxide to form a uniform solution, the pH value of the solution is adjusted to obt...

example 1

[0067] (1) the concentrated sulfuric acid (H 2 SO 4 ) and hydrogen peroxide (H 2 o 2 ) according to the volume ratio of 3:1 to form a 20ml mixed solution, then add 1g of silicon particles in an 80°C water bath for 6h, wash and dry. Then it was dissolved in deionized water and 2ml of polydiallyldimethylammonium chloride (PDDA) was added, stirred ultrasonically for 24h, and dried by centrifugation. Then the modified silicon powder and graphene oxide were mixed to form a homogeneous solution according to the modified silicon accounted for 40% of the mass of graphene oxide, and the pH was adjusted to 4 with 2mg / mL sodium hydroxide (NaOH) solution.

[0068] (2) The mixed solution of silicon particles (Si, nano-silica powder) and graphene oxide (GO) mixed uniformly was pumped into a film per 10ml, and then put into a freeze-drying agent to dry at -50°C.

[0069] (3) The composite membrane obtained in step (2) was put into a tube furnace, and kept at 500 °C for 5 h under an inert...

example 2

[0071] (1) the concentrated sulfuric acid (H 2 SO 4 ) and hydrogen peroxide (H 2 o 2 ) according to the volume ratio of 3:1 to form a 20ml mixed solution, then add 1g of silicon particles in a 75°C water bath for 5h, wash and dry. Then it was dissolved in deionized water and 2ml of polydiallyldimethylammonium chloride (PDDA) was added, stirred ultrasonically for 24h, and dried by centrifugation. Then the modified silicon powder and graphene oxide were mixed according to the modified silicon accounted for 30% of the mass of graphene oxide to form a homogeneous solution and adjusted to PH=6 with 1.6mg / mL sodium hydroxide (NaOH) solution.

[0072] (2) The uniformly mixed Si and GO mixed solution was pumped into a film every 8ml, and then dried in a freeze-drying agent at -46°C.

[0073] (3) The composite membrane obtained in step (2) was put into a tube furnace, and kept at 460 °C for 5 h under an inert gas atmosphere, and finally a composite membrane structure of C@Si / rGO wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com