A flexible phase change material for thermal control of electronic devices

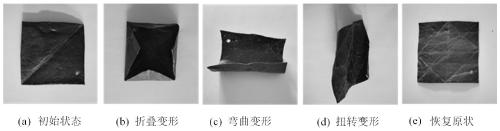

A technology of phase change materials and electronic equipment, applied in heat exchange materials, modification through conduction heat transfer, cooling/ventilation/heating modification, etc., can solve problems such as inability to separate crystal phases, fracture damage, and high surface contact thermal resistance , to achieve the effect of improving thermal control performance, increasing the use of space and cost, and good coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of octadecyl flexible phase change material, the specific operation steps are as follows:

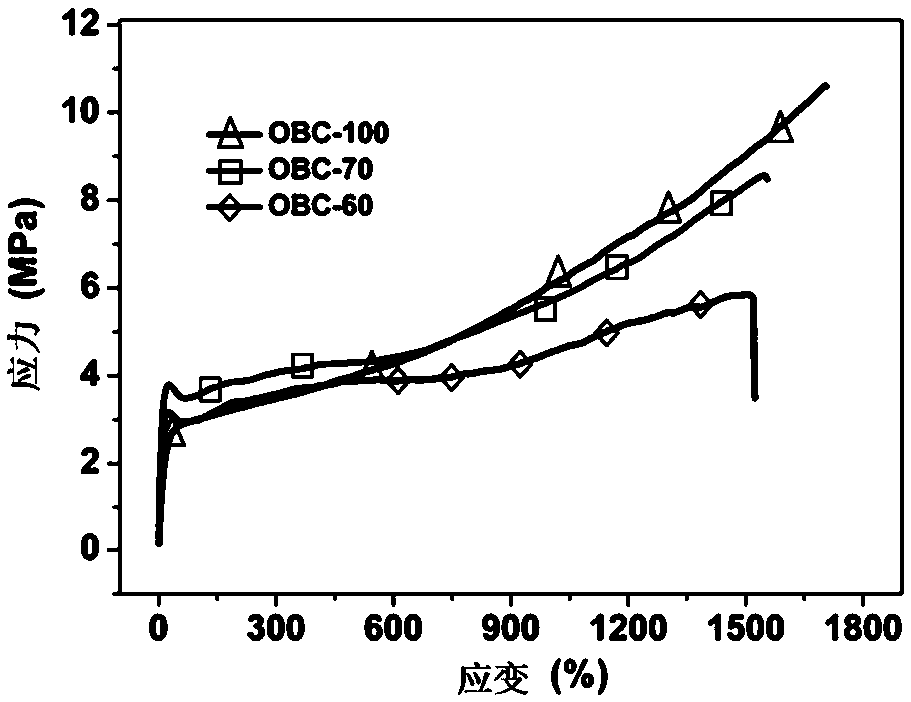

[0037] In step (1), 150 g of octadecane and 50 g of olefin block copolymer (OBC) are taken; octadecane is the phase change matrix, the phase change temperature is 26.2°C, and the phase change latent heat is 201.6 J / g; OBC is the support carrier.

[0038] Step (2), place 150g of octadecane in an oil bath kettle body and heat it at a constant temperature at 40°C for about 30 minutes until it is completely melted;

[0039] Step (3), add 50g OBC, the temperature is 170℃, and the speed of the stirrer is set to 30r / min. Heat for 30min while stirring, and stir the two substances evenly until the OBC is completely melted, and a uniformly mixed molten composite is obtained. Things. At the same time, the cutter for surface treatment of the phase change material and the mold for holding the molten composite are respectively placed on a copper plate at 50°C for preheating.

[0040] Step...

Embodiment 2

[0047] The operation steps for preparing paraffin-based flexible phase change materials are as follows:

[0048] Step (1): Take 160 g of paraffin wax, 40 g of olefin block copolymer (OBC) and 6 g of expanded graphite (EG01). Paraffin wax is the phase change matrix, the phase change temperature is 52.6℃, the latent heat of phase change is 210J / g; OBC is the support carrier; EG01 is the thermal conductivity enhancer, the particle size is 282um, and the expansion is 550 times. The dosage of EG01 is 3% of the total mass of paraffin wax and OBC.

