Thermal control film on surface of magnesium lithium alloy, and preparation method of thermal control film

A magnesium-lithium alloy, thermal control film technology, applied in surface reaction electrolytic coating, coating, anodizing and other directions, can solve the problems of difficult implementation, low absorption, lack of thermal control coating preparation technology for magnesium-lithium alloy, etc. The effect of improved thermal control performance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The method for preparing the magnesium-lithium alloy high-emission-low-absorption thermal control film layer of the present invention is carried out according to the following steps: pretreatment→installation→oxidation→cleaning→drying, specifically including the following steps:

[0036] Step (1), pretreatment: Use absolute ethanol or acetone to clean the surface of the magnesium-lithium alloy to remove oil stains and cutting fluids on the surface of the magnesium-lithium alloy parts; then put the magnesium-lithium alloy parts into the In sodium hydroxide aqueous solution, wash at a temperature of 80°C to 90°C for 1min to 3min, take it out, wash it with clean water and dry it;

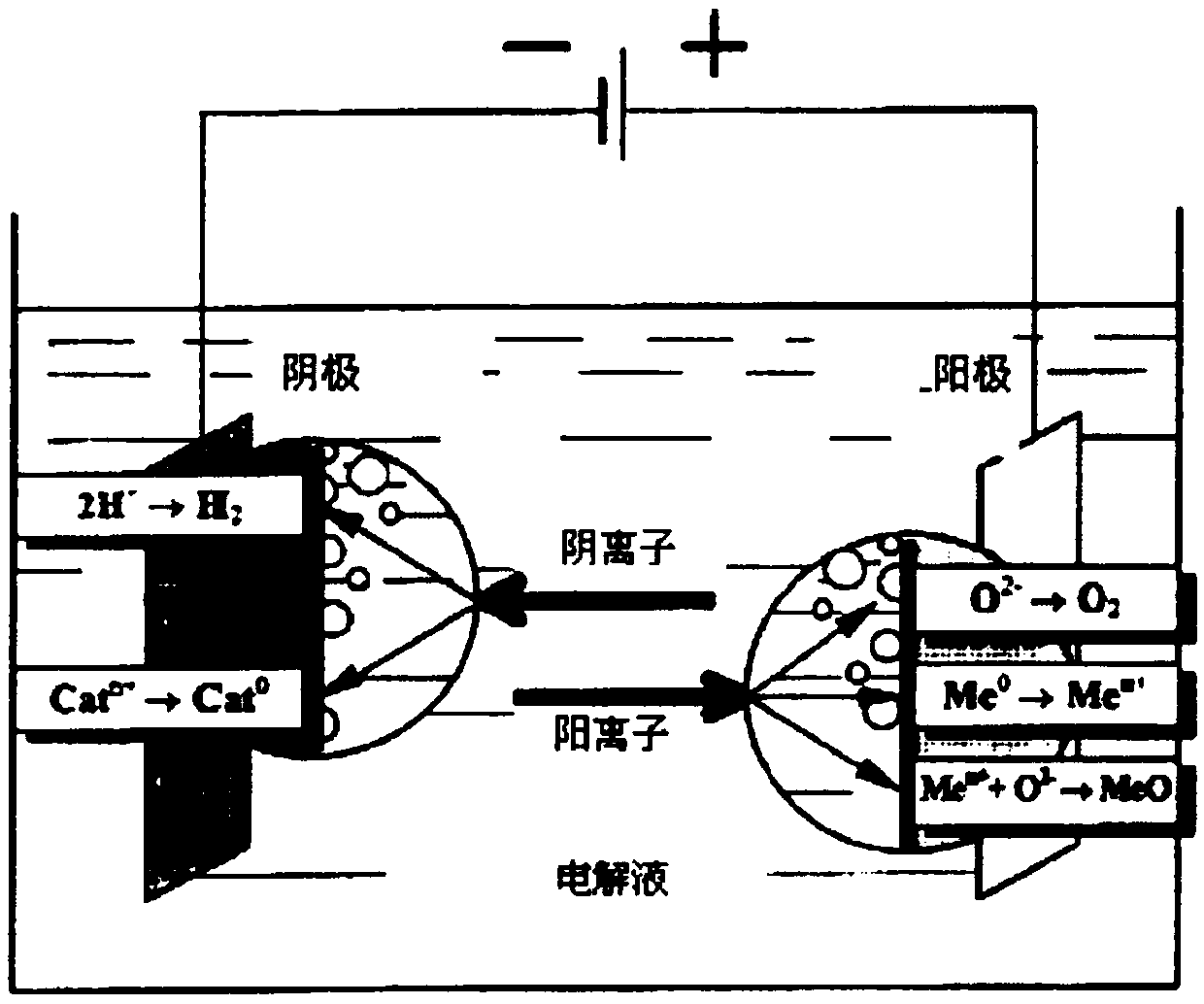

[0037] Step (2), preparing the electrolyte: prepare the electrolyte required for oxidation according to the following ratio, place the prepared electrolyte in the stainless steel oxidation tank, use the magnesium-lithium alloy parts as the anode, and the stainless steel oxidation tank as the cath...

