Flexible OSR second surface mirror thermal control coating and preparation method and application thereof

A technology of secondary surface mirror and thermal control coating, which is used in coatings, aerospace vehicle thermal protection devices, aerospace safety/emergency devices, etc. The effect of pasting, improving thermal control performance, and broadening the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

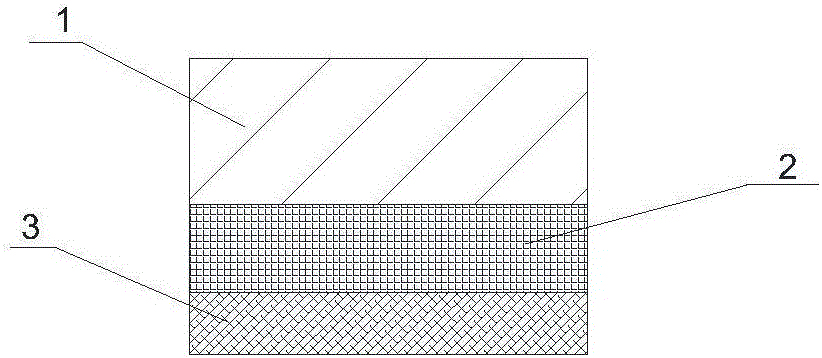

[0026] The structure of a flexible OSR secondary surface mirror thermal control coating involved in this embodiment is as follows: figure 1 As shown, it includes a flexible glass substrate 1, a metal reflective layer 2 (generally silver, aluminum, etc.) The thickness of the film layer is less than 10μm, and the thickness ratio of the metal reflective layer and the anti-oxidation film layer is close to 1:1, and can be adjusted according to the performance requirements.

[0027] The preparation method of the flexible OSR secondary surface mirror thermal control coating provided in this embodiment includes the following steps:

[0028] Metal reflective layer is plated on the single side surface of flexible glass substrate, and anti-oxidation layer is plated on the surface of described metal reflective layer, and the thermal radiation performance of the flexible OSR secondary surface mirror thermal control coating that obtains is:

[0029] Solar absorption ratio: αs≤0.12.

[003...

Embodiment 2

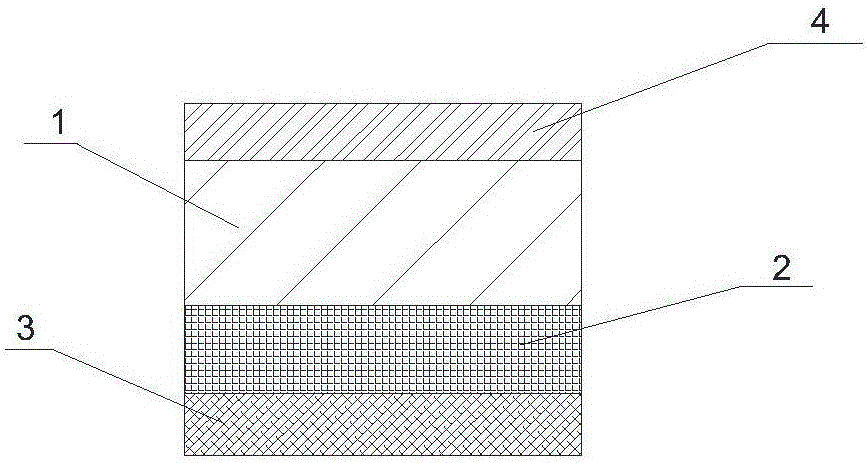

[0032] The structure of a flexible OSR secondary surface mirror thermal control coating involved in this embodiment is as follows: figure 2 As shown, it includes a conductive layer 4 (generally ITO film), a flexible glass substrate 1, a metal reflective layer 2 (generally silver, aluminum, etc.) and an anti-oxidation film layer 3 (generally nickel Chrome alloy), the thickness of conductive layer, metal reflective layer and anti-oxidation film layer is less than 10 μm, the thickness ratio of conductive layer, metal reflective layer and anti-oxidation film layer is close to 1:4:5, and can be adjusted according to performance requirements.

[0033] The preparation method of the OSR secondary surface mirror thermal control coating provided in this embodiment comprises the following steps:

[0034] On both sides of the flexible glass substrate, a conductive layer and a metal reflective layer are plated respectively, and an anti-oxidation layer is plated on the surface of the metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com