Patents

Literature

78 results about "Solar absorptance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar Absorptance. The solar absorptance of a surface is the fraction of the sun's radiation that the surface absorbs. Solar absorptance is a factor in the calculation of the PV array temperature.

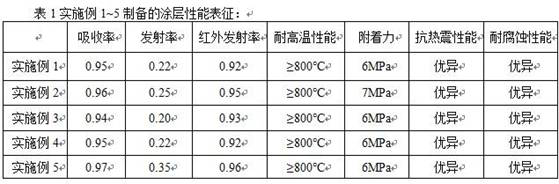

Method for preparing solar selective heat-absorbing coating with spinel pigment as light-absorbing agent

ActiveCN102286243AHigh solar absorption rateLow emissivityPolyurea/polyurethane coatingsRadiation-absorbing paintsSolar absorptancePhotopigment

The invention relates to a method for preparing a solar selective heat absorbing paint by using a spinel type pigment as a light absorbent, which belongs to the field of solar heat utilization. The method comprises the steps of uniformly dispersing a nanoscale spinel type pigment as well as resin, a solvent and auxiliaries by using a ball milling method; and then adding a curing agent to obtain the solar selective heat absorbing paint. It is shown in the experiment that the paint is uniformly coated on a metal substrate by using a spraying method; and the solar selective heat absorbing paint obtained after being cured at room temperature shows higher solar energy absorption rate (0.93-0.95) and lower emissivity (0.18-0.30); and the photothermal conversion efficiency of a solar heat collector can be effectively improved; moreover, the coating has the advantages of good mechanical property, stronger weather resistance and service life of more than 45 years.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

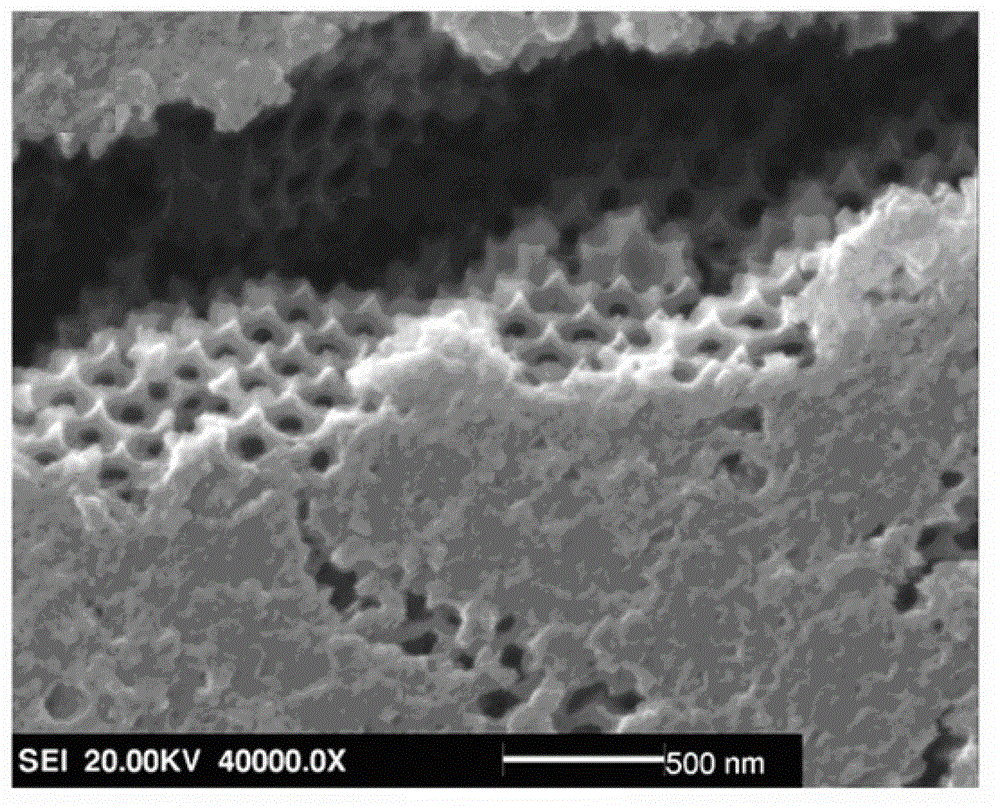

Preparation method of electrochromic film having photonic crystal structure

ActiveCN102978674AHigh densityImprove coloring efficiencyNon-linear opticsElectrolytic organic material coatingSolar absorptancePhotonic crystal structure

The invention relates a preparation method of an electrochromic film having a photonic crystal structure. The preparation method solves the problem that the existing electrochromic material has irreversibility so that material reflectivity is not improved and solar absorptance is not reduced. The preparation method of the electrochromic film having a photonic crystal structure comprises the following steps of 1, base material surface treatment, 2, colloidal solution preparation, 3, film-type colloidal crystal template preparation, 4, solution preparation, 5, electrode preparation and 6, film electrochemical preparation. A polyaniline photonic crystal film having an inverse opal structure and prepared by the preparation method has excellent electrochromism response performances. The preparation method can be used for the field of preparation and production of the electrochromic film having a photonic crystal structure.

Owner:HARBIN INST OF TECH

Thermal control coatings

Owner:THE BOEING CO

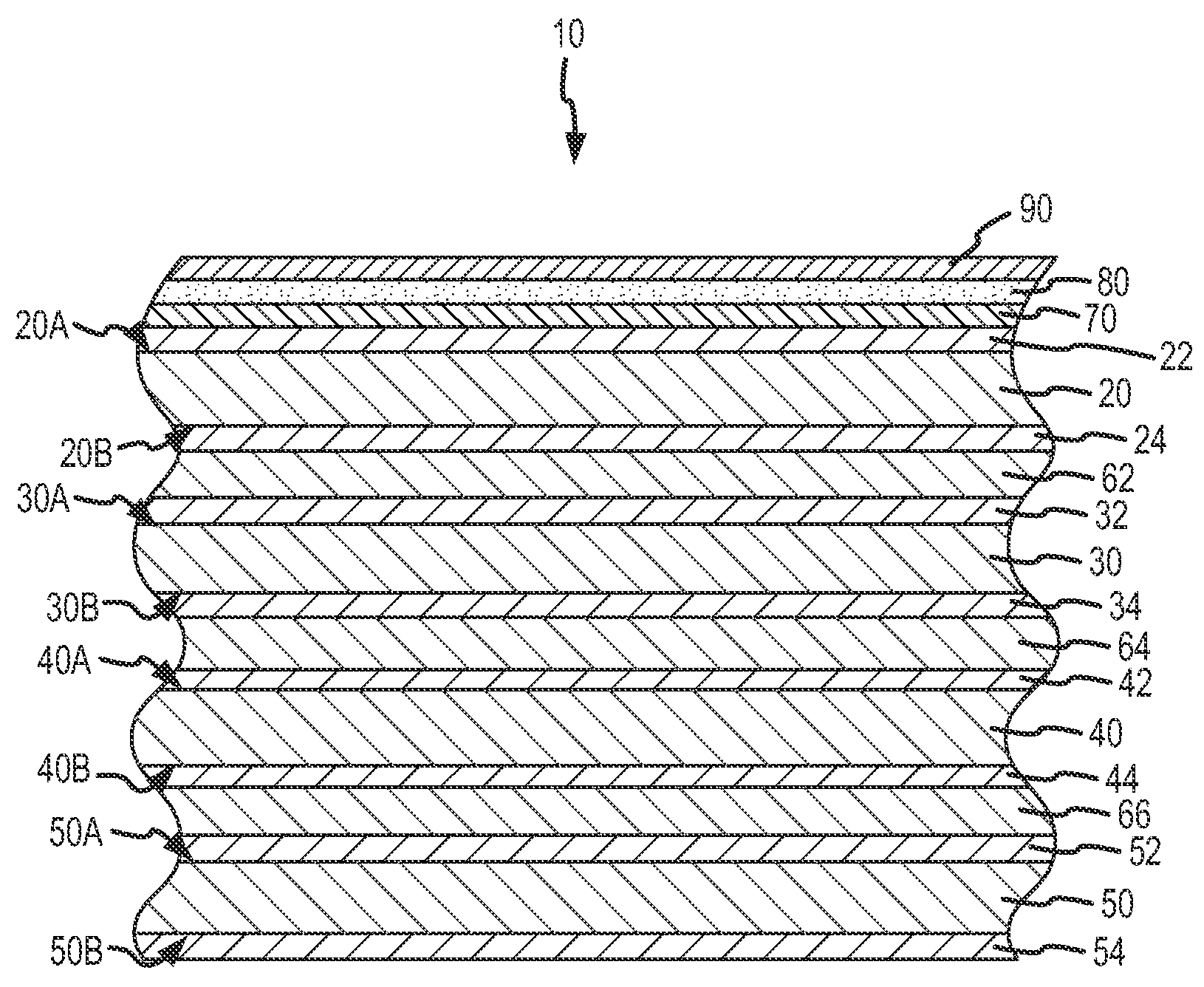

Anti-contamination coated multi-layer insulation

ActiveUS7252890B1Reduce presenceImprove efficiencySynthetic resin layered productsCosmonautic thermal protectionSolar absorptanceUltraviolet

