Patents

Literature

30results about How to "Good heat control effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

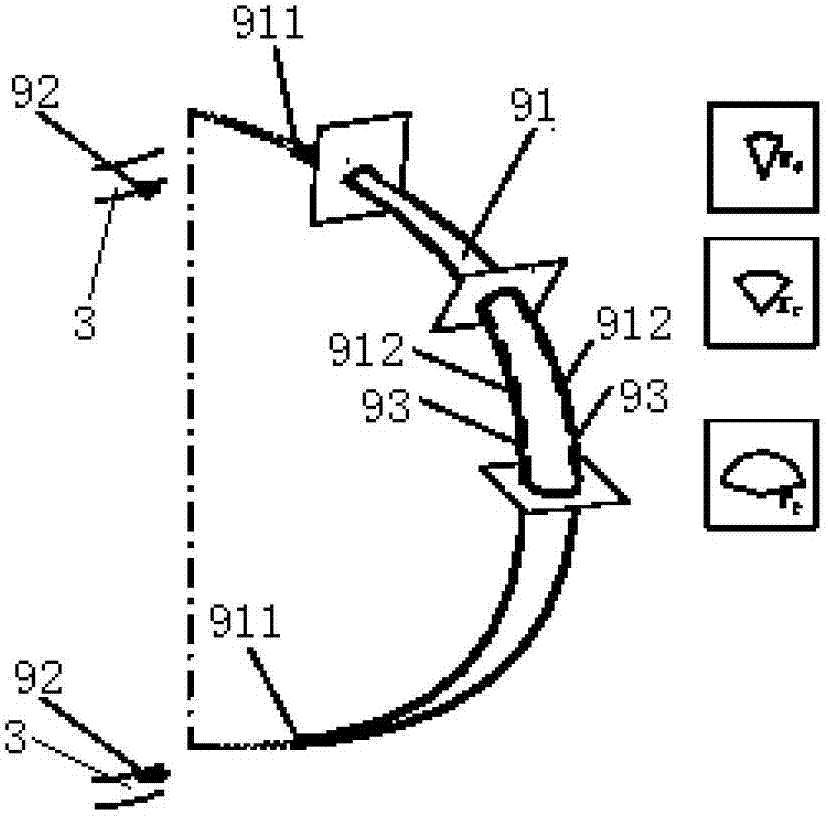

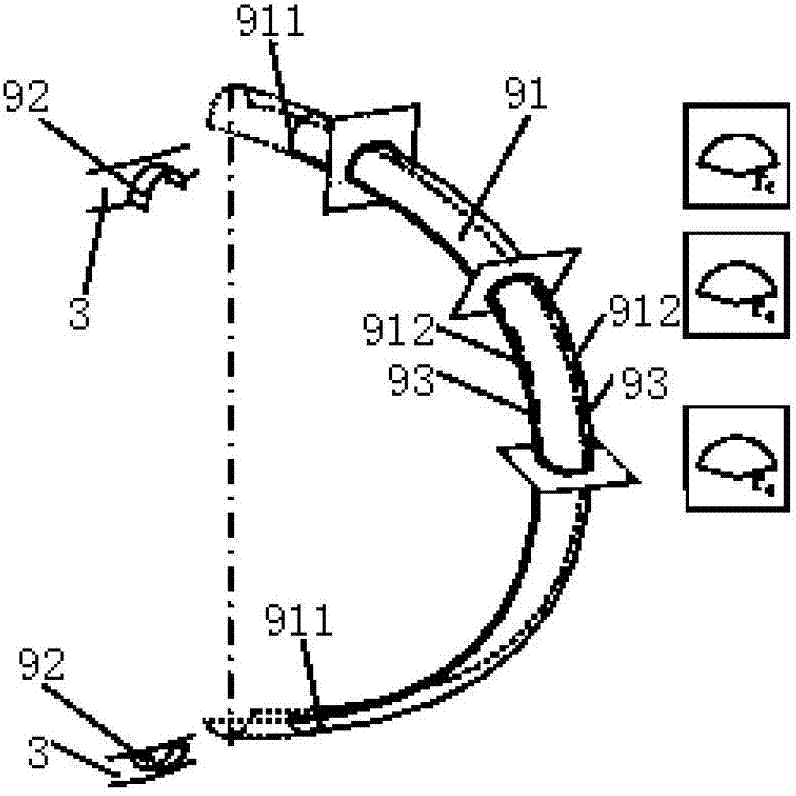

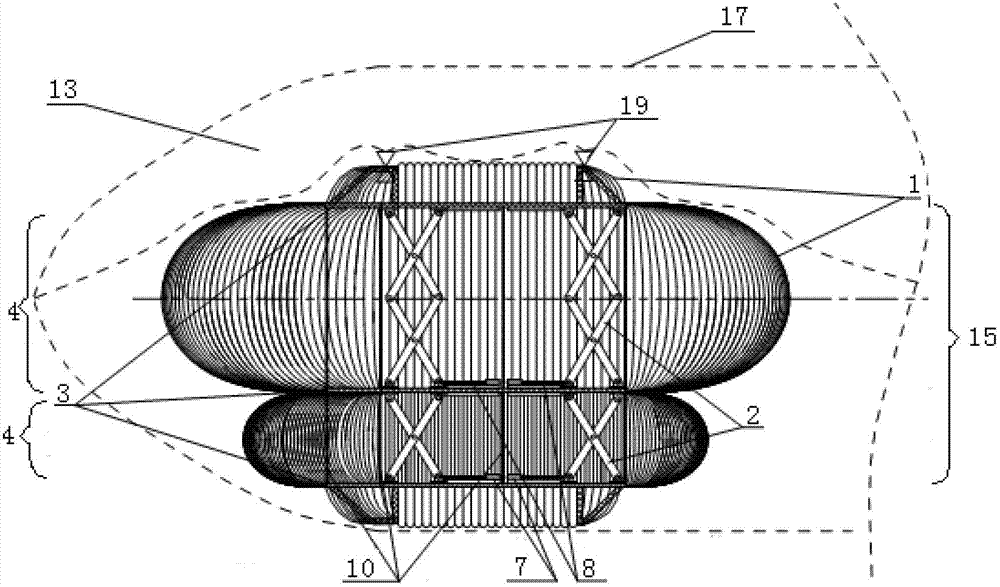

Airship airbag with shape-control frames

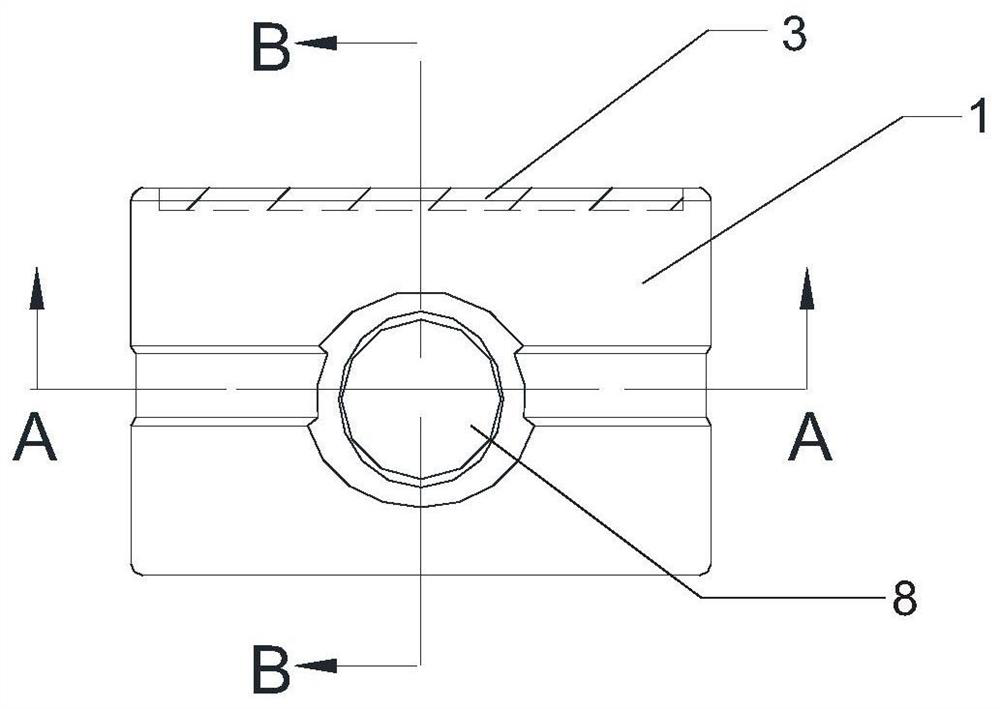

The invention relates to an airship airbag with shape-control frames. The airship airbag with the shape-control frames comprises an airbag casing (1) and the shape-control frames; the airtight flexible airbag casing (1) is arranged on the outer layer of the air bag, is of a laminated structure on the whole and consists of a plurality of layered structures; the inside of every layered structure is fixedly connected with the shape-control frames which comprises a plurality of pairs of vertically-arranged folding frames (2) and two pairs of shaping frames (3) respectively hinged to two ends of the folding frames (2); the airbag casing (1) of every layered structure (4) is formed by splicing the airtight film covering pieces (91) of a plurality of convex curved surface unit (9), and every convex curved surface unit (9) not only comprises one elongated airtight film covering piece (91) but also comprises a pair of end-edge fixing parts (92) on the shaping frames (3) and a pair of pulling-resistant straps (93). The airship airbag with the shape-control frames can make full use of the space inside an airship, is good in regularity of expansion and shrinkage deformation and good in repeatability and stability, and can bear relative large overpressure when being inflated and expanded fully.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

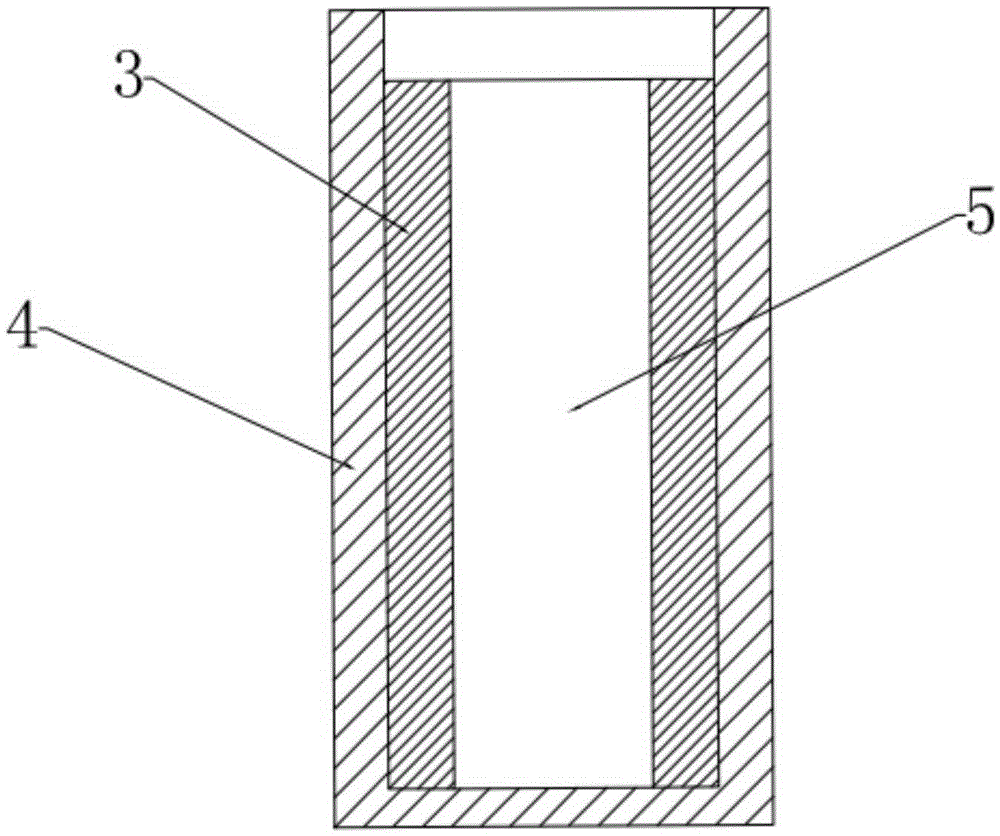

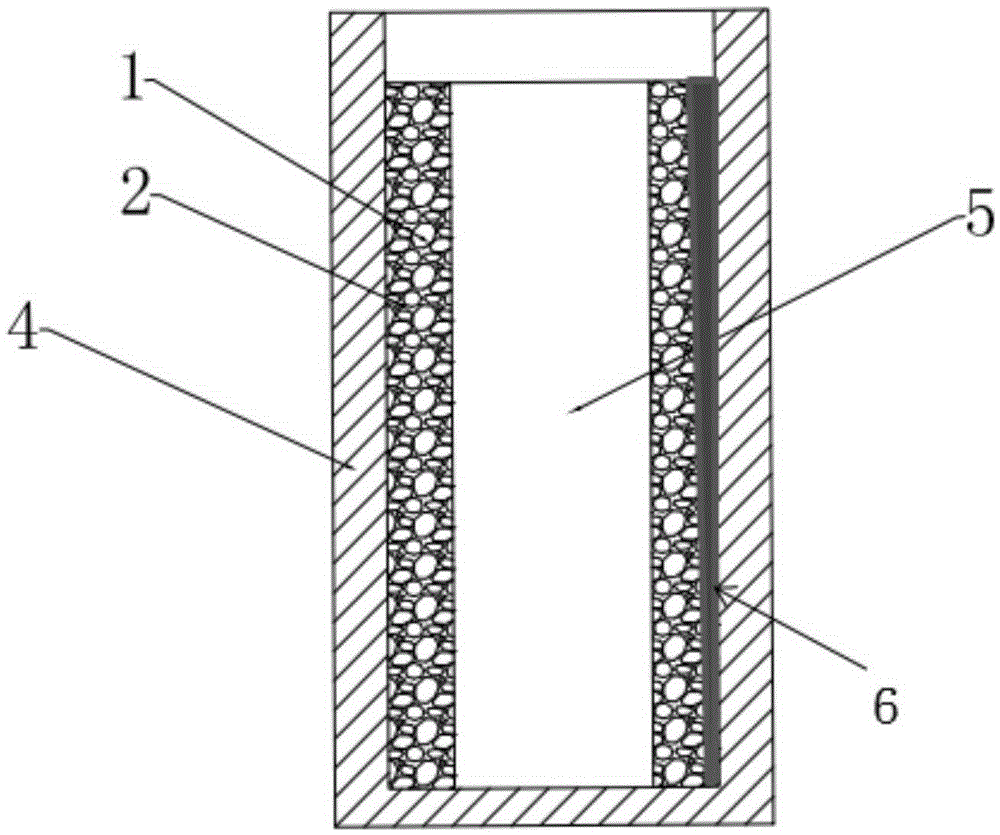

Combined heat dissipating device provided with fins and foam heat conduction structure

ActiveCN105356004AReduce temperature riseIncrease the heat exchange areaSecondary cellsPhase-change materialLithium-ion battery

