Nitrogen-doped composite planar metal lithium anode, preparation and application of nitrogen-doped composite planar metal lithium anode in lithium metal battery

A composite plane, metal lithium technology, used in lithium batteries, electrode manufacturing, battery electrodes, etc., can solve the problems of low Coulomb efficiency and large volume effect, achieve long cycle life, relieve dendrites, and relieve expansion and contraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

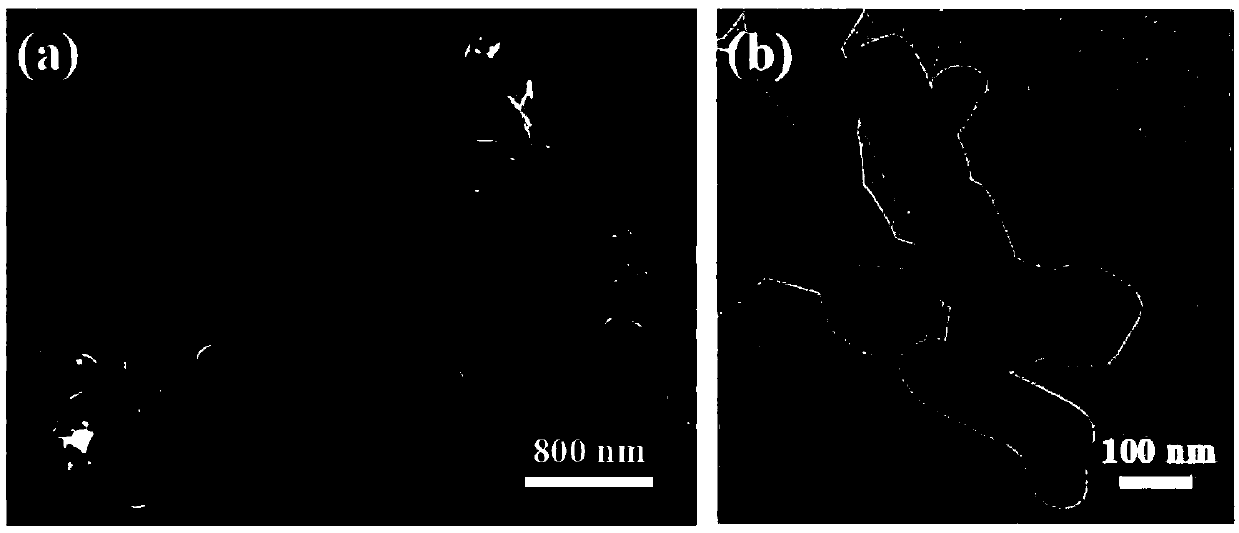

[0057] Carbon nanocages with internal chambers (with a specific surface area of 104.7 m 2 / g, the carbon wall thickness is 6nm, and the size of the inner cavity accounts for 92% of the total volume)( figure 1 ) placed in an argon atmosphere containing ammonia (ammonia content 50vol.%), after heat treatment at 800° C. for 3 h, nitrogen-doped carbon nanocages (nitrogen doping amount is 2.2 at.%). Then mixed with polyvinylidene chloride according to the mass ratio of 90% (nitrogen-doped carbon nanocages / polyvinylidene chloride is 90%), and then coated on copper foil (8μm) to prepare double-sided nitrogen-doped carbon nanocages Modified copper foil electrodes (30 μm coating thickness). This electrode is used as the working electrode, and the metal lithium sheet is used as the counter electrode, and 1 MLiTFSI / DOL: DME (volume ratio = 1: 1) contains 1wt.% LiNO 3 Carry out pouch battery assembly for the electrolyte, at 3mA / cm 2 Under the current density, the charge-discharge cyc...

