Titanium alloy surface thermal-control wear-resistant coating and preparation method thereof

A titanium alloy, wear-resistant technology, applied in the field of thermal control wear-resistant coating and its preparation, thermal control wear-resistant coating on the surface of titanium alloy and its preparation, can solve the problems of poor hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Take a titanium alloy test piece with a size of 60×60mm, go through the processes of alkali washing and pickling in sequence, and prepare the electrolyte according to the following mass and volume ratio: sodium aluminate 3g / L, sodium phosphate 10g / L, sodium carbonate 5g / L , the solvent is water. The titanium alloy test piece is placed in the electrolyte and connected to one electrode of the power supply, and the other electrode of the power supply is connected to the stainless steel plate and placed in the electrolyte at the same time. The unidirectional pulse current waveform is adopted, and the frequency of the power supply is 50Hz. During the plasma electrolytic oxidation treatment, the voltage is 490V, and the oxidation current density is 2A / dm 2 , processing time 120min. The resulting thermal control coating has a solar absorption ratio of 0.70, a hemispherical emissivity of 0.86, and a coating hardness of 1100HV.

Embodiment 2

[0039] Take a titanium alloy test piece with a size of 60×60mm, go through the processes of alkali washing and pickling in sequence, and prepare the electrolyte according to the following mass and volume ratio: sodium aluminate 10g / L, sodium tetraborate 10g / L, sodium acetate 5g / L L, the solvent is water. The titanium alloy test piece is placed in the electrolyte and connected to one electrode of the power supply, and the other electrode of the power supply is connected to the stainless steel plate and placed in the electrolyte at the same time. The unidirectional pulse current waveform is adopted, and the frequency of the power supply is 100Hz. During the plasma electrolytic oxidation treatment, the voltage is 510V, and the oxidation current density is 8A / dm 2 , processing time 90min. The solar absorption ratio of the generated thermal control coating is 0.72, the hemispherical emissivity is 0.87, and the hardness of the coating is 1200HV.

Embodiment 3

[0041] Take a titanium alloy test piece with a size of 60×60mm, go through the processes of alkali washing and pickling in sequence, and prepare the electrolyte according to the following mass and volume ratio: sodium aluminate 15g / L, sodium pyrophosphate 15g / L, sodium sulfate 5g / L L, the solvent is water. The titanium alloy test piece is placed in the electrolyte and connected to one electrode of the power supply, and the other electrode of the power supply is connected to the stainless steel plate and placed in the electrolyte at the same time. A single-phase pulse current waveform is adopted, and the frequency of the power supply is 200Hz. During the plasma electrolytic oxidation treatment, the voltage is 520V, and the oxidation current density is 15A / dm 2 , processing time 60min. The solar absorption ratio of the generated thermal control coating is 0.73, the hemispherical emissivity is 0.85, and the microhardness of the coating is 1300HV.

