Novel antistatic white thermal control coating and preparation method thereof

A thermal control coating and anti-static technology, which is applied in coatings, conductive coatings, and devices for coating liquid on the surface, etc., can solve the problem that the volume resistivity does not reach antistatic, thermal control coatings cannot be used normally, and resistivity Large and other problems, to achieve the effect of good adhesion, strong implementability, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

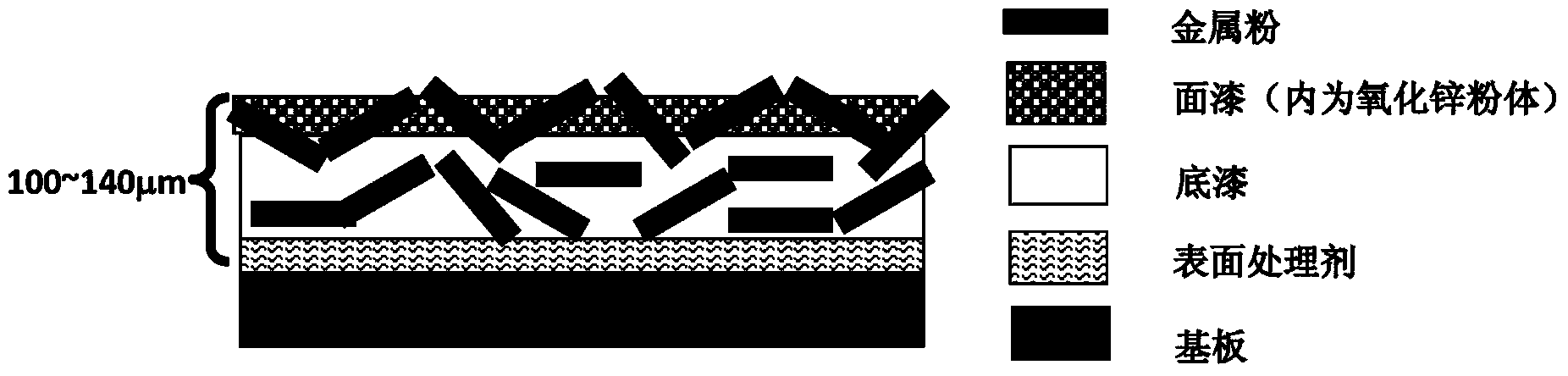

[0042] The novel antistatic white thermal control coating of the present embodiment is as figure 1 As shown, the coating includes a surface treatment agent layer, a primer layer and a topcoat layer from the inside to the outside; the primer layer and the topcoat layer all use room temperature curing silicone resin as the matrix resin; in the primer layer A plurality of sheet-shaped metal powders are arranged in a cross-overlapping manner, and one end of some sheet-shaped metal powders extends to the topcoat layer; white zinc oxide is also distributed in the topcoat layer.

[0043] The specific preparation method of the novel antistatic white thermal control coating of the present embodiment comprises the following steps:

[0044] 1) Primer coating configuration: Add flake metal powder to epoxy-modified polymethylphenylsiloxane, mix and stir, add xylene, mix, and ultrasonically stir evenly; by mass percentage: flakes in the primer Shaped metal mixed powder (copper powder: silv...

Embodiment 2

[0096] The novel antistatic white thermal control coating of the present embodiment is as figure 1 As shown, the coating includes a surface treatment agent layer, a primer layer and a topcoat layer from the inside to the outside; the primer layer and the topcoat layer all use room temperature curing silicone resin as the matrix resin; in the primer layer A plurality of sheet-shaped metal powders are arranged in a cross-overlapping manner, and one end of some sheet-shaped metal powders extends to the topcoat layer; white zinc oxide is also distributed in the topcoat layer.

[0097] The preparation method of the novel antistatic white thermal control coating of the present embodiment is the same as embodiment 1, the difference is:

[0098] 1) Primer coating configuration: add flake metal powder to the room temperature curing silicone resin, mix and stir, add butyl acetate, mix, and ultrasonically stir evenly; by mass percentage: in the primer, flake metal aluminum powder ( The ...

Embodiment 3

[0110] The novel antistatic white thermal control coating of the present embodiment is as figure 1 As shown, the coating includes a surface treatment agent layer, a primer layer and a topcoat layer from the inside to the outside; the primer layer and the topcoat layer all use room temperature curing silicone resin as the matrix resin; in the primer layer A plurality of sheet-shaped metal powders are arranged in a cross-overlapping manner, and one end of some sheet-shaped metal powders extends to the topcoat layer; white zinc oxide is also distributed in the topcoat layer.

[0111] The preparation method of the novel antistatic white thermal control coating of the present embodiment is the same as embodiment 1, the difference is:

[0112] 1) Primer coating configuration: add flake metal powder to the room temperature curing silicone resin, mix and stir, add xylene, mix, and ultrasonically stir evenly; by mass percentage: in the primer, flake metal mixed powder (aluminum Powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com