Embodiment 2

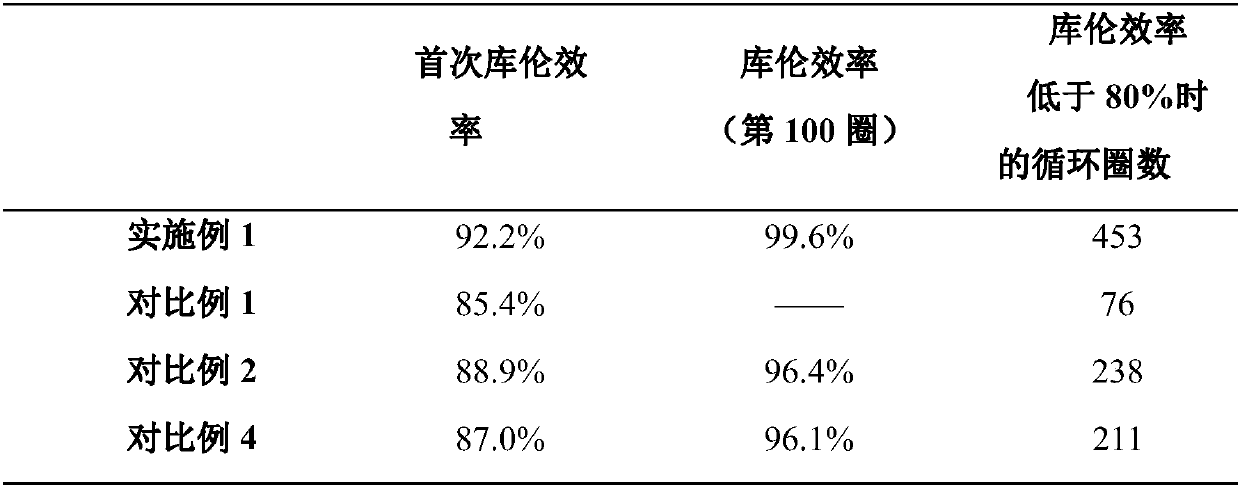

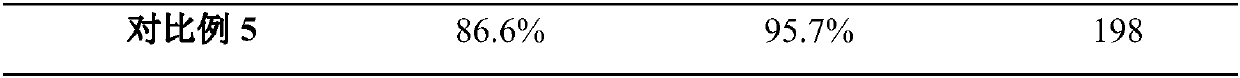

[0067] Example 1 full battery case:

[0068] The copper foil electrode modified by the nitrogen-doped carbon nano-cage prepared in Example 1 is used as a working electrode, and then at 1mA / cm 2 At a current density of 5mAh / cm 2 On the copper foil electrode modified by nitrogen-doped carbon nanocages to prepare a composite negative electrode material, and then form a soft-packed lithium-sulfur battery with a mesoporous carbon positive electrode rich in S, in 1M LiTFSI / DOL:DME (volume ratio=1:1) Contains 1wt.% LiNO 3 In the electrolyte solution, the charge-discharge cycle test was carried out at 1C. The relevant results of the tests are shown in Table 2.

Embodiment 3

[0078] Carbon nanocages with internal cavities (with a specific surface area of 232.7m 2 / g, the carbon wall thickness is 7nm, and the internal cavity size accounts for 94% of the total volume) is placed in the argon atmosphere (nitrogen content 40vol.%) containing nitrogen, after 800 ℃ of heat treatment 5h, the nitrogen-doped carbon nanocage ( Nitrogen doping amount is 2.2 at.%). Then mixed with polyvinylidene chloride according to the mass ratio of 90%, and then coated on copper foil, titanium foil, nickel foil, iron foil, cobalt foil (20μm) to prepare double-sided nitrogen-doped carbon nanocage modified copper Foil, titanium foil, nickel foil, iron foil, cobalt foil electrode (coating layer thickness is 60μm). These electrodes are used as working electrodes, and metal lithium sheets are used as counter electrodes, with 1M LiTFSI / DOL:DME (volume ratio=1:1) containing 1wt.% LiNO 3 Carry out pouch battery assembly for the electrolyte, at 4mA / em 2 Under the current density...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com