Antistatic thermal control coating composition and its preparation method and application

An antistatic and composition technology, applied in the field of antistatic thermal control coating composition and its preparation, can solve the problems of spacecraft abnormality, failure, discharge, etc., and achieves simple construction, low vacuum outgassing, and good coating conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment relates to an antistatic thermal control coating composition and its preparation method, and the application of the antistatic thermal control coating composition in the preparation of a new antistatic white thermal control coating.

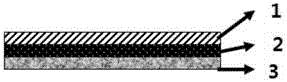

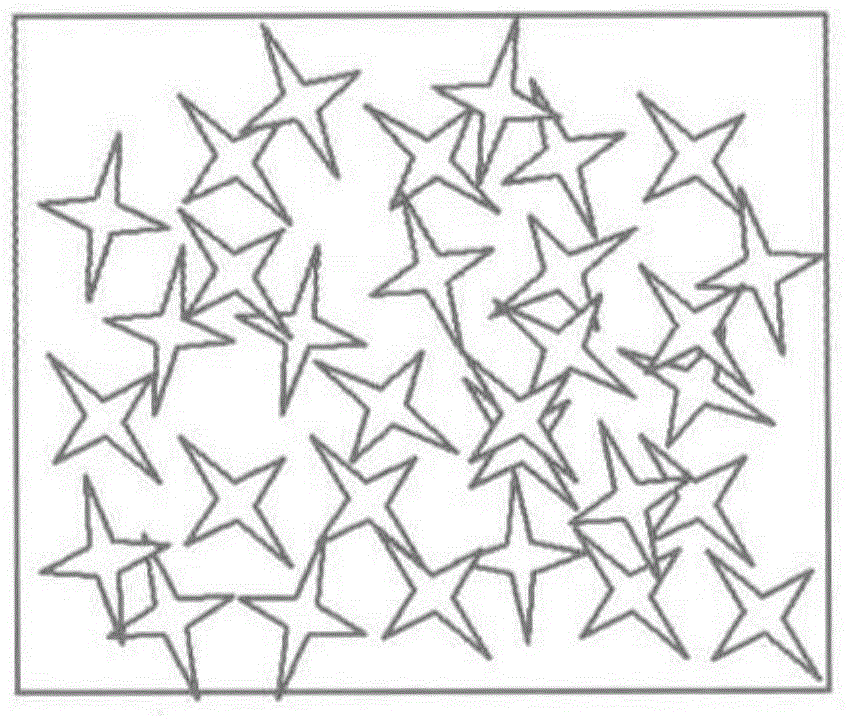

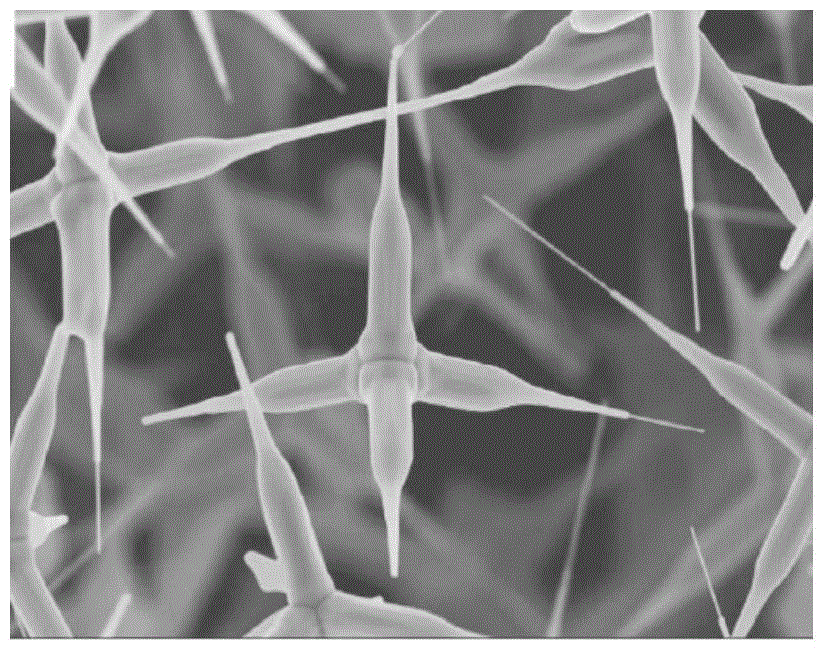

[0036] The novel antistatic white thermal control coating of the present embodiment is as figure 1 As shown, the coating is upward from the base material 3 and is composed of two layers of coatings with different components; the bottom coating is called the primer layer 2, which is composed of modified organic fluorine resin and zinc oxide with a special spatial configuration; coating The coating on the surface becomes the topcoat layer 1, which is composed of multifunctional methyl silicone resin and modified zinc oxide.

[0037] The novel antistatic white thermal control coating of the present embodiment adopts two-component antistatic thermal control coating composition, and this coating composition comprises primer coat...

Embodiment 2

[0045] This embodiment relates to an antistatic thermal control coating composition and its preparation method, and the application of the antistatic thermal control coating composition in the preparation of a new antistatic white thermal control coating.

[0046] This embodiment is basically the same as Embodiment 1, the difference is:

[0047] 1) Primer coating preparation: Add modified zinc oxide powder to the phosphorus-containing modified organic fluorine resin, mix and stir, add butyl acetate, mix, and ultrasonically stir evenly; by mass percentage: modify zinc oxide in the primer The powder accounts for 60wt% of the solid content of the coating, the modified organic fluororesin accounts for 40wt% of the total coating, the mass ratio of the modified organic fluororesin and the modified zinc oxide powder is 60:40, and the butyl acetate diluent is used in an amount of Add 0.1 times of the total weight of the modified zinc oxide powder filler and the modified organic fluori...

Embodiment 3

[0051] This embodiment relates to an antistatic thermal control coating composition and its preparation method, and the application of the antistatic thermal control coating composition in the preparation of a new antistatic white thermal control coating.

[0052] This embodiment is basically the same as Embodiment 1, the difference is:

[0053] 1) Primer coating preparation: Add modified zinc oxide powder to phosphorus-containing modified organic fluorine resin, mix and stir, add xylene, mix, and ultrasonically stir evenly; by mass percentage: modify zinc oxide powder in the primer Accounting for 50wt% of the solid content of the paint, the modified organic fluororesin accounts for 50wt% of the total amount of the paint, the mass ratio of the modified organic fluororesin and the modified zinc oxide powder is 50:50, and the xylene diluent is modified according to its amount. Add 0.15 times of the total weight of zinc oxide powder filler and modified organic fluorine resin.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size distribution | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com