A kind of nitrogen self-doping carbon-coated silicon oxide negative electrode material, preparation method and application thereof

A silicon oxide and negative electrode material technology, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of difficult control of cost and component content, unsuitable for large-scale industrial production, poor cycle stability and other problems, and achieve good Electronic conductivity, improved performance, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

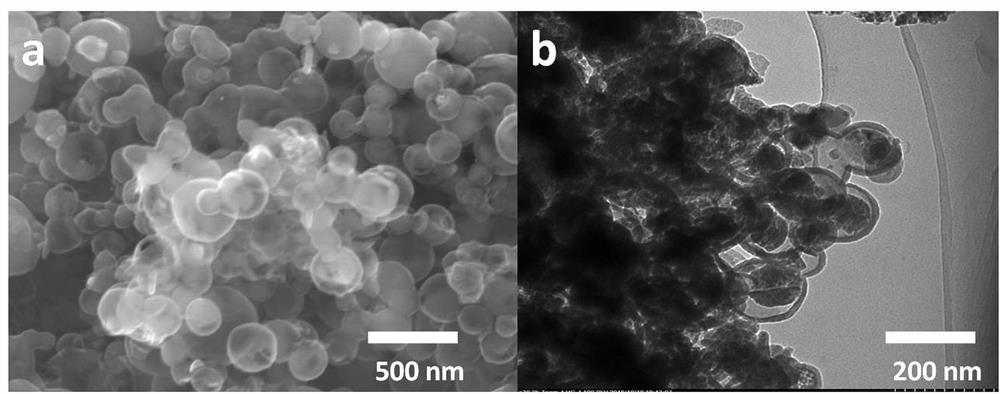

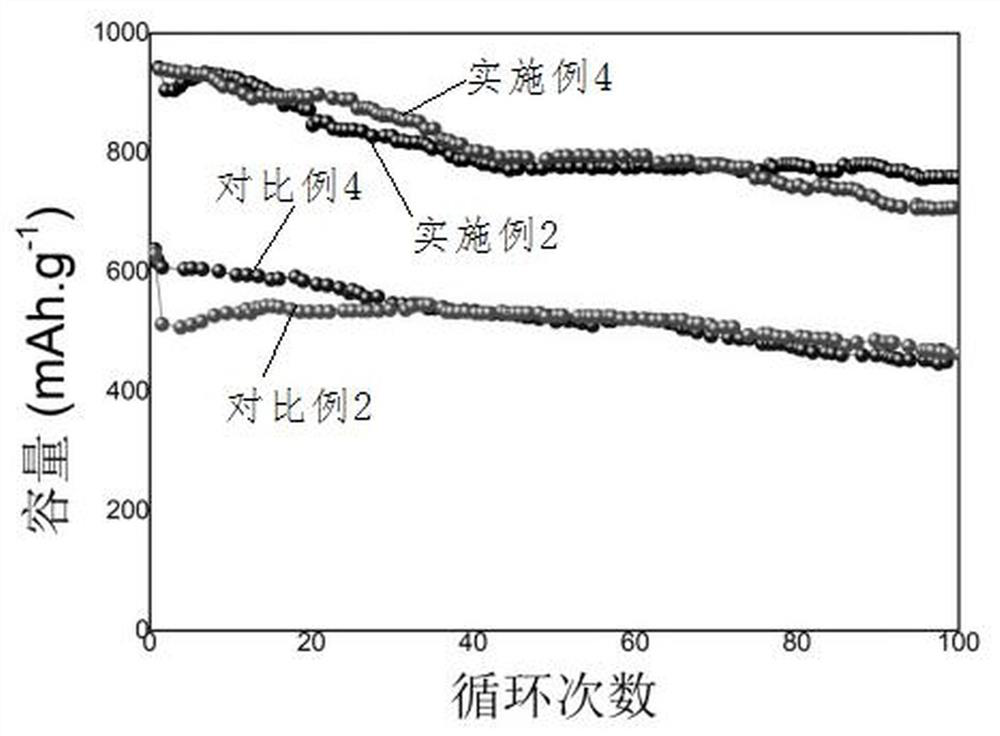

Image

Examples

Embodiment 1

[0030] This embodiment 1 provides a method for preparing a nitrogen self-doped carbon-coated silicon oxide negative electrode material, which specifically includes the following steps:

[0031] (1) Take 40mL of trimethylbenzene and 10mL of di-block copolymer or tri-block copolymer, the mass ratio is 1:0.4, put into 200ml of 50% alcohol aqueous solution, the speed is 200r / min, and stir;

[0032] (2) Dissolve 2 g of dopamine in 200 mL of deionized aqueous solution to form a dopamine aqueous solution, then add the dopamine aqueous solution in equal proportions to step (1), and stir for 2 hours;

[0033] (3) In the mixed solution of step (2), dropwise add ammonia water of 25wt% by weight, adjust the pH to 8, stir for 4h, and polymerize to form a colloidal mixed substance A;

[0034](4) Put the mixed substance A obtained in step (3) with a sufficient amount of ethanol solution in a hydrothermal reaction kettle, conduct a hydrothermal reaction at 120°C for 2-4 hours, and then place ...

Embodiment 2

[0038] This embodiment 2 provides a method for preparing a nitrogen self-doped carbon-coated silicon oxide negative electrode material, which specifically includes the following steps:

[0039] (1) Take 40mL of trimethylbenzene and 10mL of di-block copolymer or tri-block copolymer, the mass ratio is 1:0.4, put into 200ml of 50% alcohol aqueous solution, the speed is 200r / min, and stir;

[0040] (2) Dissolve 2 g of dopamine in 200 mL of deionized aqueous solution to form a dopamine aqueous solution, then add the dopamine aqueous solution in equal proportions to step (1), and stir for 2 hours;

[0041] (3) In the mixed solution of step (2), add dropwise the weight percent of 25wt% ammonia water, adjust the pH to 8, stir for 4h, and polymerize to form a colloidal mixed substance A;

[0042] (4) Put the mixed substance A obtained in step (3) with a sufficient amount of ethanol solution in a hydrothermal reaction kettle, conduct a hydrothermal reaction at 120°C for 2-4 hours, and t...

Embodiment 3

[0046] This embodiment 3 provides a method for preparing a nitrogen self-doped carbon-coated silicon oxide negative electrode material, which specifically includes the following steps:

[0047] (1) Take 4mL of trimethylbenzene and 1mL of diblock copolymer or triblock copolymer, the mass ratio is 1:0.4, put into 20ml of 50% alcohol aqueous solution, and stir at a speed of 200r / min;

[0048] (2) Dissolve 0.2 g of dopamine in 20 mL of deionized aqueous solution to form a dopamine aqueous solution, then add the dopamine aqueous solution into step (1) in equal proportions, and stir for 2 hours;

[0049] (3) In the mixed solution of step (2), add dropwise the weight percent of 25wt% ammonia water, adjust the pH to 8, stir for 4h, and polymerize to form a colloidal mixed substance A;

[0050] (4) Put the mixed substance A obtained in step (3) with a sufficient amount of ethanol solution in a hydrothermal reaction kettle, conduct a hydrothermal reaction at 120°C for 2-4 hours, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com