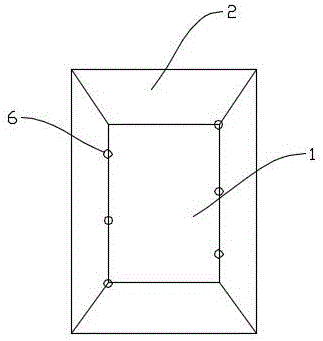

Wooden door leaf

A technology for door leaf and wooden door, applied in door leaf, spray device, single handheld device, etc., can solve the problems of syneresis, water absorption expansion, slow drying speed, etc., increase friction area and contact area, prevent water absorption expansion or aging, Reduce the effect of locally varying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

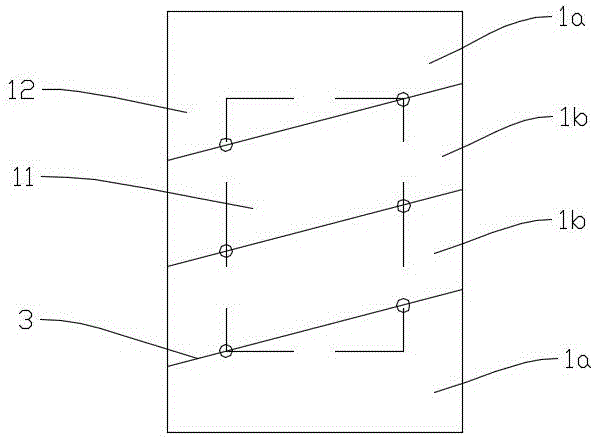

[0029] In embodiment one:

[0030] Both the inner surface and the outer surface of the metal ring are provided with threads, the plunger 5 and the metal ring are threaded, the length of the plunger 5 is equal to the thickness of the door leaf, and the top surface and the bottom surface of the plunger 5 are Both are provided with a plug head 6 covering the top surface and the bottom surface of the plunger 5, and the plug head 6 is made of glass, metal or diamond.

Embodiment 2

[0031] In the second embodiment:

[0032] The inner and outer surfaces of the metal ring are provided with threads, and the plunger 5 and the metal ring are threaded. There are two plungers 5, which are respectively inserted from two entrances of the metal ring. The bottom surfaces of the plungers 5 fit together, and the top surfaces of the two plungers 5 are provided with a plug head 6, which covers the top surface of the plunger 5, and the plug head 6 is made of glass or metal or diamond. Made, this method is generally used to assemble the plunger.

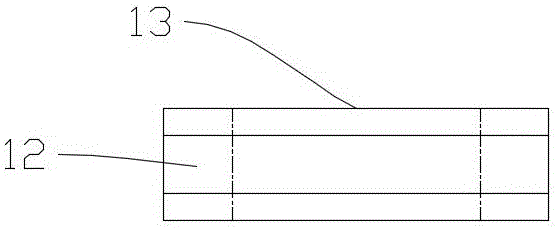

[0033] refer to Figure 7 , a device for filling the wooden door with desiccant, including an air pump, an air pipe, a spray gun, and a recovery container. The air pump can be an electronic air pump or a manual air pump, and the recovery container can be an object with a certain expansion capacity, such as a balloon. The air pipe connects the air pump to the spray gun, and the recovery container matches the door leaf. The spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com