A kind of preparation method of wear-resistant and corrosion-resistant nickel-based alloy coating

A nickel-based alloy, corrosion-resistant technology, applied in metal material coating process, coating, melt spraying and other directions, can solve the problems of low efficiency, high cost, unfavorable mass production, etc., to achieve cost reduction, good bonding strength, Beneficial for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

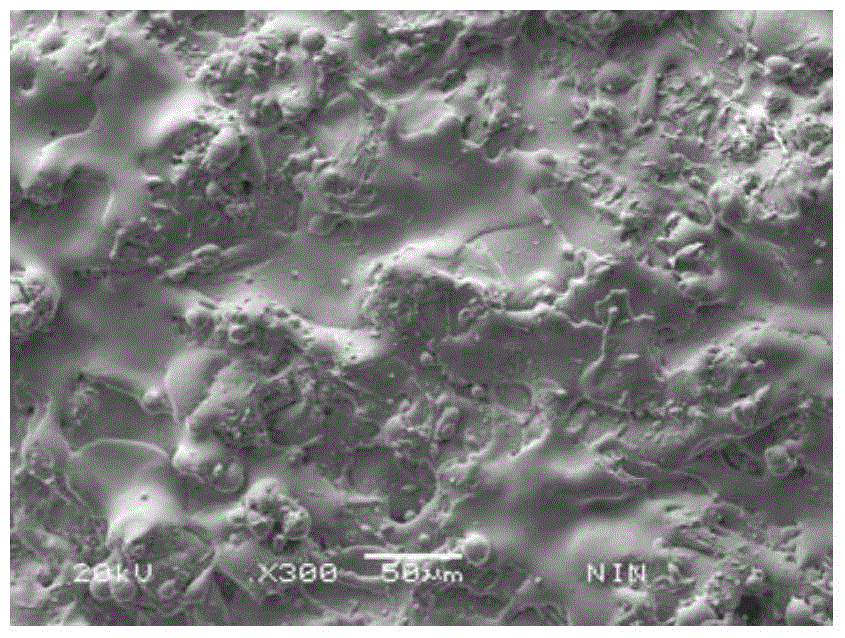

Image

Examples

Embodiment 1

[0025] 1) Surface cleaning of the workpiece: use sandpaper to polish the surface of the workpiece to be sprayed, so that the surface reveals a metallic luster;

[0026] 2) Sandblasting roughening: use white corundum as the spraying material, and perform sandblasting roughening on the surface of the workpiece cleaned in step 1), wherein the white corundum sand particle size is 60-100 mesh, and the sandblasting distance is 100-150mm;

[0027] 3) Surface cleaning of the workpiece: use acetone to clean the surface of the workpiece after sandblasting and roughening;

[0028] 4) Clamping: place the workpiece on the rotating fixture;

[0029] 5) Thermal spraying: HEP-Jet supersonic plasma spraying system and SG-100 plasma spray gun are used to spray a layer of nickel alloy coating with a thickness of 50 μm on the cleaned surface of the workpiece. The spraying process parameters are: power 40KW, The powder feeding rate is 30g·min -1 , the main steam flow rate is 90L·min -1 , The sp...

Embodiment 2

[0032] 1) Surface cleaning of the workpiece: use sandpaper to polish the surface of the workpiece to be sprayed, so that the surface reveals a metallic luster;

[0033] 2) Sandblasting coarsening: using white corundum as the spraying material, carry out sandblasting roughening on the surface of the workpiece to be sprayed after cleaning in step 1), wherein the white corundum sand particle size is 60-100 mesh, and the sandblasting distance is 100-150mm;

[0034] 3) Surface cleaning of the workpiece: use acetone to clean the surface of the workpiece to be sprayed after sandblasting and roughening;

[0035] 4) Clamping: place the workpiece on the rotating fixture;

[0036] 5) Thermal spraying: HEP-Jet supersonic plasma spraying system and SG-100 plasma spray gun are used to spray a layer of nickel alloy coating with a thickness of 50 μm on the surface of the workpiece after cleaning. The spraying process parameters are: power 35KW, The powder feeding rate is 25g·min -1 , the ma...

Embodiment 3

[0039] 1) Surface cleaning of the workpiece: use mechanical processing to clean the surface of the workpiece to be sprayed, so that the surface reveals a metallic luster;

[0040] 2) Sand blasting coarsening: use white corundum as the spraying material, and perform sand blasting roughening on the surface of the workpiece to be sprayed after cleaning in step 1), wherein the white corundum sand particle size is 60-100 mesh, and the sand blasting distance is 100-150mm;

[0041] 3) Surface cleaning of the workpiece: use acetone to clean the surface of the workpiece to be sprayed after sandblasting and roughening;

[0042] 4) Clamping: place the workpiece on the rotating fixture;

[0043] 5) Thermal spraying: HEP-Jet type supersonic plasma spraying system and SG-100 type plasma spray gun are used to spray a layer of nickel alloy coating with a thickness of 50 μm on the surface of the workpiece after cleaning. The spraying process parameters are as follows: power 30KW, The powder f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com