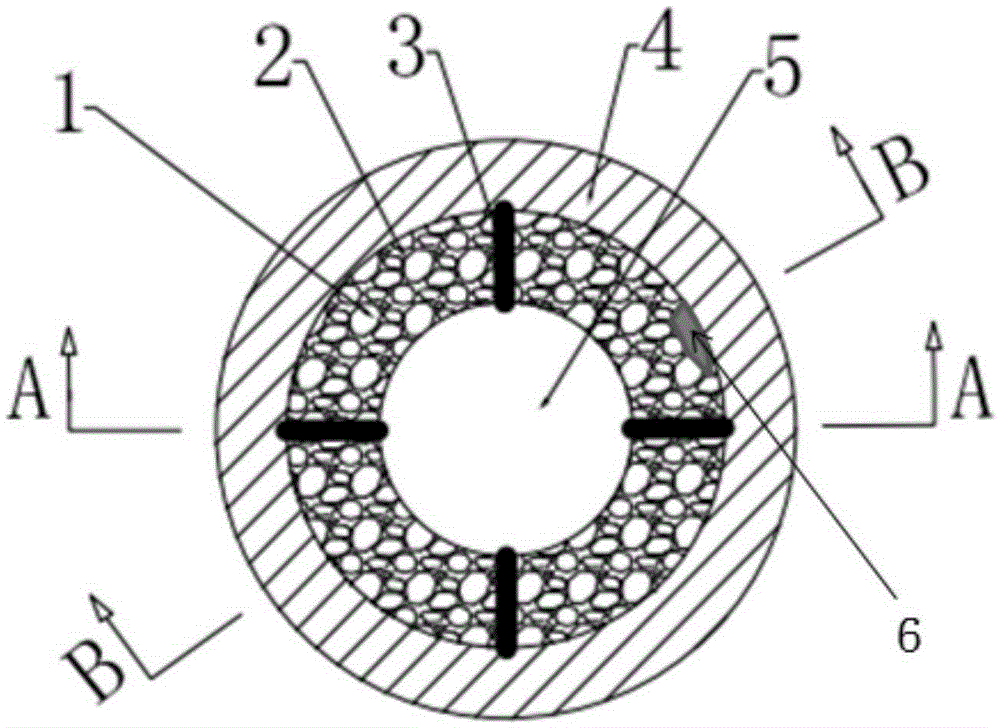

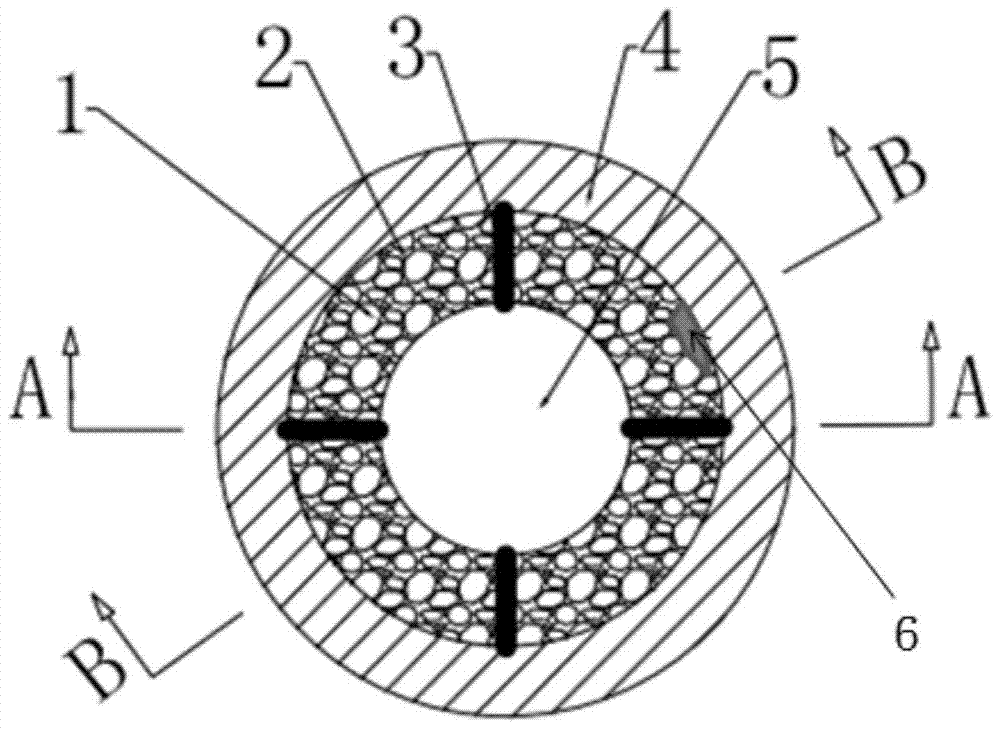

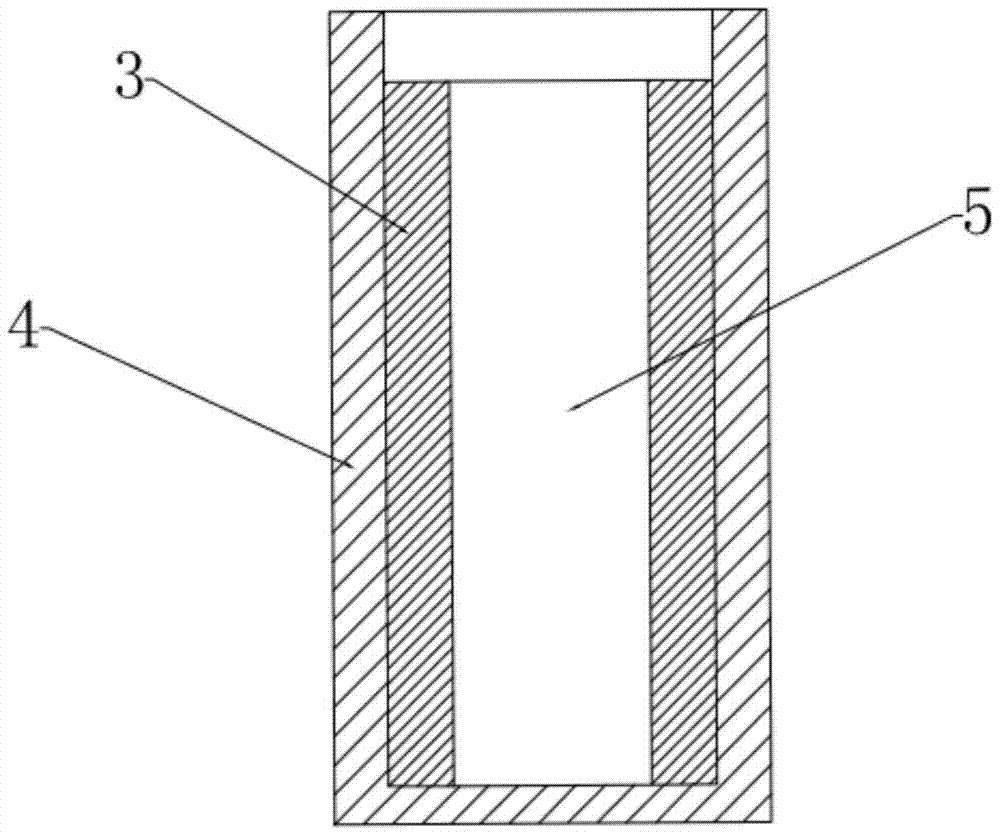

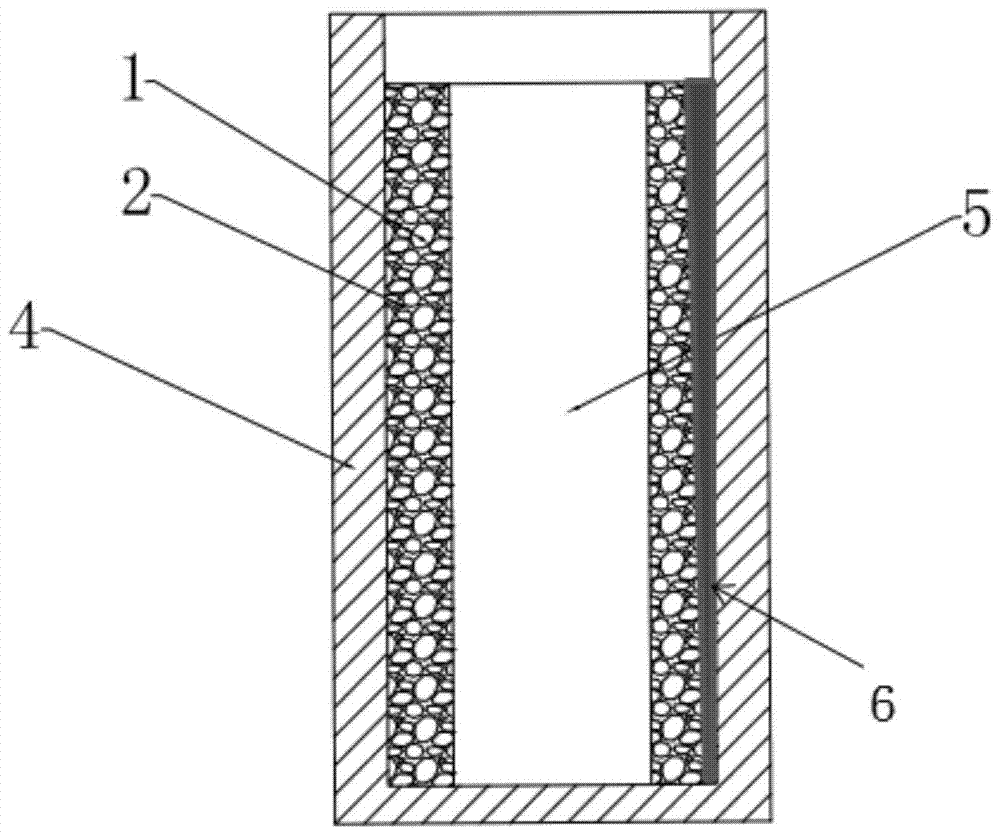

The invention relates to a combined heat dissipating device provided with fins and a foam heat conduction structure and used for assisting heat dissipation of an individual battery (5). The combined heat dissipating device comprises a shell sleeve (4) sleeving the individual battery (5), wherein a foam structure fills the space between the shell sleeve (4) and the individual battery (5), the foam structure (2) is full filled with a phase-change material (1), multiple fins (3) separating the foam structure (2) are further arranged between the shell sleeve (4) and the individual battery (5), and the two sides of each fin (3) are respectively in tight fit with the shell sleeve (4) and the individual battery (5). Compared with the prior art, the combined heat dissipating device has the advantages of effectively reducing the temperature of a lithium ion battery and preventing thermal runaway.

Owner:SHANGHAI MAKESENS ENERGY STORAGE TECH CO LTD

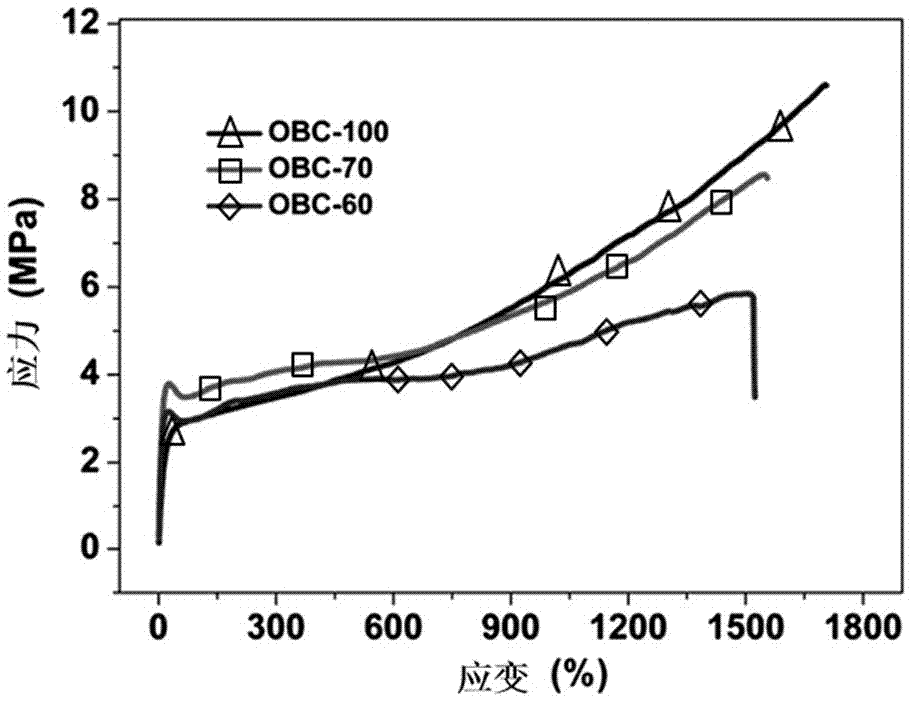

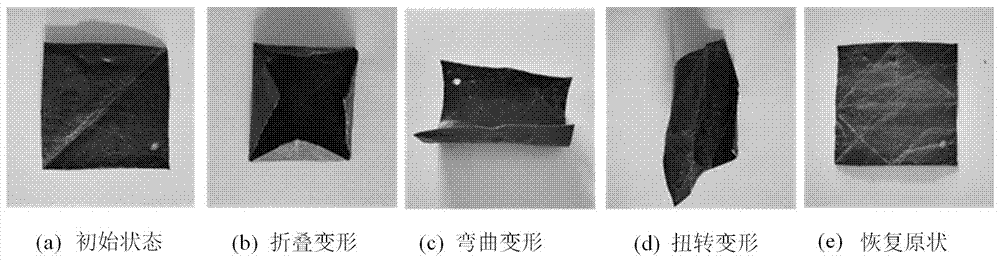

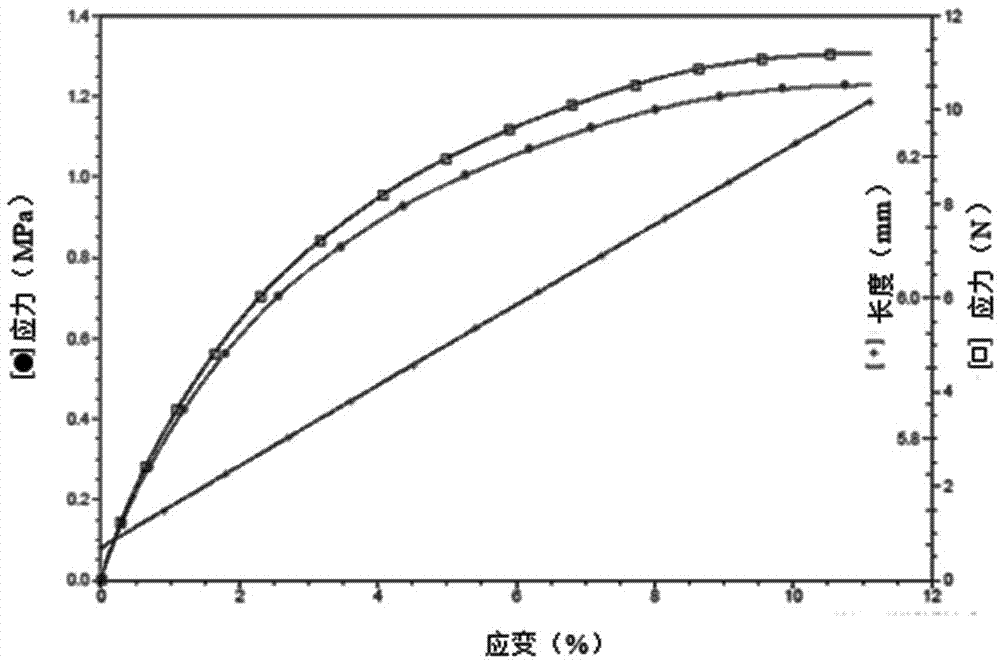

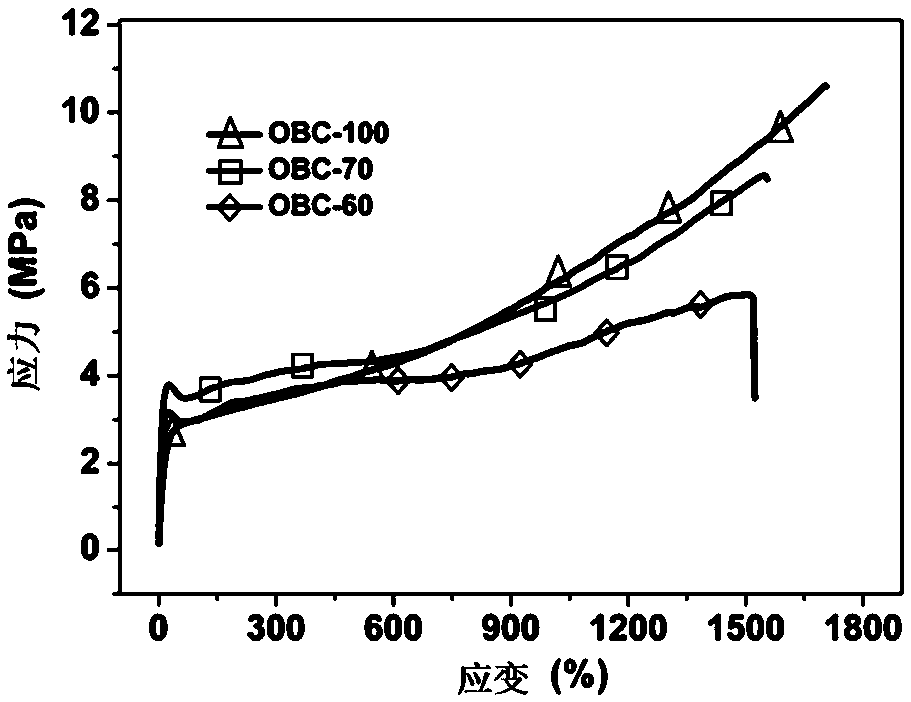

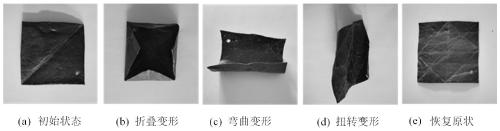

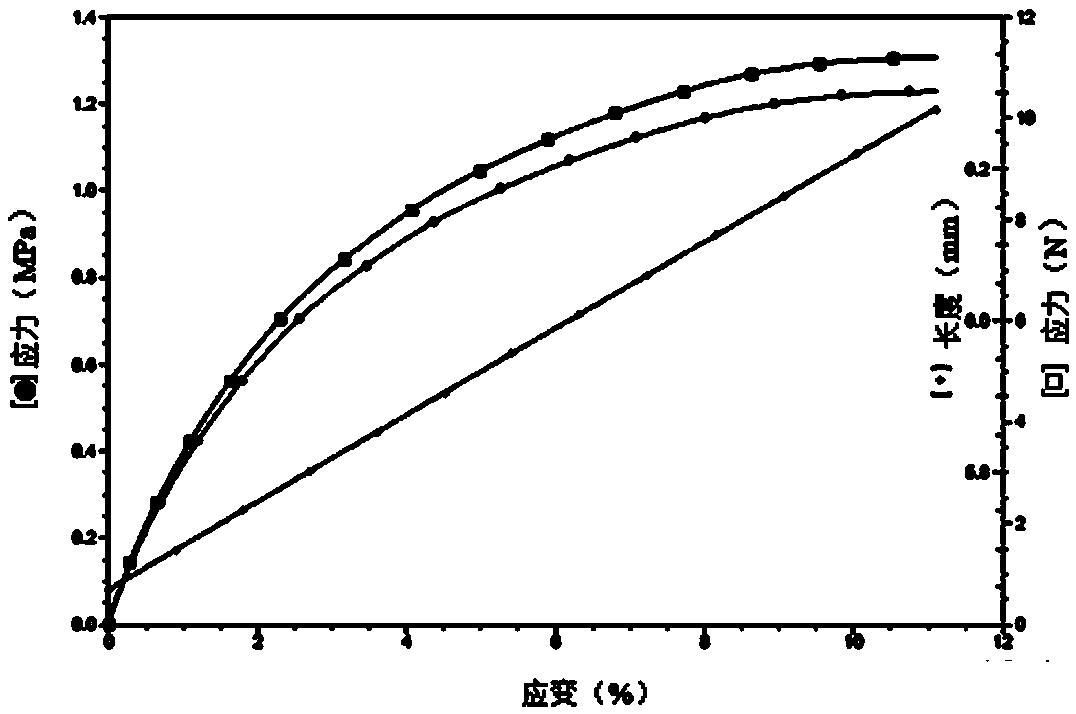

Flexible phase-change material for electronic device thermal control

ActiveCN107254297AImprove flexibilityHigh strengthHeat-exchange elementsModifications by conduction heat transferPhase changeElectric equipment

The invention relates to a flexible phase-change material for electronic device thermal control. The flexible phase-change material comprises a phase-change substrate and a support carrier. The support carrier is an elastic polymer. The flexible phase-change material is prepared by the following steps: heating the phase-change substrate and the support carrier in the certain temperature, and placing in the environment of which the temperature is higher than the phase-change temperature after completely fusing and mixing, cooling and rolling. The flexible phase-change material can produce the deformation, such as elastic stretching, bending and torsion, while the temperature is higher than the phase transformation point. The flexible phase-change material is adhered to the surface of the heat production part or filled in clearances between a hot plate and a packaging component while used for the electronic device thermal control. The phase-change material has the good flexibility, so the phase-change material has the performance of a thermal interface material, and is capable of reducing the contract thermal resistance. The flexible phase-change material is capable of solving the problems that the installation is difficult and the contract thermal resistance is larger because the common phase-change material is excessive hard in the thermal control process of the electronic device, and greatly improving the thermal control performance.

