Abrasive material comprising reactive inorganic endothermic compound

A technology of inorganic compounds and abrasive materials, used in abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of complicating grinding and reducing frictional heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

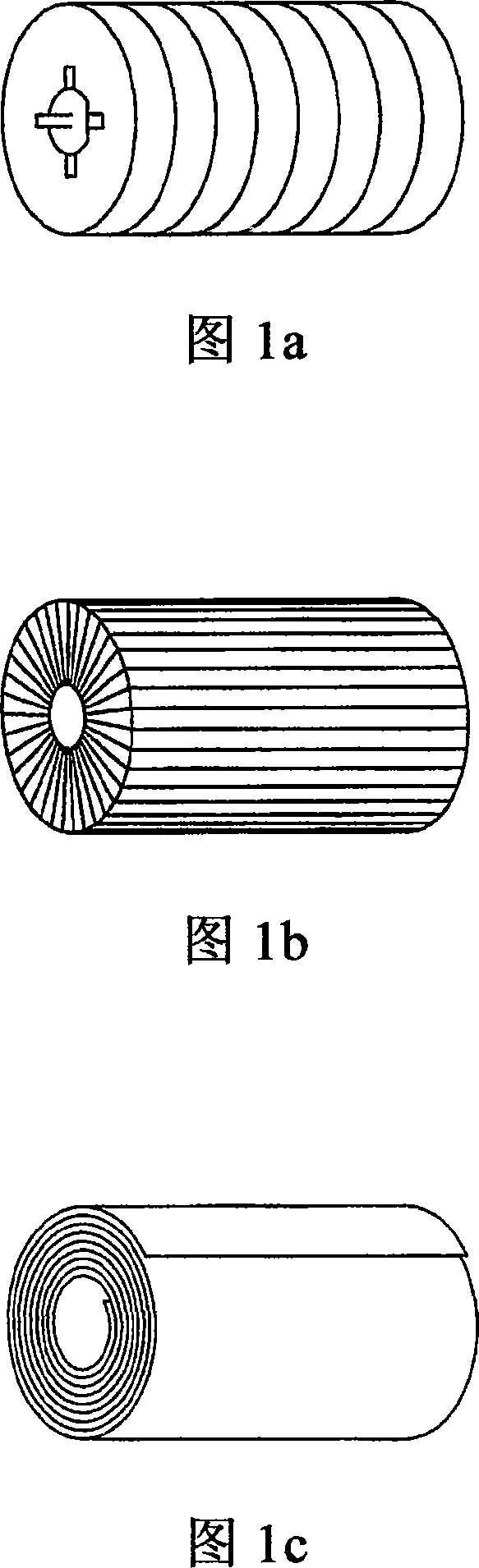

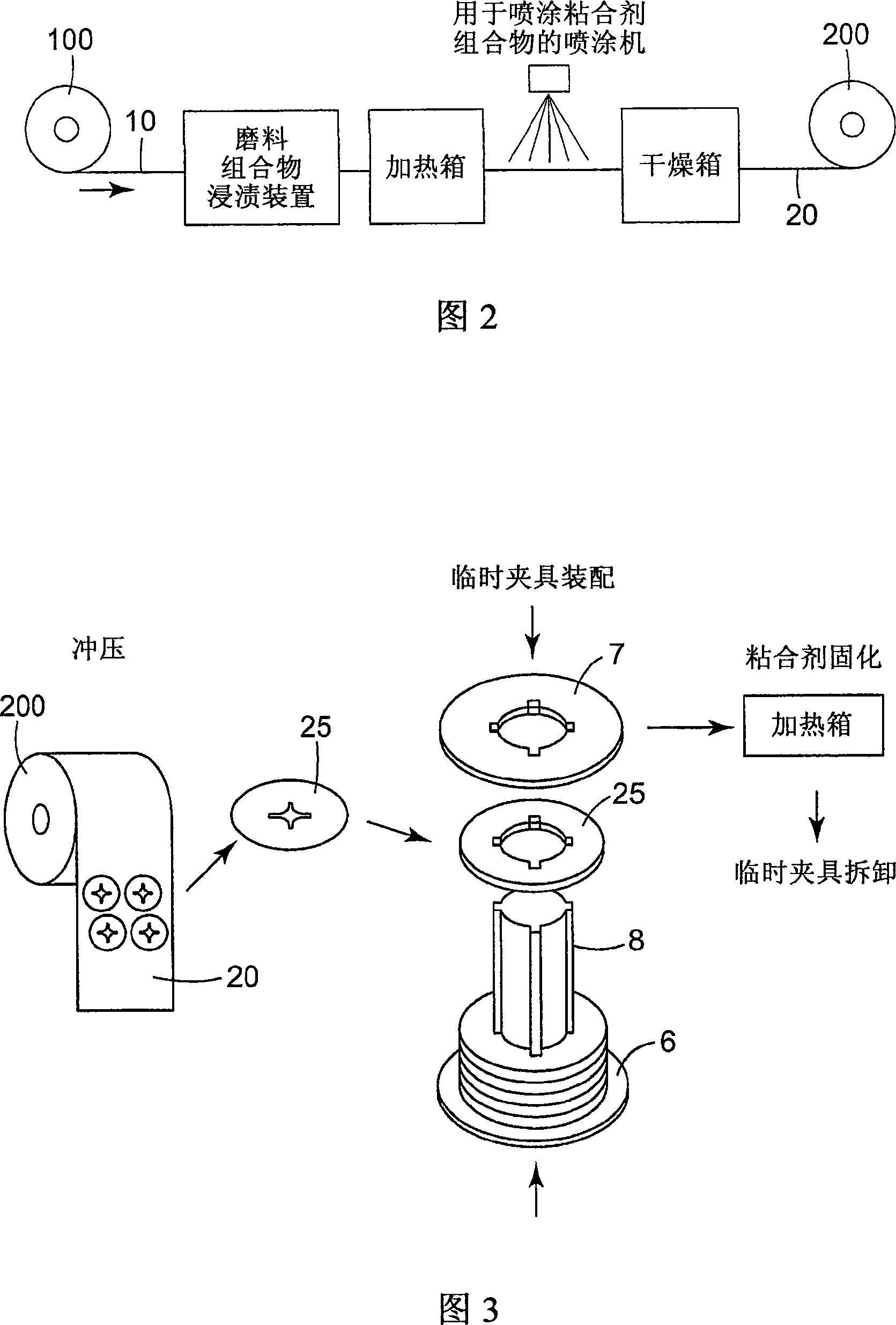

Image

Examples

preparation example Construction

[0027] In the preparation of such a polyurethane resin, a polyol component, a curing agent component thereof, and the like are generally used. Examples of such curing agents are: isocyanates such as 4,4'-methylene bis-2-chloroaniline (MOCA); isocyanates blocked with ketoxime; p,p'-methylene dianiline, which is 4,4'-Methylenebisaniline p-terminated phenol; melamine type resin (for example, "MELAN 5100" manufactured by Hitachi Chemical Co., Ltd.) and the like. A preferred example is a polyurethane resin in which the content of the curing agent is 3% by weight to 10% by weight in terms of NCO content or melamine content.

[0028] Aqueous binder precursors can be used in the present invention. Aqueous binder precursors are binder precursors that primarily use water as a solvent. The aqueous binder precursor generally assumes a state in which the binder resin is uniformly dispersed in water, which is called an emulsion or suspension state. Resins that can be uniformly dispersed ...