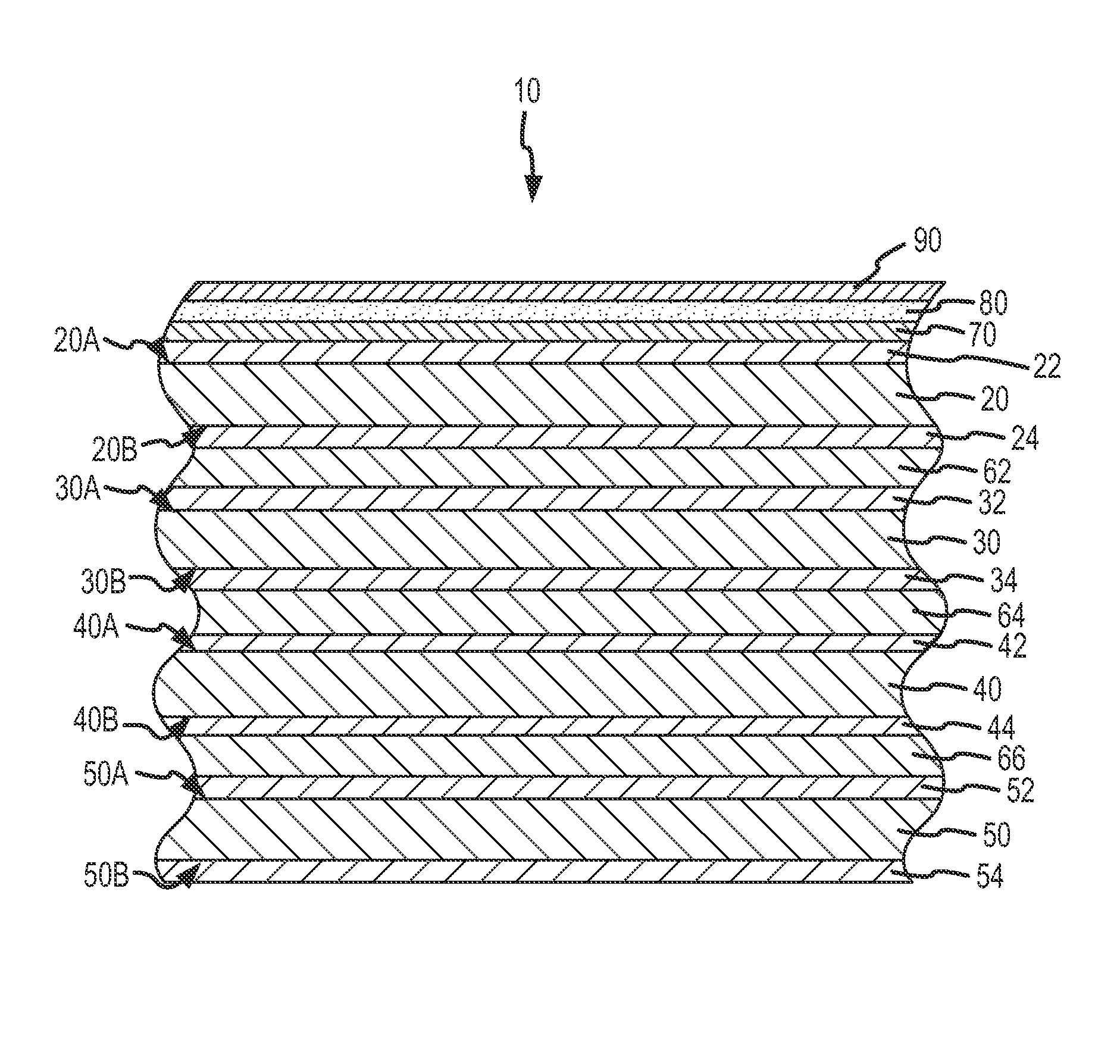

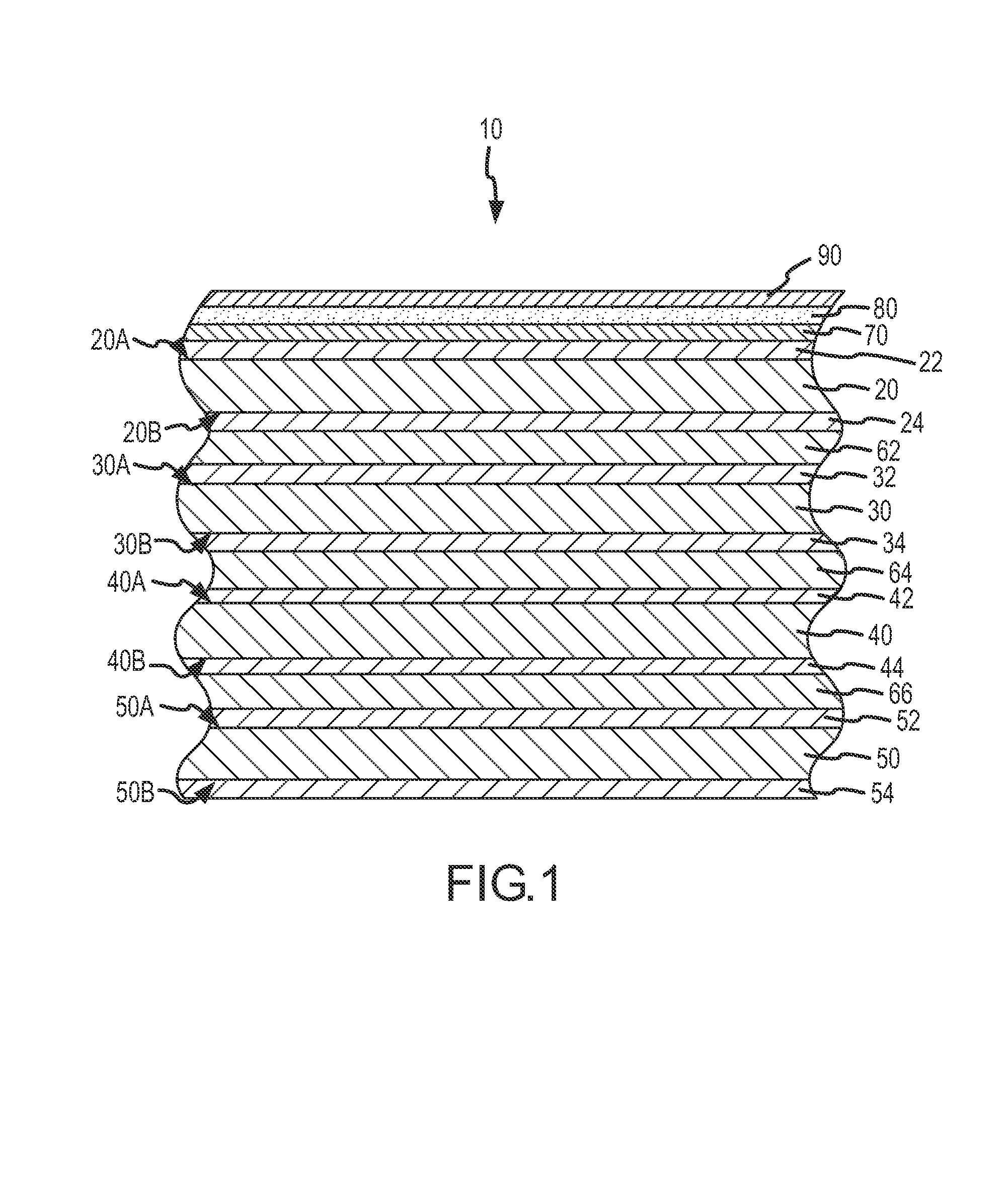

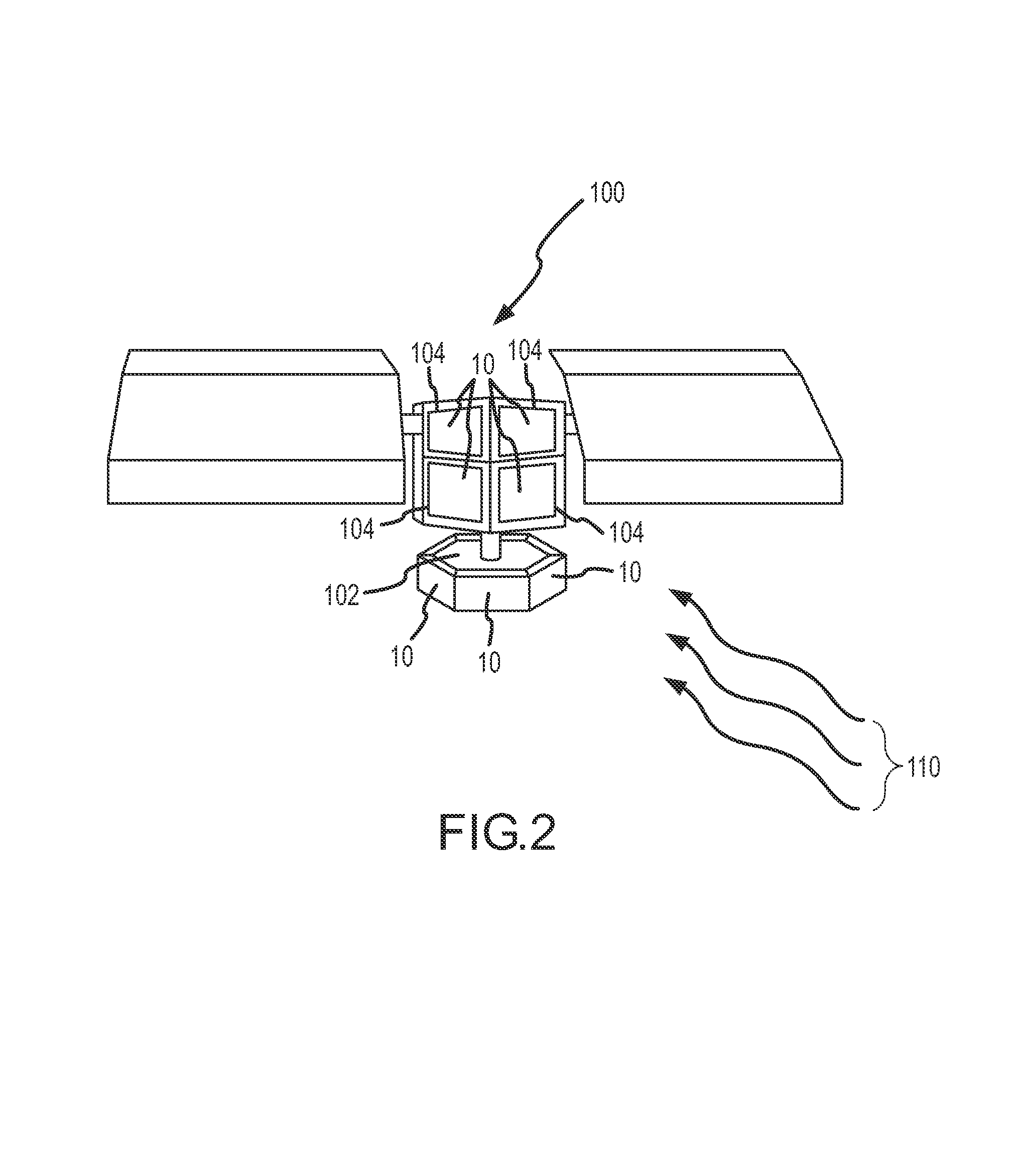

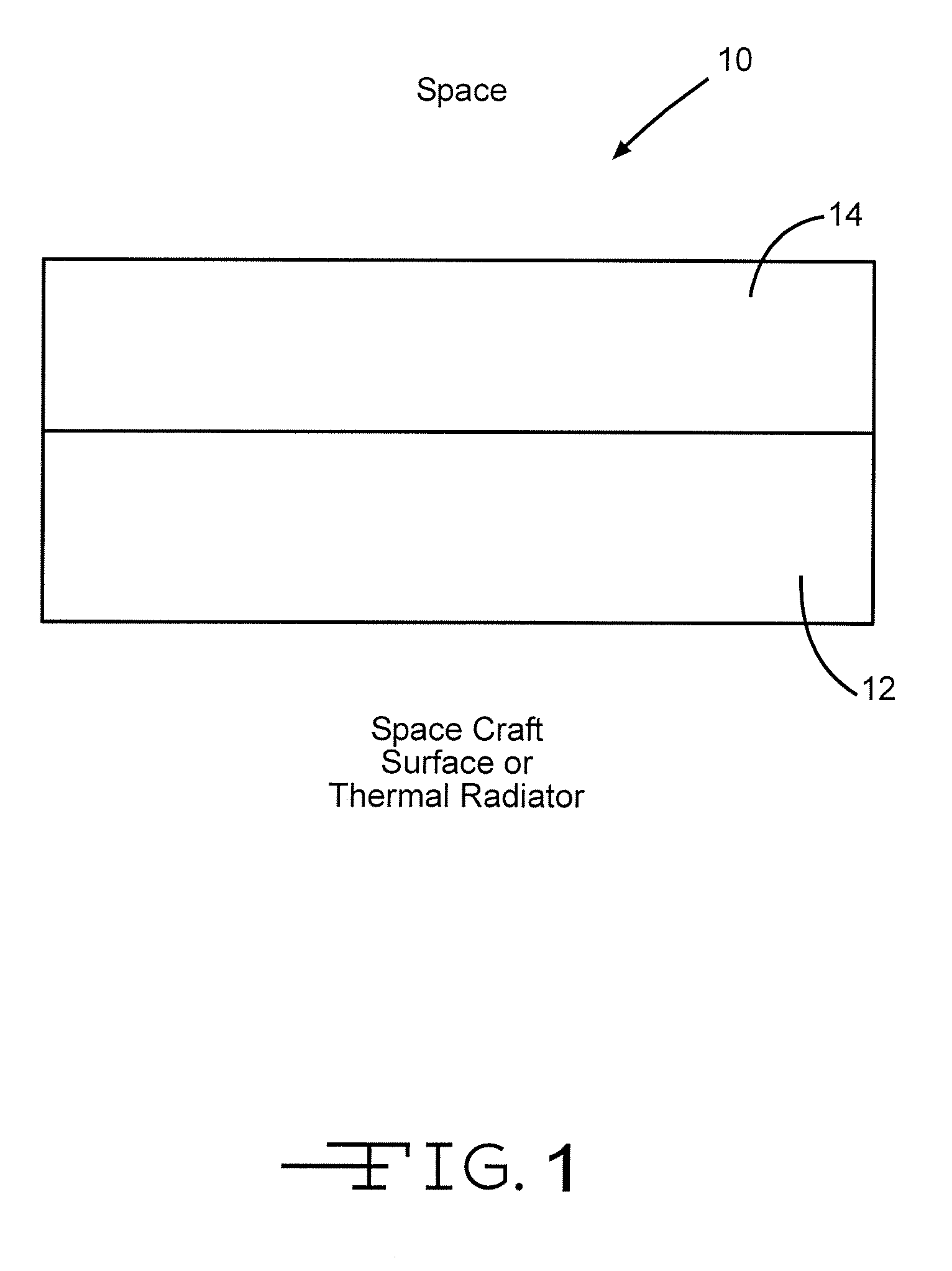

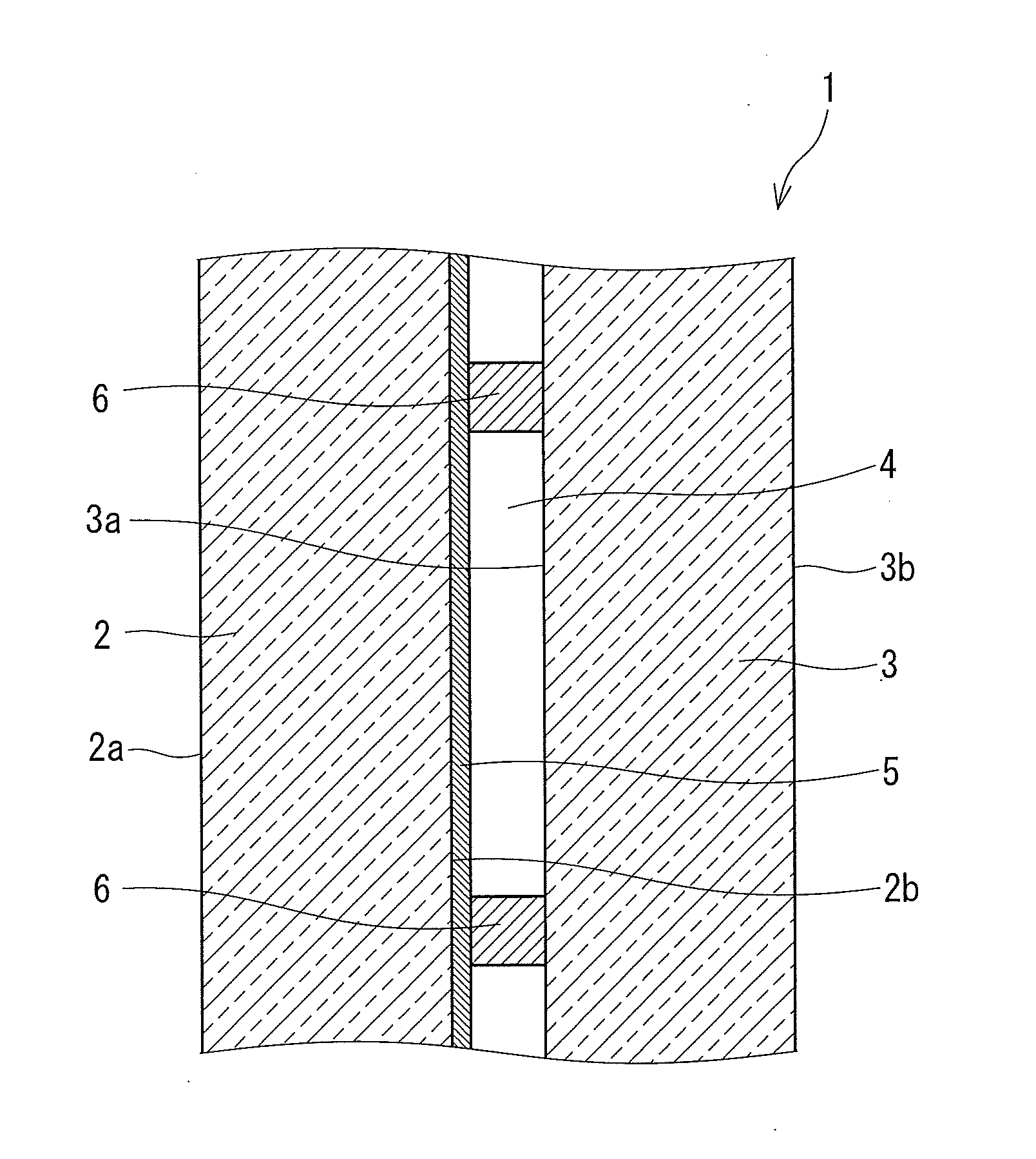

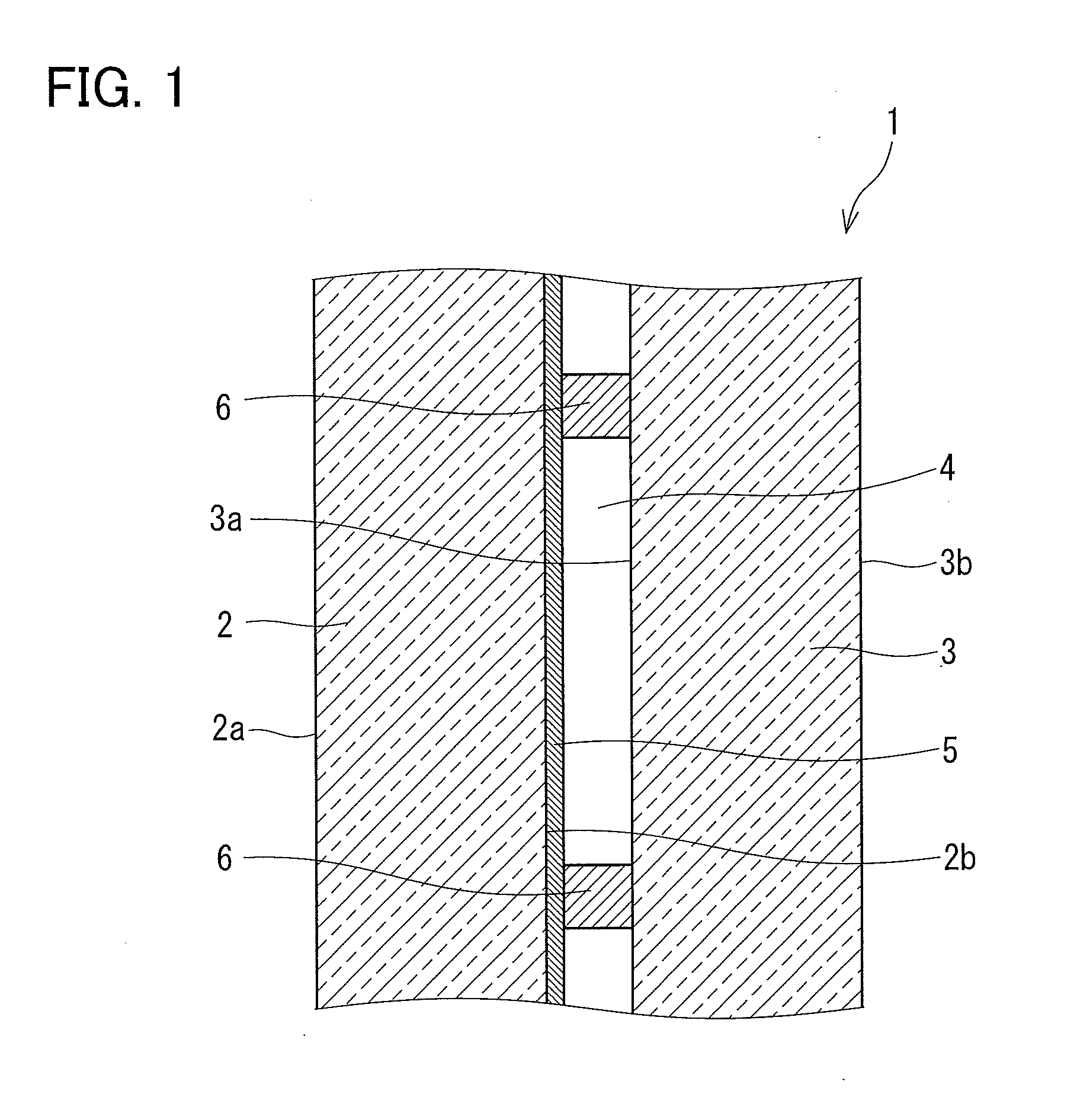

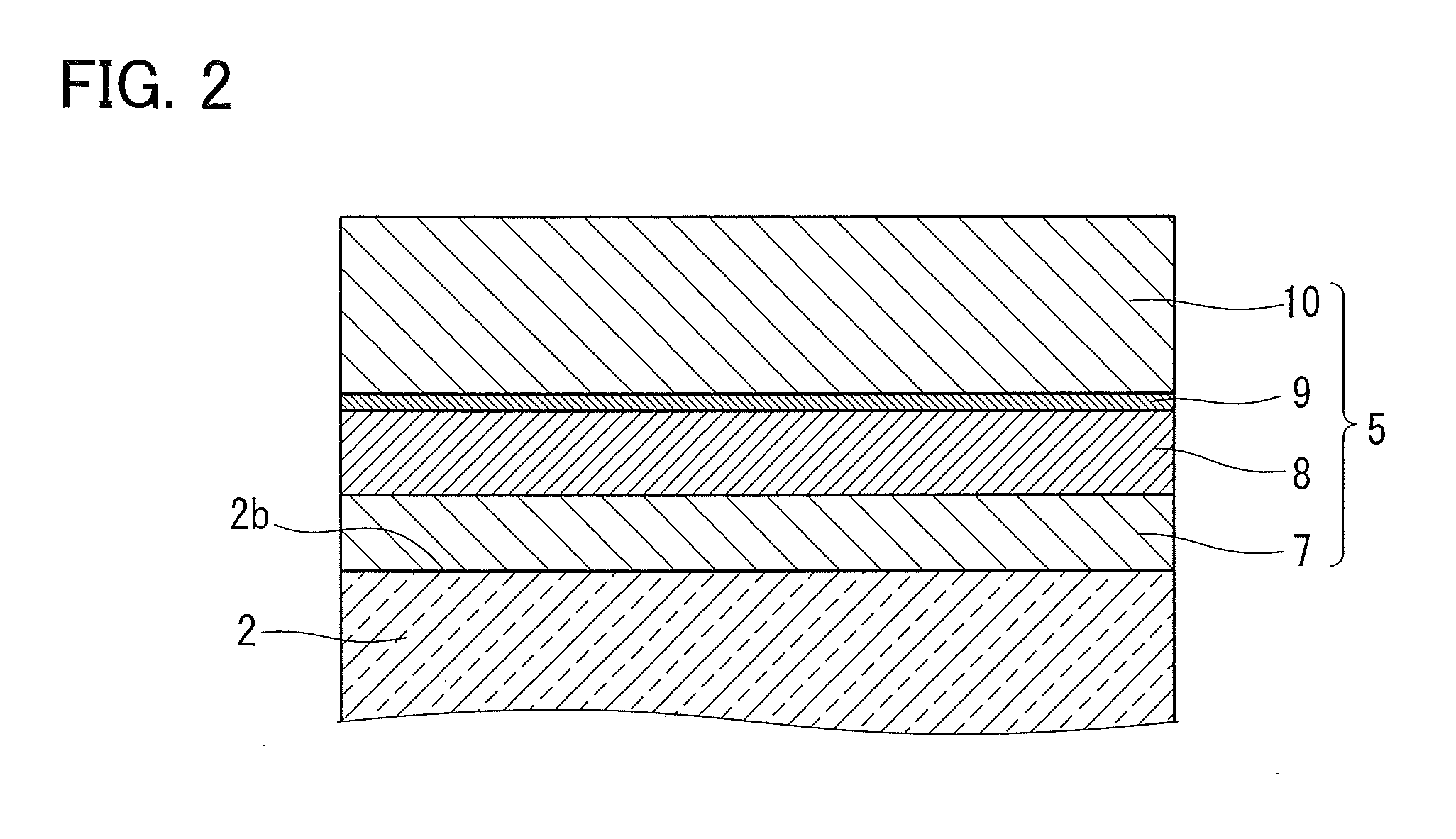

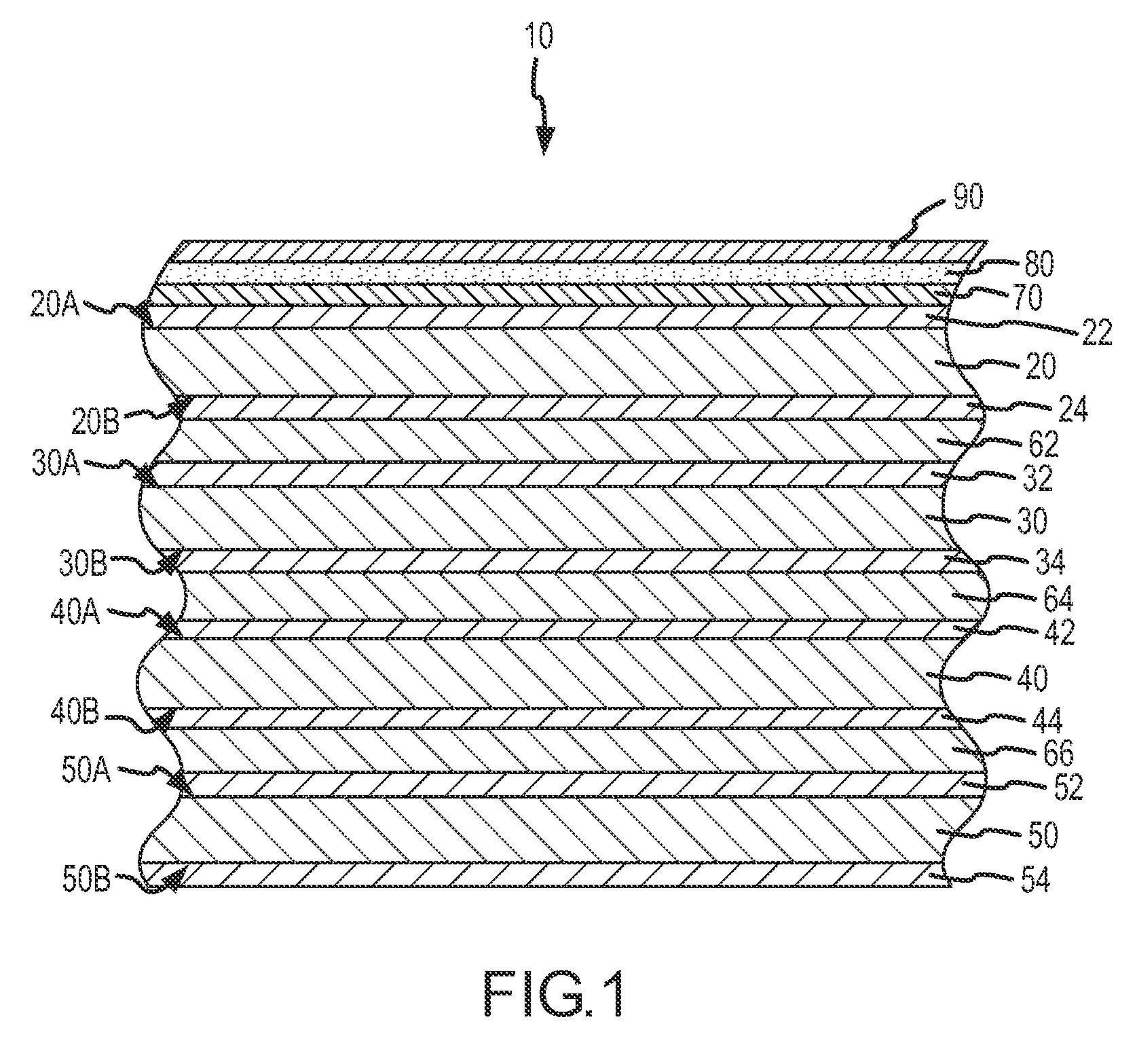

A multi-layer insulation (MLI) blanket with enhanced contamination inhibiting properties and a method for inhibiting the formation of organic residues on the outer surface of a MLI blanket are provided. In one embodiment, a MLI blanket (10) attachable to a spacecraft or other structure includes a plurality of metallized layers (20, 30, 40, 50) separated by mesh layers (60, 62, 64). An anti-contamination coating (80) comprised of a photocatalytic material is disposed between a high emittance layer (70) that overlies the outer surface (20A) of the outer metallized layer (20) and an outer electrically conductive layer (90). When exposed to ultraviolet or near-ultraviolet radiation components present in solar radiation, the anti-contamination coating (80) catalyzes the breakdown of organic residues on the outer surface of the MLI blanket (10) thereby maintaining the reflective properties of the MLI blanket (10) and ensuring that solar absorptance of the MLI blanket (10) is maintained at or below an acceptable threshold level.