Owner:UNIV OF SCI & TECH OF CHINA

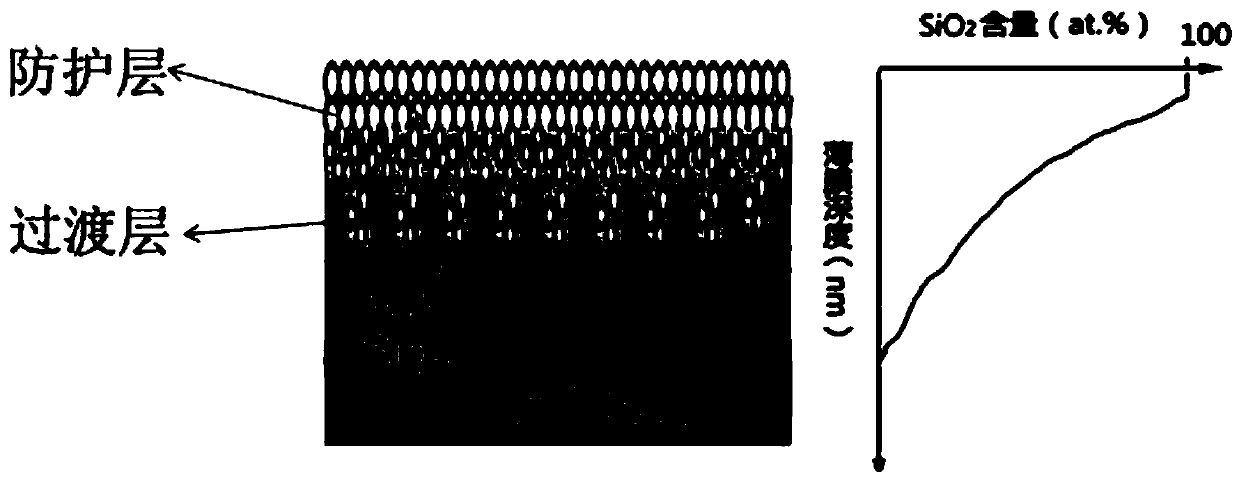

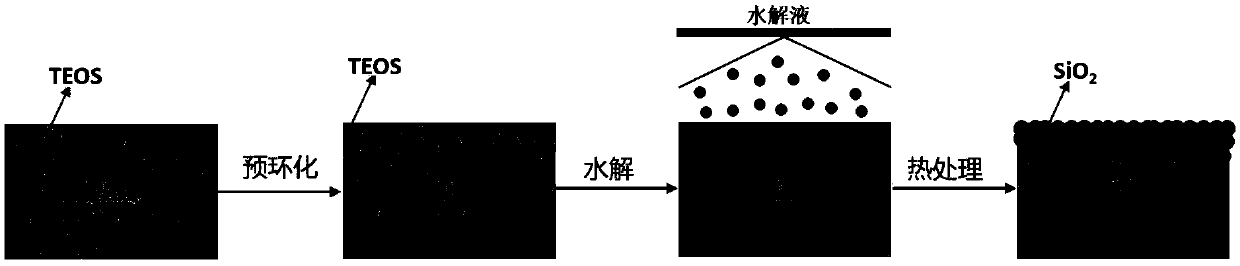

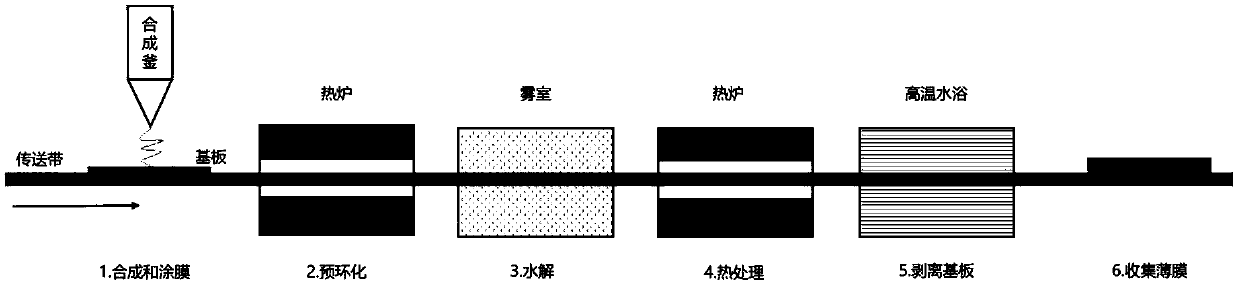

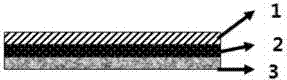

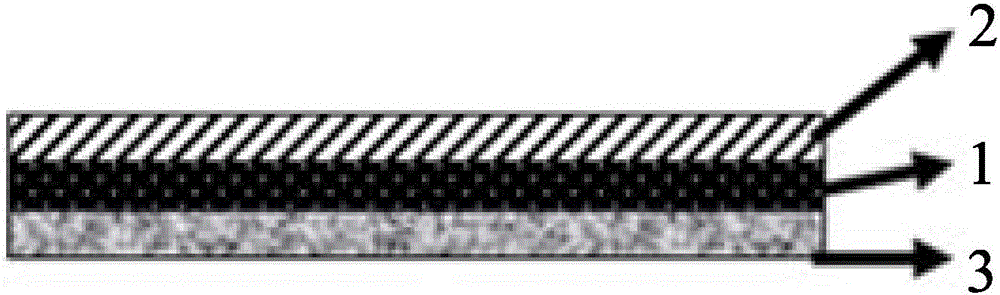

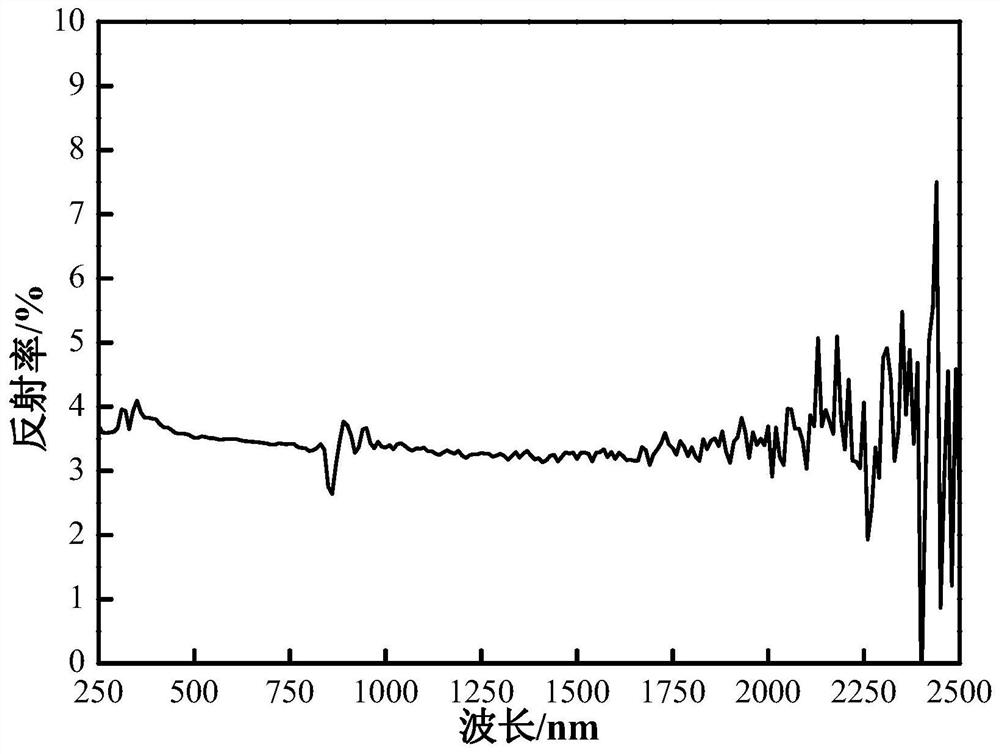

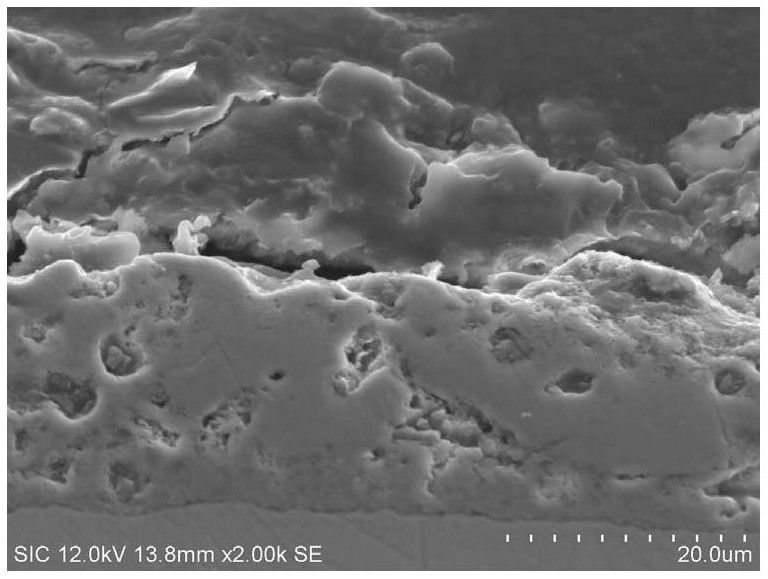

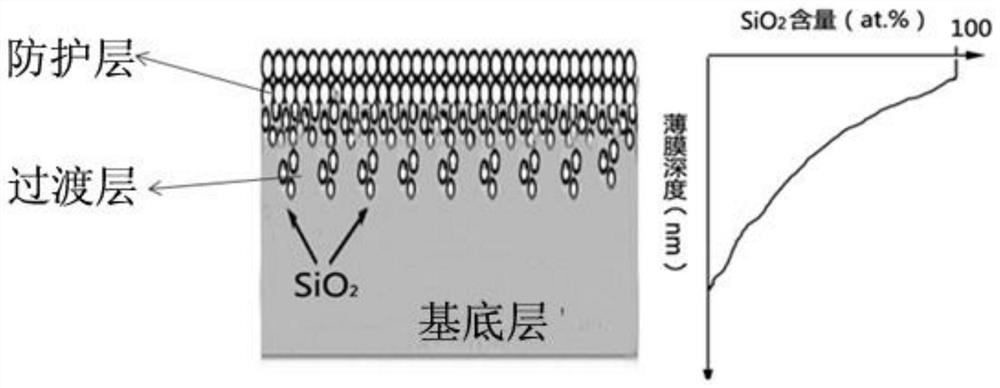

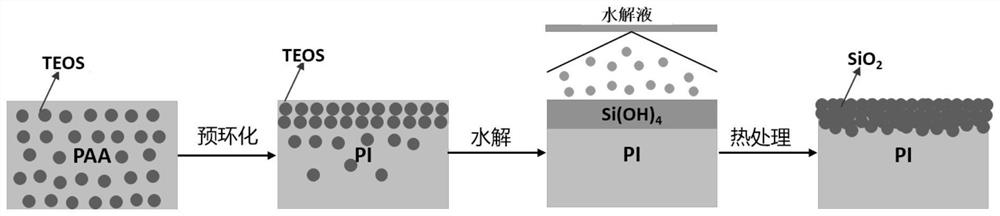

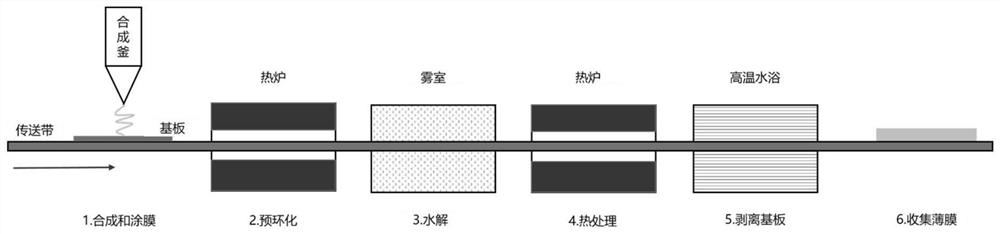

Silicon-containing atomic oxygen resistant polyimide film composition and preparation method thereof

The invention provides a silicon-containing atomic oxygen resistant polyimide film material and a preparation method thereof. The film material comprises a base film layer, a transition layer and a surface protective layer, which are arranged in sequence. The base film layer comprises a modified polyimide substrate and a nano-SiO2 filler; the transition layer is a Si-O-Si and polyimide interpenetrating network structure; and the surface protective layer is a pure silicon dioxide layer. According to the atomic oxygen resistant polyimide film prepared by the invention, the color is pale yellow;the thickness is 50-80 microns; tensile strength is greater than or equal to 200 MPa; insulating strength is greater than or equal to 230 V / microns; the total atomic oxygen accumulation is 7.83*1022 atom / cm<2>; mass loss rate after 10 years of operation in the earth orbit is less than or equal to 10%, and the optical performance change is less than or equal to 10%. After the coating undergoes 100high-low temperature thermal cycle tests of minus 100 to 100 DEG C, the coating has no obvious crack but has stable optical performance and good mechanical properties.

Owner:SHANGHAI INST OF SATELLITE EQUIP

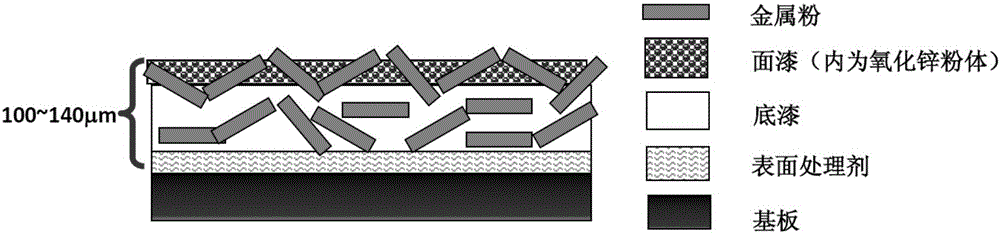

Novel antistatic white thermal control coating and preparation method thereof

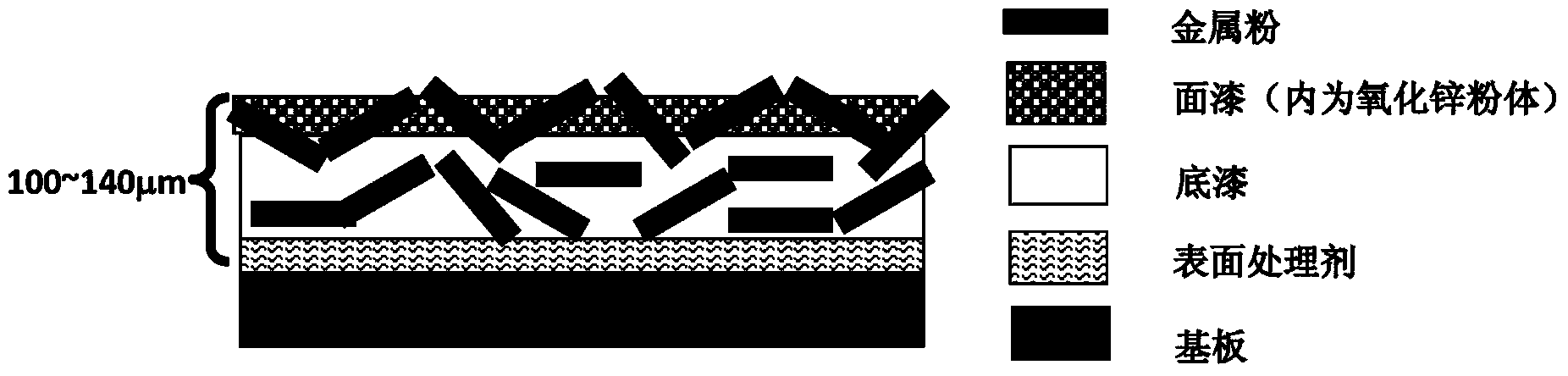

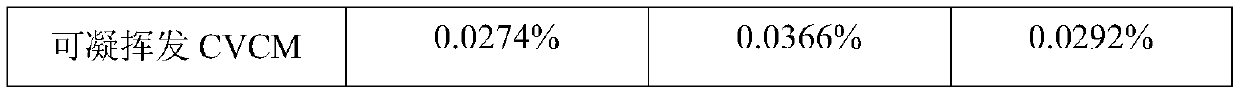

ActiveCN103666248ANo crackNo peelingPretreated surfacesSpecial surfacesSolar absorptanceThermal control

The invention discloses a novel antistatic white thermal control coating and a preparation method thereof; wherein the coating, from interior to exterior, comprises a surface treatment agent layer, a prime coat layer and a finishing coat layer; the prime coat layer and the finishing coat layer all use room temperature curing type organic silicone resin as a matrix resin; a plurality of sheet-shaped metal powders are crossedly overlapped and arranged in the prime coat layer, and one ends of part of the sheet-shaped metal powders extend to the finishing coat layer; and white zinc oxide is distributed in the finishing coat layer. The coating provided by the invention is white, thickness is 100-140mum, solar absorptance is 0.24-0.29, hemispherical emissivity is 0.85-0.91, total mass loss TML is less than 1%, a collected volatile condensable material CVCM is less than 0.1%, and volume resistivity rhoV is not less than 107 ohm*m. The coating, through 100 times of high and low temperature heat cycle test in a temperature range from -100 to 100 DEG C, has advantages of non-cracking, non-spalling, non-foaming and non-discoloring phenomena, stable optical property and good adhesion force, and can basically satisfy demand of a spacecraft on the antistatic white thermal control coating.

Owner:SHANGHAI INST OF SATELLITE EQUIP

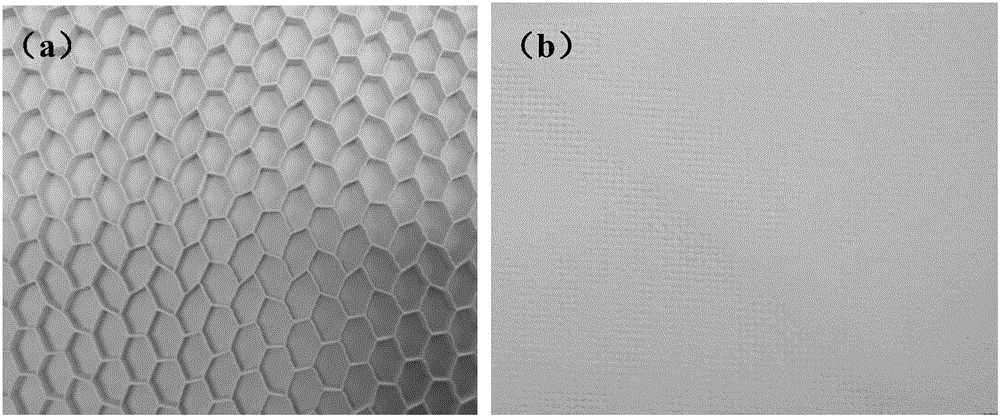

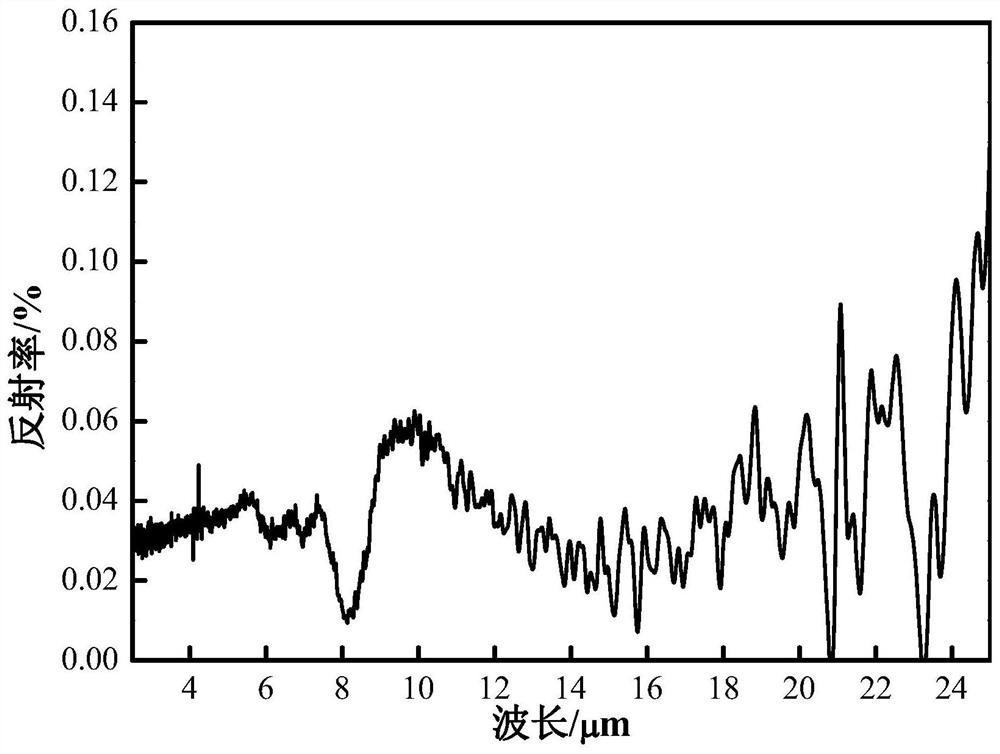

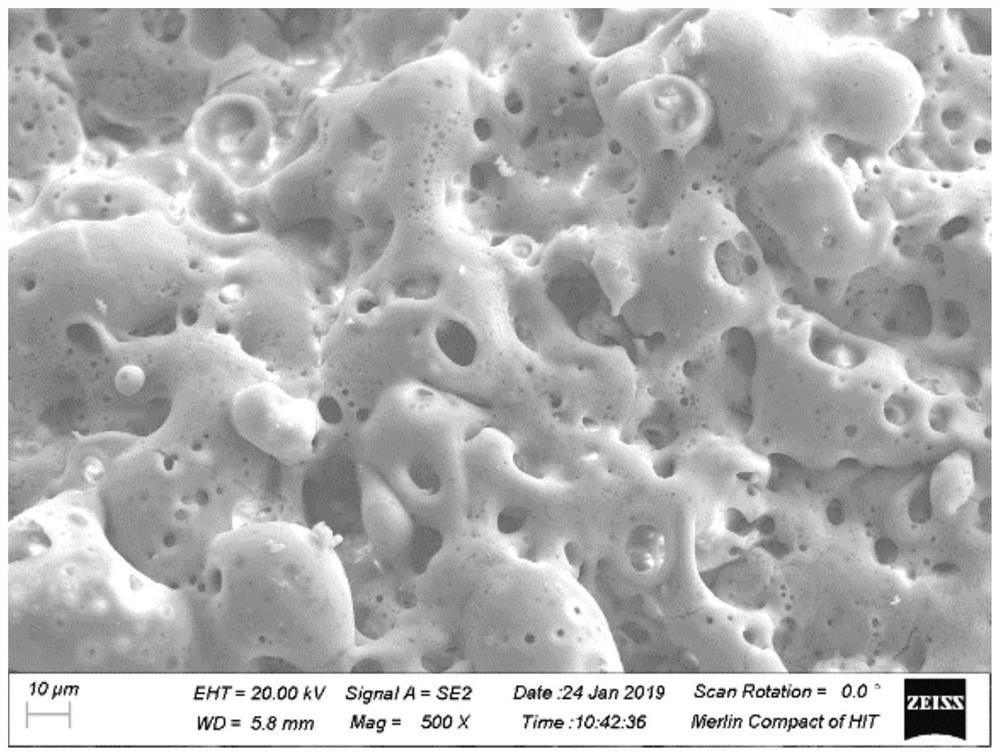

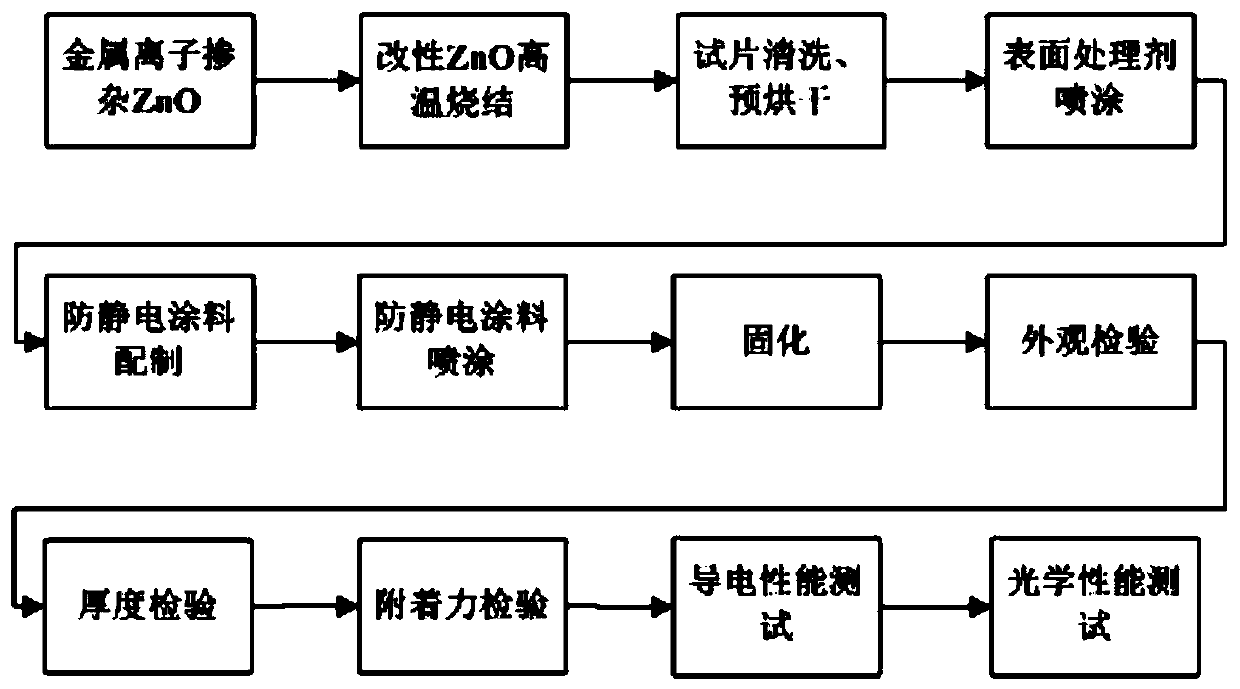

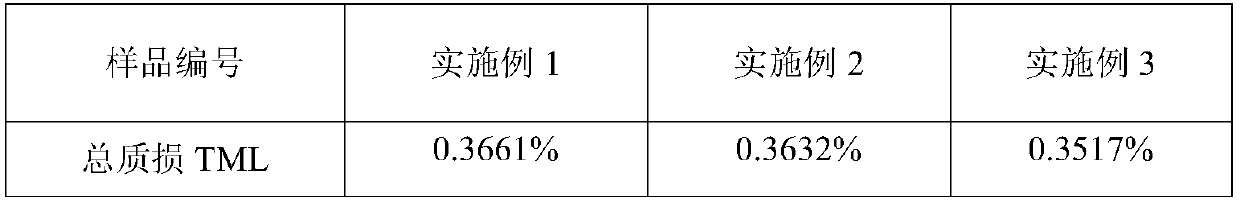

Antistatic thermal control coating composition, preparation method and applications thereof

ActiveCN104774510AGood heat control effectEasy constructionElectrically-conductive paintsOmegaThermal control

The invention discloses an antistatic thermal control coating composition, a preparation method and applications thereof. The coating composition comprises priming paint and finish paint. The priming paint is composed of a matrix namely organic fluorine resin and a filling material namely modified zinc oxide powder; wherein the zinc oxide is capable of forming vertical channels in the priming paint layer. The finish paint is composed of a matrix namely methyl silicone resin with multiple functional groups and a filling material namely modified zinc oxide powder; wherein part of the filling material penetrates the interface between the priming paint layer and the finish paint layer. The prepared antistatic thermal control coating has a white color, a thickness of 130 to 200 [mu]m, a solar absorption ratio of 0.20 to 0.25, a hemispherical emissivity of 0.85 to 0.91, a total mass loss (TML) not more than 1%, collectable volatile condensed mass (CVCM) not more than 0.1%, and a volume resistivity ([rho]v) not more than 107 [omega].m. The coating does not have the phenomenon of cracking, peeling, bubbling, and fading after 100 times of high-low temperature thermal cycle experiments in a temperature range of -100 to 100 DEG C, the optical properties of the coating is stable, and the adhesive force of the coating is high.