Embodiment 1

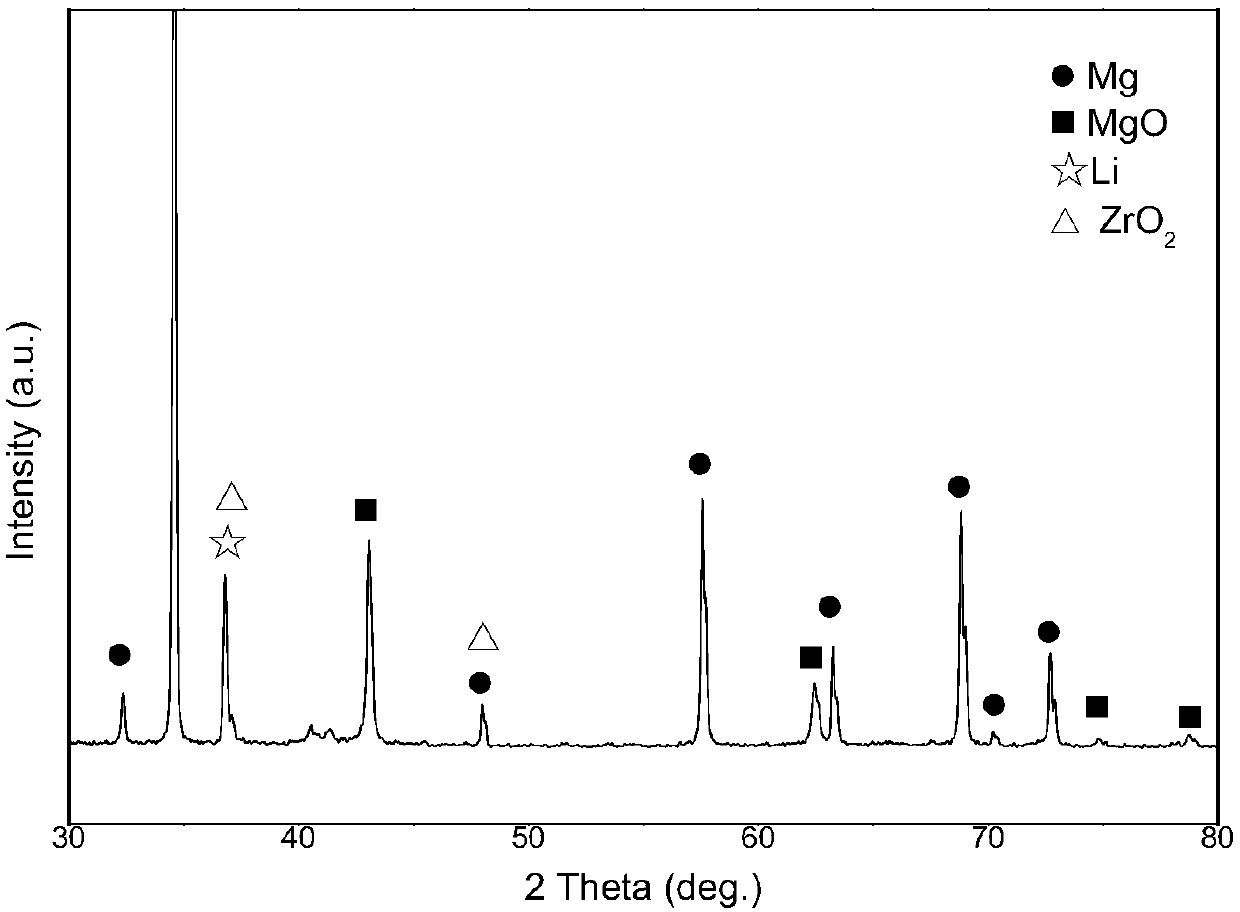

[0058] The preparation method of the high-emission-low-absorption thermal control coating of magnesium-lithium alloy parts is carried out according to the following steps: 1. Part surface pretreatment: use absolute ethanol or acetone to clean the surface of magnesium-lithium alloy parts, and remove oil stains and cutting fluids on the parts surface ; Then put the magnesium-lithium alloy parts into the sodium hydroxide aqueous solution with a concentration of 45g / L, wash them at a temperature of 85°C for 2 minutes, take them out, clean them with clean water, and dry them; 3 SiO 4 10g / L, potassium fluozirconate K 2 ZrF 6 15g / L, potassium fluoride KF 2g / L, potassium hydroxide KOH 2g / L, dissolve respectively; pour the above solution into the stainless steel oxidation tank and mix, use the parts as anode and the stainless steel oxidation tank as cathode, respectively in Φ3 Tap the M3 external thread at one end of the aluminum wire, tap the M3 internal thread on the magnesium-lit...

Embodiment 2

[0062] The preparation method of the high-emission-low-absorption thermal control coating of magnesium-lithium alloy parts is carried out according to the following steps: 1. Part surface pretreatment: use absolute ethanol or acetone to clean the surface of magnesium-lithium alloy parts, and remove oil stains and cutting fluids on the parts surface ; Then put the magnesium-lithium alloy parts into the sodium hydroxide aqueous solution with a concentration of 45g / L, wash them at a temperature of 85°C for 2 minutes, take them out, clean them with clean water, and dry them; 3 SiO 4 10g / L, potassium fluozirconate K 2 ZrF 6 15g / L, potassium fluoride KF 2 1g / L, potassium hydroxide KOH 2 Dissolve 1g / L separately; pour the above solution into the stainless steel oxidation tank and mix, use the part as the anode and the stainless steel oxidation tank as the cathode, respectively tap the M3 external thread on one end of the Φ3 aluminum wire, and tap the M3 internal thread on the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com