Silicon-carbon composite material, preparation method thereof and lithium ion battery

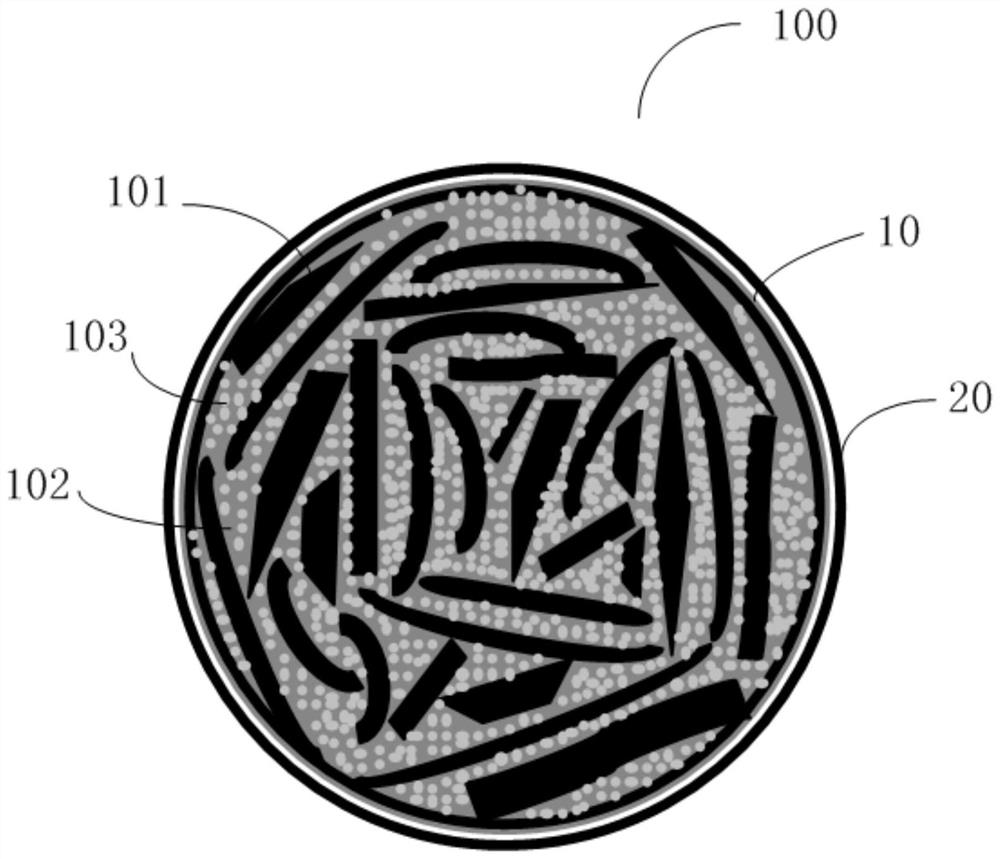

A silicon carbon composite material, silicon material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low structural stability of composite materials, uneven dispersion of nano-silicon, large internal pores, etc., to improve the structure. Stability and energy density, avoid excessive expansion and shrinkage, and the effect of small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

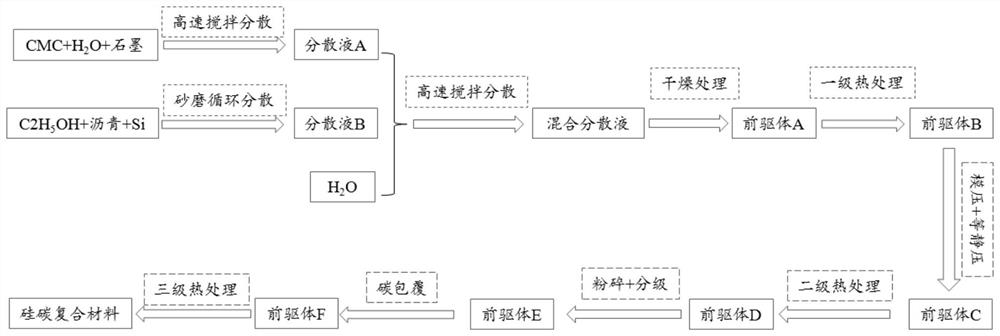

[0057] Correspondingly, an embodiment of the present invention also provides a method for preparing a silicon-carbon composite material, including:

[0058] S101, adding the graphite material into the sodium carboxymethyl cellulose aqueous solution, stirring and dispersing evenly to obtain a dispersion A;

[0059] S102, wet the silicon material with C1-C4 alcohol, and uniformly disperse it in water together with the amorphous carbon precursor, to obtain a dispersion B;

[0060] S103, add dispersion A and dispersion B to water and mix, stir and disperse evenly to obtain a mixed dispersion;

[0061] S104, drying the mixed dispersion to obtain a primary precursor;

[0062] S105, subjecting the first-level precursor to first-level heat treatment, molding treatment, cold isostatic pressing treatment and second-level heat treatment in sequence, and crushing and grading to obtain the second-level precursor;

[0063] S106. Coating the secondary precursor with carbon and tertiary hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com