Owner:SHANGHAI INST OF SATELLITE EQUIP

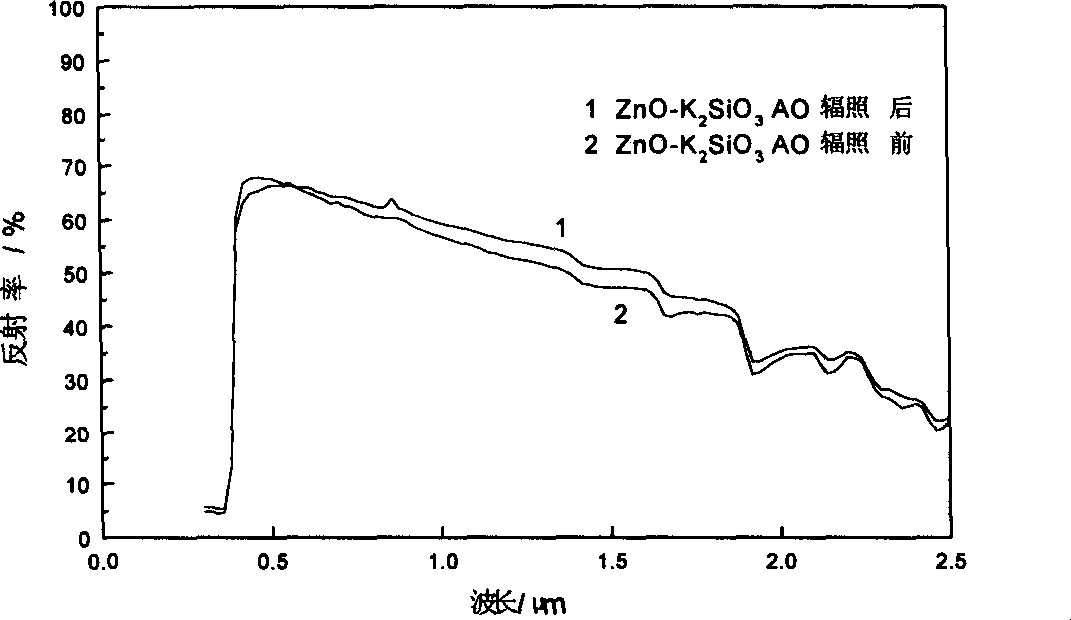

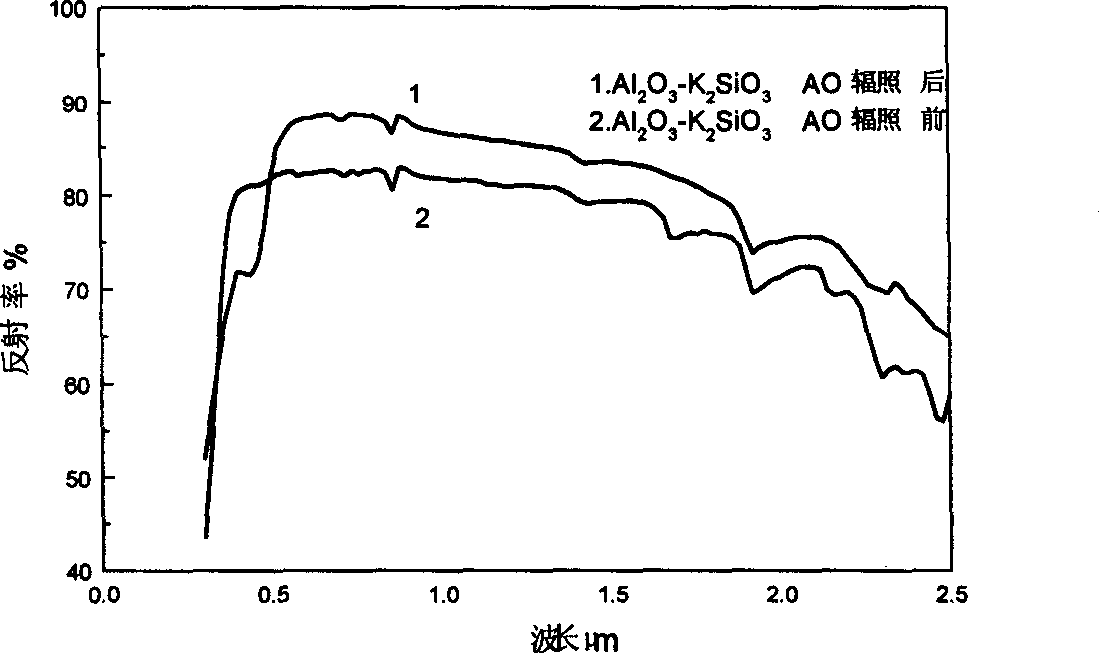

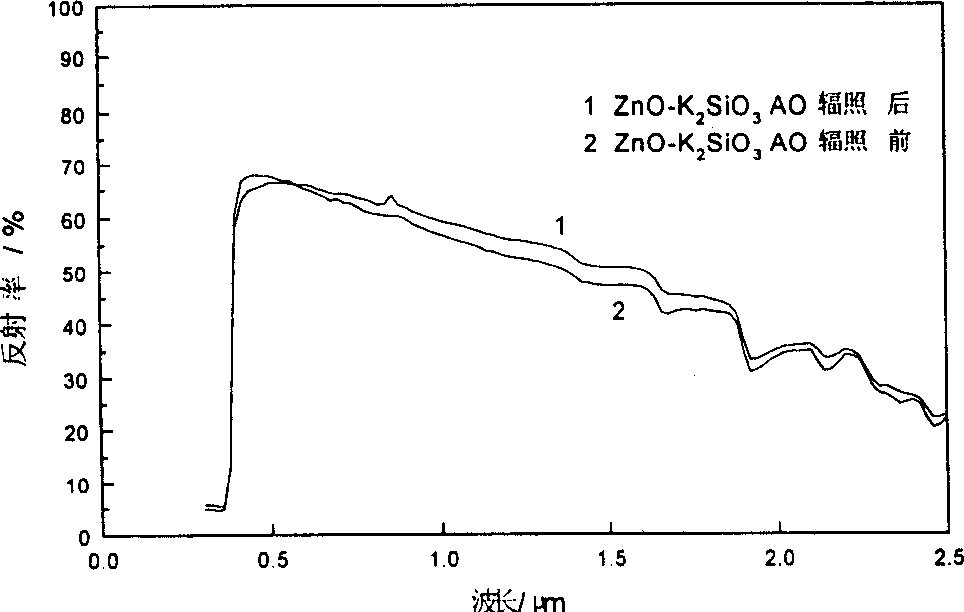

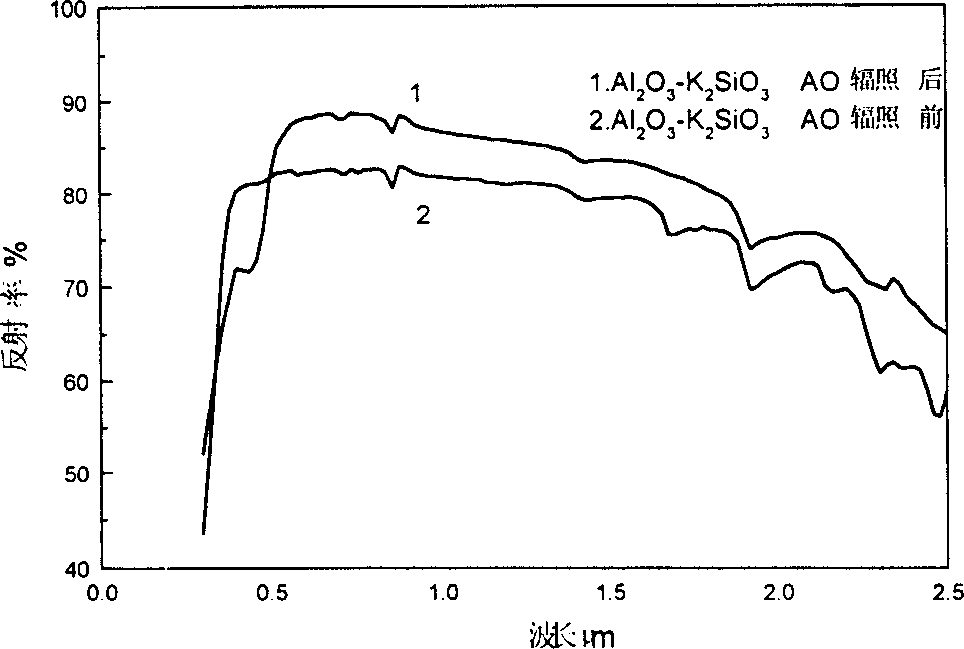

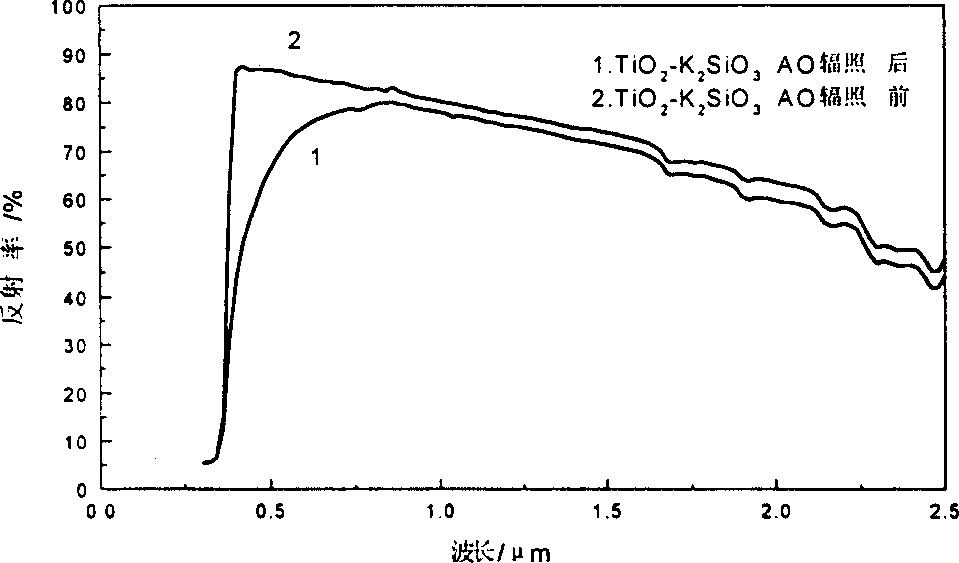

Low sunlight absorptivity alumina-potassium silicate paintcoat for heat control and its preparing method

A thermally controlled alumina-potassium silicate coating with low solar absorptivity for artificial satellite, space aircraft, etc is prepared from potassium silicate, diethanolamine, emulsifier, sodium hexametaphosphate, disperser, defoaming agent, light calcium carbonate, heavy calcium carbonate, talc power, mica powder, alumina powder and water through preparing slurry and proportionally mixing with phenylacrylic acid emulsion. Its advantages are high space stability, resistance to atomic oxygen corrosion, and thermal control effect, and low heat absorptivity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

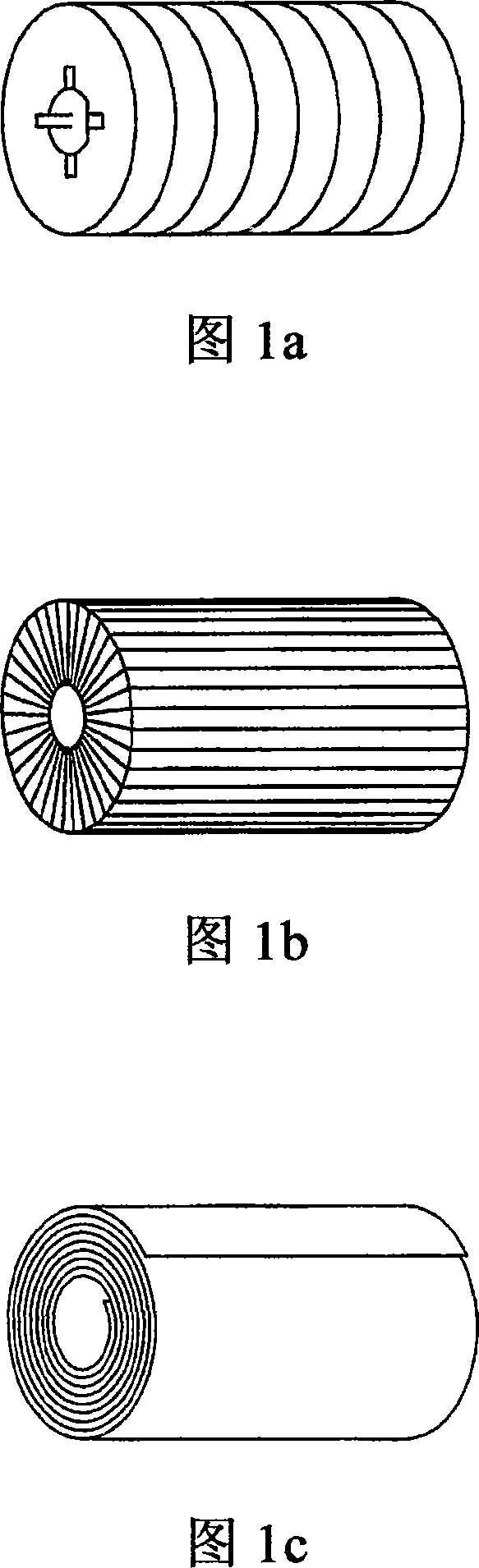

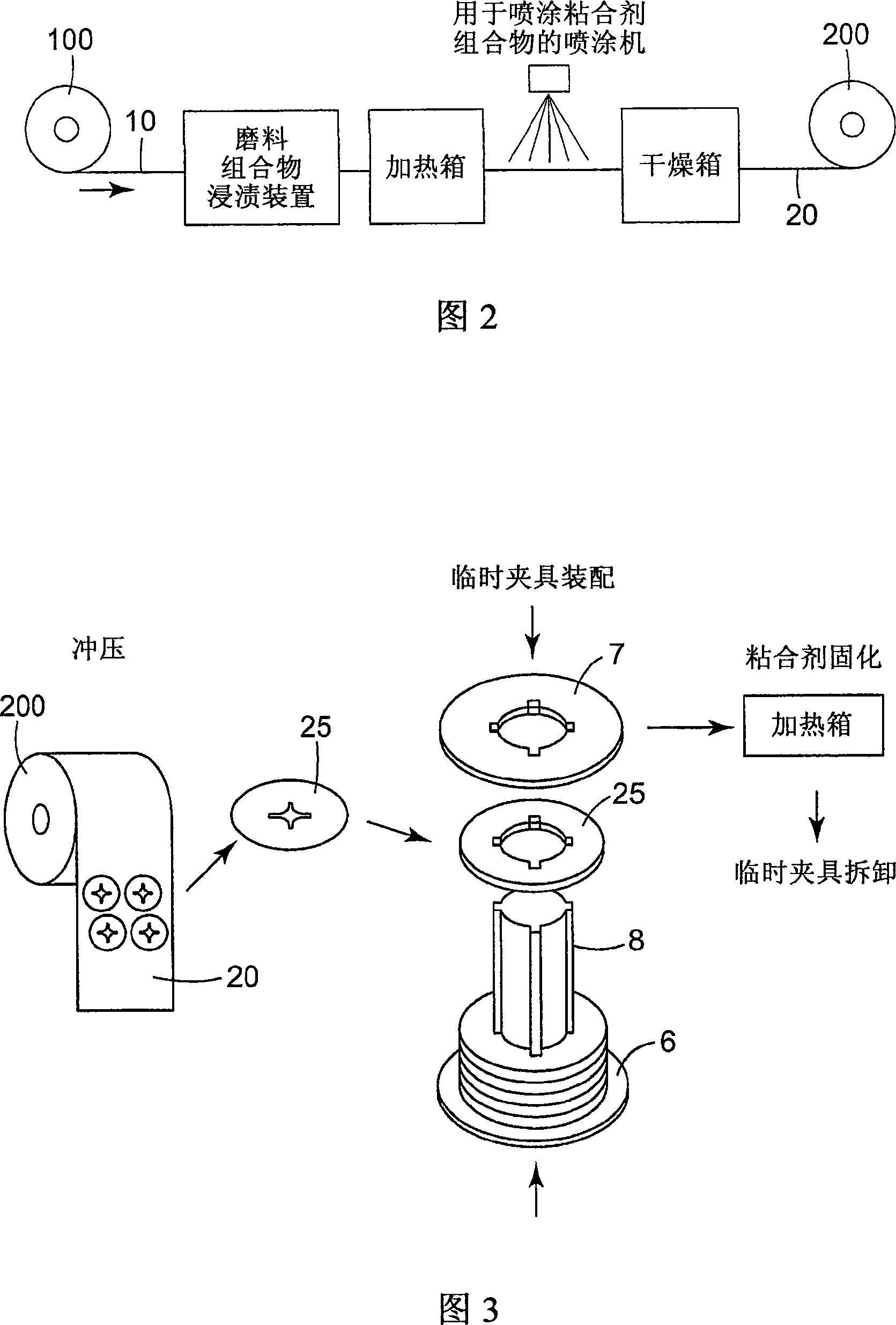

Abrasive material comprising reactive inorganic endothermic compound

InactiveCN101094749AGood heat control effectDoes not smudgeAbrasion apparatusChemical compoundMaterials science

The invention provides a nonwoven fabric abrasive material, which comprises a reactive inorganic endothermic compound.