[0049] Step (2), place 160g of paraffin wax in an oil bath kettle body at a constant temperature of 60°C for about 30 minutes, until it melts completely;

[0050] Step (3), add 40 g of olefin block copolymer (OBC), set the temperature to 170°C, set the speed of the stirrer to 30r / min, heat for 30 minutes while stirring, and stir the two substances evenly until the OBC is completely melted. A molten composite of evenly mixed paraffin and OBC is...

Embodiment 3

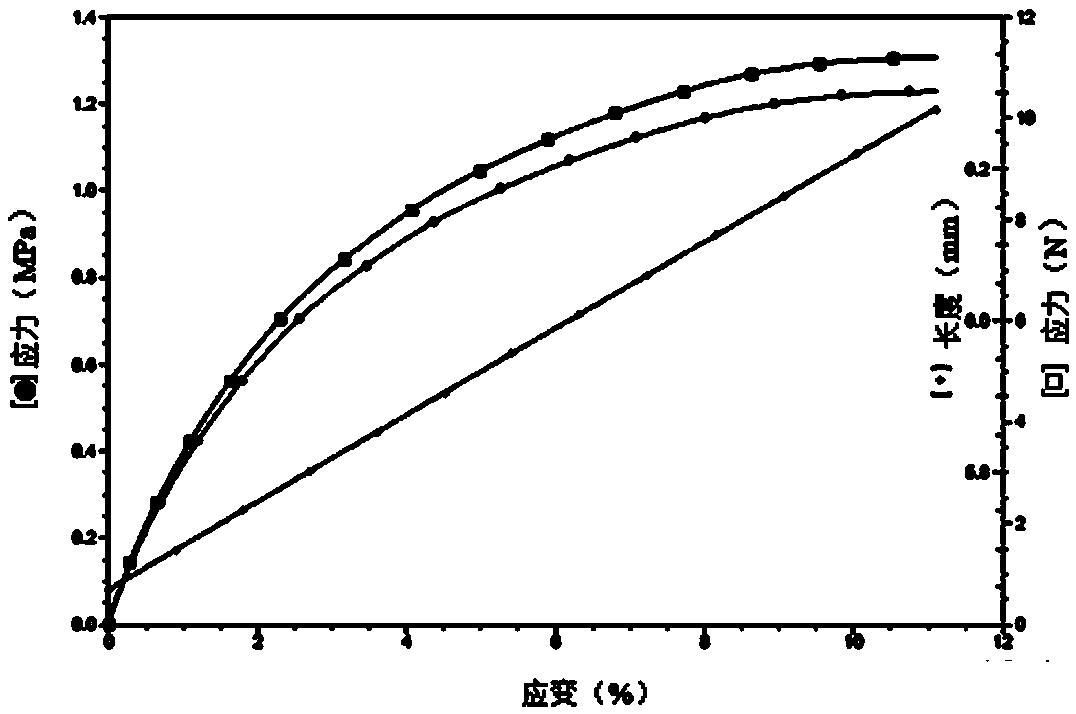

[0056] The operation steps for preparing polyethylene glycol-based flexible phase change materials are as follows:

[0057] Step (1), take 140g polyethylene glycol, 60g polyurethane and 10g carbon nanotubes.

[0058] Polyethylene glycol is the phase change matrix, the relative molecular mass is 10000, the phase transition temperature is 67.18℃, the phase change latent heat is 187.3J / g; the polyurethane is the support carrier; the mass ratio of polyethylene glycol to polyurethane is 70:30. Carbon nanotubes are heat conduction enhancers. The model of carbon nanotubes is CNTS107, with a diameter of more than 50nm and a length of 10-20μm.

[0059] Step (2): Put 140g polyethylene glycol in the kettle body and heat it at 70°C for 30 minutes until the polyethylene glycol is completely melted;

[0060] Step (3), add 60g of polyurethane, set the temperature to 190°C, set the speed of the stirrer to 35r / min, turn on the vacuum pump to ensure that the kettle body maintains a vacuum degree of 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com