Owner:LOCKHEED MARTIN CORP

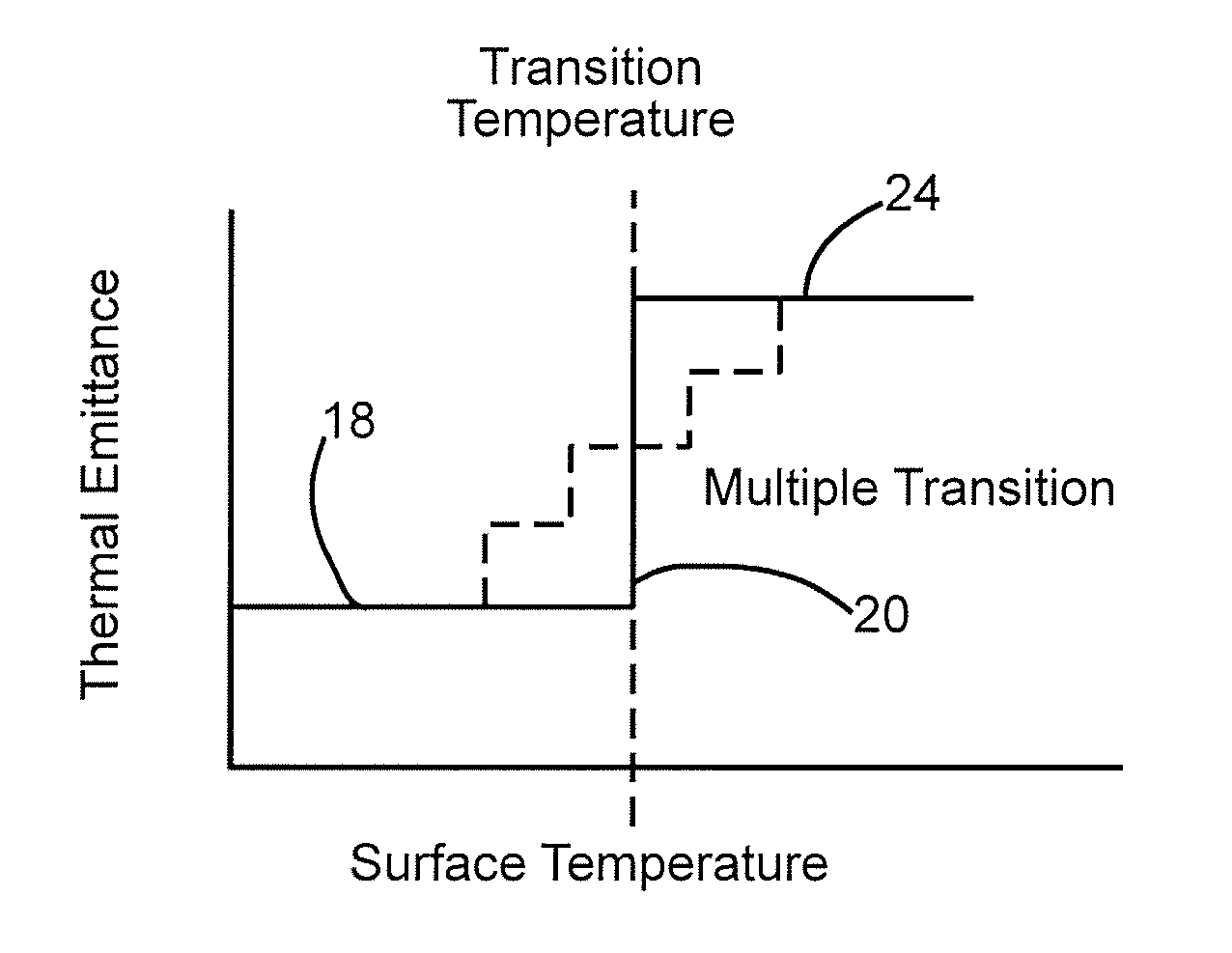

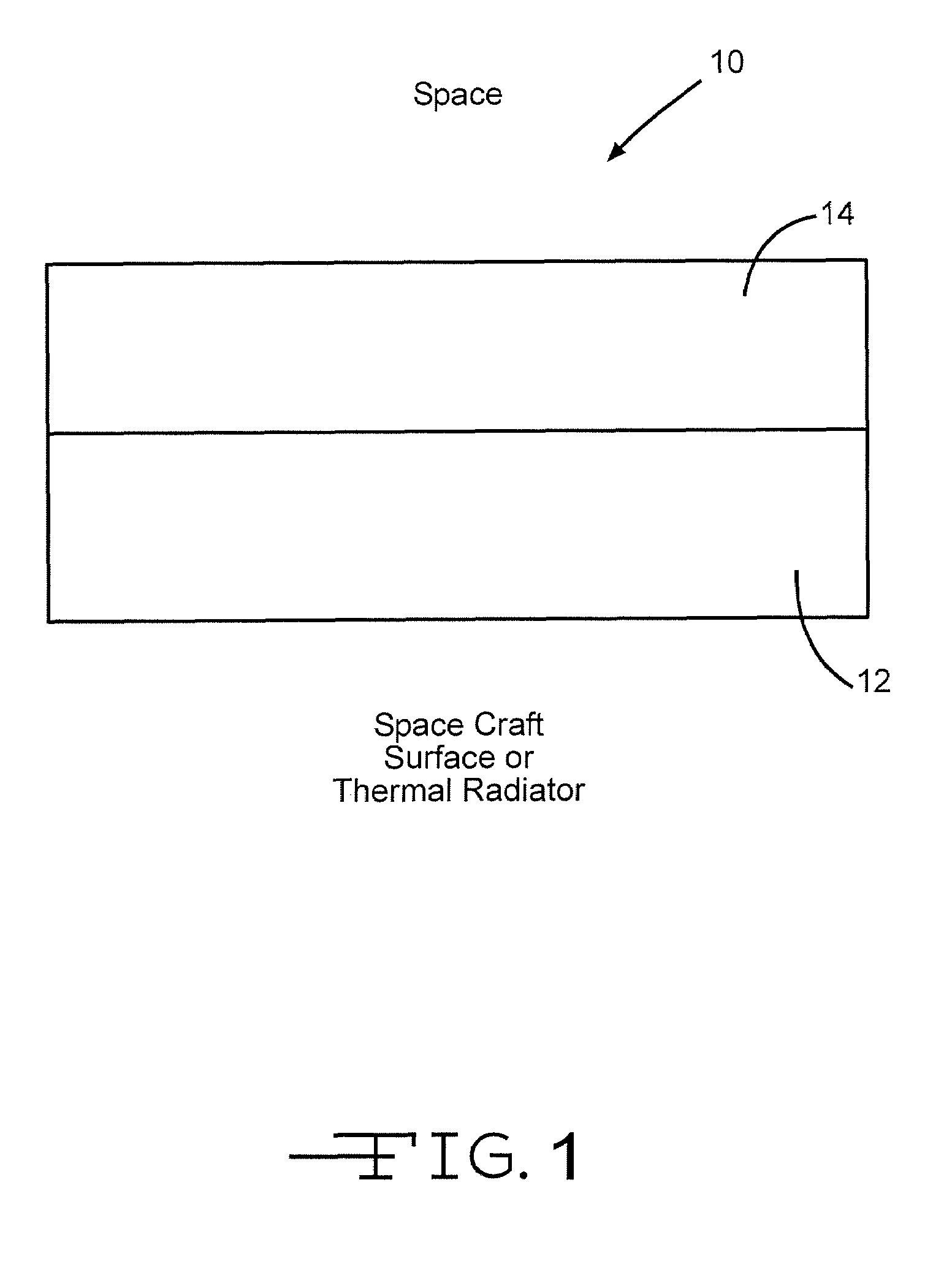

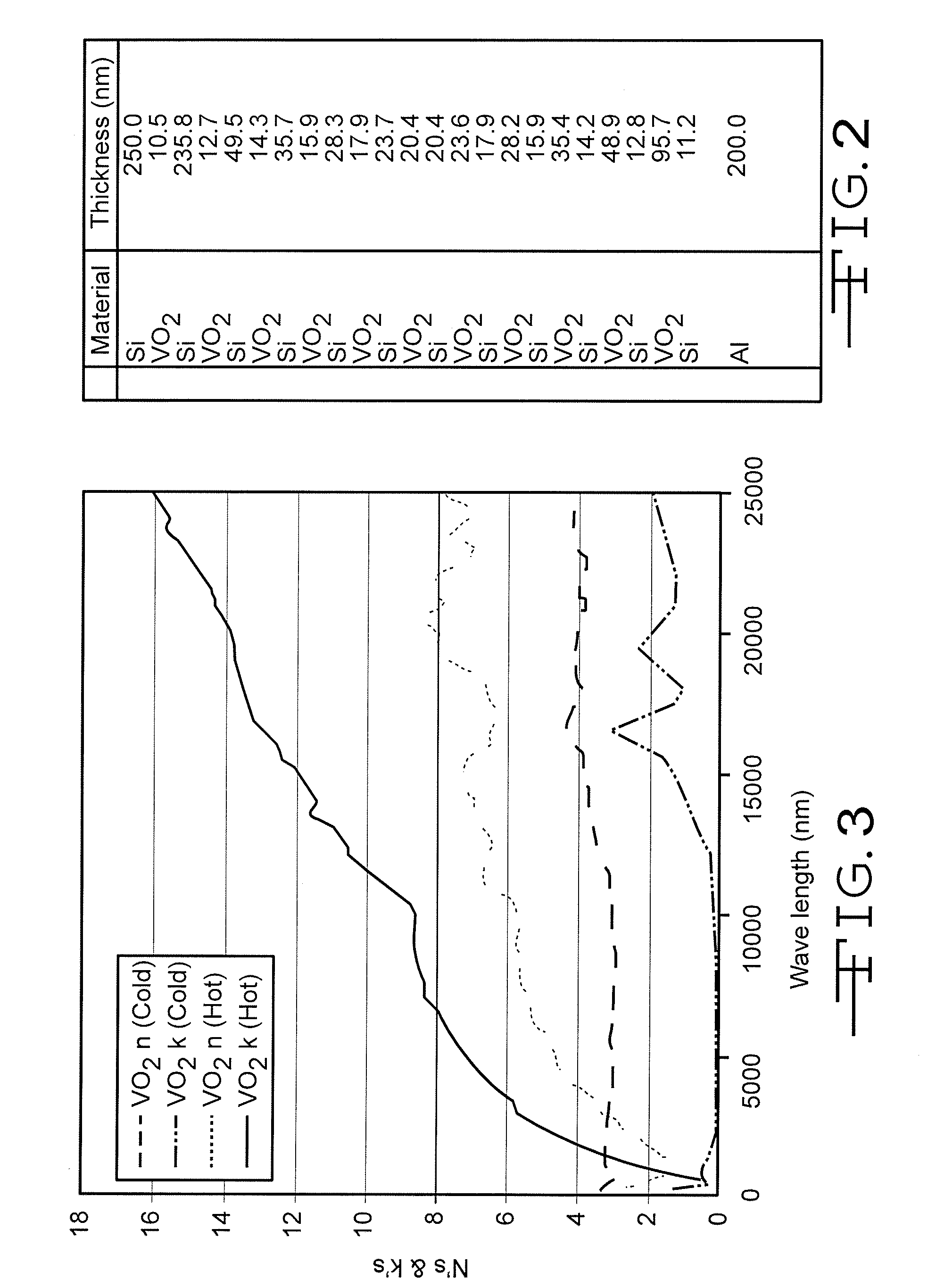

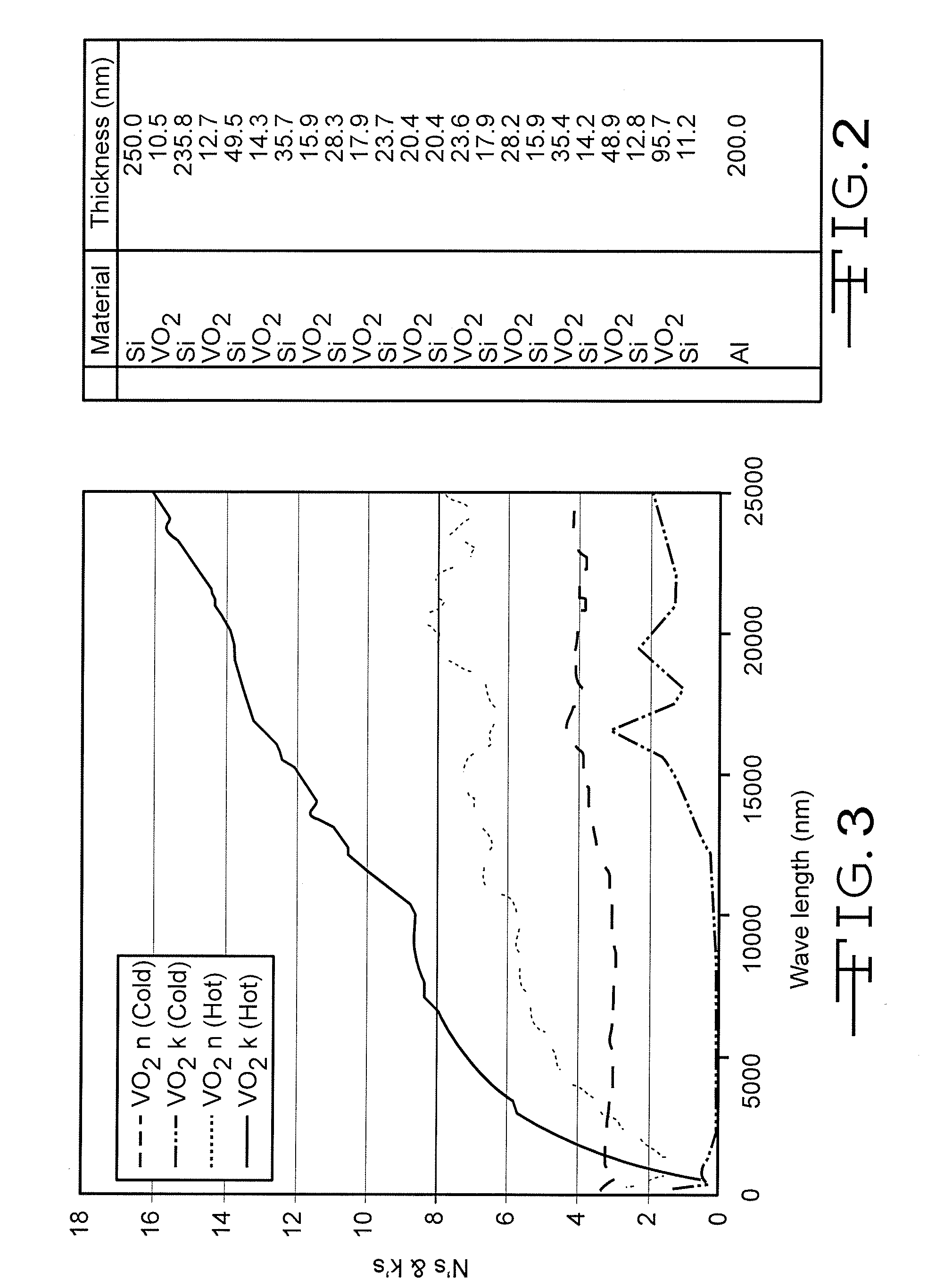

Thermal control coatings

The invention discloses differing embodiments of thermal control coatings, spacecraft components having coatings, and methods for controlling the temperature of a component. In one embodiment, a thermal control coating under the invention may include one or more thermochromic multi-layer coatings and one or more solar rejection multi-layer coatings. The thermal control coating may have one or more transition temperatures at which the solar absorptance of the solar rejection coating substantially stays the same, while a thermal emittance of the thermochromic coating substantially changes.

Owner:THE BOEING CO

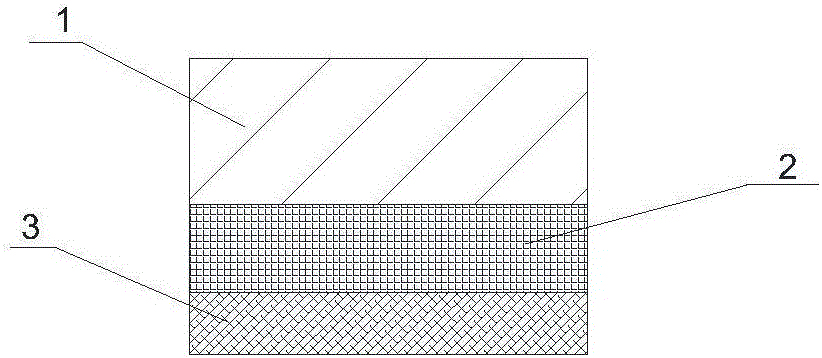

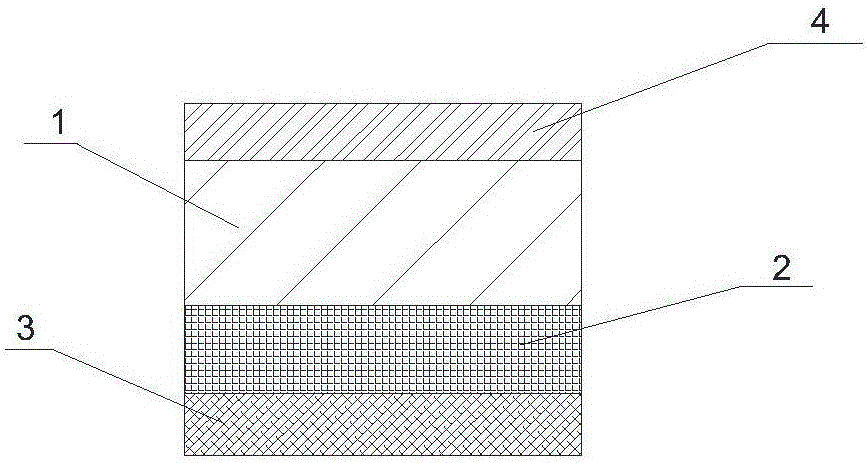

Flexible OSR second surface mirror thermal control coating and preparation method and application thereof

InactiveCN106336128ASolve the problem that surface paste cannot be implementedSolve problems such as fragile productsCosmonautic thermal protectionCoatingsEmissivitySolar absorptance

The invention provides a flexible OSR second surface mirror thermal control coating. The thermal control coating comprises a flexible glass substrate. One side of the flexible glass substrate is firstly coated with a metal reflecting layer and then coated with an anti-oxidation layer. If there is requirement on conductibility, the other side of the flexible glass substrate is coated with a conductive film layer. The fundamental principle of the invention is to adopt a vacuum magnetron sputtering and coating technology. By coating at two sides of the flexible glass substrate, the flexible OSR second surface mirror thermal control coating with a certain physical properties, namely solar absorptance (alpha s) and emittance (epsilon h) is obtained. The flexible OSR second surface mirror thermal control coating can be pasted onto a curved surface of spacecrafts such as a satellite, etc. to raise thermal control performance. Then, the problem that a traditional rigid OSR second surface mirror thermal control coating cannot realize curved surface pasting and a product is easy to crack is effectively solved; and application range of the OSR second surface mirror thermal control coating is widened.

Owner:SHANGHAI YUDA IND

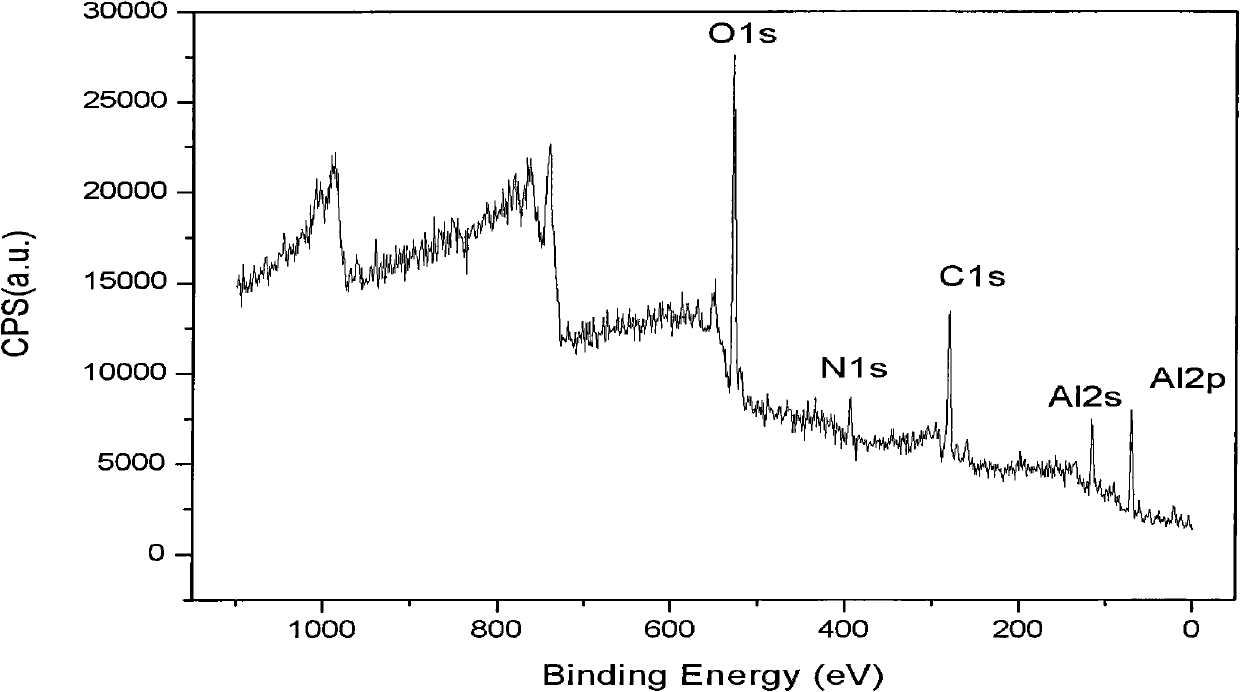

Hydrosol for preparing solar photo-thermal conversion absorption film

InactiveCN102357658ANo pollution in the processSimple preparation processSolid/suspension decomposition chemical coatingAbsorptanceSolar absorptance

The invention provides a hydrosol for preparing a solar photo-thermal conversion absorption film. Water is used as a solvent in the hydrosol; a transition metallic M salt, an aluminum salt and a chelating agent are used as raw materials; the transition metallic M salt and the aluminum salt are respectively prepared into an M sol and an Al2O3 sol together with the chelating agent; and the M sol and the Al2O3 sol are mixed and added with a wetting agent to form an M-Al2O3 mixed sol, namely the hydrosol. The M-Al2O3 mixed sol for preparing the absorption film is prepared by using the environment-friendly water as the solvent; the sol preparation method is simple, feasible, easily obtainable in raw materials and low in cost; after the M-Al2O3 mixed sol added with the wetting agent forms a film on a metal substrate, an M-Al2O3 absorption layer can be directly obtained by thermal treatment under inert atmosphere; the film preparation process is simple, convenient and low in equipment requirement, and has no pollution to the environment; and the solar absorption rate of the prepared single-layer M-Al2O3 film can reach 0.86, and the emissivity of the film is only 0.03.

Owner:FUZHOU UNIV

Solar selective absorbing coating and preparation method thereof

ActiveCN101660117AEasy to implementEasy to controlSolar heat devicesVacuum evaporation coatingEmissivitySolar absorptance

The invention discloses a solar selective absorbing coating which mainly consists of an infrared high reflectivity metal layer, a diffusion impervious layer, an absorbing layer and an antireflection layer in sequence; the absorbing layer is composed of a metal-medium composite material film which is expressed as SS-Ox-AlNyOz, the metal-medium composite material film is composed of metal SS molecular group, trace oxide formed by combining SS and O, and medium AlNyOz; and the antireflection layer medium material film is expressed as AlNiOj. The coating of the invention is easy to realize and simple to regulate and control in terms of preparation technique; the coating is suitable to be used in vacuum or air under low and medium temperature environment; the performance of the coating is stable; and the solar absorptance alpha thereof is more than 0.92, and the emissivity ratio thereof is less than or equal to 0.08.