Owner:3M INNOVATIVE PROPERTIES CO

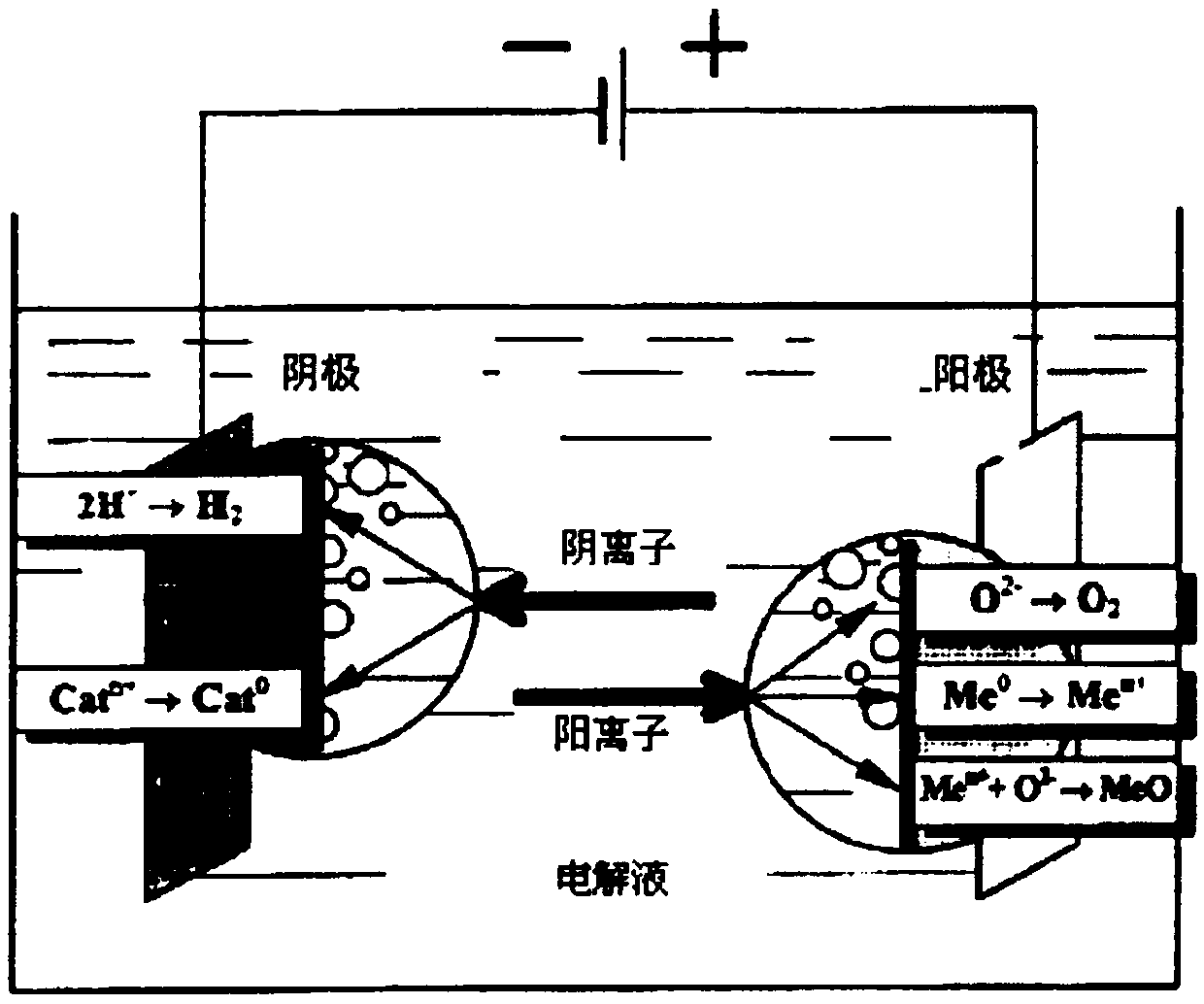

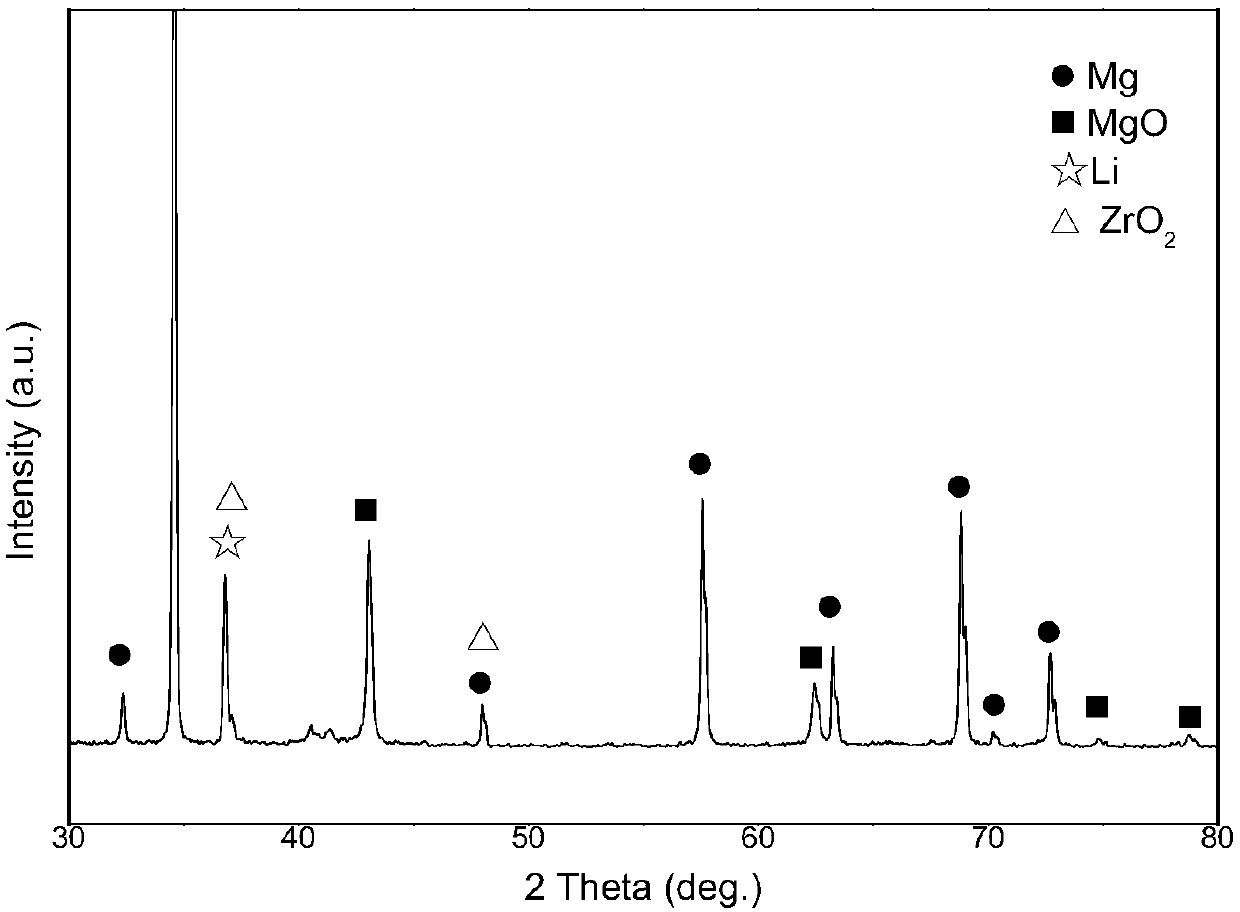

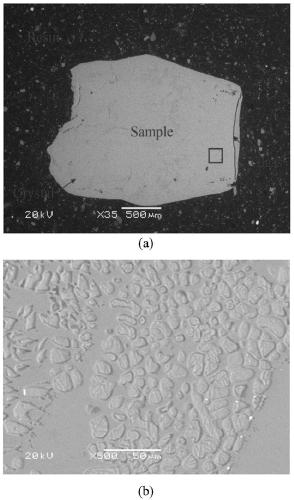

Thermal control film on surface of magnesium lithium alloy, and preparation method of thermal control film

InactiveCN109537024AGuaranteed bondingGood heat control effectAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention relates to thermal control film on the surface of magnesium lithium alloy, and a preparation method of the thermal control film. According to the preparation method, because a micro-arcoxidation electrolyte system suitable for the magnesium lithium alloy is built on the basis of a lot of solution screening experiments, electrical parameters matched with the solution system are created on the basis of a lot of electrical parameter optimization tests, the binding force of the film prepared on the surface of the magnesium lithium alloy is guaranteed, and the composition of the filmis changed by doping the electrolyte with zirconium salt, then remarkable improvement on thermal control performance of the film is achieved, and the thermal control film meeting the requirements forthermal control of a spacecraft product is prepared on the surface of the magnesium lithium alloy finally. According to the thermal control film on the surface of the magnesium lithium alloy, a micro-arc oxidation technology is adopted, the magnesium lithium alloy is used as a substrate, one layer of ceramic film grows on the surface of the magnesium lithium alloy in an in-situ manner, the film is doped with the zirconium oxide with good thermal control performance, infrared emittance of the film ranges from 0.80 to 0.90, the solar absorptance ranges from 0.20 to 0.30, the part dimensions andthe assembly accuracy of the magnesium lithium alloy are not affected, and the film can be applied to spacecrafts instead of organic coatings.

Owner:BEIJING SATELLITE MFG FACTORY

Novel antistatic white thermal control coating and preparation method thereof

ActiveCN103666248BNo crackNo peelingPretreated surfacesSpecial surfacesSolar absorptanceMaterials science

The invention discloses a novel antistatic white thermal control coating and a preparation method thereof; wherein the coating, from interior to exterior, comprises a surface treatment agent layer, a prime coat layer and a finishing coat layer; the prime coat layer and the finishing coat layer all use room temperature curing type organic silicone resin as a matrix resin; a plurality of sheet-shaped metal powders are crossedly overlapped and arranged in the prime coat layer, and one ends of part of the sheet-shaped metal powders extend to the finishing coat layer; and white zinc oxide is distributed in the finishing coat layer. The coating provided by the invention is white, thickness is 100-140mum, solar absorptance is 0.24-0.29, hemispherical emissivity is 0.85-0.91, total mass loss TML is less than 1%, a collected volatile condensable material CVCM is less than 0.1%, and volume resistivity rhoV is not less than 107 ohm*m. The coating, through 100 times of high and low temperature heat cycle test in a temperature range from -100 to 100 DEG C, has advantages of non-cracking, non-spalling, non-foaming and non-discoloring phenomena, stable optical property and good adhesion force, and can basically satisfy demand of a spacecraft on the antistatic white thermal control coating.

Owner:SHANGHAI INST OF SATELLITE EQUIP

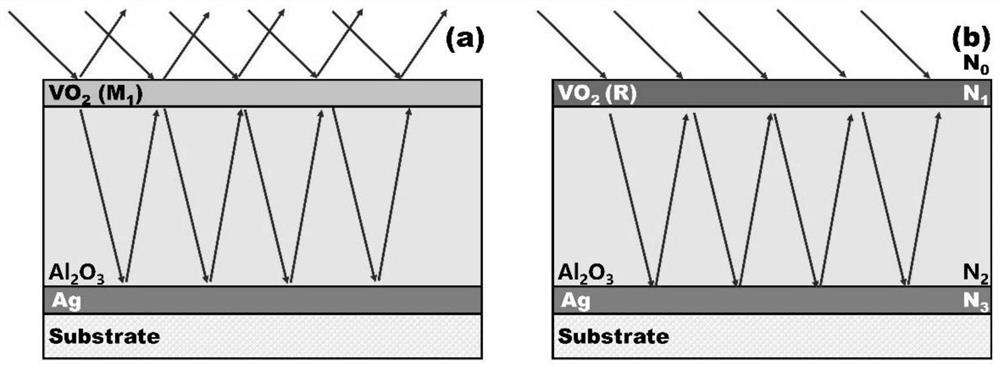

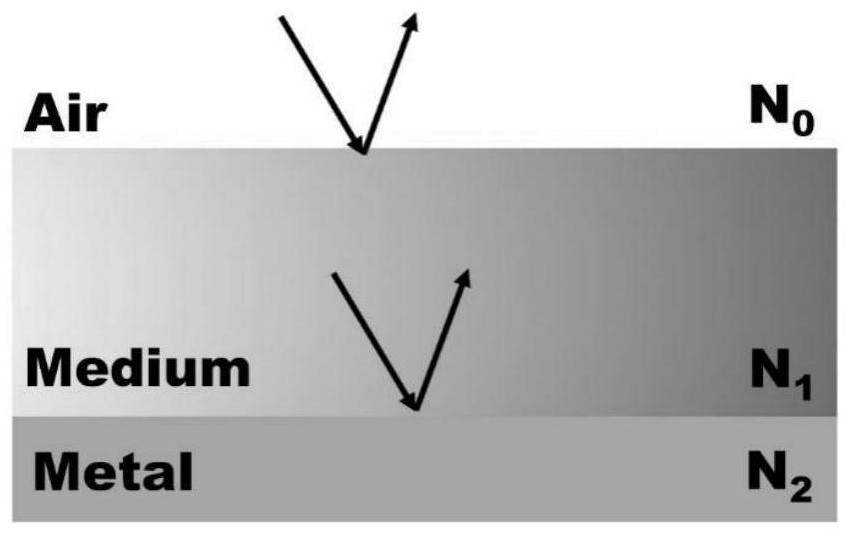

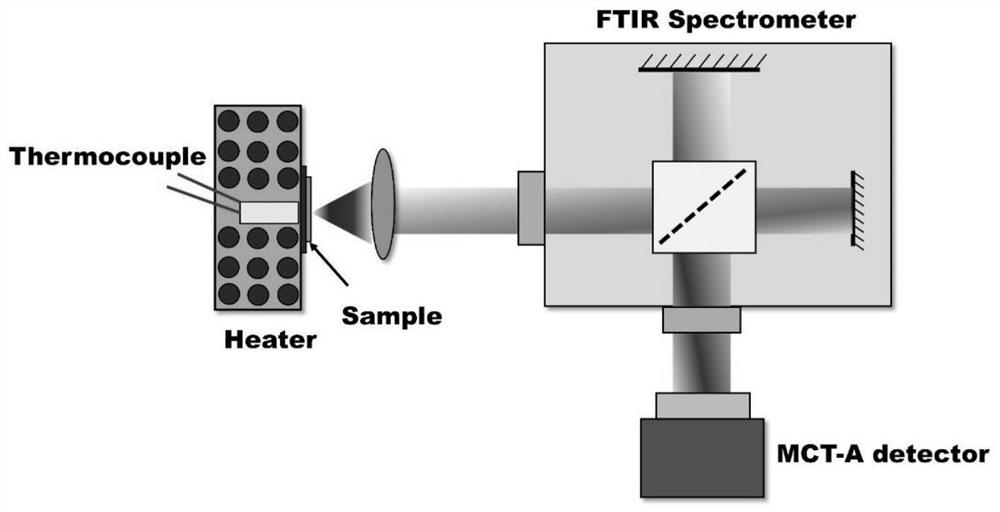

VO2-based multi-layer thin film structure and preparation method of VO2-based multi-layer thin film structure product

ActiveCN114231922ARealize intelligent infrared responseGood heat control effectFinal product manufactureVacuum evaporation coatingAbsorptanceMetallic aluminum

The invention discloses a VO2-based multilayer film structure and a preparation method of a product thereof, and relates to the technical field of thermal control of spacecrafts. A magnetron sputtering method is utilized, a monocrystalline silicon wafer in the (100) direction is used as a substrate, and a metal titanium target, a metal silver target, a metal aluminum target and a metal vanadium target are sequentially adopted for preparing the VO2-based multilayer film structure. The VO2-based multi-layer thin film structure prepared by the invention can enable an intelligent thermal control radiation device to realize low-temperature low thermal conductivity, high-temperature high thermal conductivity and low solar absorptivity, and has good thermal control performance and thermal shock resistance, the sunlight absorptivity can reach 27.5%, the integral emissivity within the range of 5-15 microns is 0.26 and 0.91 at room temperature and 100 DEG C respectively, and the VO2-based multi-layer thin film structure can be applied to the intelligent thermal control radiation device. And the modulation amplitude of the emissivity can reach 0.65.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

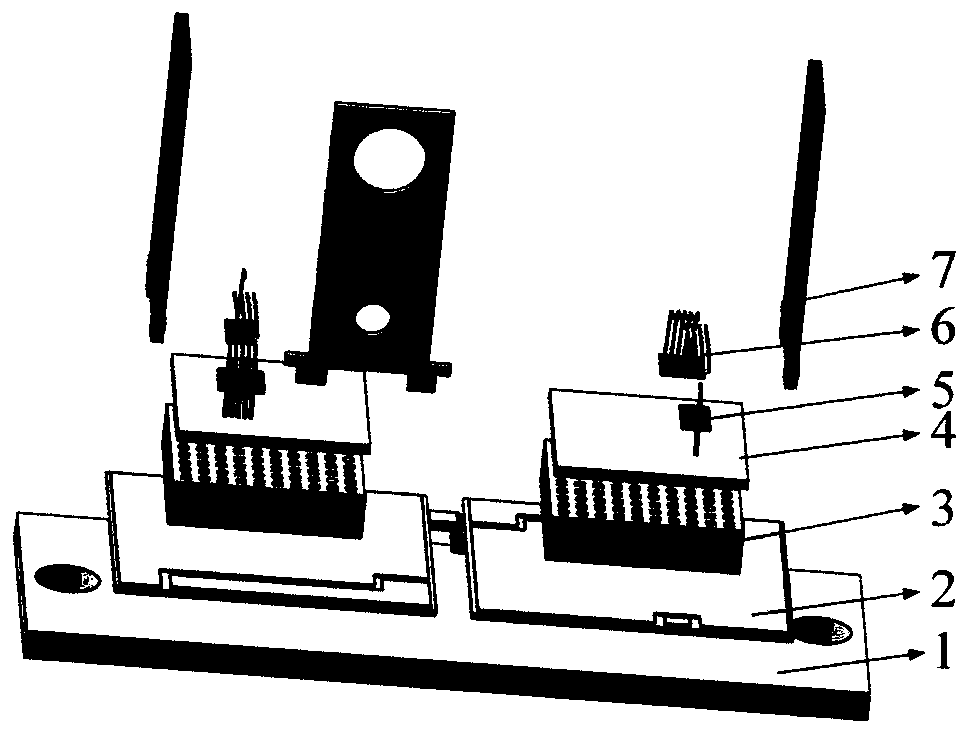

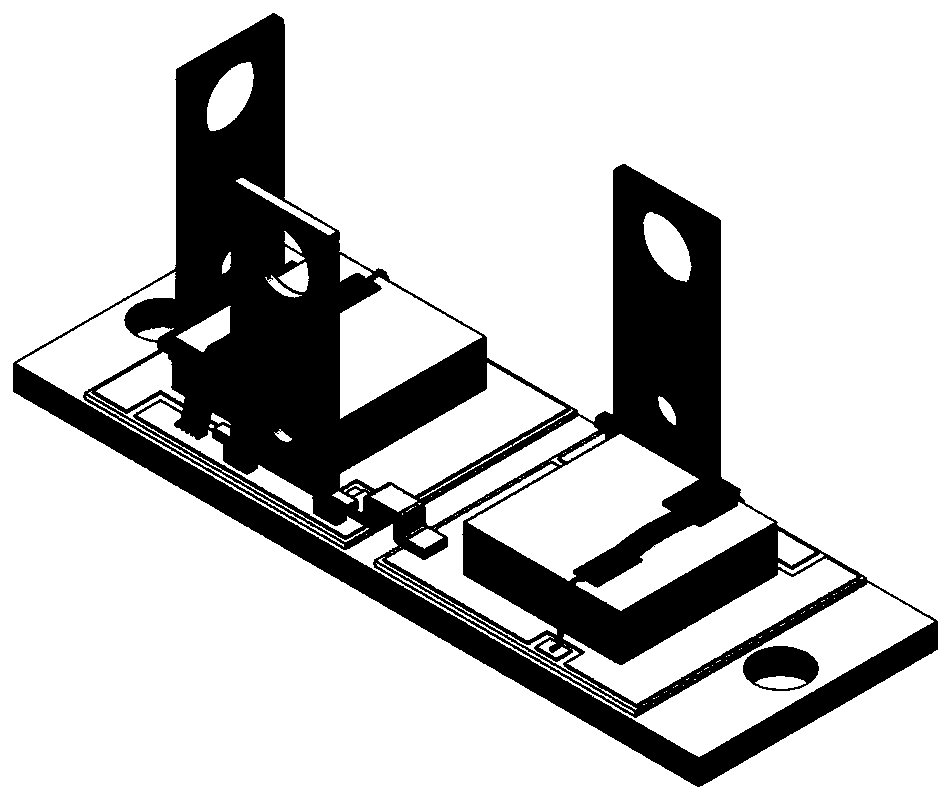

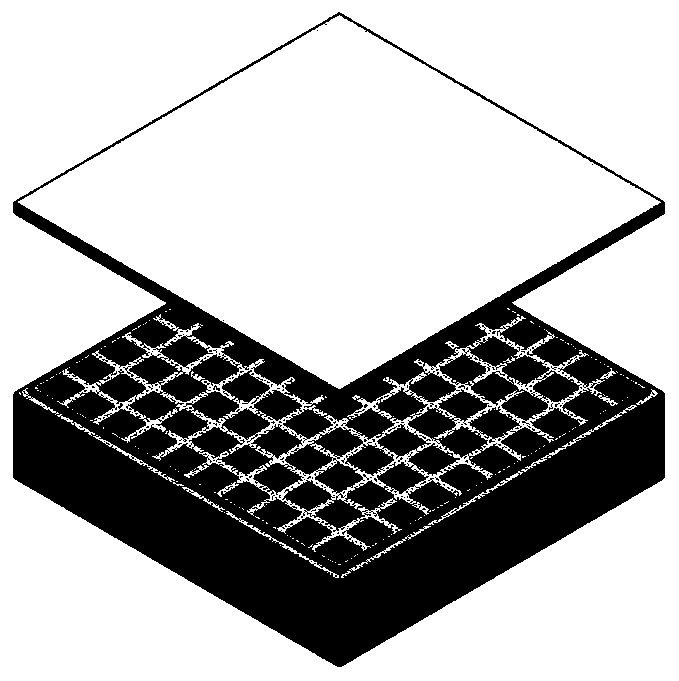

A power module based on phase change material and its manufacturing method

InactiveCN108682664BHigh thermal conductivityHigh strengthSemiconductor/solid-state device detailsSolid-state devicesCapacitanceSemiconductor chip

The invention provides a power module based on phase change material and a manufacturing method thereof, which belong to the technical field of power modules. The power module comprises a substrate (1), a ceramic copper-clad plate (2), a phase-change module and a power terminal (7). The upper surface of the substrate (1) is rectangular, a plurality of ceramic copper-clad plates are respectively arranged on the substrate (1), and the ceramic copper-clad plates (2) are connected through a copper bar. The phase-change module is arranged on the ceramic copper-clad plate (2), and a plurality of power terminals (7) are arranged on a power terminal mounting end. The phase change module comprises a heat transfer enhancing frame (3) and a sealing cover (4), and the heat transfer enhancing frame (3)is filled with phase change material. A power semiconductor chip (5) is welded to the outer surface of the sealing cover. The invention is advantageous in that the power module with short-time and controllable junction temperature is provided, which can respond to transient temperature rise of the power module, and is suitable for occasions when short-circuit current is actively provided for supporting the power grid voltage during a power grid fault period, and other impact power occasions of electromagnetic ejection and super-capacitor charging.

