Preparation method for aqueous low-solar-absorptance antistatic coating

A solar absorption ratio and anti-static technology, applied in coatings, conductive coatings, etc., can solve the problems of low solar absorption ratio and poor thermal control performance, achieve low solar absorption ratio, low powder resistance, and improve appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the water-based low solar absorption ratio antistatic coating of the present invention comprises the following steps:

[0031] Step (1), adding deionized water, neutralizer, thickener, wetting and dispersing agent, surfactant, defoamer, antibacterial agent and pigment in the paint mixing tank, is mixed with pigment paste, and with 2000 -3000r / min high-speed stirring for 20-30min to disperse evenly, the ratio of each component in parts by mass is as follows:

[0032] 15-30 parts of deionized water 0.1-0.8 parts of neutralizer 0.2-2 parts of thickener

[0033] Wetting and dispersing agent 0.5-3 parts Surfactant 0.1-1 part Defoamer 0.1-2 parts

[0034] 0.1-0.5 parts of antibacterial agent 1-10 parts of pigment;

[0035] The pigment added therein is a white pigment, and the preferred particle size of the present invention is titanium dioxide with a particle size of 0.1-10 μm, which has the characteristics of strong hiding power and good dispersib...

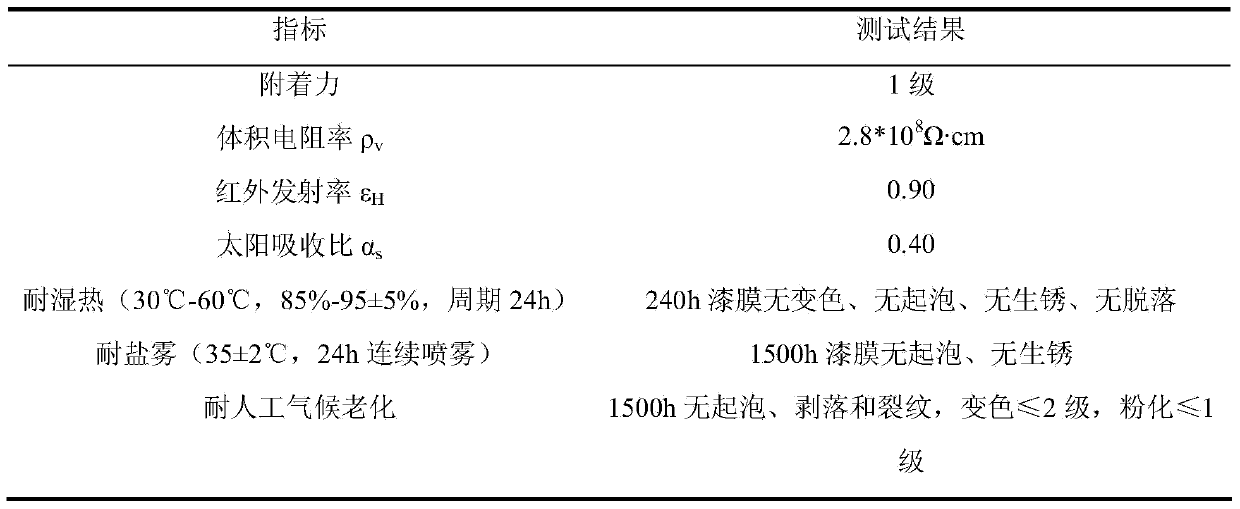

Embodiment 1

[0047] This embodiment includes the following steps:

[0048] (1) Add 240g of deionized water, 2.0g of neutralizer (50% DMEA aqueous solution), 2.4g of thickener (hydroxyethyl cellulose), and 9.0g of wetting and dispersing agent (BYK-190) into the paint mixing tank , surfactant (BYK-348) 1.0g, defoamer (BYK-022) 1.5g, antibacterial agent (KathonLXE) 1.0g, add additives while stirring, after stirring evenly, add rutile titanium dioxide 40g (grain 0.3-2μm in diameter), stirred at 3000r / min for 25min, and set aside.