Owner:HIMIN SOLAR

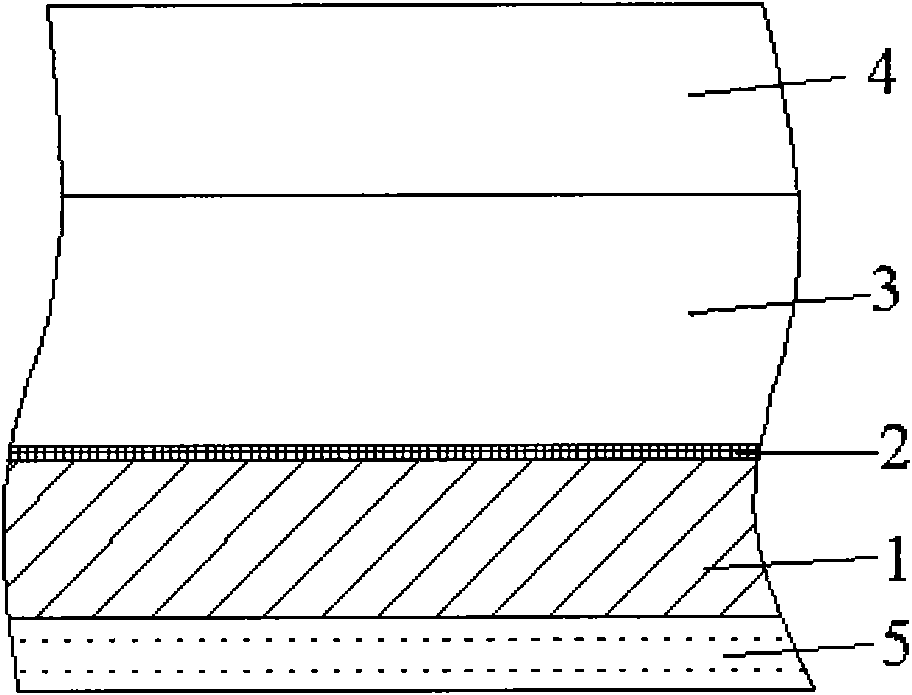

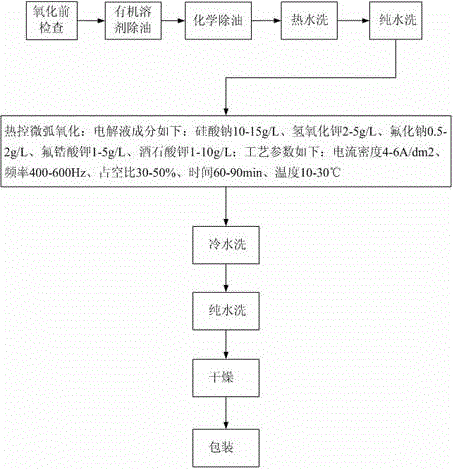

Method for preparing low-absorptance high-emissivity thermal control coating on magnesium alloy surface through micro-arc oxidation technology

InactiveCN105442020AImprove bindingImprove corrosion resistanceAnodisationAbsorptancePlasma electrolytic oxidation

Te invention discloses a method for preparing a low-absorptance high-emissivity thermal control coating on a magnesium alloy surface through a micro-arc oxidation technology. The process flow of the method comprises detecting before oxidation, removing oil through an organic solvent, chemically removing oil, washing with hot water, washing with pure water, performing micro-arc oxidation, washing with cold water, washing with pure water, drying and packaging. In the micro-arc oxidation step, an electrolyte is composed of 10-15 g / L of sodium silicate, 2-5 g / L of potassium hydroxide, 0.5-2 g / L of sodium fluoride, 1-5 g / L of potassium hexafluorozirconate, and 1-10g / L of potassium tartrate hemihydrates; and the technology parameters comprise that the electric current density is 4-6 A / dm2, the frequency is 400-600 Hz, the duty ratio is 30-50%, the time is 60-90 min, and the temperature is 10-30 DEG C. Therefore, the obtained thermal control coating possesses the emissivity of 0.86 or more and solar absorptance of 0.35 or less, is uniform and dense, good in binding force with a matrix and good corrosion resistance.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

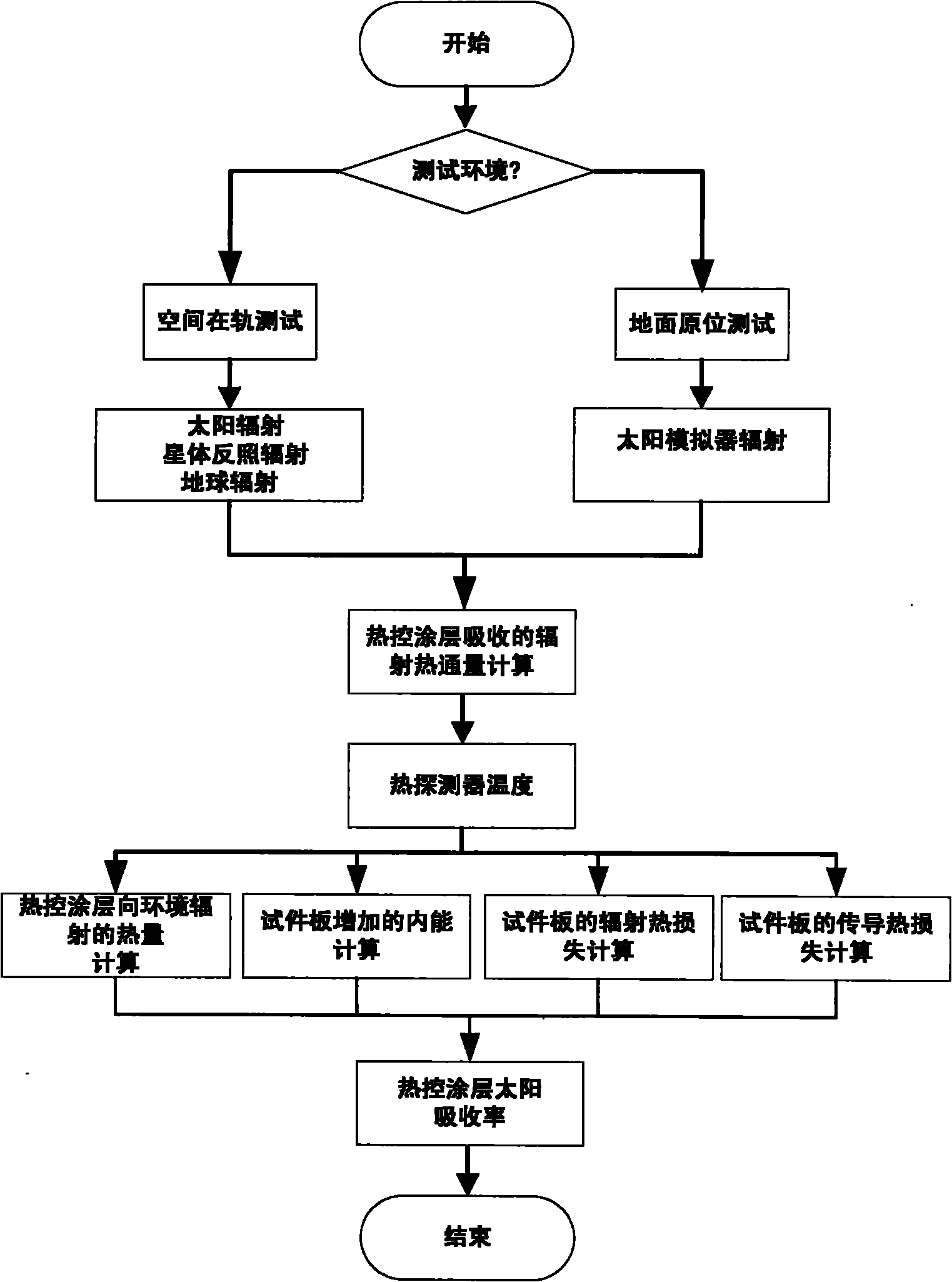

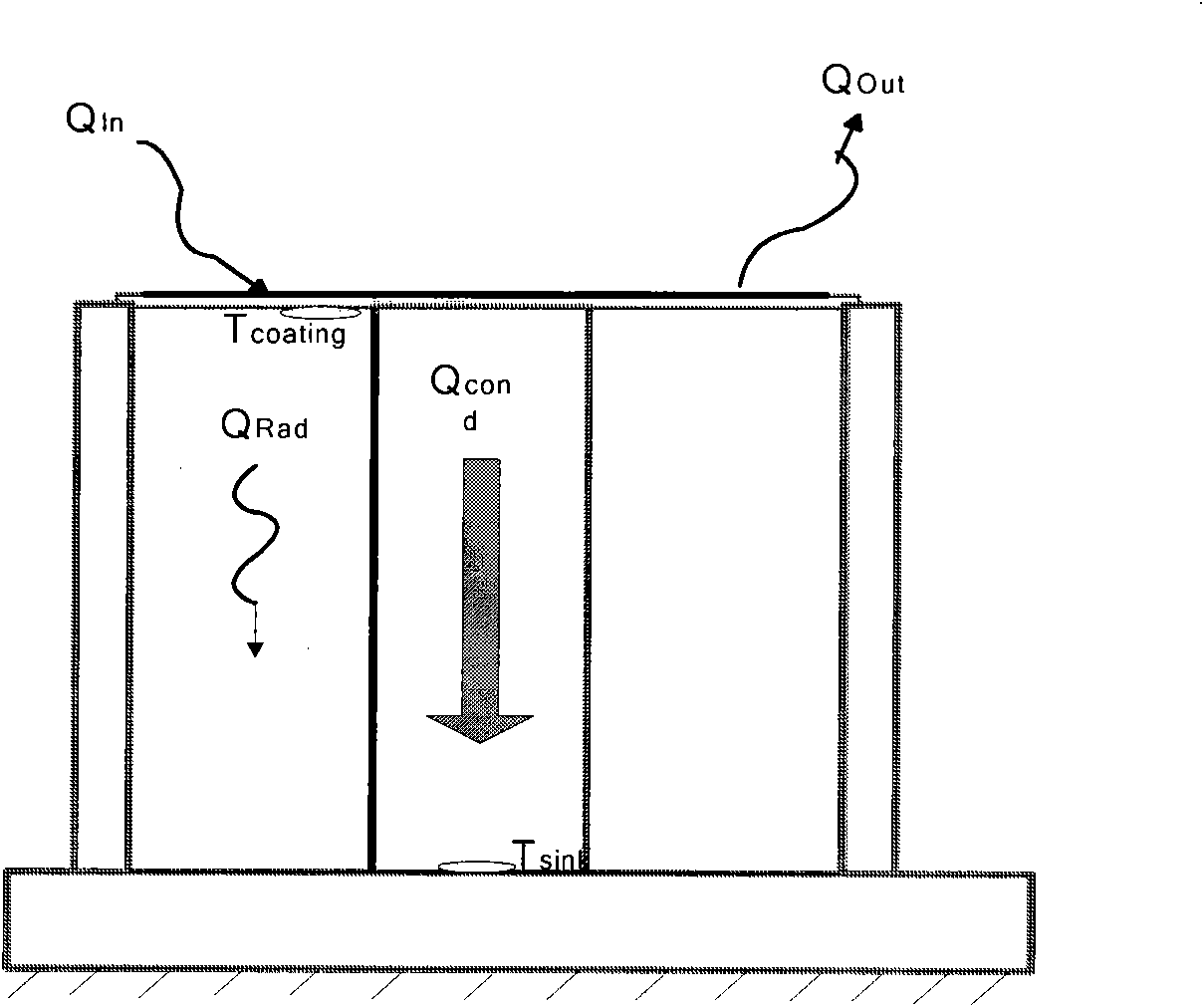

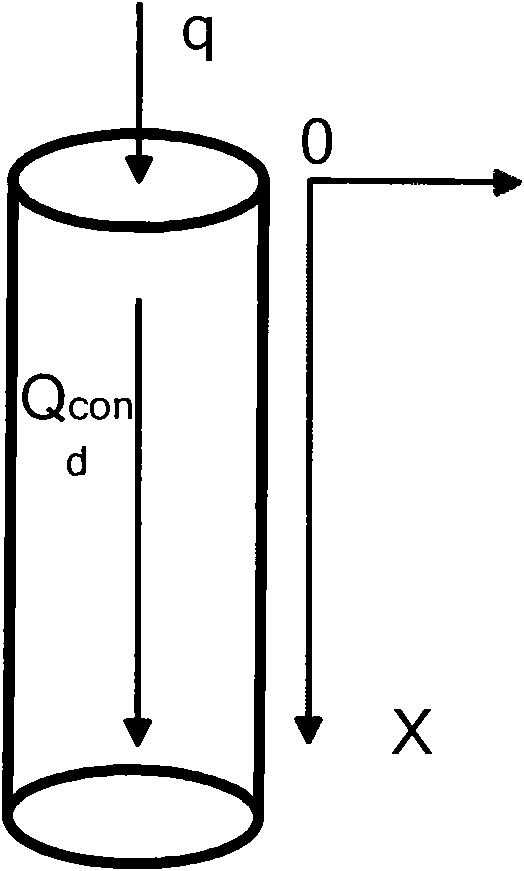

Measuring method of solar absorptance of thermal control coating

The invention relates to a measuring method of the solar absorptance of a thermal control coating, which is characterized in that the heat measuring method is used for obtaining the optical performance of the thermal control coating. The method comprises the following steps: firstly, uniformly applying the thermal control coating on a thin metal test piece plate capable of measuring the temperature at real time; multiplying the solar absorptance of the thermal control coating by the irradiation heat for calculating the irradiation flux absorbed by the thermal control coating; then, measuring the temperature of the thermal control coating at real time, and calculating and obtaining the heat radiated by the thermal control coating to the space according to the Stefan-Boltzmann law; and analyzing and calculating each kind of heat loss in the space environment of the thermal control coating through the test piece plate, and calculating and obtaining the solar absorptance of the thermal control coating according to the principle of conservation of energy. The method calculates the solar absorptance of the thermal control coating through testing the temperature of the thermal control coating, so a detector with the detection precision of 0.1 degree is selected, and the precision of the calculated solar absorptance of the thermal control coating can reach 0.001.