Owner:CHONGQING UNIV

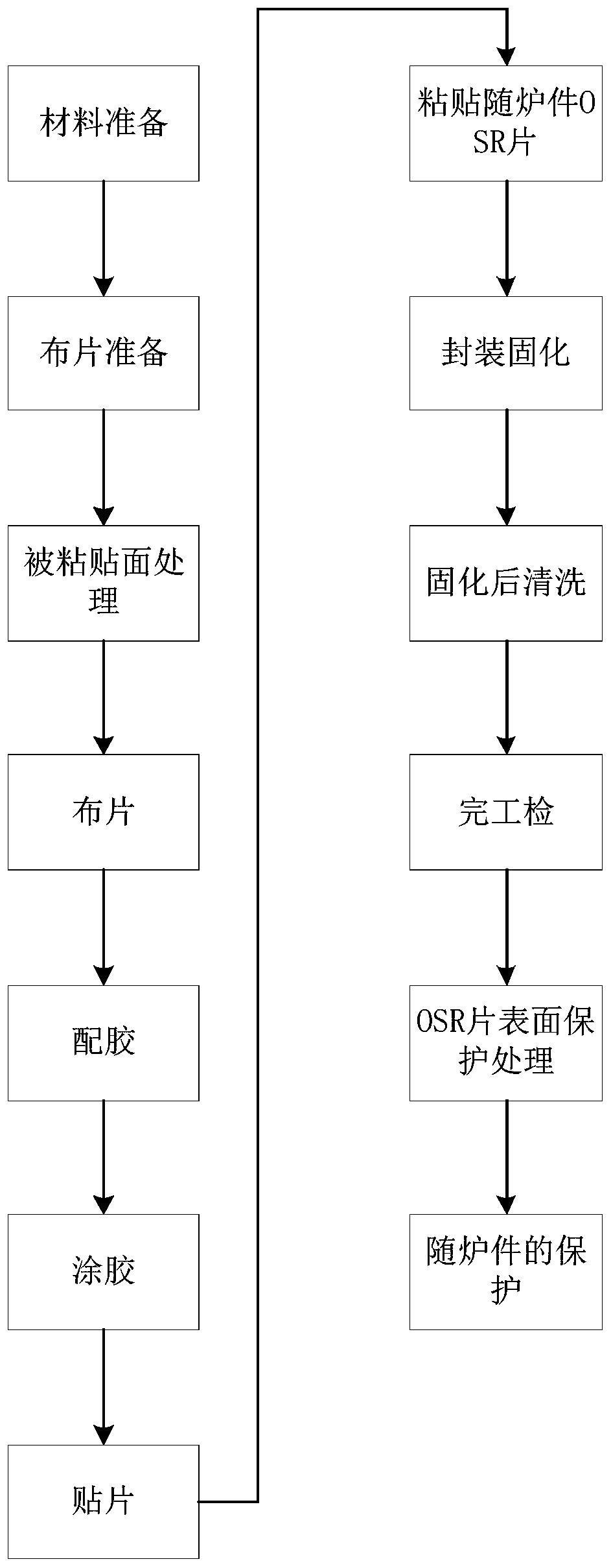

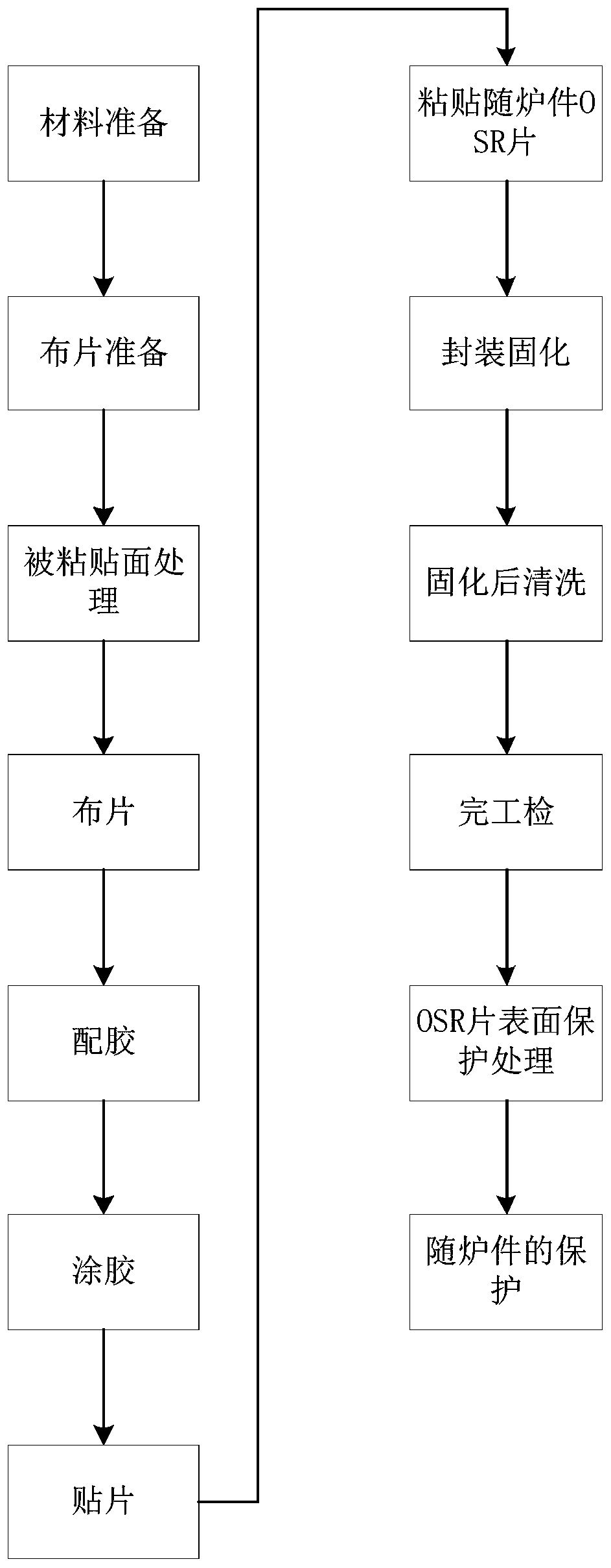

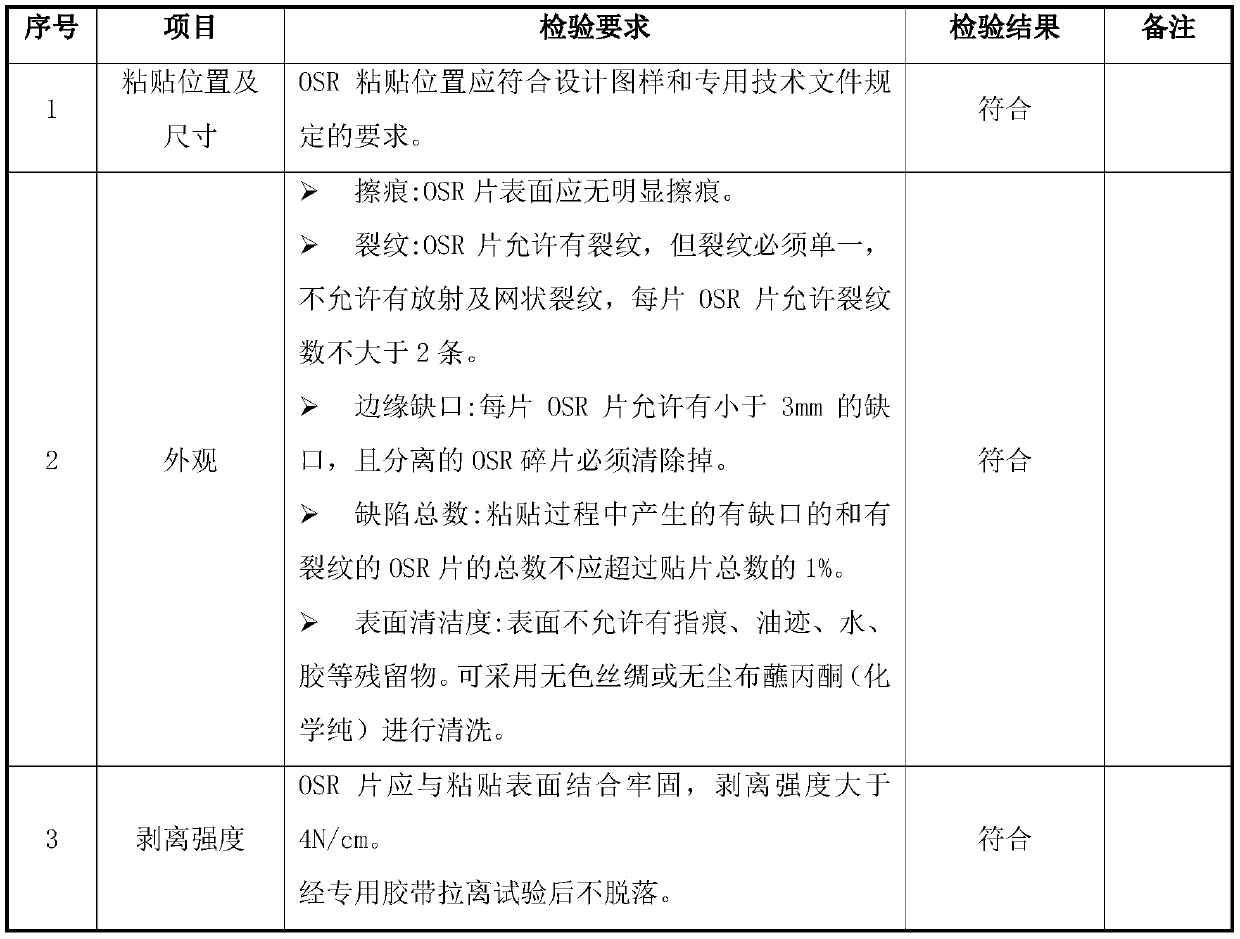

Optical solar reflector thermal-control coating on satellite solar panel surface and preparation method of coating

InactiveCN109705645AGood heat control effectGood coating conductivityAdhesive processes with surface pretreatmentRadiation-absorbing paintsAdhesive cementElectrically conductive adhesive

The invention provides an optical solar reflector thermal-control coating on the satellite solar panel surface and a preparation method of the coating. The coating comprises the following components:an optical solar reflector, a conductive adhesive and a surface treatment agent, wherein the conductive adhesive is an adhesive formed by mixing an A component, a B component and silver powder according to a predetermined ratio, and the surface treatment agent includes a KH550 silane coupling agent. The coating provided by the invention has better coating electrical conductivity on the basis thatgood thermal control performance (solar absorption ratio and hemispherical emissivity) of the coating is ensured, and the coating has very good adhesion after subjected to surface treatment.

Owner:SHANGHAI INST OF SATELLITE EQUIP

Preparation method of thermal-control and corrosion-resistant integrated film of magnesium-lithium alloy

InactiveCN106835240AAchieve preparationGood heat control effectAnodisationMicro arc oxidationCorrosion resistant

The invention discloses a preparation method of a thermal-control and corrosion-resistant integrated film of a magnesium-lithium alloy. The preparation method comprises the following steps: a thermal-control microarc oxidation film is prepared on the surface of the magnesium-lithium alloy; and the thermal-control microarc oxidation film is subjected to perfluoroalkyl surface modification. The prepared thermal-control and corrosion-resistant integrated film is good in thermal control effect, good in corrosion-resistant effect and uniform in density and has the good binding force with a substrate.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

High-temperature shape-stabilized phase-change composite material and preparation method thereof

ActiveCN111393858ASimple preparation processGood heat control effectHeat-exchange elementsFlight vehicleMissile

The invention discloses a high-temperature shape-stabilized phase-change composite material and a preparation method thereof. According to the composite material, a high-temperature phase change microcapsule or high-temperature shape-stabilized phase change powder is used as a phase change functional filler, ceramic precursor resin is used as a matrix phase of the composite material, the phase change thermophysical property is adjusted by adjusting the content of phase change functional filler in the composite material, the composite material can be cured at room temperature or heated and cured by adopting a mould pressing process, the phase change temperature of the composite material ranges from 200 DEG C to 900 DEG C, and the highest use temperature reaches 900 DEG C. The high-temperature shape-stabilized phase-change composite material is simple in preparation process and can be cured or heated at room temperature and is excellent in thermal control performance and can be used forthermal control of aircraft structures and instruments and equipment such as missile, rocket, ship and aircraft and improves the thermal control capability and has potential wide application prospectsin the civil field.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

A flexible phase change material for thermal control of electronic devices

ActiveCN107254297BImprove flexibilityHigh strengthHeat-exchange elementsModifications by conduction heat transferEngineeringMelt mixing

The invention relates to a flexible phase-change material for electronic device thermal control. The flexible phase-change material comprises a phase-change substrate and a support carrier. The support carrier is an elastic polymer. The flexible phase-change material is prepared by the following steps: heating the phase-change substrate and the support carrier in the certain temperature, and placing in the environment of which the temperature is higher than the phase-change temperature after completely fusing and mixing, cooling and rolling. The flexible phase-change material can produce the deformation, such as elastic stretching, bending and torsion, while the temperature is higher than the phase transformation point. The flexible phase-change material is adhered to the surface of the heat production part or filled in clearances between a hot plate and a packaging component while used for the electronic device thermal control. The phase-change material has the good flexibility, so the phase-change material has the performance of a thermal interface material, and is capable of reducing the contract thermal resistance. The flexible phase-change material is capable of solving the problems that the installation is difficult and the contract thermal resistance is larger because the common phase-change material is excessive hard in the thermal control process of the electronic device, and greatly improving the thermal control performance.

Owner:UNIV OF SCI & TECH OF CHINA

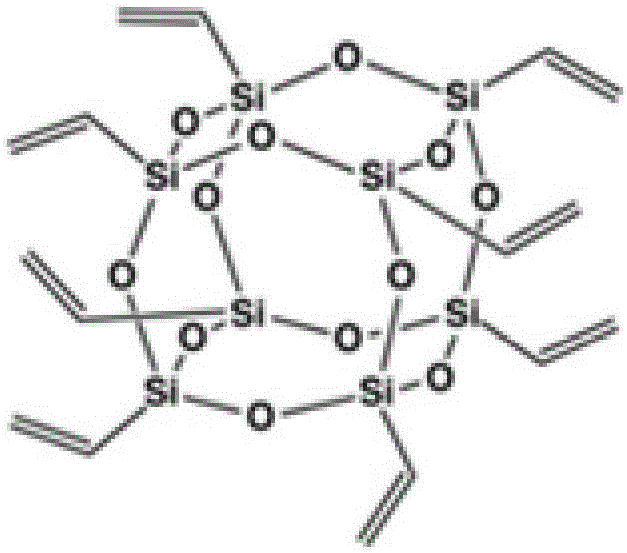

POSS-modified long life thermal control coating combination and preparation method thereof

The invention discloses a POSS-modified long life thermal control coating combination and a preparation method thereof. The composition comprises a priming paint, a finish paint, and a substrate; a priming paint organic solvent and modified organic fluororesin and zinc oxide powder with mass ratio of 60-75: 25-40; and an finish paint organic solvent and modified multi functional groups methyl silicone resin and zinc oxide powder with mass ratio of 65-75: 25-35. The prepared POSS-modified long life white thermal control coating can prolong the life of space usage and increases stability, the performance of the long life heat thermal control coating prepared by the coating combination is stable, space environment-resistant capability is stronger, the coating construction is simple and is easy to learn, has strong enforcement performance, has longer design and usage time in space environment, and can satisfy the requirement of high-stability white thermal control coating on the product, the adhesive force through 100 times of temperature impact tests between the temperature of -100-+100 DEG C is good, and the vacuum discharge quantity is low.

Owner:SHANGHAI INST OF SATELLITE EQUIP

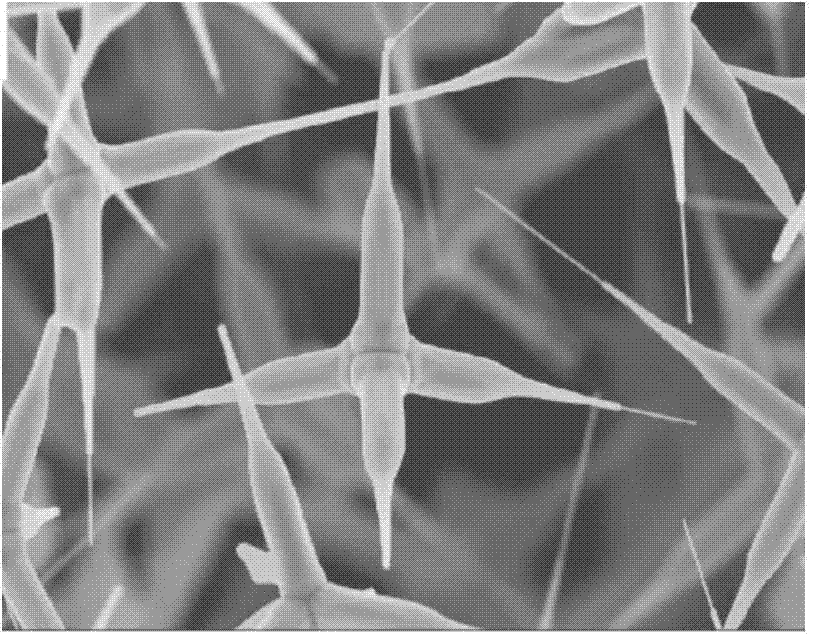

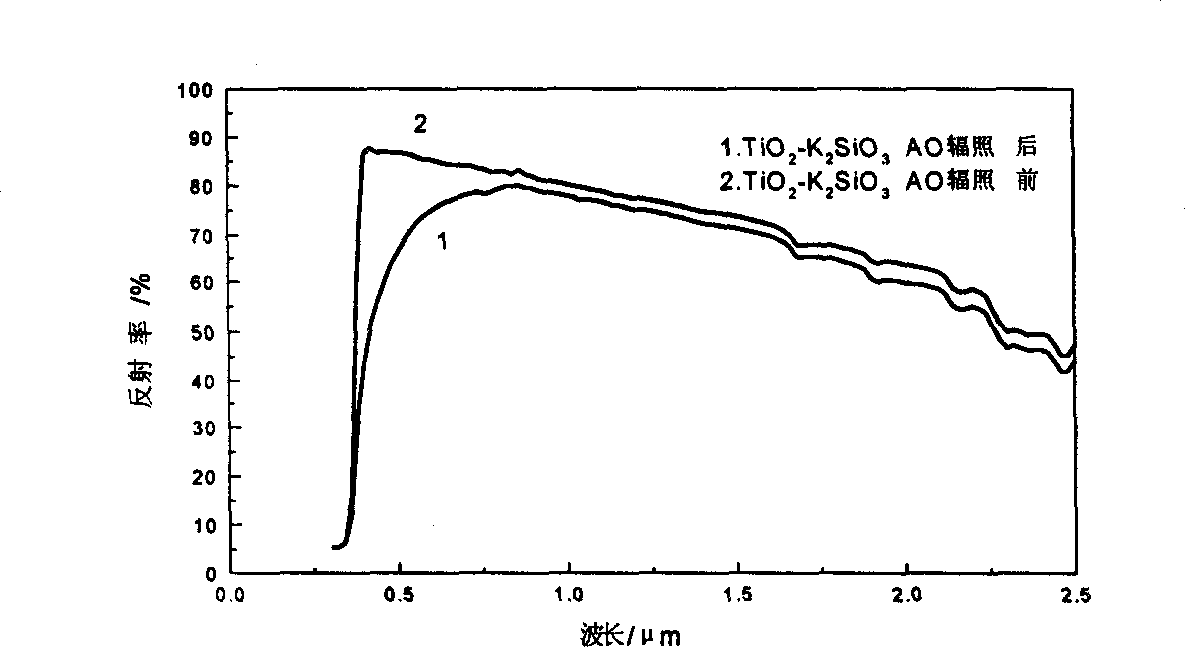

Low sunlight absorptivity alumina-potassium silicate paintcoat for heat control and its preparing method

