Preparation method of high-entropy ceramic material with good light absorption performance

A ceramic material and light absorption technology, applied in the field of solar energy absorption materials and high entropy ceramic materials, can solve the problems of complex process, complex process, uncontrollable and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh CuO9.546g (0.12mol), MgO5.239g (0.12mol), Fe 2 O 3 9.581g (0.06mol), ZnO10.579g (0.12mol), TiO 210.387g (0.12mol) powder; sphere: material: water mass ratio of 3: 1: 3 The milling beads, raw materials and ultra pure water was poured into a ball mill jar; ball mill jar and placed on a ball mill station, for a first hours of milling, speed of 450r / min, 10min pause then, as a period of a ball mill, a ball mill for 1 hour and then over 10min, speed of 450r / min, a total of 7 hours to give a mixed powder milling; ball milling the resultant mixed powder was dried, milled and then placed in box resistance furnace, heated air atmosphere to 780 deg.] C (heating rate of 12 ℃ / min) calcined for 2 hours, and then air quenching to room temperature after calcination, to obtain single-phase (Cu, Mg, Fe, Zn , Ti) 3 O 4 Ceramic high entropy.

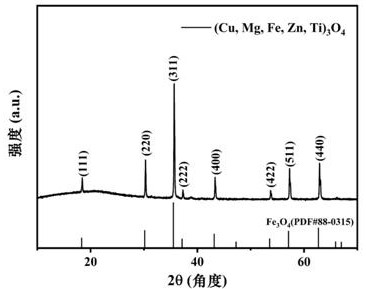

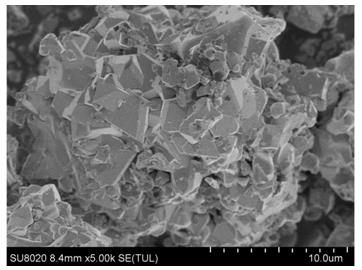

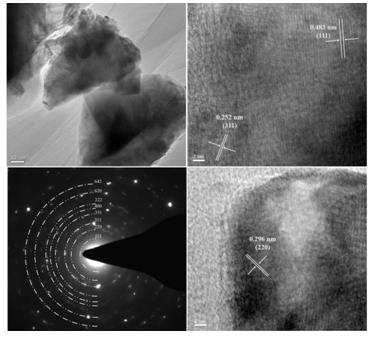

[0034] figure 1 Is (Cu, Mg, Fe, Zn, Ti) prepared 3 O 4 High entropy XRD pattern ceramic oxide material, the ICDD database spectrum and Fe ...

Embodiment 2

[0041] Weigh CuO9.546g (0.12mol), MgO5.239g (0.12mol), Fe 2 O 3 9.581g (0.12mol), Cr 2 O 3 9.119 g (0.06mol), Co 3 O 4 9.632g (0.04mol) powder; sphere: material: water mass ratio of 2: 1: 3 The milling beads, raw materials, ultra-pure water was poured into a ball mill jar, and placed on a ball mill pot station, for a first hours of milling, speed of 300r / min, 10min pause then, as a period of a ball mill, a ball mill for 1 hour and then over 10min, speed of 300r / min, a total mixed powder was ball milled for 5 hours; followed by ball milling the mixed powder obtained was dried grinding; then placed in box resistance furnace in air atmosphere heated to 500 deg.] C (heating rate of 10 ℃ / min) was calcined for 1 hour and cooled to room temperature and finally quenched in liquid nitrogen, to obtain single-phase (Cu, Mg, Fe , Cr, Co) 3 O 4 Ceramic high entropy.

[0042] Figure 7 Is the (Cu, Mg, Fe, Cr, Co) 3 O 4 Ceramic high entropy XRD pattern of the spectrum and Fe ICDD database ...

Embodiment 3

[0045] Weigh CuO10.342 g (0.13mol), MnO 2 13.041g (0.13mol), Cr 2 O 3 9.879g (0.065mol), Co 3 O 4 9.632g (0.043mol), ZnO10.579g (0.13mol) powder; sphere: material: water mass ratio of 4: 1: 3 The milling beads, raw materials and ultra pure water was poured into a ball mill jar; and placed in a jar mill station on a ball mill, a ball mill for 1 hour before, the rotation speed of 400r / min, 10min pause then, as a period of a ball mill, a ball mill for 1 hour again after 10min, the rotational speed of 400r / min, in total powder mixture ball milled for 9 hours; the resulting mixture is then ball-milled powder was dried, milled; then placed in box resistance furnace heated to 1140. deg.] C in an air atmosphere (heating rate 12 ℃ / min), calcined for 9 hours and finally cooled to room temperature with the furnace, single phase the (Cu, Mn, Cr, Co, Zn) 3 O 4 Ceramic high entropy.

[0046] Figure 8 The preparation of the (Cu, Mn, Cr, Co, Zn) 3 O 4 Ceramic high entropy XRD pattern of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solar absorptance | aaaaa | aaaaa |

| solar absorptance | aaaaa | aaaaa |

| solar absorptance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com