Owner:BEIHANG UNIV

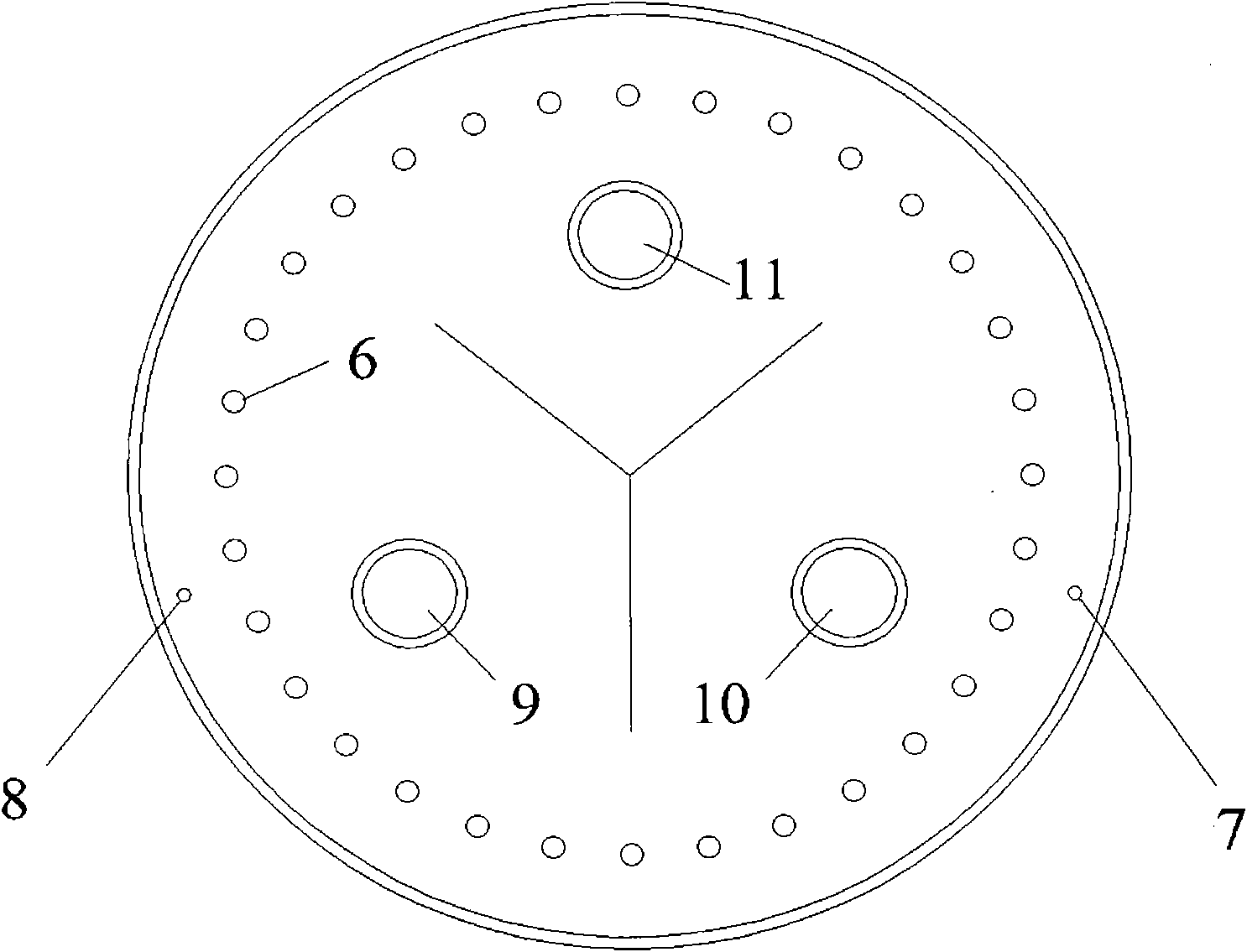

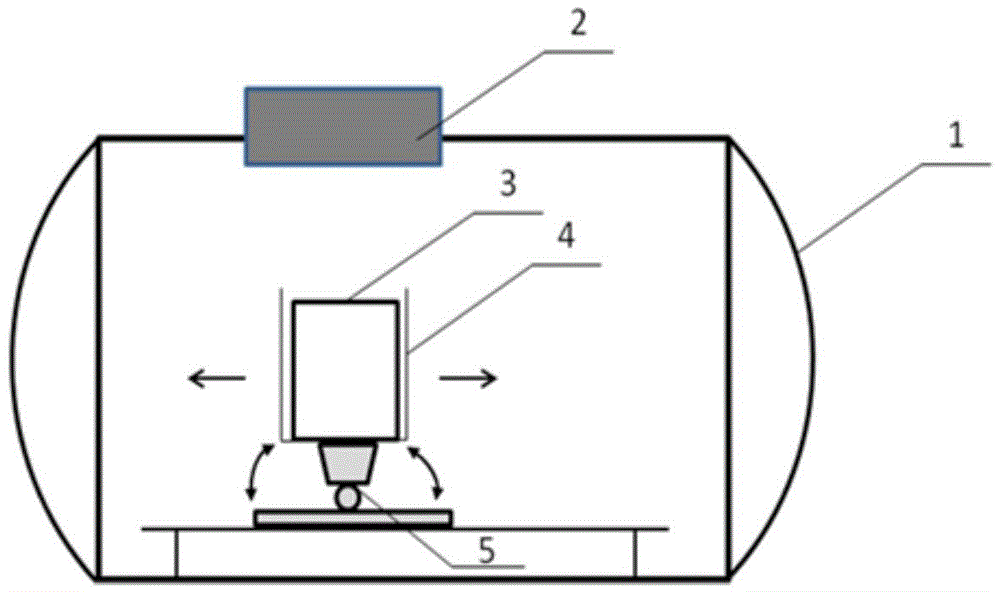

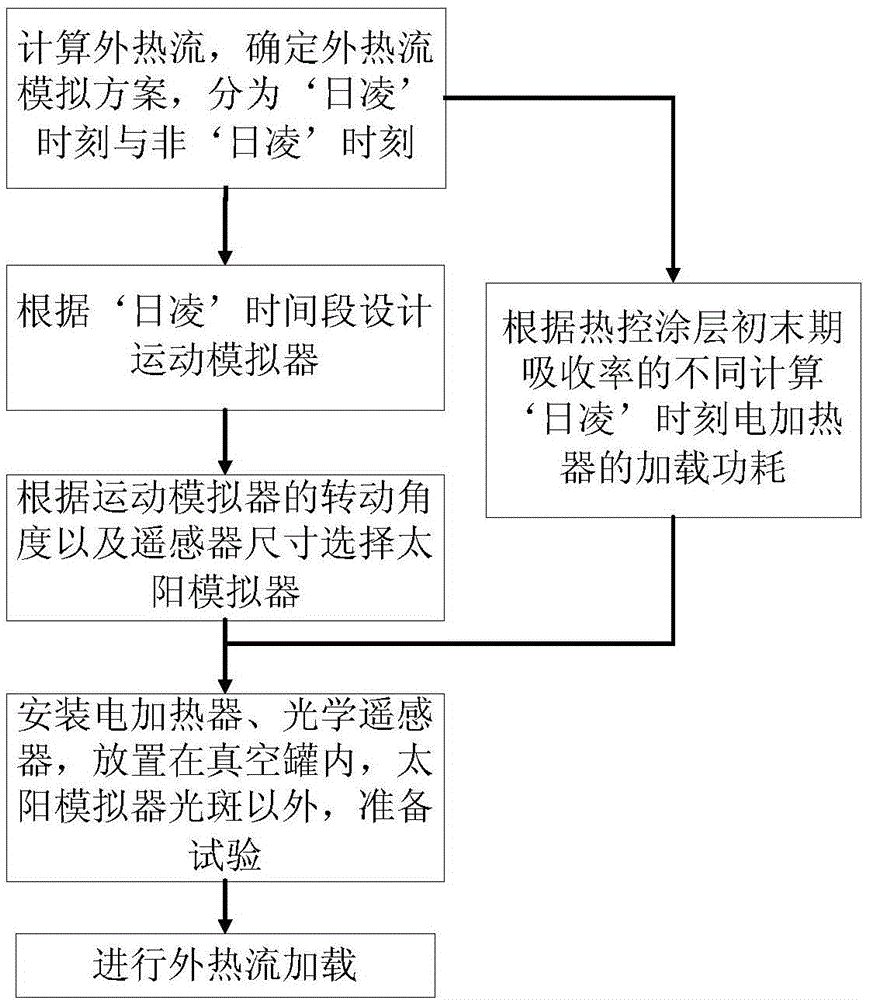

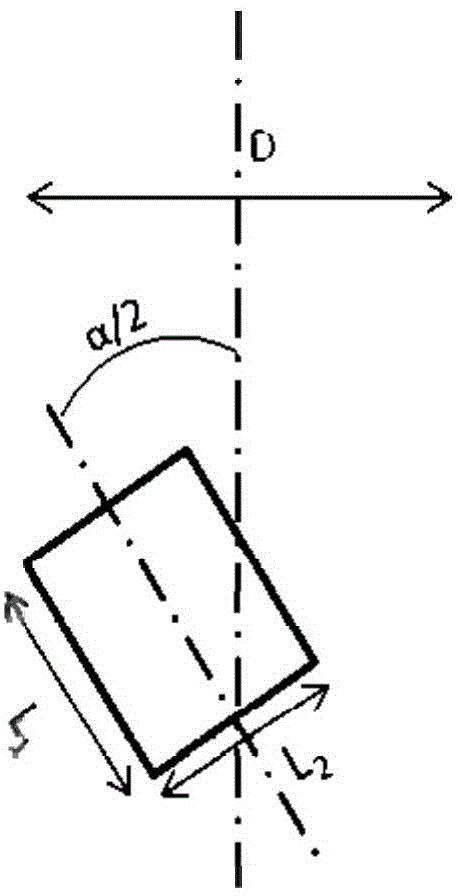

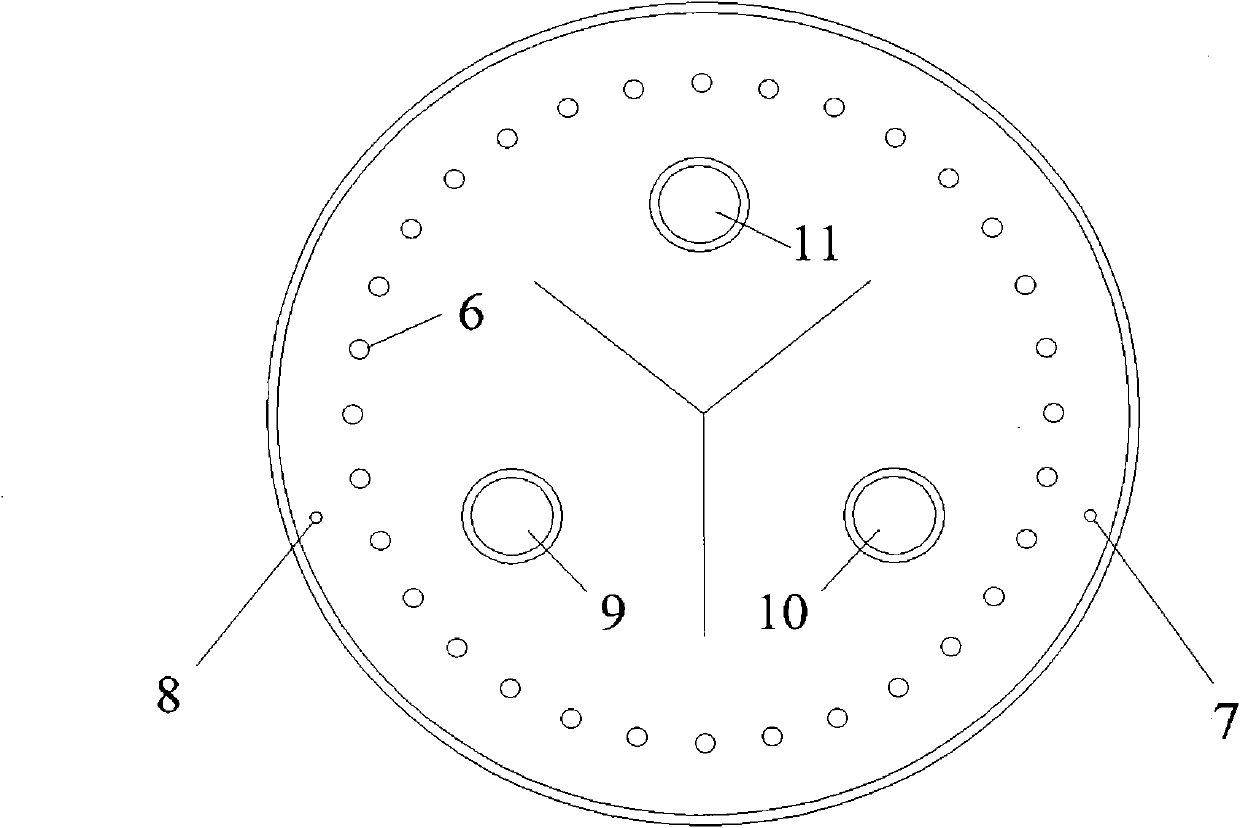

High-orbit optical remote sensor vacuum hot test external heat flow simulation method

ActiveCN104803012ADoes not affect surface stateAchieve absorptionCosmonautic condition simulationsOrbital periodSolar absorptance

A high-orbit optical remote sensor vacuum hot test external heat flow simulation method comprises the steps of firstly determining solar radiation heat flow according to on-orbit solar absorptance of an optical remote sensor (3), secondarily arranging the optical remote sensor (3) in a vacuum environment simulation chamber (1), then determining a 'sun outage' time period by judging whether the solar radiation heat flow Q1 (t) absorbed by an optical system within a orbit period is 0 or not, determining the time period of the Q1 (t) unequal to 0 as the 'sun outage' time period, adopting a solar simulator (2) and electric heater combined simulation scheme to perform outer heat flow simulation, determining that the time period of the Q1 (t) equal to 0 is a 'non-sun outage' time period, and adopting an independent electric heater simulation scheme to perform outer heat flow simulation. The problem that an existing non-contact space optical remote sensor outer heat flow simulation method does not have a solar spectral energy spectrum characteristic and directionality is solved, energy distribution of solar spectrum of the remote sensor on orbit can be accurately simulated, simulation accuracy is high, and project realization is promoted.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

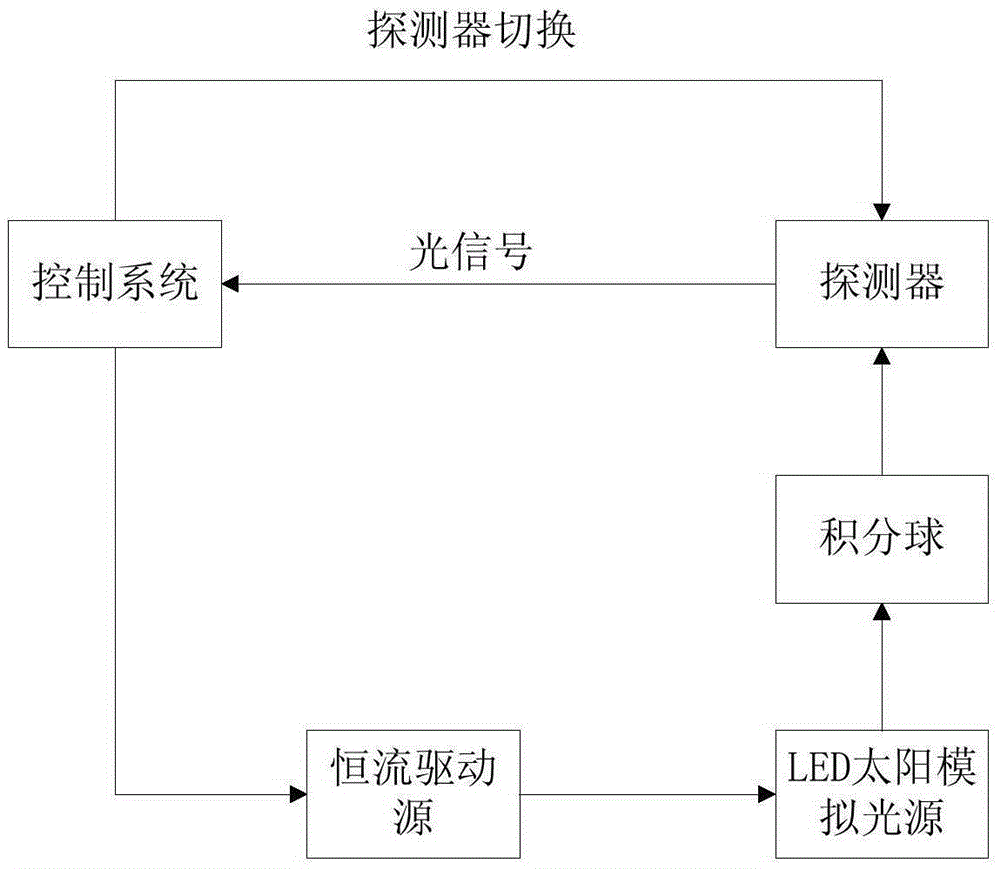

Portable solar absorptance testing instrument

ActiveCN105259115AAvoid the disadvantage of narrow spectral rangeCompact structureMaterial analysis by optical meansSolar absorptanceDiffuse reflection

The invention provides a portable solar absorptance testing instrument which comprises a control system, a constant-current drive source, an LED solar simulative light source, an integrating sphere and a detector. The control system controls the constant-current drive source to drive the LED solar simulative light source, receives an illuminance output signal and outputs solar absorptance of a sample to be tested under the current wavelength. The constant-current drive source drives the LED solar simulative light source to generate a light source at a set waveband. The LED solar simulative light source is embedded in a light source hole of the integrating sphere, generates the light source at the set waveband and outputs the light source. The integrating sphere is provided with the sample to be tested, a detector hole and the light source hole. The detector detects diffuse reflection light of the inner wall of the integrating sphere and generates the illuminance output signal. A light-emitting device covering a broadband light source, the detector and the large integrating sphere are used, a high-diffuse-reflection polytetrafluoroethylene material high in reflection is pressed on the inner wall of the integrating sphere, the detector or the light-emitting device is installed on the outer wall of the integrating sphere, and the testing instrument has the advantages of being wide in spectral range, compact in structure, good in solar spectrum fitting characteristic and high in measurement precision.

Owner:BEIJING SATELLITE MFG FACTORY

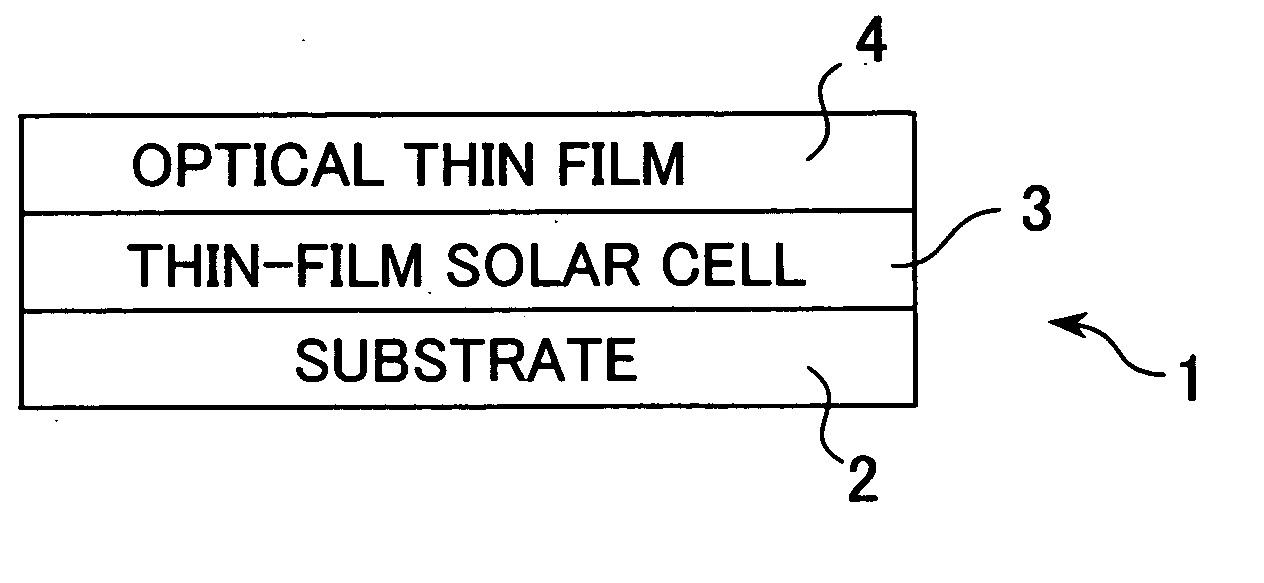

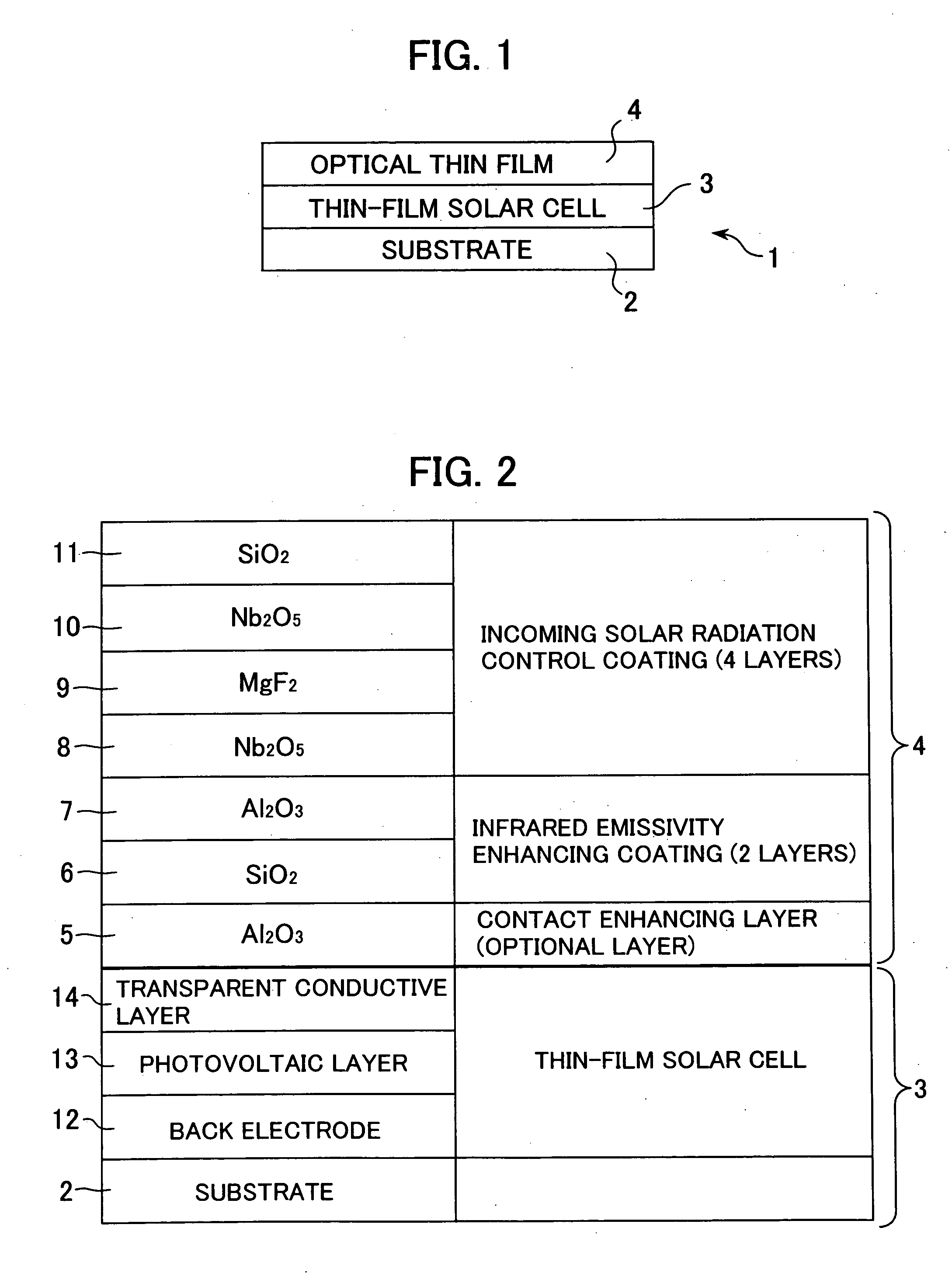

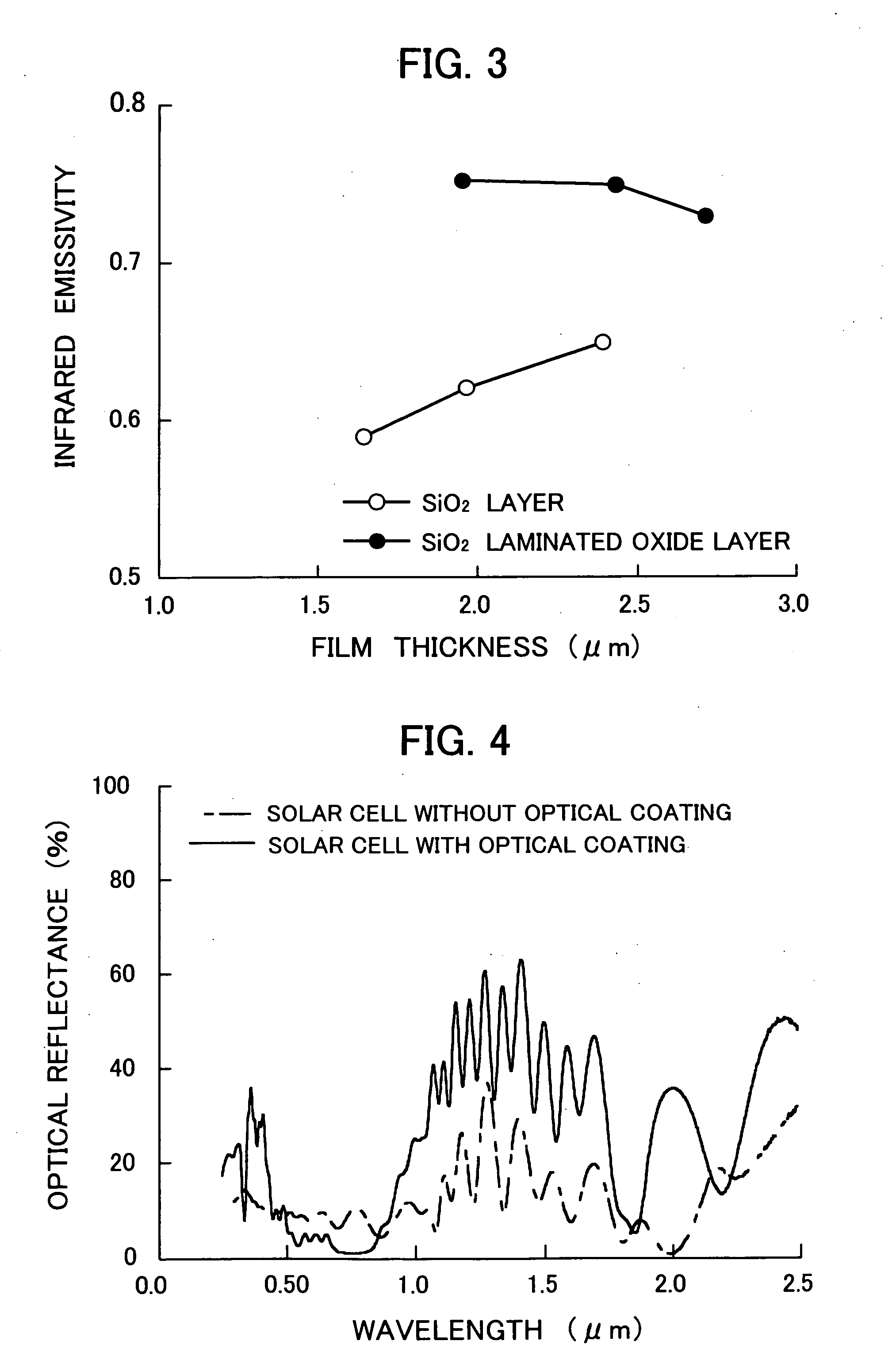

Optical thin film for solar cells and method of forming the same

InactiveUS20060243320A1Adequate thermal radiative characteristicEliminate needSemiconductor/solid-state device manufacturingPhotovoltaic energy generationSpace environmentGas phase