The invention provides a low solar absorption rate alumina-potassium silicate thermal control coating and a preparation method thereof. The coating consists of potassium silicate, diethanolamine, emulsifier, sodium hexametaphosphate, dispersant, defoamer, Light and heavy calcium carbonate, talcum powder, mica powder, alumina powder and water form a slurry, which is mixed with phenylacrylic acid emulsion at a weight ratio of 1:0.4-0.9. The coating of the present invention has stable space behavior, significant anti-atomic oxygen erosion effect, low heat absorption rate, and good thermal control effect, and is suitable for low-earth orbit vehicles such as satellites, manned spacecraft, space stations, space shuttles and other spacecraft and various types of space. detector.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

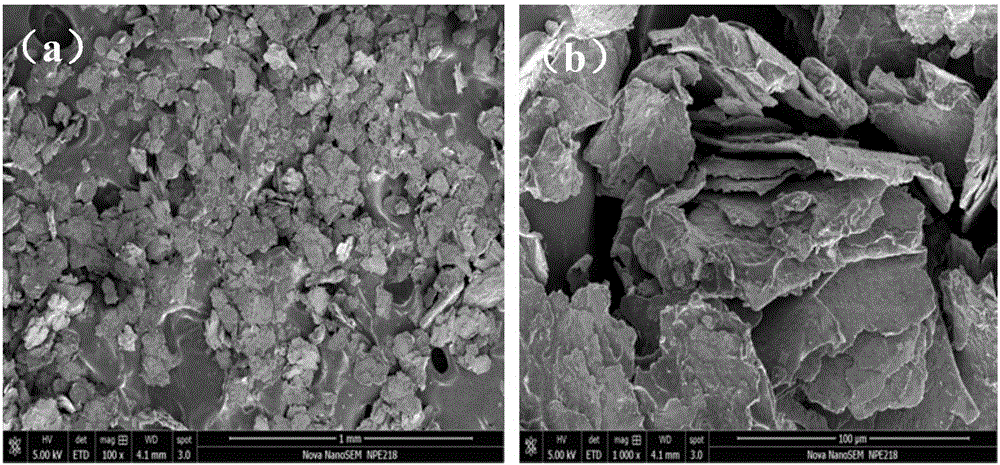

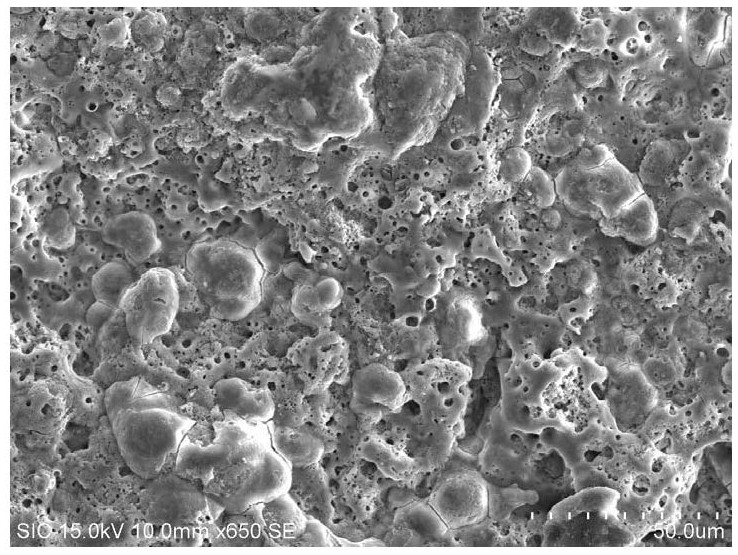

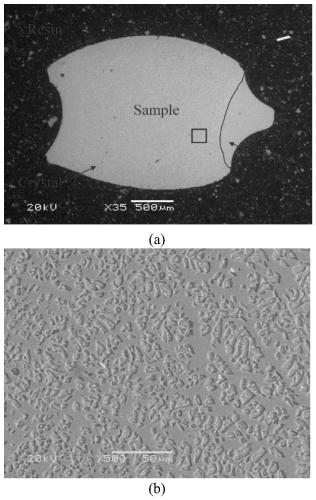

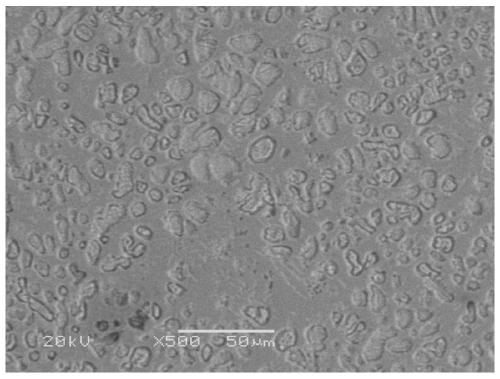

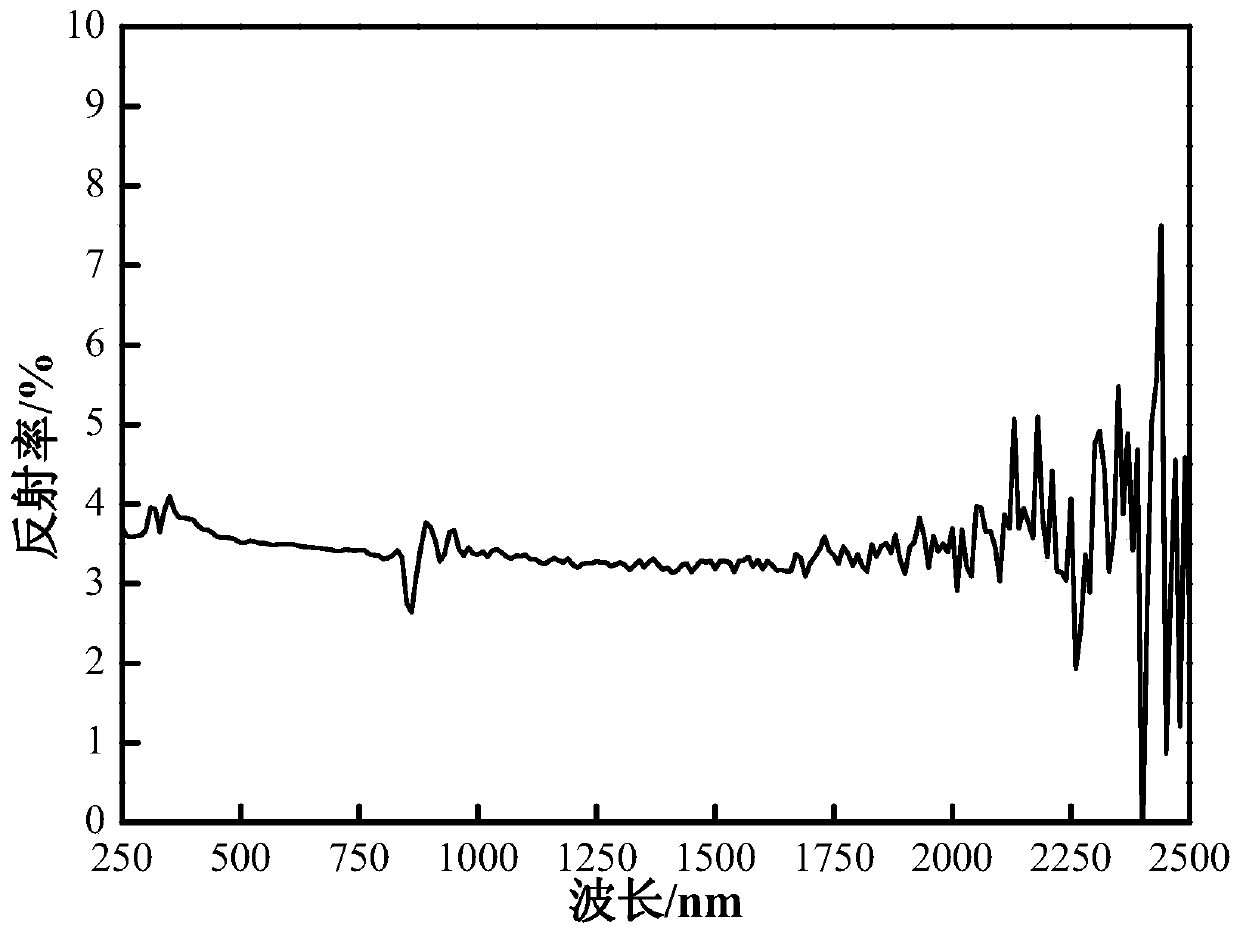

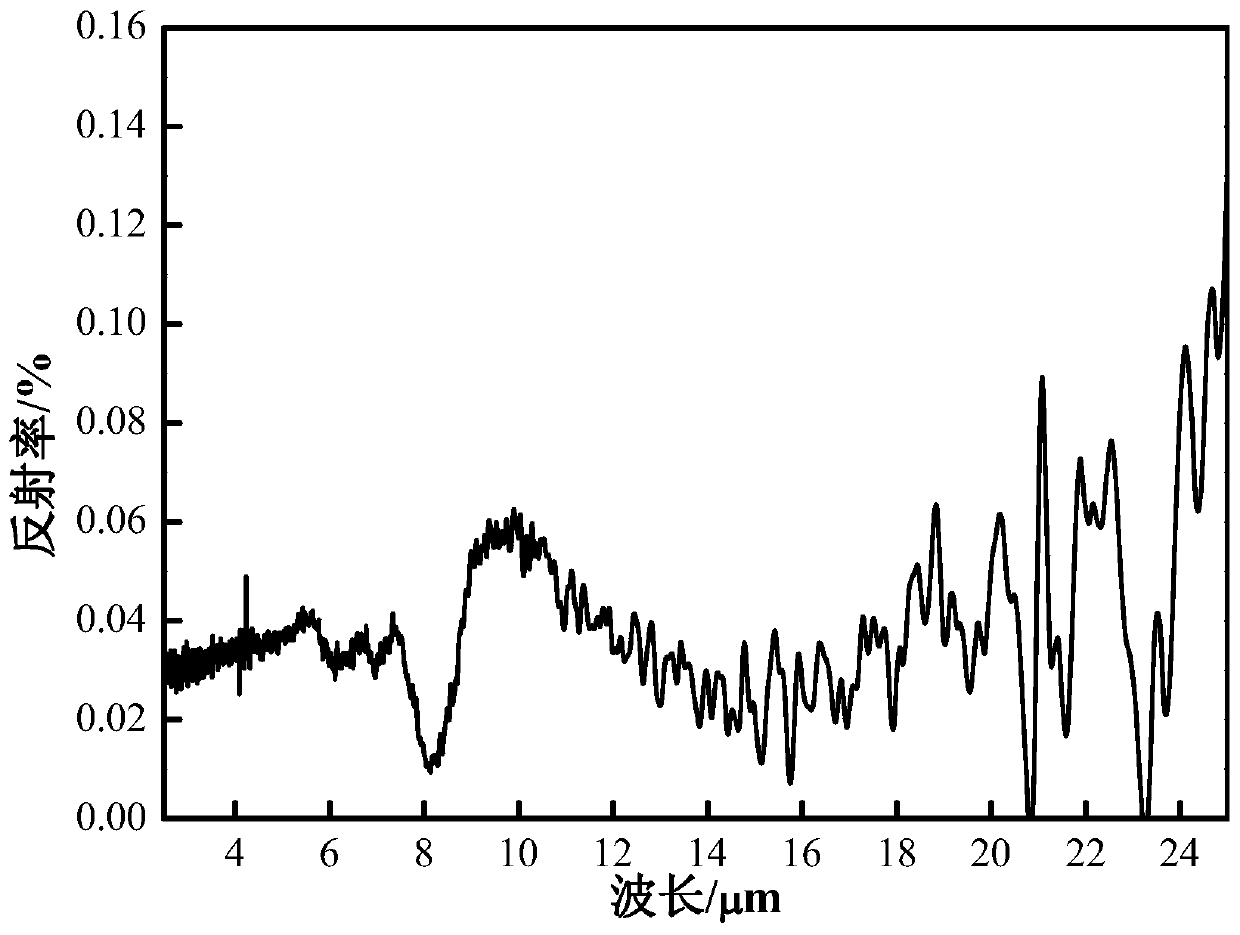

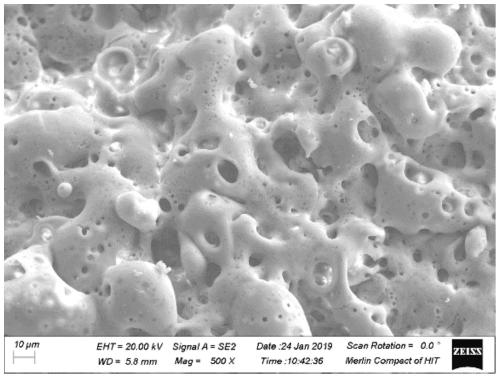

A kind of preparation method of high absorption rate high emissivity coating

ActiveCN109943874BSimple preparation processPromote absorptionAnodisationElectrolytic agentMicro arc oxidation

The invention discloses a method for preparing a coating with high absorptivity and high emissivity, which relates to a method for preparing a coating. The purpose of the present invention is to solve the problem that the coating prepared by the existing magnesium-lithium alloy surface treatment technology has poor bonding force, instability, easy aging and falling off, low absorption rate and low emissivity, which are unfavorable for its application on spacecraft . Methods: 1. Pretreatment of specimens; 2. Preparation of thermal control coating with high absorption and high emissivity in silicate electrolyte system by micro-arc oxidation. The thermal control coating prepared by the invention has higher absorptivity and emissivity and good thermal control performance. The invention can obtain a coating with high absorptivity and high emissivity.

Owner:HARBIN INST OF TECH

Low resistivity filler and preparation method of antistatic thermal control coating

ActiveCN106752906BGood heat control effectGood coating conductivityElectrically-conductive paintsMaterials scienceLow resistance

Owner:SHANGHAI INST OF SATELLITE EQUIP

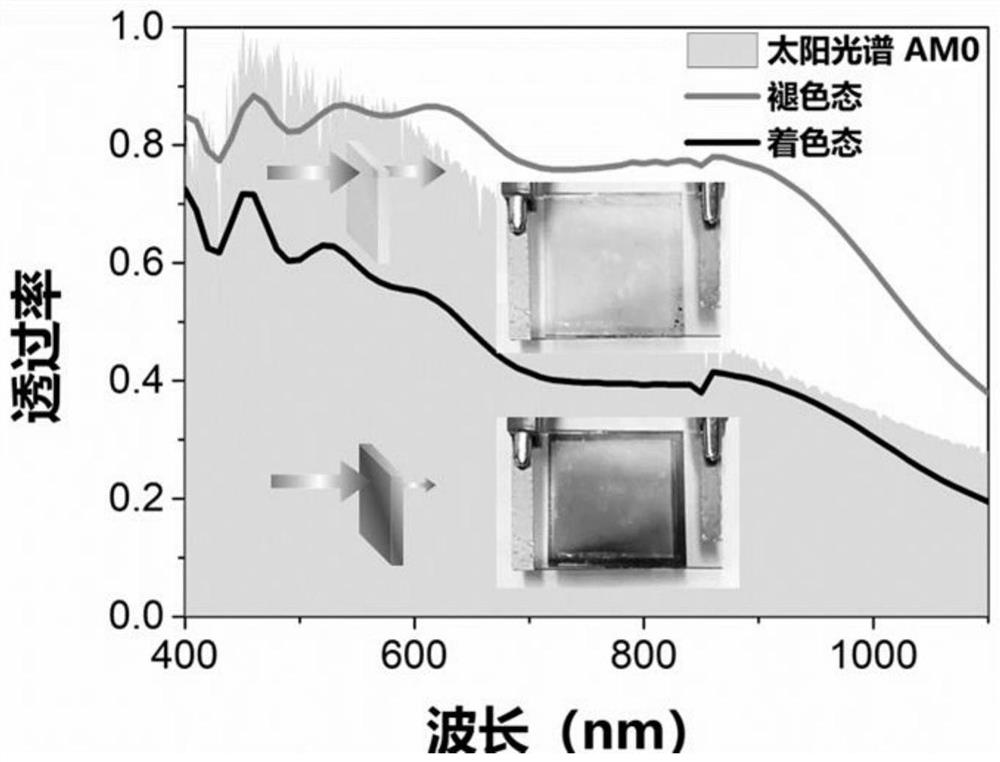

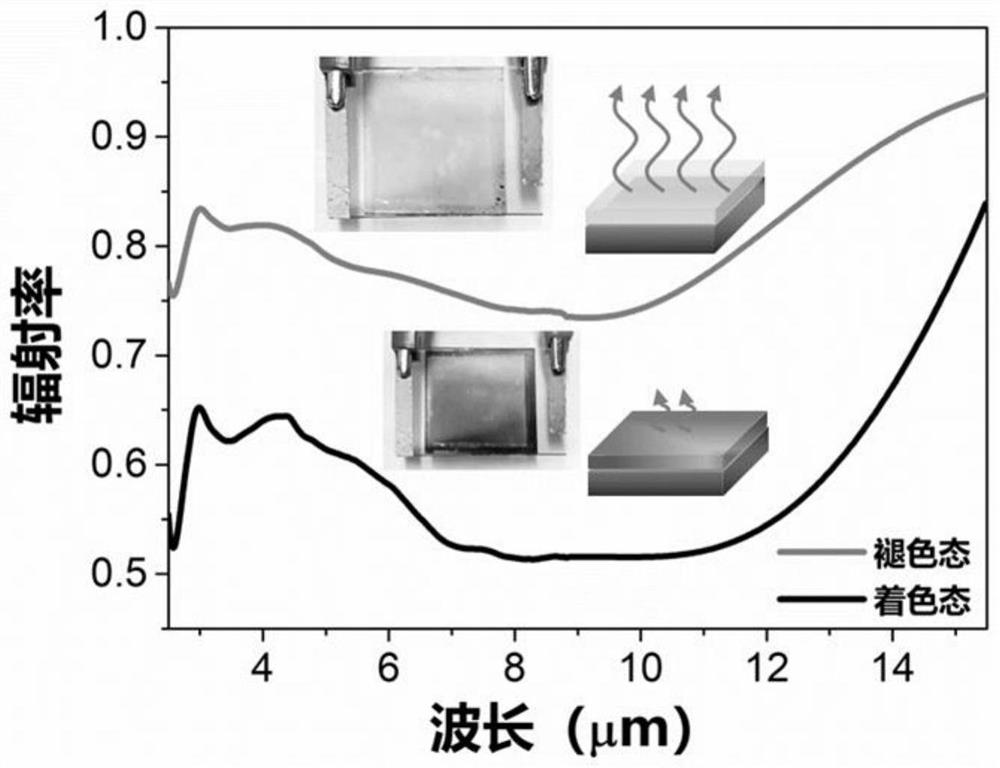

Visible to mid-infrared band electrochromic thin film device with adjustable light performance and preparation method

ActiveCN111913329BImprove light performanceImprove infrared radiation rateVacuum evaporation coatingSputtering coatingOptical propertyHeat management

The invention discloses an electrochromic thin film device with adjustable light performance in the visible to mid-infrared band and a preparation method thereof. The preparation method comprises the following steps: S1: select a substrate, and perform pretreatment on the substrate; S2: after the treatment Prepare a high transmittance conductive layer on the substrate; S3: deposit WO on the high transmittance conductive layer 3 layer as the color change layer, then in the WO 3 Continue to deposit Ta on the layer 2 o 5 As an electrolyte layer, and then annealed to obtain crystalline WO 3 ; S4: Continue to deposit metal oxide as an ion storage layer, and then repeat step S2 on the basis of metal oxide to obtain an electrochromic thin film device; wherein, if the substrate is a transparent conductive material, the step is directly carried out on the processed substrate S3. The electrochromic thin film device obtained by this method can regulate light performance from visible to infrared light, and can design components for different wavelength bands to obtain various discoloration and heat management performances.

