A method of heat transfer and heat dissipation with large heat and high heat flux based on high-dimensional thermoelectricity

A technology with high heat flux density and heat dissipation method, applied in the direction of machine operation, machines using electric/magnetic effects, temperature control using digital devices, etc., can solve the problem of heat transfer efficiency of heat pipe technology, limited transmission distance, and unsatisfactory products Structural requirements, low working temperature range, etc., to achieve the effect of ensuring cleanliness and humidity, high cost performance, and small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

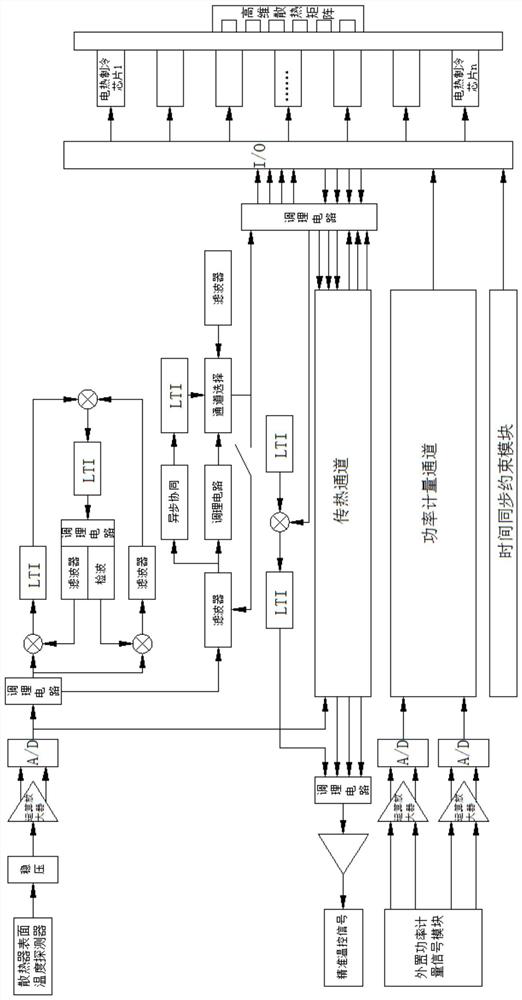

[0013] according to figure 1 As shown, this embodiment provides a method for heat transfer and heat dissipation with large heat and high heat flux density based on high-dimensional thermoelectricity, including a high-dimensional heat dissipation matrix, a time synchronization constraint module, a thermoelectric cooling chip, a temperature data acquisition / transmission module, and a temperature detector , control / temperature measurement module, heat transfer channel and external power measurement signal module, the temperature data acquisition / transmission module collects and transmits the real-time temperature data on the temperature detector in real time, and the control / temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com