[0049] (2) Add 450g of water-based hydroxyacrylic acid dispersion to the pigment slurry obtained in (1), stir well, then add 300g of conductive zinc oxide (particle size is 0.5-5μm), and then add defoamer (BYK-022) 3.0 g, rheology modifier (BYK-381) 6.0g, using shear dispersion equipment, 2000r / min dispersion 20min, to prepare water-based coating components.

[0050] (3) Pour the coating components in step (2) into a jar, add 120 g of HDI trimer, stir evenly, and ...

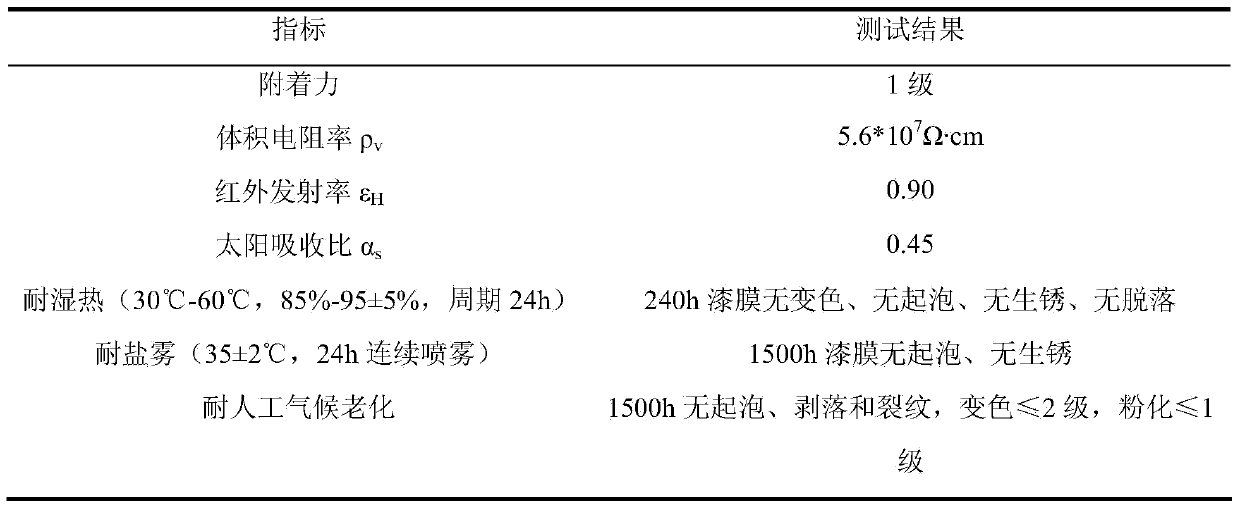

Embodiment 2

[0056] This embodiment includes the following steps:

[0057] (1) Add 240g of deionized water, 2.0g of neutralizer (50% DMEA aqueous solution), 2.0g of thickener (hydroxyethyl cellulose), and 8.0g of wetting and dispersing agent (BYK-190) into the paint mixing tank , surfactant (BYK-348) 1.0g, defoamer (BYK-022) 1.6g, antibacterial agent (KathonLXE) 1.2g, add additives while stirring, after stirring evenly, add rutile type titanium dioxide 40g (grain 0.3-2μm in diameter), stirred at 2500r / min for 25min, and set aside.

[0058] (2) Add 420g of water-based hydroxyacrylic acid dispersion to the pigment slurry obtained in (1), stir well, then add 260g of conductive potassium titanate (particle size is 5-10μm), and then add defoamer (BYK-022) 3.0g, rheology modifier (BYK-381) 6.0g, apply shear dispersion equipment, 2000r / min disperse for 20min, and prepare water-based coating components.

[0059] (3) Pour the coating components in step (2) into a jar, add 100 g of HDI biuret, sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com