Owner:SHANGHAI JIAOTONG UNIV +1

Antistatic thermal control coating composition and its preparation method and application

ActiveCN104774510BUniform coating on the surfaceNo bubblesElectrically-conductive paintsOmegaThermal control

The invention discloses an antistatic thermal control coating composition, a preparation method and applications thereof. The coating composition comprises priming paint and finish paint. The priming paint is composed of a matrix namely organic fluorine resin and a filling material namely modified zinc oxide powder; wherein the zinc oxide is capable of forming vertical channels in the priming paint layer. The finish paint is composed of a matrix namely methyl silicone resin with multiple functional groups and a filling material namely modified zinc oxide powder; wherein part of the filling material penetrates the interface between the priming paint layer and the finish paint layer. The prepared antistatic thermal control coating has a white color, a thickness of 130 to 200 [mu]m, a solar absorption ratio of 0.20 to 0.25, a hemispherical emissivity of 0.85 to 0.91, a total mass loss (TML) not more than 1%, collectable volatile condensed mass (CVCM) not more than 0.1%, and a volume resistivity ([rho]v) not more than 107 [omega].m. The coating does not have the phenomenon of cracking, peeling, bubbling, and fading after 100 times of high-low temperature thermal cycle experiments in a temperature range of -100 to 100 DEG C, the optical properties of the coating is stable, and the adhesive force of the coating is high.

Owner:SHANGHAI INST OF SATELLITE EQUIP

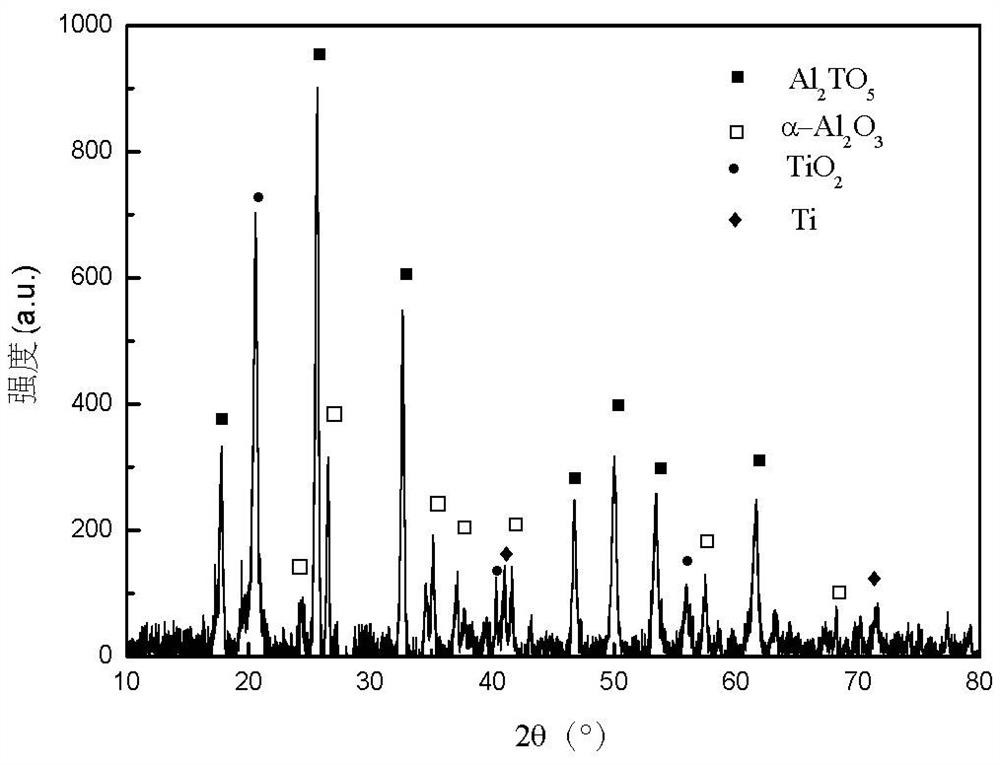

Titanium alloy surface thermal-control wear-resistant coating and preparation method thereof

PendingCN113943964AGood heat control effectSurface reaction electrolytic coatingAlloy surfaceAluminate

The invention discloses a titanium alloy surface thermal-control wear-resistant coating and a preparation method thereof. The preparation method comprises the steps that a titanium alloy is placed in electrolyte containing aluminate, and in the plasma electrolytic oxidation process, direct-current pulse current is utilized to enable a dielectric film on the surface of the titanium alloy to be broken down, so that plasma micro-arc discharge is generated, and the thermal-control wear-resistant coating on the surface of the titanium alloy grows in situ; and the thermal-control wear-resistant coating is prepared from 40 to 50 weight percent of aluminum titanate, 30 to 40 weight percent of titanium oxide and 10 to 30 weight percent of aluminum oxide.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

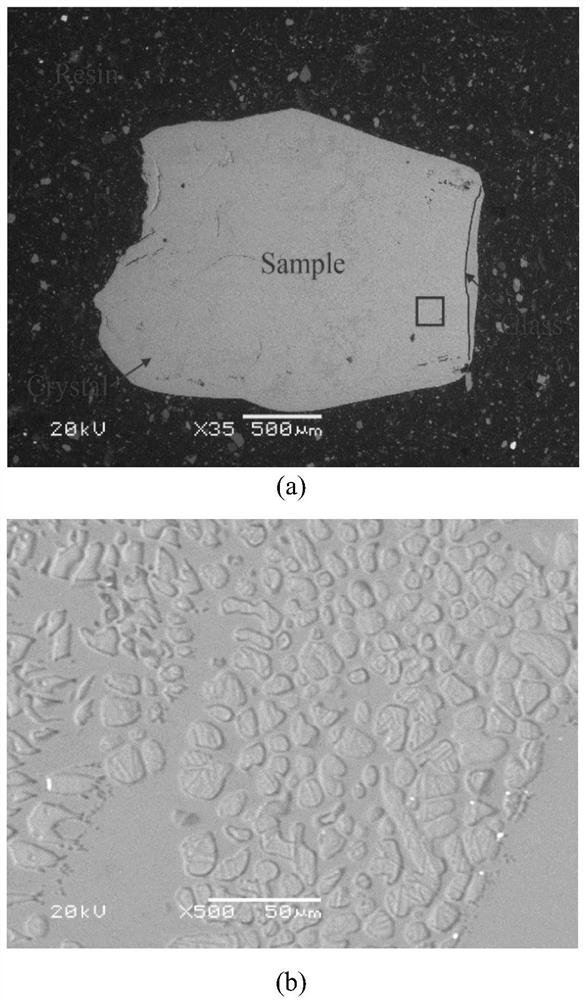

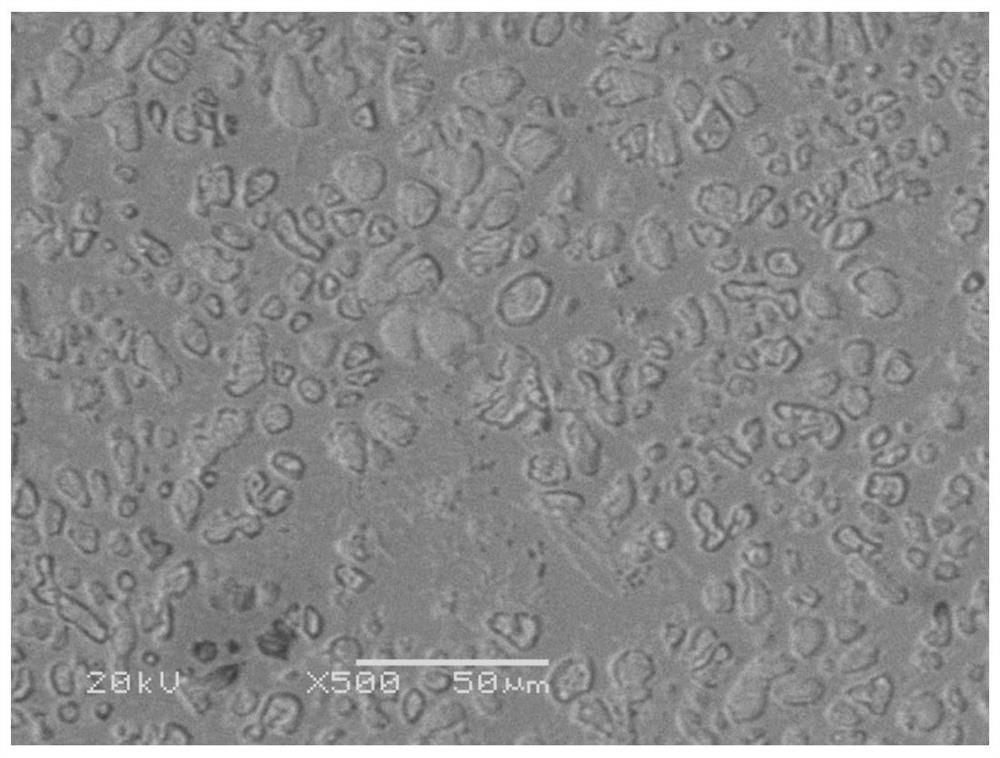

Application of casting powder in high-casting-speed continuous casting peritectic steel

The invention designs a casting powder application process capable of avoiding the defects of transverse and longitudinal cracks and the like on the surface of a casting blank when peritectic steel issubjected to high-pulling-speed continuous casting. The casting powder is used for peritectic steel high-casting-speed continuous casting. The casting powder is prepared from the following componentsin percentage by mass: 37%-40% of CaO, 28%-32% of SiO2, 0.5%-2% of Al2O3, 1%-4% of MgO, 1.0%-8% of MnO and Fe2O3, 3%-18% of Na2O, 2.0%-4.0% of Li2O, and 3%-15% of F<->, wherein the mass ratio of theMgO to the Al2O3 is (1-2):1, and in the casting powder, the ratio of binary alkalinity CaO to the SiO2 is 1.2-1.3. The average crystal size of a crystalline phase separated out of the casting powder is smaller than 8 microns, and the crystalline phase is single cuspidine, and the precipitated phase is uniformly distributed in the casting powder crystallization layer.

Owner:CENT SOUTH UNIV

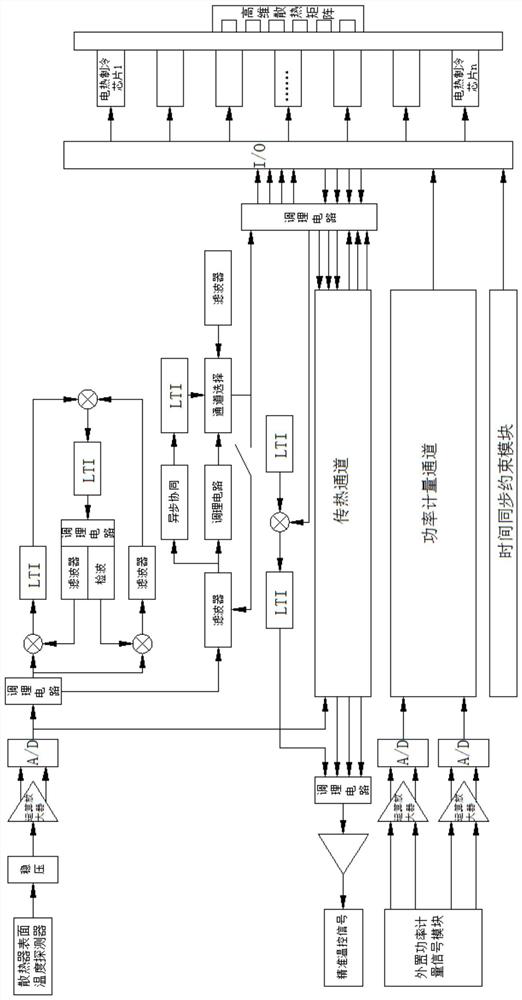

A method of heat transfer and heat dissipation with large heat and high heat flux based on high-dimensional thermoelectricity

ActiveCN111488010BImprove cleanlinessGuaranteed humidityTemperature control using digital meansEfficient regulation technologiesTemperature controlHeat flux

Owner:SHENZHEN JIANJU SCI & TECH LTD

Method for preparing high-absorptivity and high-emissivity coating

The invention discloses a method for preparing a high-absorptivity and high-emissivity coating, and relates to a coating preparation method. The method aims to solve the problems that a coating prepared through an existing magnesium lithium alloy surface treatment technology is poor in binding force, instable, prone to ageing and disengaging and low in absorptivity and emissivity and application of the method to space vehicles cannot be facilitated. The method includes the steps that first, test piece pretreatment is conducted; and second, the high-absorptivity and high-emissivity thermal control coating is prepared in a silicate electrolyte system through a micro-arc oxidation method. The thermal control coating prepared through the method has high absorptivity and emissivity, and the thermal control performance is good. By adoption of the method, the high-absorptivity and high-emissivity coating can be obtained.

Owner:HARBIN INST OF TECH

Composite cooling device with fins and foam heat conduction structure

ActiveCN105356004BReduce temperature riseIncrease the heat exchange areaSecondary cellsEngineeringHeat sink

The invention relates to a combined heat dissipating device provided with fins and a foam heat conduction structure and used for assisting heat dissipation of an individual battery (5). The combined heat dissipating device comprises a shell sleeve (4) sleeving the individual battery (5), wherein a foam structure fills the space between the shell sleeve (4) and the individual battery (5), the foam structure (2) is full filled with a phase-change material (1), multiple fins (3) separating the foam structure (2) are further arranged between the shell sleeve (4) and the individual battery (5), and the two sides of each fin (3) are respectively in tight fit with the shell sleeve (4) and the individual battery (5). Compared with the prior art, the combined heat dissipating device has the advantages of effectively reducing the temperature of a lithium ion battery and preventing thermal runaway.

Owner:SHANGHAI MAKESENS ENERGY STORAGE TECH CO LTD

Application of a Mold Flux in High Speed Continuous Casting Peritectic Steel

The invention designs a mold slag application process for avoiding defects such as transverse and longitudinal cracks on the surface of a slab during high-speed continuous casting of peritectic steel. The mold flux is used for high-speed continuous casting of peritectic steel; the mold flux is composed of the following components in terms of mass percentage: CaO 37%-40%, SiO 2 28%~32%;Al 2 o 3 0.5% to 2%, MgO 1% to 4%, and MgO / Al by mass ratio 2 o 3 =1‑2:1; MnO+Fe 2 o 3 1.0%~8%;Na 2 O 3%~18%, Li 2 O 2.0%~4.0%; F ‑ 3% to 15%; in the mold flux, the binary basicity CaO / SiO 2 1.2 to 1.3. The average crystal size of the precipitated crystal phase of the mold flux designed in the present invention is less than 8 μm, and the crystal phase is a single lance spar; and the precipitated phase is uniformly distributed in the mold flux crystal layer.

Owner:CENT SOUTH UNIV

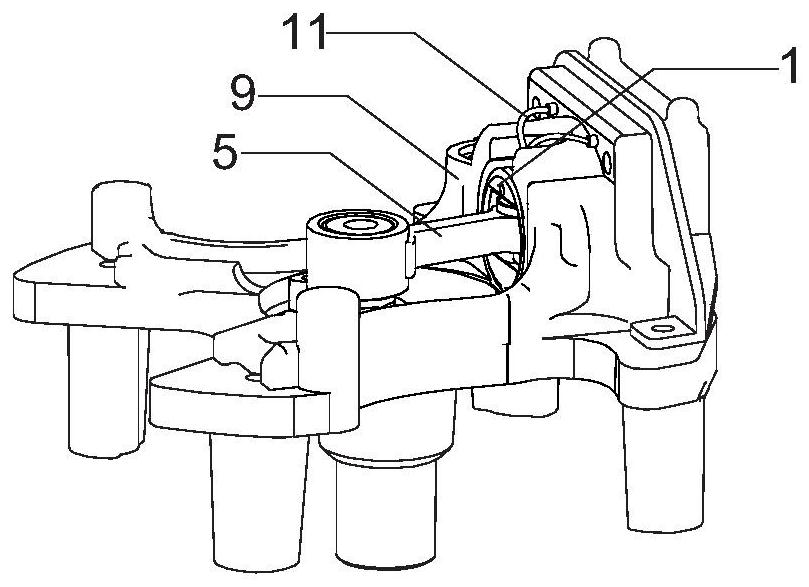

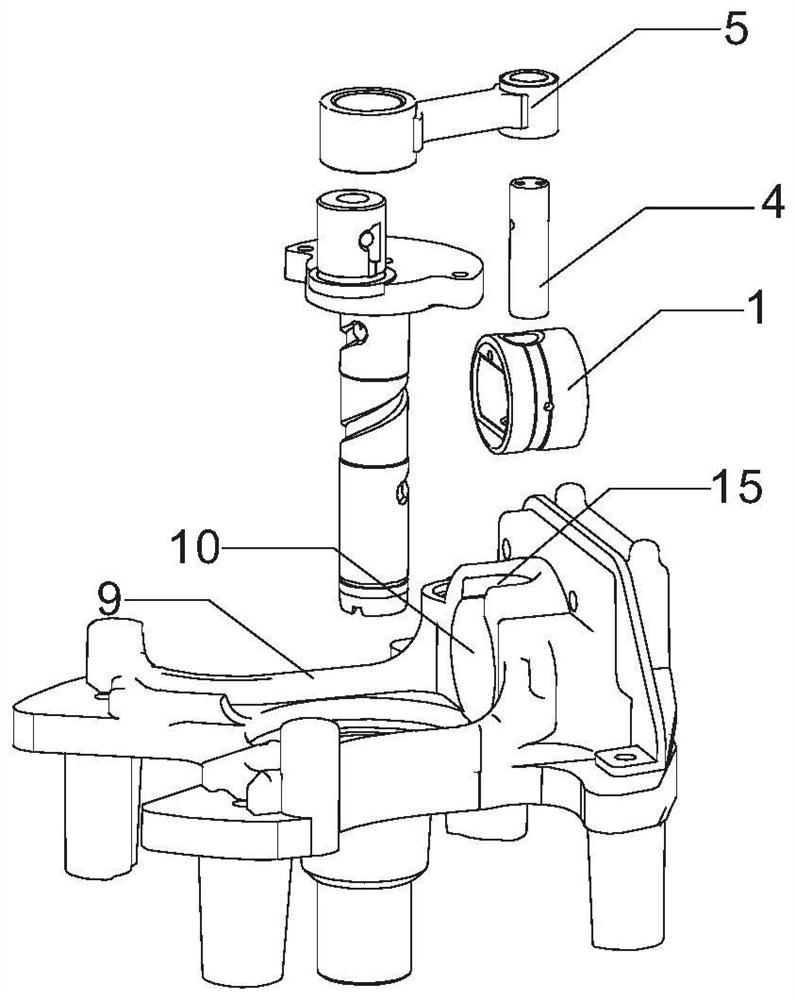

Piston heat control device for refrigerator compressor

InactiveCN111622929AImprove energy efficiency ratioReduce output power lossPositive displacement pump componentsPositive-displacement liquid enginesThermodynamicsIcebox

The invention discloses a piston heat control device for a refrigerator compressor. A piston is connected onto a crank through a connecting rod, the connecting rod is rotatably connected with the interior of a connecting rod inserting hole of the piston, the piston heat control device for the refrigerator compressor comprises a heat insulation part and a piston cooling mechanism, the heat insulation part is arranged on the end face of the piston, and the piston cooling mechanism can cool the piston. Due to the addition of the heat insulation part, the heat insulation performance of the pistonis increased, and the piston can be prevented from conducting additional heat energy onto chamber air. In addition, the piston cooling mechanism can cool the piston, and heat energy which is not beneficial to the piston is guided to the outside in time through heat exchange, so that the output power loss of the whole compressor is reduced by the measures, the energy is saved, and the efficiency isimproved.

Owner:JIAXIPERA COMPRESSOR

Silicon-containing atomic oxygen resistant polyimide film composition and preparation method thereof

ActiveCN109651812BGood heat control effectImprove mechanical propertiesThin membraneNetwork structure

The invention provides a silicon-containing atomic oxygen-resistant polyimide film material and a preparation method thereof. The film material includes a base film layer, a transition layer and a surface protection layer arranged in sequence; the base film layer includes a modified Polyimide matrix and nano-SiO 2 filler; the transition layer is an interpenetrating network structure of Si-O-Si and polyimide; the surface protection layer is a pure silicon dioxide layer. The atomic oxygen-resistant polyimide film prepared by the present invention is light yellow, with a thickness of 50-80 μm, a tensile strength ≥ 200 MPa, a dielectric strength ≥ 230 V / μm, and a total accumulation of atomic oxygen of 7.83×10 22 atom / cm 2 (10 years in low-Earth orbit) The mass loss rate after action is ≤10%, and the optical performance change is ≤10%. Stable performance and good mechanical properties.

Owner:SHANGHAI INST OF SATELLITE EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com