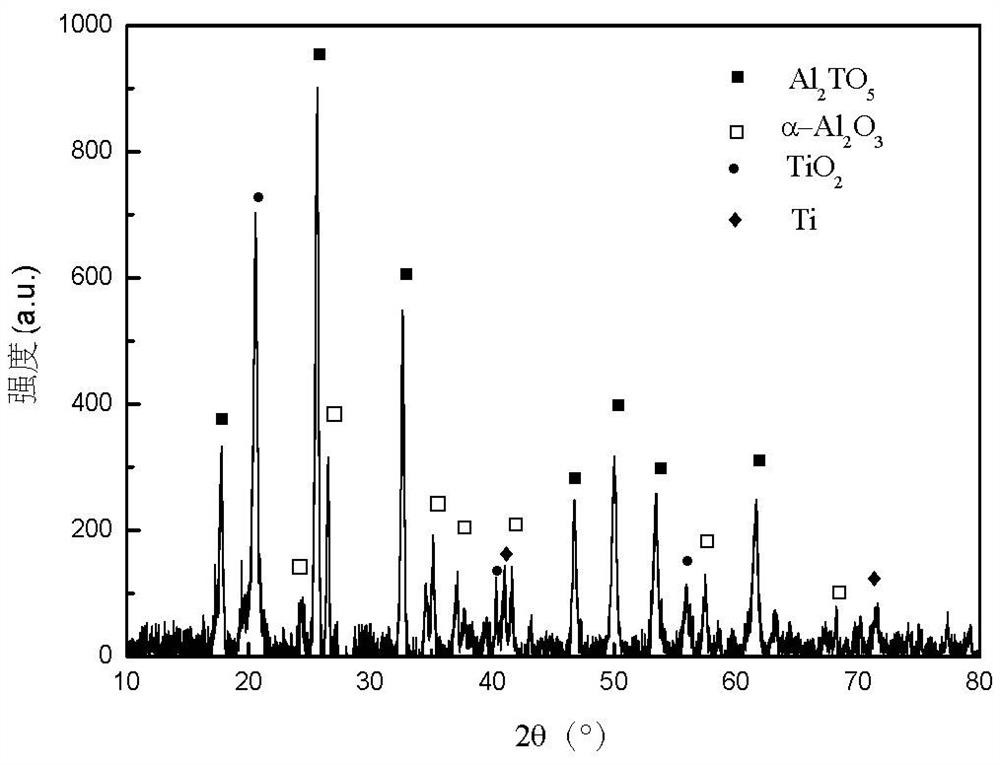

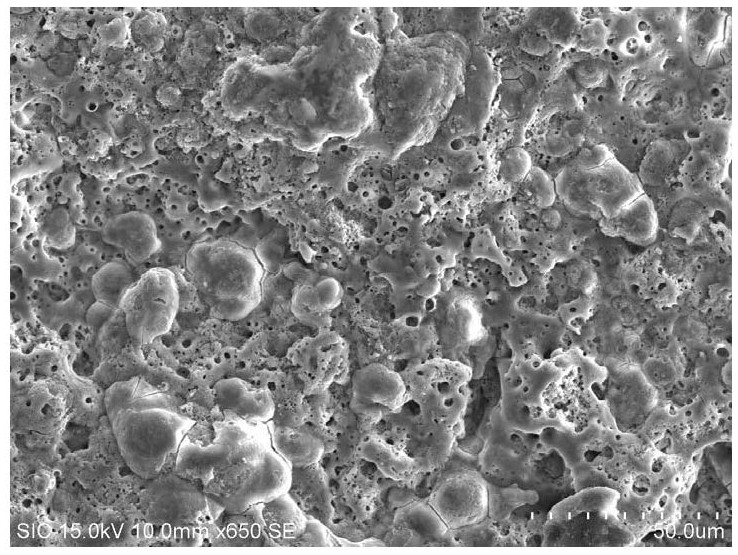

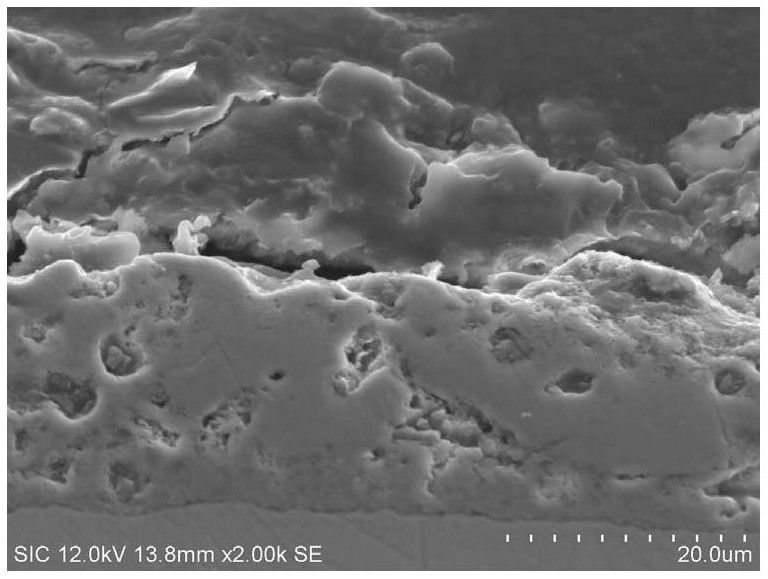

[0042] figure 1 The phase c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com