example 1

[0065] Aluminum hydroxide ("B103", manufactured by Nippon Keikinzoku K.K. Co.) was used as the reactive inorganic endothermic compound. As a binder resin, "BONTIGHTER HUX-380" polyurethane resin emulsion manufactured by Asahi Denka Co., Ltd. was used. The physical properties of the polyurethane resin (after curing) are as follows: the tensile strength is 38 MPa (5500 psi), the percentage elongation is 500%, the Shore D hardness is 45, and the elastic modulus is 8.4 MPa. Aluminum hydroxide ("WA8000", manufactured by Fujimi Co., Ltd.) the average particle size of which was 1 micron was used as abrasive grains. In addition, prepare a kind of endless nonwoven fabric that is made of nylon 6,6 fiber of 6 denier * 38 millimeters as nonwoven fabric, the basis weight of this endless nonwoven fabric is 440g / m 2 , a thickness of 10 mm and a diameter of 10 cm.

[0066] 50 parts of aluminum hydroxide as a reactive inorganic endothermic compound and 300 parts of abrasive grains were added...

example 2

[0070] Nonwoven fabric abrasive disks were prepared in a manner similar to that described in Example 1, except that no abrasive particles were used, and the abrasive test was performed. Inspection of the ground surface of the workpiece revealed no smearing. Other results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com