Method for preparing boron-nitrogen co-doped carbon aerogel

A carbon aerogel and aerogel technology, applied in the direction of nano-carbon, nanotechnology, etc., can solve the problems of reducing electric double layer overlap, low density, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

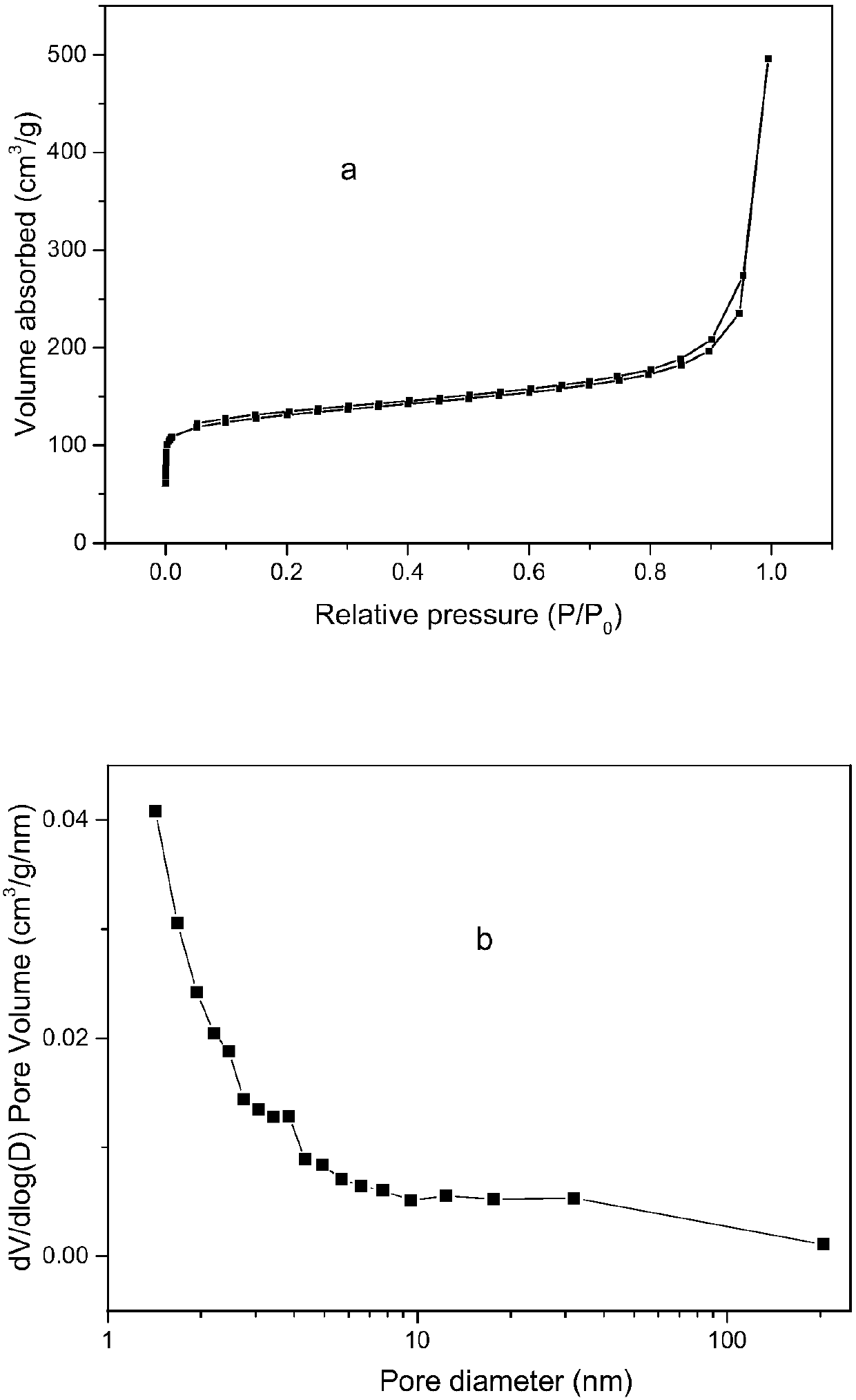

Embodiment 1

[0027] Embodiment 1: adopt resorcinol (R), formaldehyde (F), boric acid (B), melamine (M), graphene oxide (GO) to be reactant, anhydrous sodium carbonate (C) is catalyst, deionized Water (DI) is the solvent, according to R / F=1:2, R / C=200:1, R / B=1:0.1, B / M=2.4:1, the dry weight of GO and the total dry weight of the reaction system The weight ratio is 0.01, and the total solid content of the reaction system is 20wt%. Mix and stir resorcinol, boric acid, and DI, condense and reflux, and react at 180°C for 30 minutes; mix and stir melamine and formaldehyde solution, and heat at 80°C React for 30 minutes; cool the reacted solution, mix and stir, add anhydrous sodium carbonate, and stir evenly; ultrasonicate 1.4wt% GO solution for 30 minutes, add it to the mixed solution, stir evenly, pour it into an ampepin and seal it. Cross-linking reaction at 90°C for 48 hours to obtain an organogel; then drying at 90°C for 12 hours to obtain an organic aerogel; after that, the organoaerogel was...

Embodiment 2

[0029]Embodiment 2: adopt resorcinol (R), formaldehyde (F), boric acid (B), melamine (M), graphene oxide (GO) to be reactant, anhydrous sodium carbonate (C) is catalyst, deionized Water (DI) is the solvent, according to R / F=1:2, R / C=200:1, R / B=1:1.2, B / M=2.4:1, the dry weight of GO and the total dry weight of the reaction system The weight ratio is 0.01, and the total solid content of the reaction system is 20wt%. Mix and stir resorcinol, boric acid, and DI, condense and reflux, and react at 180°C for 60 minutes; mix and stir melamine and formaldehyde solution, and stir at 80°C React for 30 minutes; cool the two reacted solutions, mix and stir, add anhydrous sodium carbonate, and stir evenly; ultrasonicate the 1.4wt% GO solution for 30 minutes, add it to the mixed solution, stir evenly, pour it into the ampepin and seal it, Cross-linking at 90°C for 48 hours to obtain an organogel; then drying at 90°C for 48 hours to obtain an organoaerogel; after that, place the organoaerogel...

Embodiment 3

[0031] Embodiment 3: adopt resorcinol (R), formaldehyde (F), boric acid (B), melamine (M), graphene oxide (GO) to be reactant, anhydrous sodium carbonate (C) is catalyst, deionized Water (DI) is the solvent, according to R / F=1:2, R / C=200:1, R / B=1:1.2, B / M=2.4:1, the dry weight of GO and the total dry weight of the reaction system The weight ratio is 0.01, and the total solid content of the reaction system is 20wt%. Mix and stir resorcinol, boric acid, and DI, condense and reflux, and react at 180°C for 60 minutes; mix and stir melamine and formaldehyde solution, and heat at 70°C React for 40 minutes; cool the two reacted solutions, mix and stir, add anhydrous sodium carbonate, and stir evenly; add 1.4wt% GO solution to the mixed solution after ultrasonication for 40 minutes, stir evenly, pour into the ampepin and seal , cross-linking reaction at 90°C for 60h to obtain an organogel; take out the gel and perform solvent exchange with acetone, and then dry at 90°C for 48h to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com