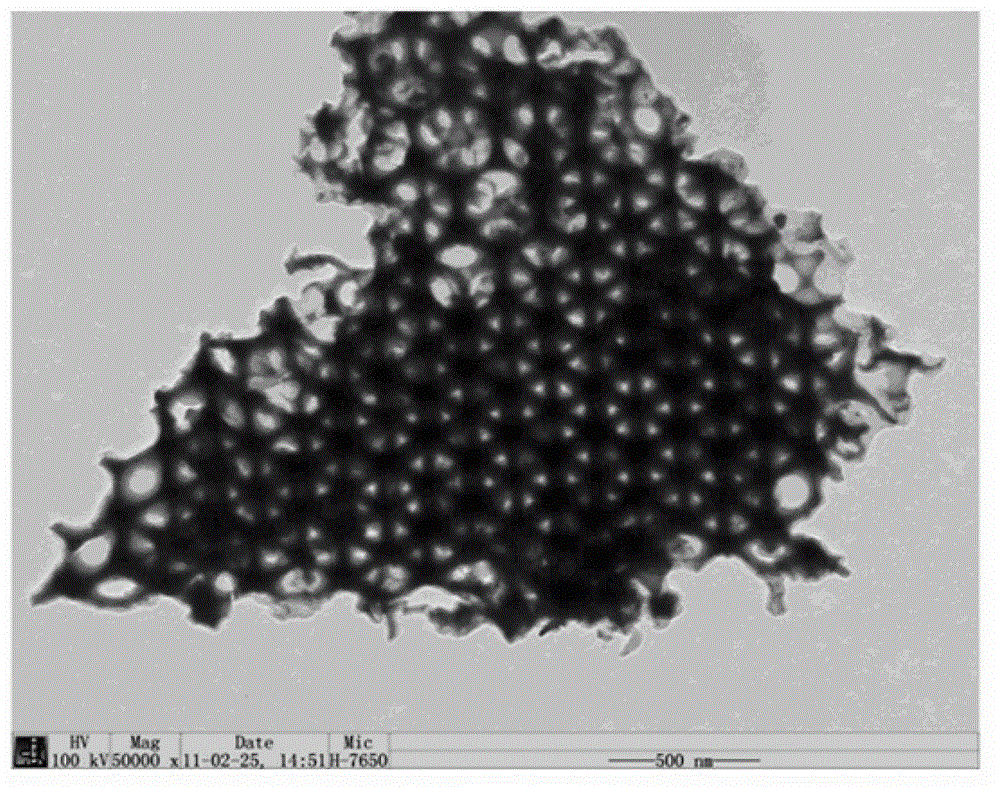

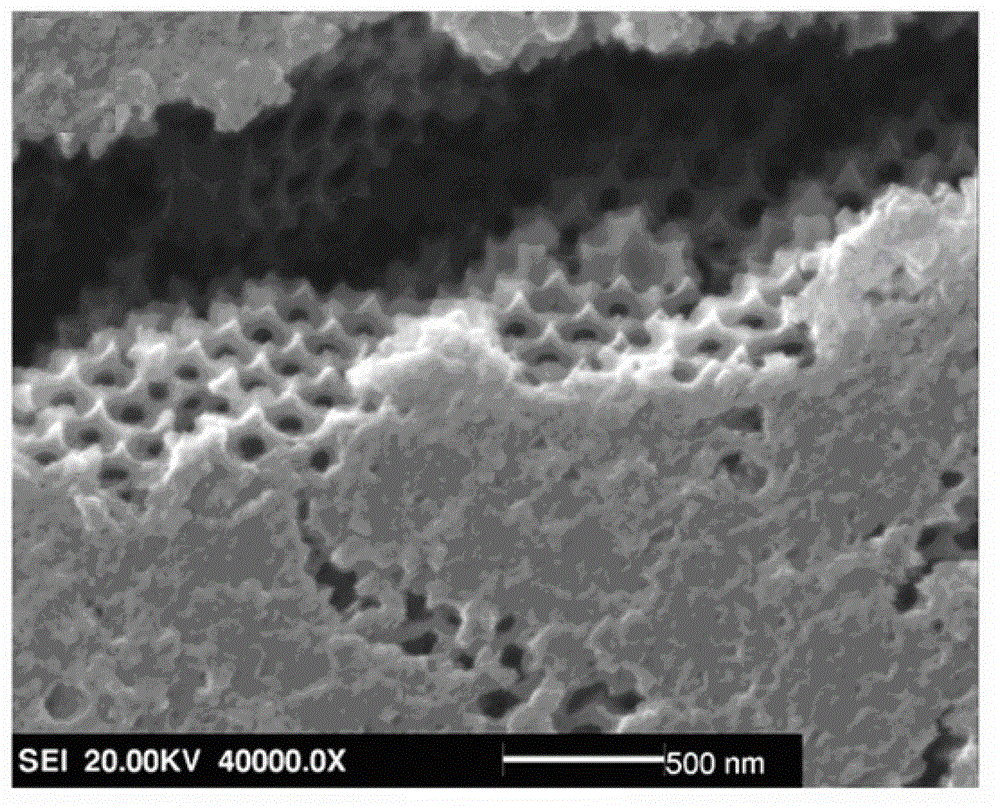

Preparation method of electrochromic film having photonic crystal structure

A photonic crystal, electrochromic technology, applied in optics, nonlinear optics, electrolytic organic material coating, etc., can solve the problems of irreversibility of electrochromic materials cannot be improved, reduce solar absorption rate, etc., and achieve excellent electrochromic response performance, improve ion diffusion coefficient, shorten the effect of ion diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the preparation method of the electrochromic thin film with photonic crystal structure in this embodiment is carried out according to the following steps:

[0018] 1. Surface treatment of the substrate material: The substrate is cleaned with acetone, methanol and ultrapure water for 10min~30min under the condition of ultrasonic power of 80W~120W, and then dried. The thickness of the substrate material is 0.01mm~1mm ITO conductive glass, FTO conductive glass, ITO-plated polyimide substrate, silver-plated polyimide substrate, gold-plated polyimide substrate or polyester substrate;

[0019] 2. Preparation of colloidal solution: Add microspheres with a diameter of 50nm~5μm into deionized water or ethanol solution to obtain a solution with a monodispersity of ≤5% and a concentration of 0.01%~1% by mass, and then undergo ultrasonic vibration Disperse to obtain a colloidal solution, and finally obtain a colloidal solution for template making after UV-o...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that in Step 1, the substrate is cleaned with acetone, methanol and ultrapure water for 15 min to 25 min under the condition of ultrasonic power of 90W-110W. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0028]Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step two, microspheres with a spherical diameter of 100nm~1μm are added to deionized water or ethanol solution to obtain monodispersity≤4%, mass percentage A solution with a concentration of 0.05%~0.5%. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com