Disclosed is an optical thin film for a thin-film solar cell, which is formed directly on a top surface of the thin-film solar cell having a transparent conductive film layer to provide a high infrared emissivity and a lower solar absorptivity to the thin-film solar cell. The optical thin film is formed through a vacuum vapor deposition process. The thin film makes it possible to provide enhanced infrared emissivity based on its reduced thickness, while suppressing unnecessary incoming solar radiation in a simplified structure to achieve a reduced solar absorptivity so as to maintain desired cell efficiency. The optical thin film of the present invention is capable of achieving reduction in weight of a solar cell, and suitable for use, particularly, in space environments.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

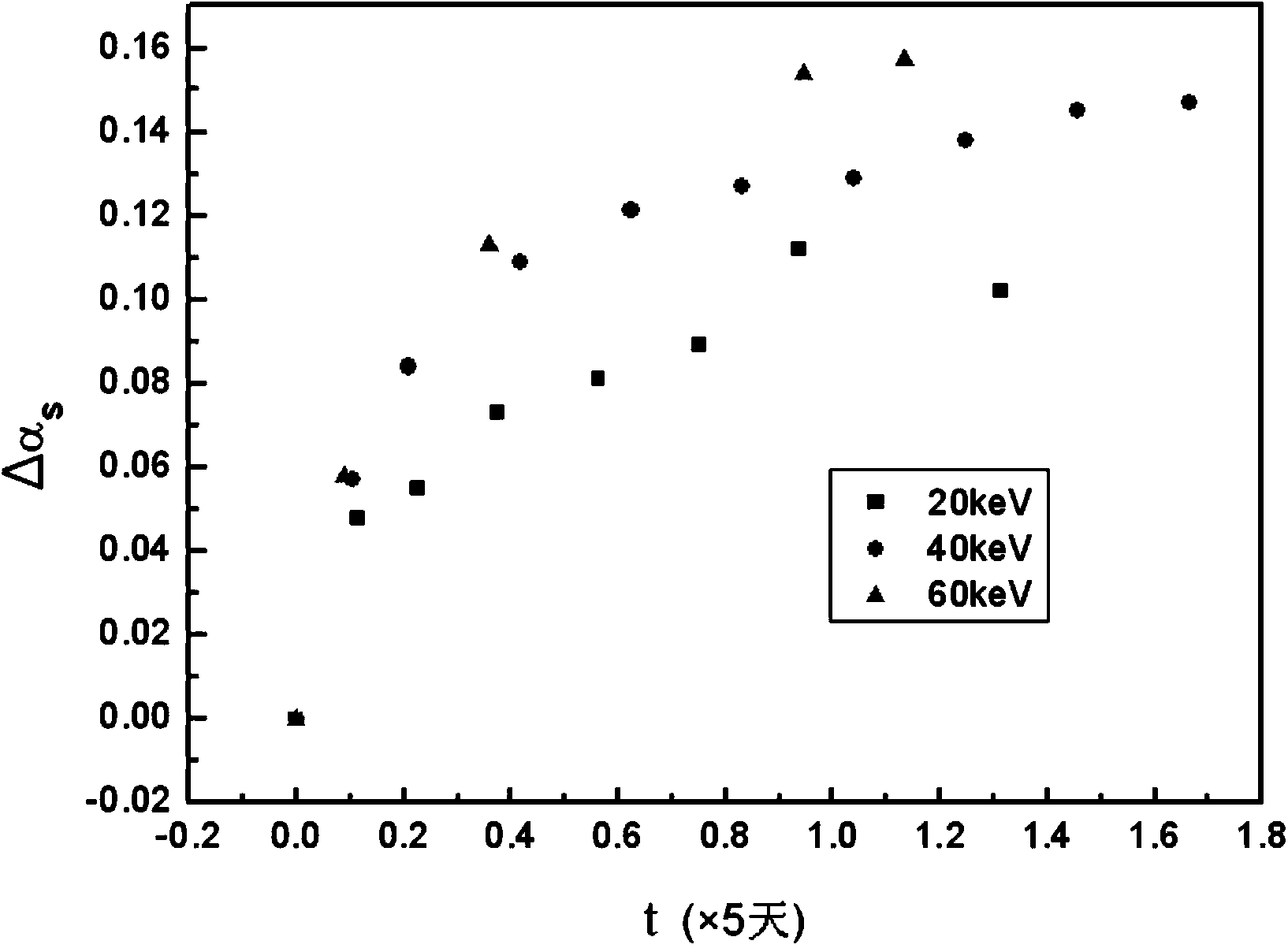

Method for determining total fluence of space radiation environment effect test of thermal control coating

The invention discloses a method for determining the total fluence of a space radiation environment effect test of a thermal control coating. According to the method, an equivalent formula when the beam current density of space continuous spectrum radiating particles is conversed into a radiating particle beam current density under certain energy is obtained according to the principle of equivalent degradation in an in-orbit and ground test on the solar absorptance of a thermal control coating, a radiation test of two groups of charged particles is carried out, curve fitting is carried out according to thermal control coating performance degradation data and radiating time data so as to determine parameters in an equivalent beam current density formula, so that the total fluence of the ground-based test can be determined. Compared with the prior art, the method has the advantages that mono-energetic electrons or protons in ground-based test equipment are adopted to simulate the injuring effect of orbit space electrons or protons on thermal control materials, and the practical operability is strong.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

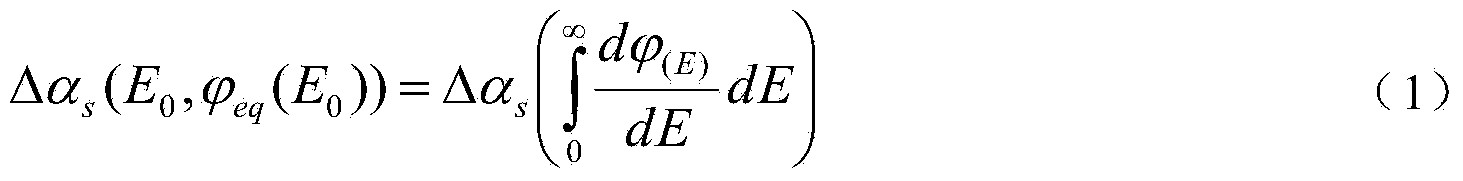

Novel antistatic white thermal control coating and preparation method thereof

ActiveCN103666248ANo crackNo peelingPretreated surfacesSpecial surfacesSolar absorptanceThermal control

The invention discloses a novel antistatic white thermal control coating and a preparation method thereof; wherein the coating, from interior to exterior, comprises a surface treatment agent layer, a prime coat layer and a finishing coat layer; the prime coat layer and the finishing coat layer all use room temperature curing type organic silicone resin as a matrix resin; a plurality of sheet-shaped metal powders are crossedly overlapped and arranged in the prime coat layer, and one ends of part of the sheet-shaped metal powders extend to the finishing coat layer; and white zinc oxide is distributed in the finishing coat layer. The coating provided by the invention is white, thickness is 100-140mum, solar absorptance is 0.24-0.29, hemispherical emissivity is 0.85-0.91, total mass loss TML is less than 1%, a collected volatile condensable material CVCM is less than 0.1%, and volume resistivity rhoV is not less than 107 ohm*m. The coating, through 100 times of high and low temperature heat cycle test in a temperature range from -100 to 100 DEG C, has advantages of non-cracking, non-spalling, non-foaming and non-discoloring phenomena, stable optical property and good adhesion force, and can basically satisfy demand of a spacecraft on the antistatic white thermal control coating.

Owner:SHANGHAI INST OF SATELLITE EQUIP

Preparation method of low-solar-absorptance high-emissivity coating on surface of titanium alloy TC4

ActiveCN104005073ALow solar absorptionHigh emissivitySurface reaction electrolytic coatingPlasma electrolytic oxidationSolar absorptance

The invention discloses a preparation method of a low-solar-absorptance high-emissivity coating on the surface of titanium alloy TC4, relates to a preparation method of a ceramic film layer on the surface of the titanium alloy TC4, and aims at solving the problems that a titanium alloy thermal control coating prepared by adopting an existing method is high in solar absorptance, low in emissivity and high in cost, a uniform coating is difficultly obtained for the surface with a complicated shape, a process is complicated and the bonding degree between the coating and a matrix body is poor. The preparation method comprises the following steps: 1, pre-processing the titanium alloy TC4; and 2, performing micro-arc oxidation. The coating prepared by adopting the method has the roughness of 4.056 microns to 13.66 microns and the thickness of 68.1 microns to 200 microns, and the thickness of the coating is adjustable; due to in-situ growth, the bonding degree is good; the emissivity of a film layer under process conditions of a highly acidic zirconate system is more than 0.96, and the absorption rate is less than 0.32.

Owner:HARBIN INST OF TECH

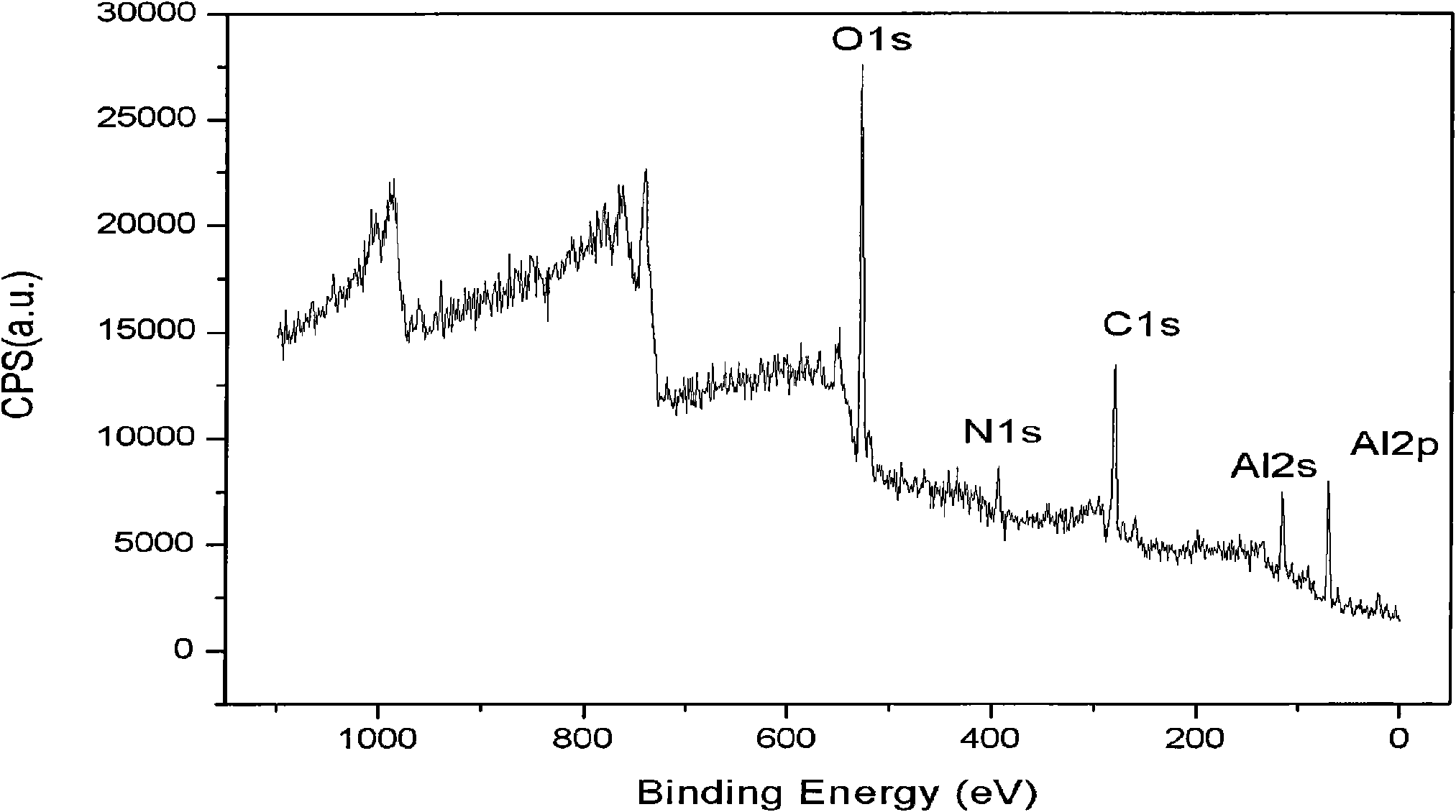

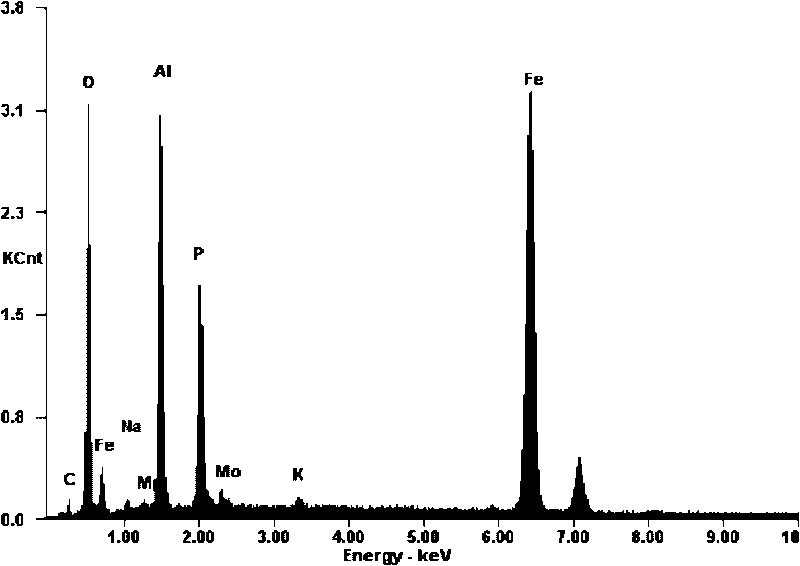

Method for preparing alumina-ferric oxide ceramic membrane with controllable solar absorptance

ActiveCN101705511ASimple processImprove processing efficiencyAnodisationOxide ceramicPlasma electrolytic oxidation

The invention discloses a method for preparing an alumina-ferric oxide ceramic membrane with controllable solar absorptance, relates to a method for preparing the alumina-ferric oxide ceramic membrane, and solves the problems that space stability, ultraviolet irradiation resistance and binding force are poor and the solar absorptance of a coating is difficult to adjust on a LY12 aluminium alloy surface with specific solar absorptance in the conventional method. The method comprises the following steps: 1, performing surface pretreatment and ultrasonic treatment on the LY12 aluminium alloy, and washing the LY12 aluminium alloy with distilled water and drying the LY12 aluminium alloy; 2, placing the dried LY12 aluminium alloy in a micro-arc oxidation electrolytic cell for electrolyzation to obtain a micro-arc oxidized LY12 aluminium alloy; and 3, placing the micro-arc oxidized LY12 aluminium alloy in the distilled water for hole sealing. The space stability and the binding force of the obtained ceramic membrane are good; the thickness of the membrane layer is controlled between 5 and 100 mu m and the ultraviolet irradiation resistance is good; and the solar absorptance can be controlled between 0.4 and 0.9.

Owner:HARBIN INST OF TECH

Method for preparing solar selective heat absorbing paint by using spinel type pigment as light absorbent

ActiveCN102286243BHigh solar absorption rateLow emissivityPolyurea/polyurethane coatingsRadiation-absorbing paintsSolar absorptancePhotopigment

The invention relates to a method for preparing a solar selective heat absorbing paint by using a spinel type pigment as a light absorbent, which belongs to the field of solar heat utilization. The method comprises the steps of uniformly dispersing a nanoscale spinel type pigment as well as resin, a solvent and auxiliaries by using a ball milling method; and then adding a curing agent to obtain the solar selective heat absorbing paint. It is shown in the experiment that the paint is uniformly coated on a metal substrate by using a spraying method; and the solar selective heat absorbing paint obtained after being cured at room temperature shows higher solar energy absorption rate (0.93-0.95) and lower emissivity (0.18-0.30); and the photothermal conversion efficiency of a solar heat collector can be effectively improved; moreover, the coating has the advantages of good mechanical property, stronger weather resistance and service life of more than 45 years.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

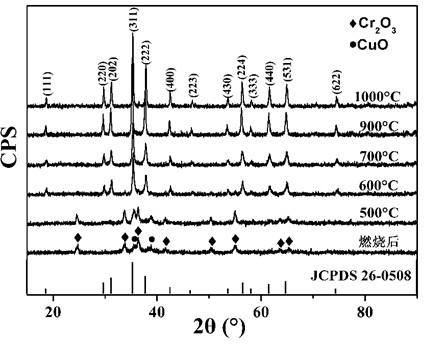

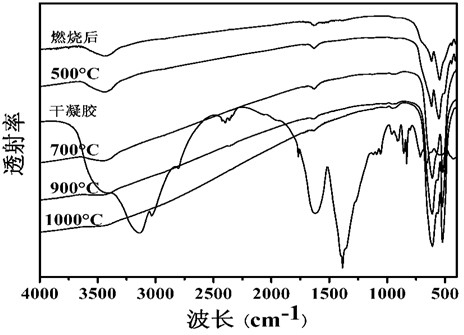

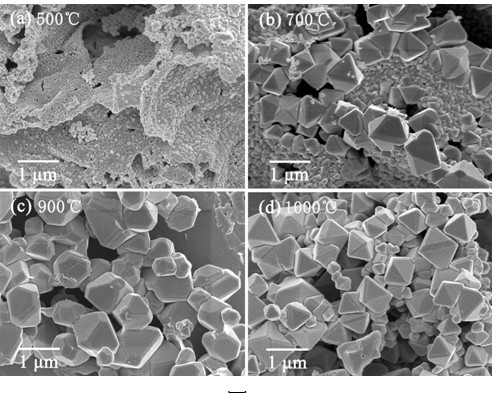

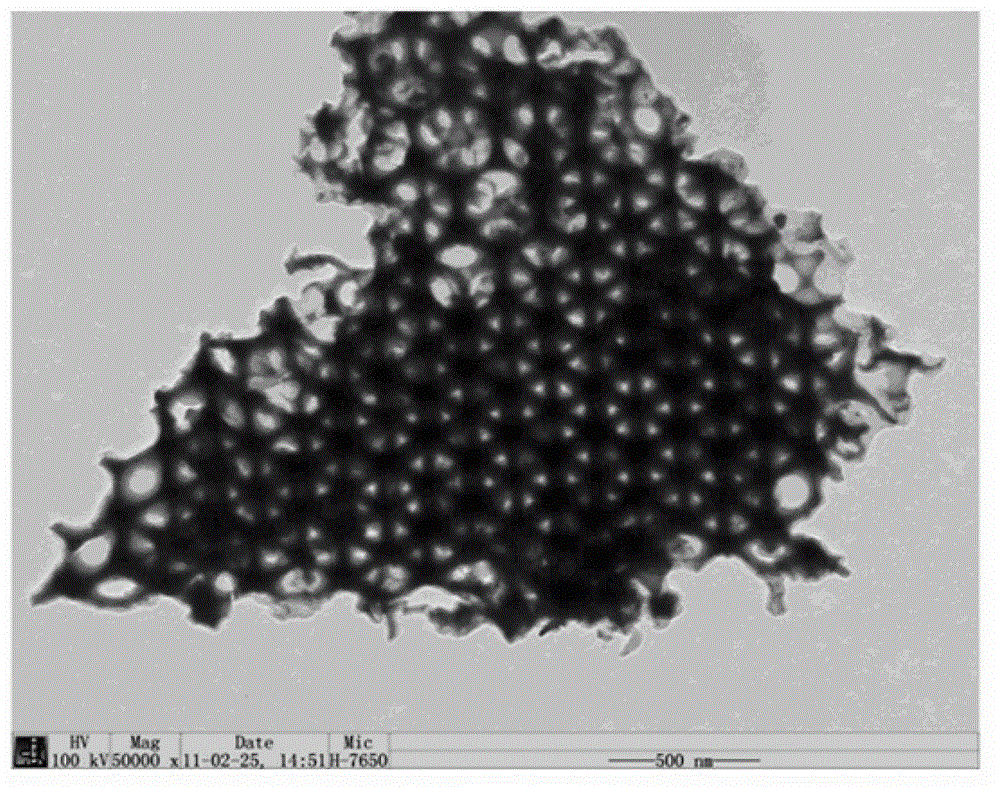

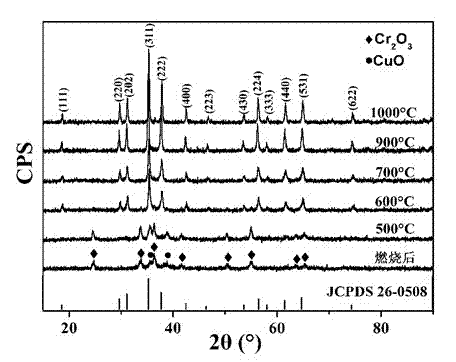

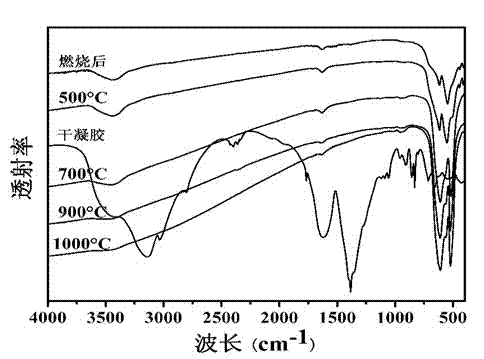

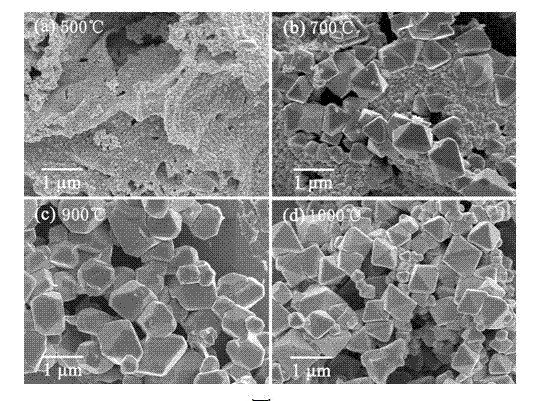

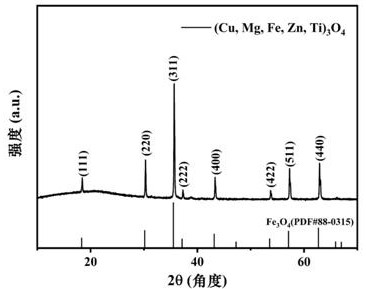

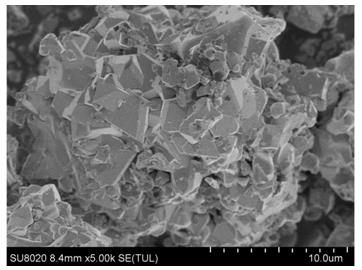

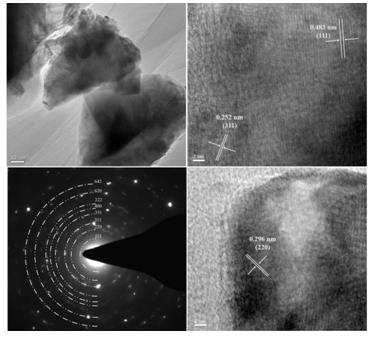

Preparation method of high-entropy ceramic material with good light absorption performance

