Silicon-containing atomic oxygen resistant polyimide film composition and preparation method thereof

A technology of oxygen polyimide and polyimide, which is applied in the field of atomic oxygen resistant polyimide film composition and its preparation, can solve the problems of satellite temperature rise and power supply power drop, and achieve good mechanical properties and The effects of good electrical properties, good adhesion, and good space environment stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment relates to a novel atomic oxygen resistant polyimide film composition and a preparation method thereof.

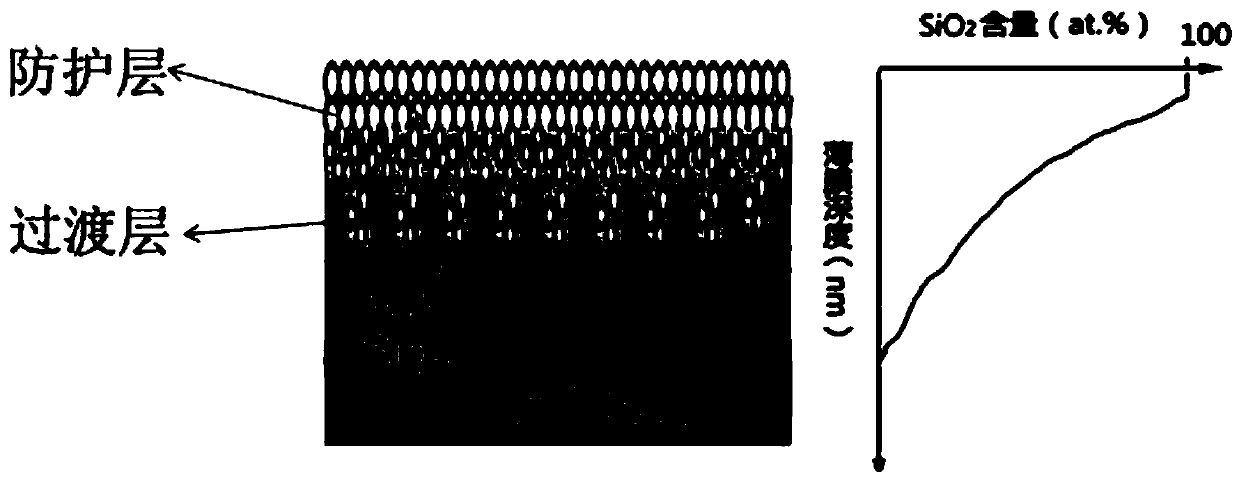

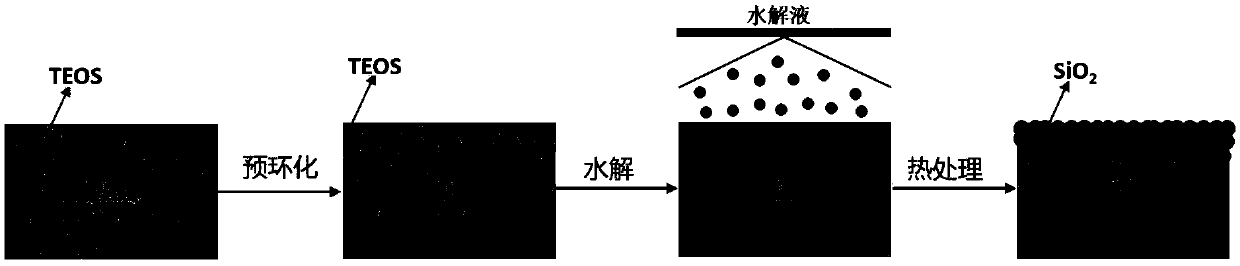

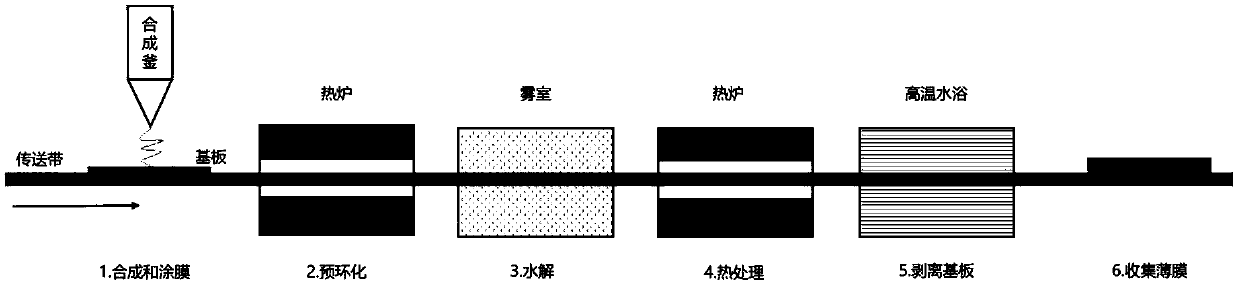

[0031] The structure of the novel atomic oxygen resistant polyimide film material prepared in this embodiment is as follows: figure 1 As shown, the three-layer structure is divided into three regions from the outside to the inside, and the protective layer is continuous SiO 2 Protective structure, transition layer is SiO 2 Interpenetrating network structure with polyimide, base layer is SiO 2 doped structure.

[0032] The new atomic oxygen-resistant polyimide film material prepared in this example adopts the interpenetrating network structure of polyimide and silicon dioxide. The entire protective structure is rooted in the polyimide through mechanical interlocking, The integrated design and preparation of imide film, the atomic oxygen resistant polyimide film has the advantages of compact structure and no cracking, etc., and realizes the suppress...

Embodiment 2

[0048] This embodiment relates to a novel atomic oxygen-resistant polyimide film composition and a preparation method thereof, which is basically the same as in Embodiment 1, except that:

[0049] The polyimide system used in this example is 6FDA / ODA system.

[0050] The atomic oxygen resistant polyimide film material obtained in this embodiment includes a base film layer, a transition layer and a surface protection layer arranged in sequence; the base film layer includes a modified polyimide matrix and nano-SiO 2 filler; the transition layer is an interpenetrating network structure of Si-O-Si and polyimide; the surface protection layer is a pure silicon dioxide layer. In the base film layer, the modified polyimide matrix and nano-SiO 2 The mass ratio of the filler is 8:2. In the transition layer, the mass ratio of Si—O—Si to polyimide is 7:3.

[0051] After testing, the properties of the novel atomic oxygen-resistant polyimide film material prepared in this embodiment are ...

Embodiment 3

[0060] This embodiment relates to a novel atomic oxygen-resistant polyimide film composition and a preparation method thereof, which is the same as in Embodiment 1, except that:

[0061] The polyimide system used in this embodiment is the BPDA / PDA system.

[0062] The atomic oxygen resistant polyimide film material obtained in this embodiment includes a base film layer, a transition layer and a surface protection layer arranged in sequence; the base film layer includes a modified polyimide matrix and nano-SiO 2 filler; the transition layer is an interpenetrating network structure of Si-O-Si and polyimide; the surface protection layer is a pure silicon dioxide layer. In the base film layer, the modified polyimide matrix and nano-SiO 2 The mass ratio of the filler is 1:9. In the transition layer, the mass ratio of Si—O—Si to polyimide is 8:2.

[0063] After testing, the properties of the novel atomic oxygen-resistant polyimide film material prepared in this embodiment are as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com