Method for preparing alumina-ferric oxide ceramic membrane with controllable solar absorptance

A solar absorptivity, alumina technology, applied in anodizing and other directions, can solve the problems of space stability, UV radiation resistance and poor adhesion, unable to adjust the solar absorptivity of the coating, etc., to achieve space stability and The effect of good bonding force, high hardness and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

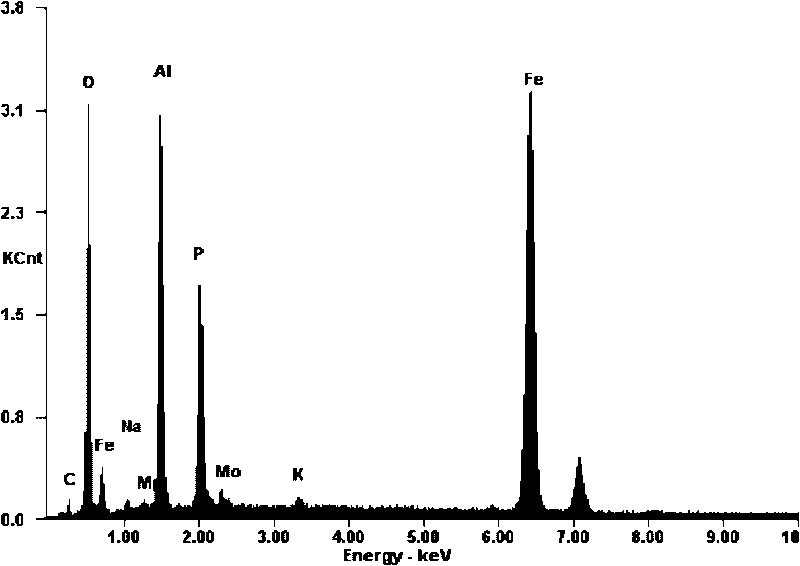

Image

Examples

specific Embodiment approach 1

[0009] Specific embodiment one: the preparation method of the aluminum oxide-iron oxide ceramic film with controllable solar absorption rate in this embodiment is realized according to the following steps: 1. The surface of LY12 aluminum alloy is pretreated by chemical degreasing process, and then cleaned with distilled water, Then put it into acetone solution for ultrasonic treatment for 1-10min, wash with distilled water and dry; React in current mode to obtain LY12 aluminum alloy after micro-arc oxidation; 3. Place the LY12 aluminum alloy after micro-arc oxidation in distilled water with a pH value of 5.5 to 6.6 and a temperature of 94 to 100°C for 5 to 40 minutes, namely Complete the preparation of alumina-iron oxide ceramic film with controllable solar absorption rate; wherein the electrolyte solution in the micro-arc oxidation electrolytic cell of step 2 is composed of sodium phosphate, ammonium fluoride, ethylenediamine, ferrous sulfate, copper acetate and ethylenediamin...

specific Embodiment approach 2

[0015] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the step 1 chemical degreasing process is to treat at a temperature of 60-70 °C for 1-3 minutes, and the degreasing agent is dissolved in sodium carbonate and trisodium phosphate Made in water, the concentration of sodium carbonate in the degreasing agent is 30-40g / L, and the concentration of trisodium phosphate is 50-60g / L. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0016] Specific embodiment 3: The difference between this embodiment and specific embodiment 2 is that in step 1, put it into the acetone solution and sonicate it for 8 minutes. Other steps and parameters are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com