The invention discloses a preparation method of a high-entropy ceramic material with good light absorption performance, the preparation method comprises the following steps: taking any five of CuO, MnO2, Fe2O3, Cr2O3, Co3O4, TiO2, ZnO and MgO powder as raw materials, carrying out ball-milling mixing, drying and grinding, then carrying out high-temperature calcination in an air atmosphere, and then cooling and grinding to obtain high-entropy ceramic with a spinel structure. The high-entropy ceramic is prepared by combining a mechanical wet grinding method and a solid-phase synthesis method, metal elements can be sufficiently and uniformly mixed, the method has the advantages of simple preparation technology, high repeatability, high production efficiency, suitability for industrial production and the like, and the prepared high-entropy ceramic is single in phase, high in purity, small in particle size and uniform in element distribution, the material has high solar energy absorptivity and good thermal stability, and can ensure the photo-thermal conversion efficiency of a solar energy absorbing material as a solar energy absorbent.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

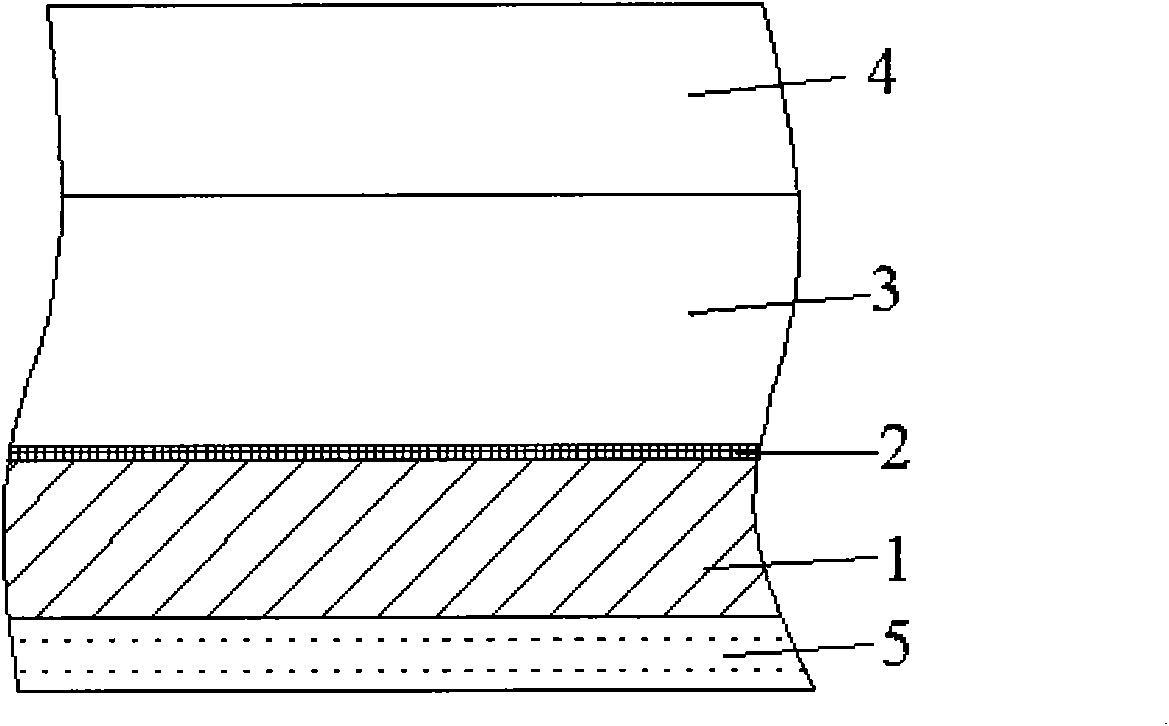

Reduced pressure double glazed glass panel

ActiveUS20150354264A1Reduce pressureEnsure adequate heatingClimate change adaptationWindows/door improvementSolar absorptanceEmissivity

The reduced pressure double glazed glass panel of the present invention includes an outside glass sheet, an inside glass sheet, and a gap portion that are joined together, with the gap portion being formed between the glass sheets and sealed under reduced pressure. Here, the outside glass sheet has a first glass surface disposed to face the outdoor space and a second glass surface disposed to face the gap portion. A Low-E film is formed on the second glass surface. The following relations hold: (Emissivity of Low-E film ∈)≦0.067; 31%≦(Solar reflectance on First glass surface RG(solar))≦40%; (48−RG(solar))%≦(Solar absorptance on First glass surface AG(solar))≦17%; (AG(solar))≦{18.3−(0.07×RG(solar))+(20×∈)}%; (Solar heat gain coefficient SHGC)≦0.50; and (Thermal transmittance U value)≦1.2 W / m2·K or less. According to the present invention, it is possible to provide a reduced pressure double glazed glass panel having sufficient heat insulating and heat shielding properties and being less susceptible to bending when exposed to solar radiation.

Owner:NIPPON SHEET GLASS CO LTD

Solar selective absorbing coating and preparation method thereof

ActiveCN101660117BEasy to implementEasy to controlSolar heat devicesVacuum evaporation coatingEmissivitySolar absorptance

The invention discloses a solar selective absorbing coating which mainly consists of an infrared high reflectivity metal layer, a diffusion impervious layer, an absorbing layer and an antireflection layer in sequence; the absorbing layer is composed of a metal-medium composite material film which is expressed as SS-Ox-AlNyOz, the metal-medium composite material film is composed of metal SS molecular group, trace oxide formed by combining SS and O, and medium AlNyOz; and the antireflection layer medium material film is expressed as AlNiOj. The coating of the invention is easy to realize and simple to regulate and control in terms of preparation technique; the coating is suitable to be used in vacuum or air under low and medium temperature environment; the performance of the coating is stable; and the solar absorptance alpha thereof is more than 0.92, and the emissivity ratio thereof is less than or equal to 0.08.

Owner:HIMIN SOLAR

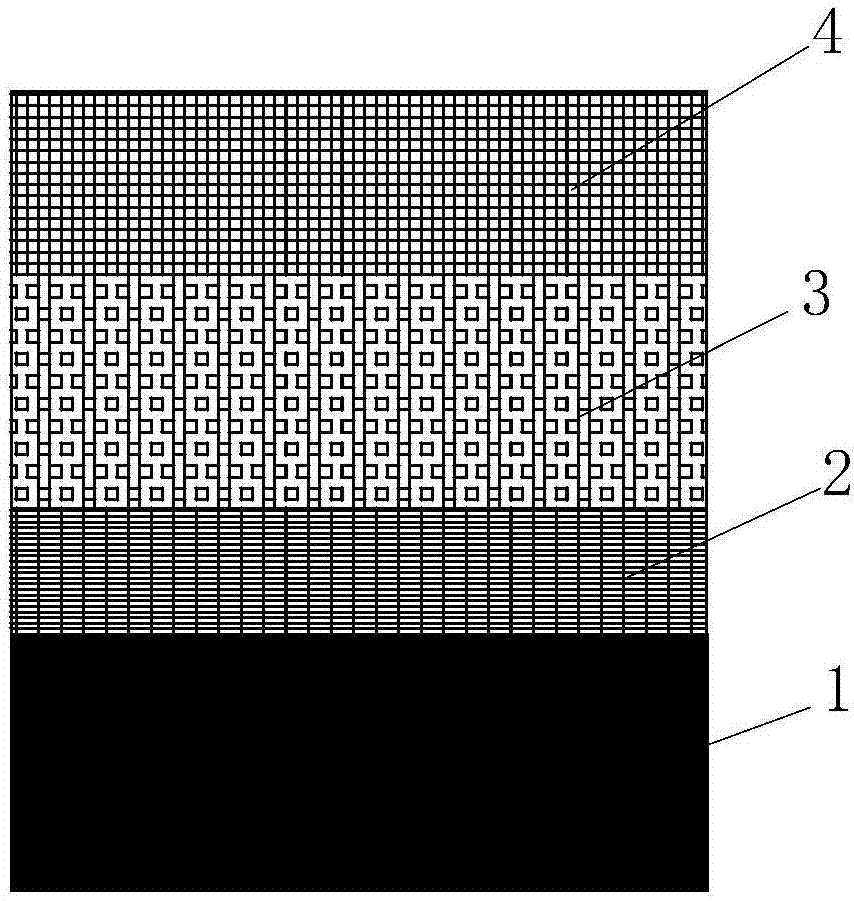

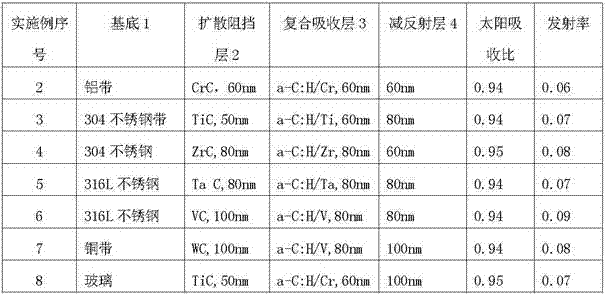

Photo-thermal conversion coating and preparation method thereof

ActiveCN107314559AWith infrared reflection functionHigh melting pointSolar heat devicesVacuum evaporation coatingSolar absorptanceEmissivity

The invention discloses a photo-thermal conversion coating and a preparation method thereof. The coating comprises a diffusion barrier layer, a composition absorption layer and an anti-reflection layer which are sequentially arranged on a substrate from bottom to top, wherein the substrate is the one that has an infrared reflection function; the diffusion barrier layer is a metal carbide layer; the composite absorption layer is a metal-doped hydrogenated diamond composite layer a-C: H / Me; and the anti-reflection layer is a hydrogenated diamond layer. The solar absorptance of the photo-thermal conversion coating disclosed by the invention is greater than 0.93, the emission rate is between 0.06 and 0.08, and the photo-thermal conversion coating has excellent optical performance. In addition, the weatherability of the coating is strong, the coating is applied to flat panel heat collectors, and the coating can be used under a high-temperature vacuum environment.

Owner:兰州大成真空科技有限公司

A kind of water-based nano high-efficiency solar heat collecting coating and preparation method thereof

The present invention specifically involves a water -based, high -efficiency solar heating coatings with nano -material as a function filler.The base material of the coating is an emulsifier modified by the ethyleic emulsion. The function fillers are nano -level lead (PBS). The aids are specially added with epoxy silicane puppets.The coating is environmentally friendly, the solar energy absorption rate is high and the reflectance is low. The coating structure is reasonable, dense, strong, and strong.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Anti-contamination coated multi-layer insulation

ActiveUS7691452B1Reduce presenceImprove efficiencyRadiation applicationsSynthetic resin layered productsSolar absorptanceUltraviolet

A multi-layer insulation (MLI) blanket with enhanced contamination inhibiting properties and a method for inhibiting the formation of organic residues on the outer surface of a MLI blanket are provided. In one embodiment, a MLI blanket (10) attachable to a spacecraft or other structure includes a plurality of metallized layers (20, 30, 40, 50) separated by mesh layers (60, 62, 64). An anti-contamination coating (80) comprised of a photocatalytic material is disposed between a high emittance layer (70) that overlies the outer surface (20A) of the outer metallized layer (20) and an outer electrically conductive layer (90). When exposed to ultraviolet or near-ultraviolet radiation components present in solar radiation, the anti-contamination coating (80) catalyzes the breakdown of organic residues on the outer surface of the MLI blanket (10) thereby maintaining the reflective properties of the MLI blanket (10) and ensuring that solar absorptance of the MLI blanket (10) is maintained at or below an acceptable threshold level.

Owner:LOCKHEED MARTIN CORP

Solvent type functional coating with good solar energy absorption and infrared radiation performance and preparation method of solvent type functional coating

InactiveCN113462285AImprove absorption rateReduce thermal emissivityFireproof paintsChemical industryOxide ceramicAbsorptance

The invention discloses a preparation method of a solvent type functional coating with good solar energy absorption and infrared radiation performance. The solvent type functional coating is prepared by taking trimethylsilyl polyhedral oligomeric silsesquioxane and vinyl polyhedral oligomeric silsesquioxane as high-temperature-resistant resins and taking a high-entropy oxide ceramic material (A) 3O4 as a functional pigment. A functional coating prepared from the coating has high solar energy absorptivity, low thermal emissivity, good infrared radiation characteristic and excellent thermal shock resistance, corrosion resistance and high temperature resistance, and has important application value in the fields of solar photo-thermal utilization, infrared enhanced heat transfer, heat dissipation, energy conservation and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Heat-absorbing coating for solar metal inner liner

InactiveCN103484001AImprove heat collection efficiencyGood heat absorptionPolyurea/polyurethane coatingsRadiation-absorbing paintsSolar absorptanceCadmium sulphide

The invention relates to a heat-absorbing coating for a solar metal inner liner. The heat-absorbing coating comprises the following components in parts by weight: 40-50 parts of ferric oxide, 10-15 parts of tetrafluoroethylene powder, 10-15 parts of selenium cadmium sulfide, 10-15 parts of manganese dioxide, 70-80 parts of single-component polyurethane resin, 80-90 parts of thermosetting acrylic resin, 5-10 parts of cobalt naphthenate solution, 40-50 parts of n-butanol, 30-40 parts of xylene and 15-20 parts of calcium chloride. The solar energy absorption rate of the product is 95%-98%, the emission rate is 15%-18%, and the heat collection efficiency of the solar metal inner liner is greatly improved; the heat-absorbing coating further has the advantages of wear resistance, resistance to acid and alkali corrosion and excellent heat absorption effect; the product further has the advantages of heat resistance, cold resistance and long service life, and can be widely produced and used for continuously replacing existing materials.

Owner:SUZHOU CHANGSHENG ELECTROMECHANICAL

A kind of solar heat conversion absorbing film system and preparation method thereof

InactiveCN102287940ASimple manufacturing methodRaw materials are easy to getSolar heat devicesSolid/suspension decomposition chemical coatingAbsorptanceSolar absorptance

The invention relates to a solar photo-thermal transforming absorbing film system and a preparation method thereof. The transformation absorbing film system is of a three-layer structure, and composed of an absorbing bottom layer, an absorbing middle layer and an antireflective top layer, wherein the absorbing bottom layer and the absorbing middle layer are prepared from M-A12O3 mixed hydrosol which is composed of transition metal M salt and aluminium salt and has different contents of the M salt; and the antireflective top layer is prepared from A 12O3 collosol, SiO2 collosol, and A12O3-SiO2mixed collosol. The solar photo-thermal transforming absorbing film system has a low preparation cost, the preparation method is simple and feasible, and no environment pollution is caused; and the optical property of the film system can meet the practical application requirement, that is to say, the solar absorptivity is greater than 0.90, and the emissivity is less than 0.10.

Owner:FUZHOU UNIV

Solar energy heat absorbing coating of vacuum pipe

InactiveCN103756559AImprove performanceImprove surface qualityPolyurea/polyurethane coatingsThermodynamicsSolar absorptance

The invention relates to a solar energy heat absorbing coating which can be used in a vacuum pipe type heat collector or other heat collectors of converting solar energy into heat energy. The solar energy heat absorbing coating is prepared from resin, pigment, a solvent and an additive. The color of the solar energy heat absorbing coating can be changed according to different pigment preparations, the solar energy heat absorbing coating is good in coordination of environment color matching, high in surface quality, stable in performance, simple in production process, low in cost and convenient and simple to use. Experiments indicate that the solar energy heat absorbing coating is uniformly coated on the outer surfaces of the vacuum pipe of the heat collector, and is high in solar energy absorbing rate (0,962-0.977) and low in emitting rate (0.24-0.29) after being cured at room temperature, and high in efficiency of converting solar energy into heat energy.

Owner:广西宾阳县荣良农业科技有限公司

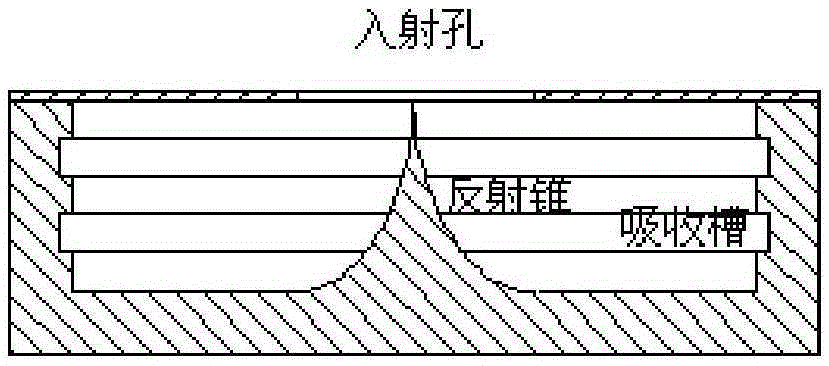

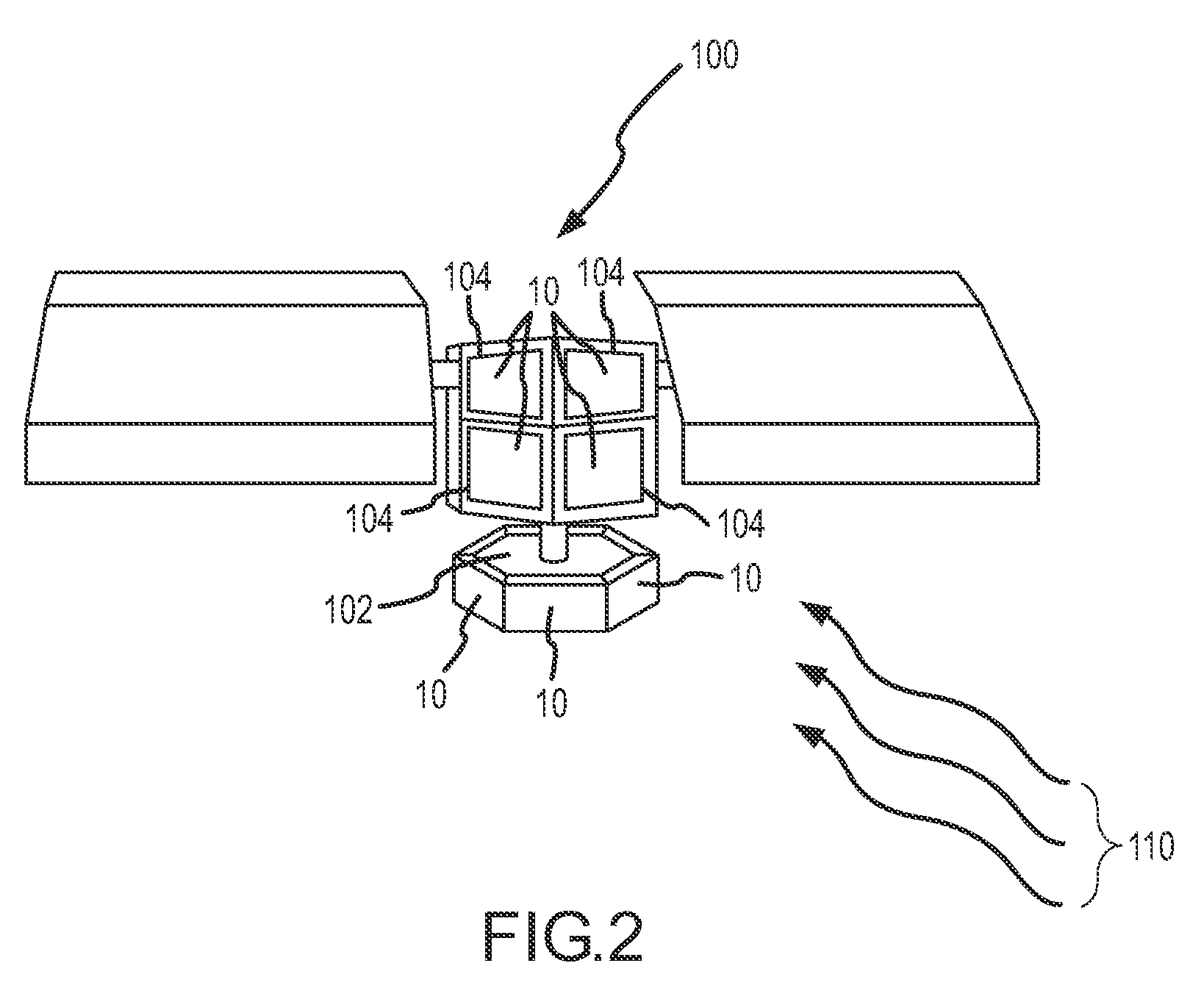

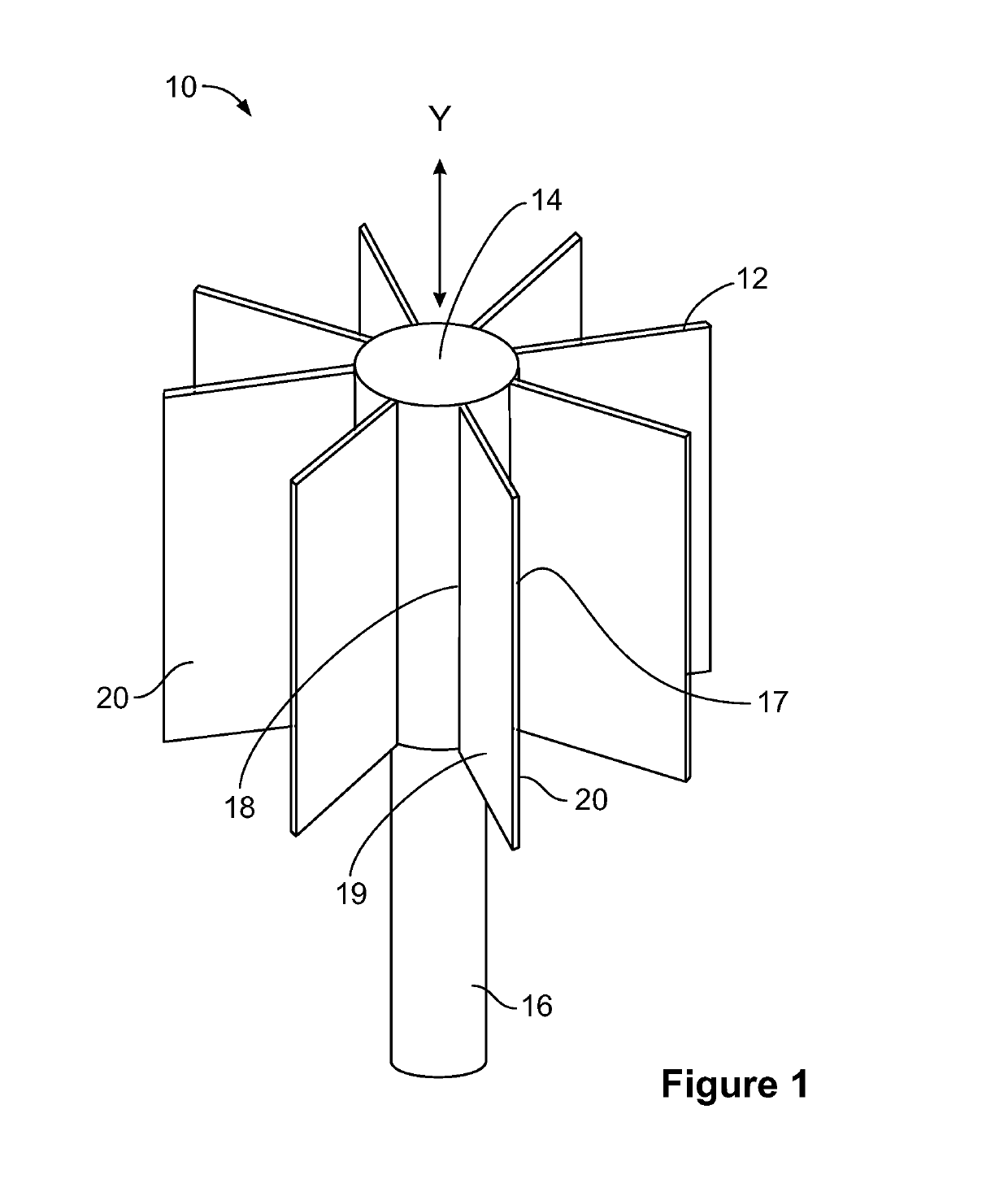

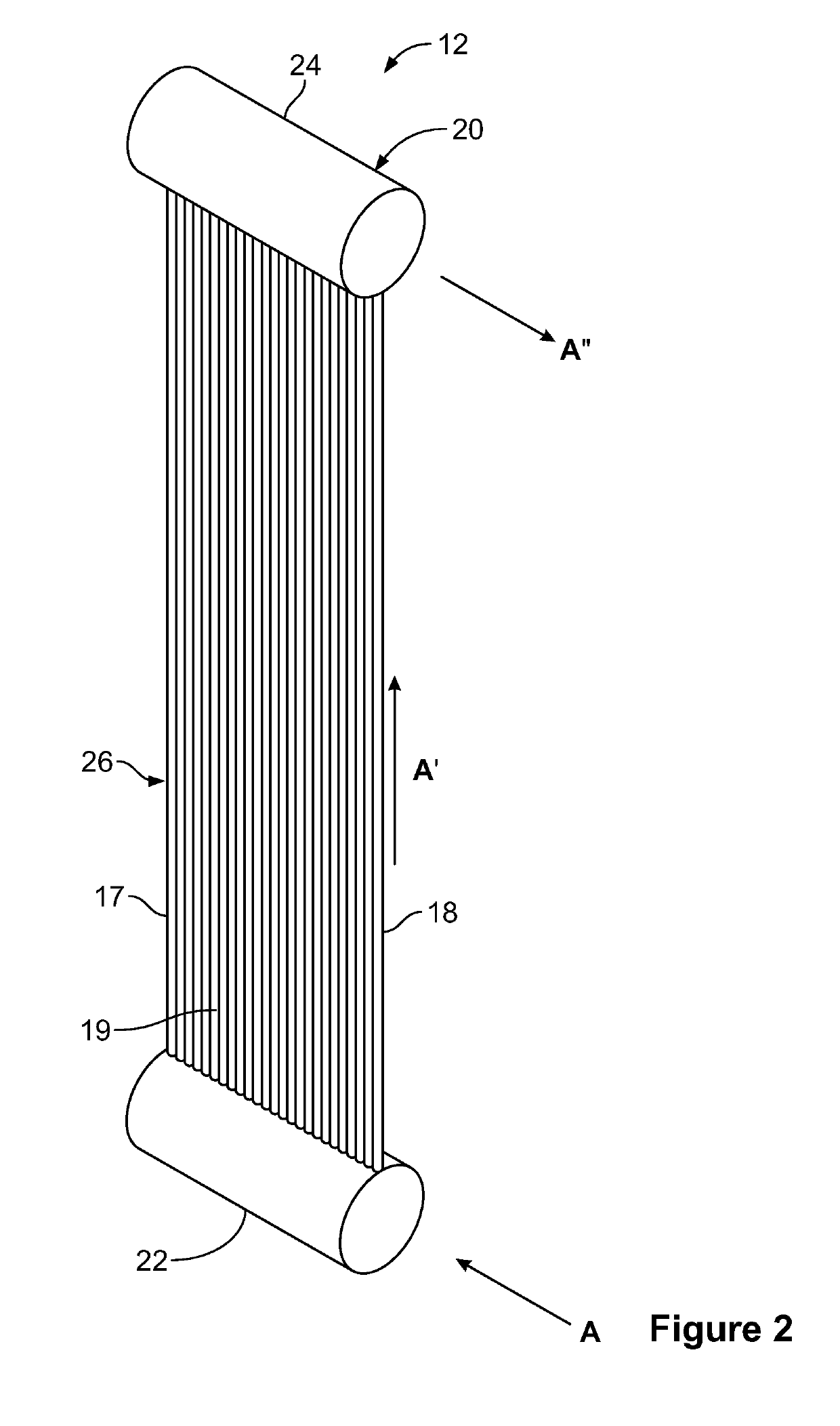

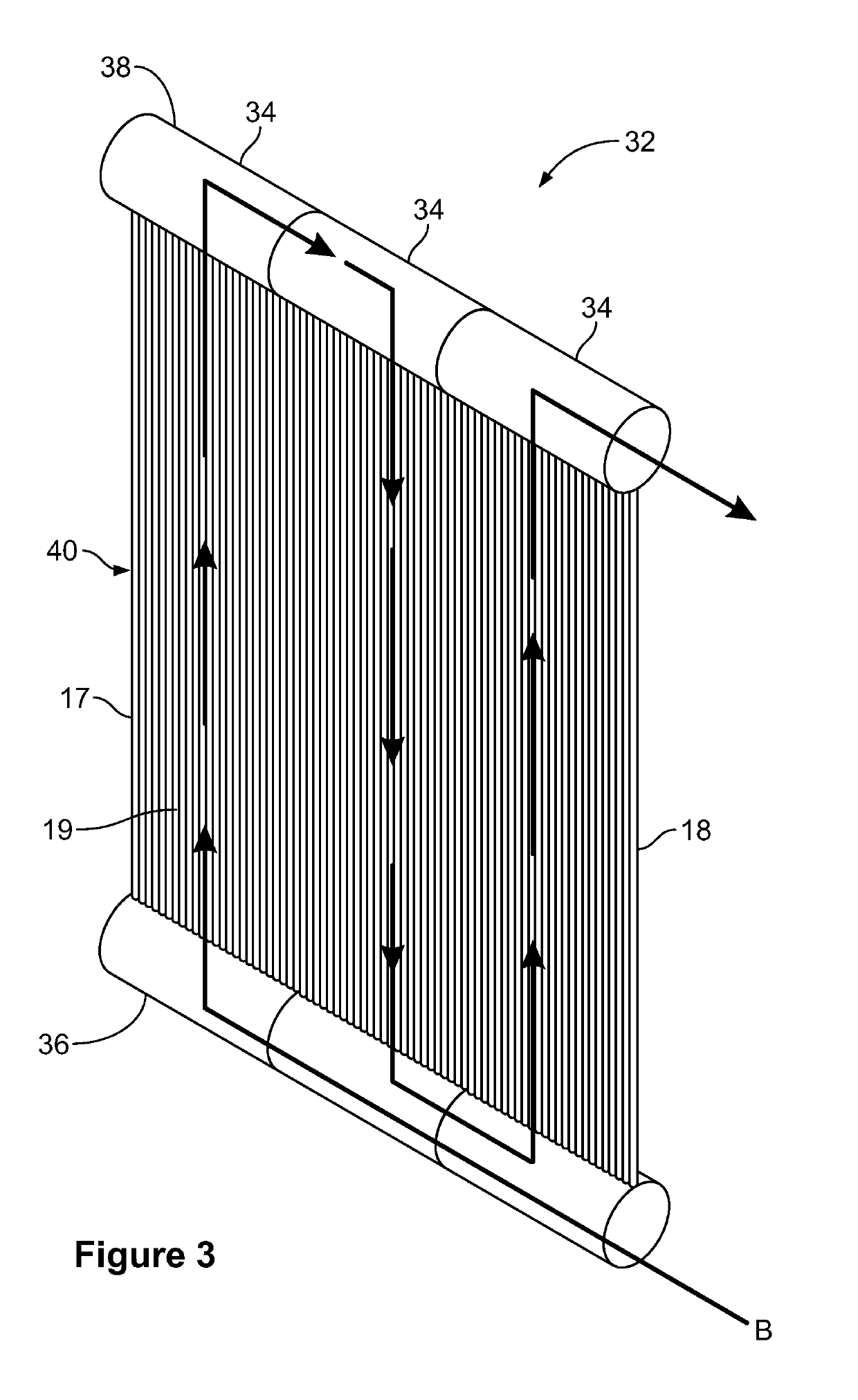

Bladed solar thermal receivers for concentrating solar power

ActiveUS10295224B1Increase solar radiationReduce heat lossSolar heating energyFluid circuit connectionsSolar absorptanceEngineering

A bladed solar thermal receiver for absorbing concentrated sunlight is disclosed. The receiver includes a plurality of panels arranged in a bladed configuration for absorbing sunlight. The bladed configurations can be radial or planar. The receiver design increases the effective solar absorptance and efficiency by providing a light trap for the incident solar radiation while reducing heat losses from radiation and convection.

Owner:AUSTRALIEN NAT UNIV +1

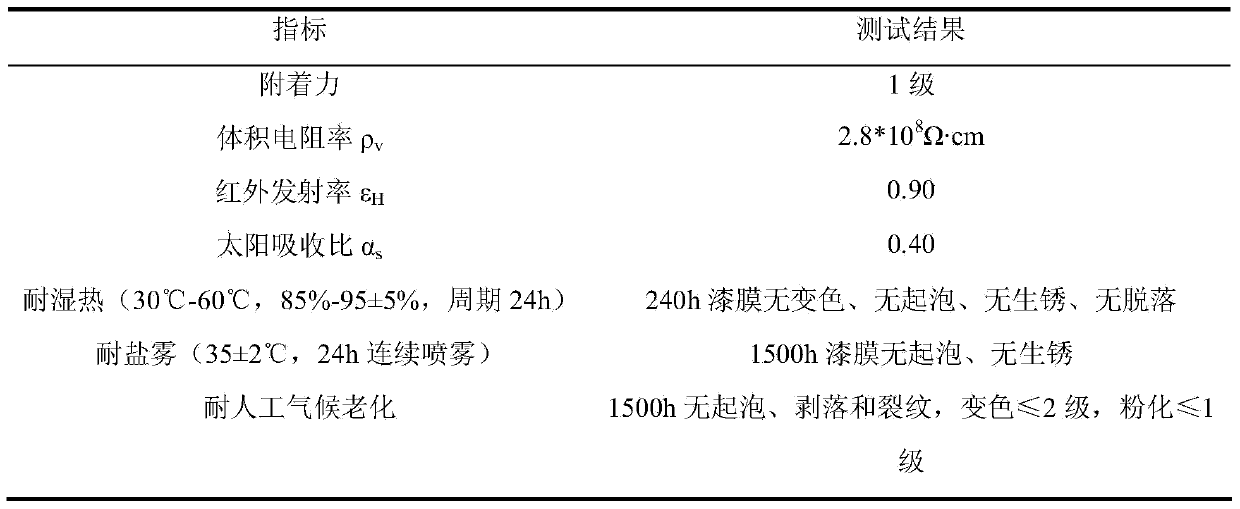

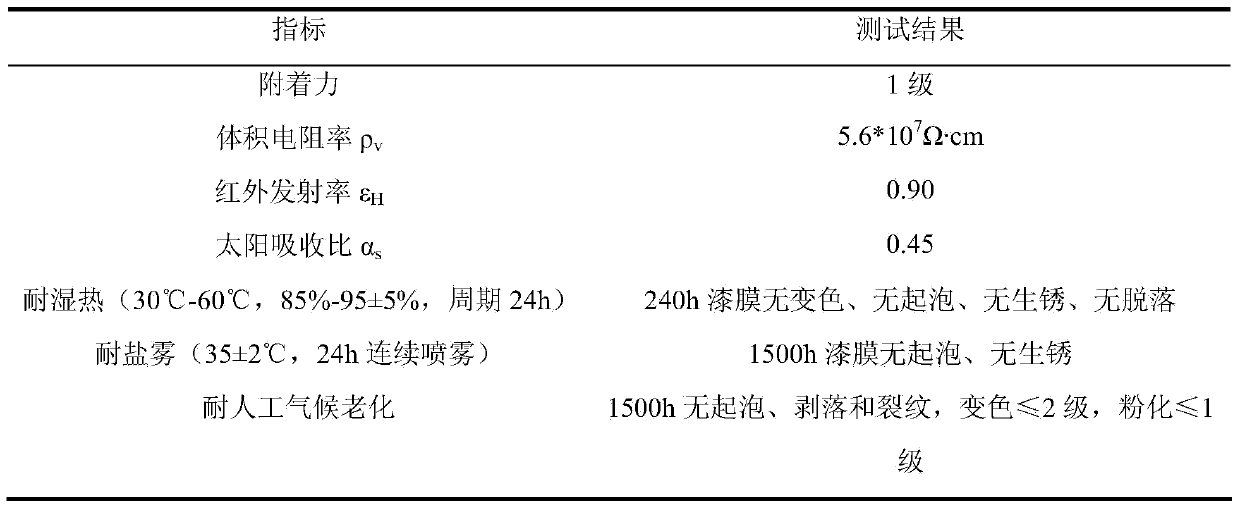

Preparation method for aqueous low-solar-absorptance antistatic coating

ActiveCN104087092AGood flexibilityImprove mechanical propertiesElectrically-conductive paintsAbsorptanceSolar absorptance

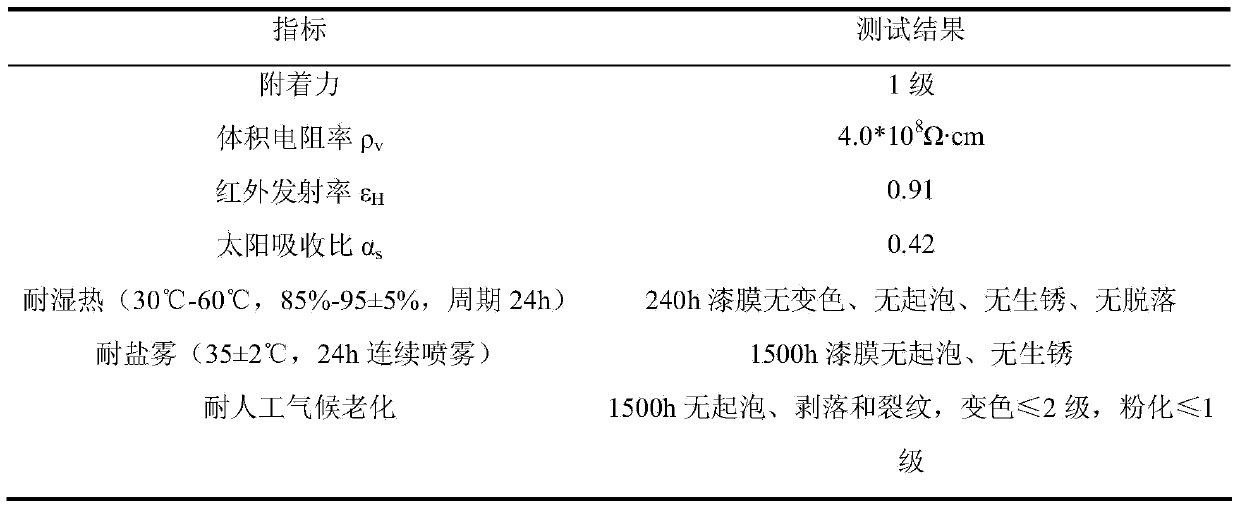

The invention relates to a preparation method for a aqueous low-solar-absorptance antistatic coating. The method comprises: (1) preparing a pigment slurry from 15-30 parts of deionized water, 0.1-0.8 part of a neutralizer, 0.2-2 parts of a thickening agent, 0.5-3 parts of a wetting dispersant, 0.1-1 part of a surfactant, 0.1-2 parts of an antifoaming agent, 0.1-0.5 part of an antiseptic and 1-10 parts of a pigment, stirring at a speed of 2000-3000 r / min for 20-30 min to uniformly disperse; (2) adding 30-50 parts of aqueous hydroxyl resin, 25-50 parts of a conductive filling material, 0.1-1 part of an antifoaming agent and 0.2-1.5 parts of a rheological modifier into the pigment slurry and stirring uniformly; (3) performing high-speed dispsersion on the paint slurry for 20-40 min, and controlling the dispersion speed to be 1500-2500 r / min; (4) adding 10-20 parts by mass of aliphatic isocyanate or alicyclic isocyanate; and (5) performing multiple times of spraying, controlling the spraying thickness at every spraying time to be 10-25 mu m and controlling the total thickness of the coating to be 80-150 mu m. The method helps to improve the environment protection performance of the product. The prepared coating has high infrared emissing ability and low solar absorptance, and also possesses excellent antistatic performance, salt-spray resistance, damp heat resistance and ageing resistance.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com