High temperature oxidation-resistant material for low-density niobium alloy and method for preparing high temperature oxidation-resistant coating from high temperature oxidation-resistant material

A high-temperature anti-oxidation and niobium alloy technology, which is applied in the direction of heating inorganic powder coating, etc., can solve the problem that the thermal expansion performance and combination performance of the anti-oxidation coating cannot meet the requirements of use, and achieve strong defect self-healing ability, uniform surface, and microstructure dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

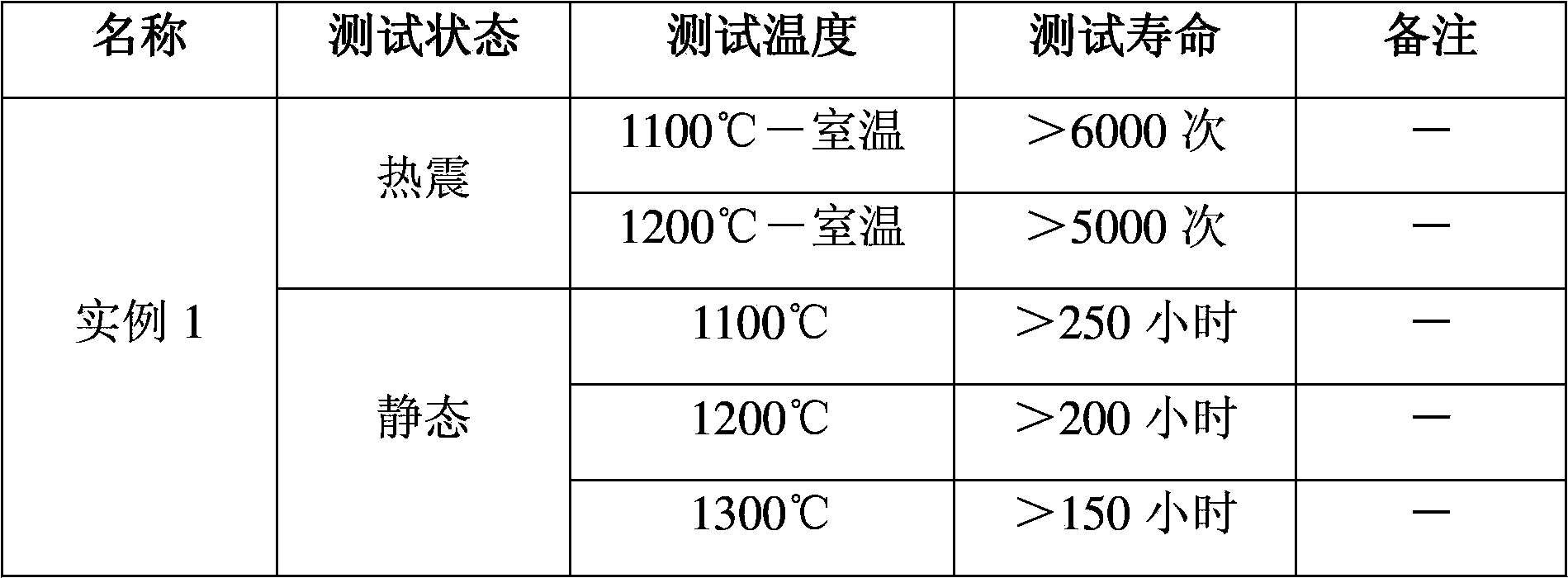

Embodiment 1

[0020] The high-temperature anti-oxidation material contains the following components by weight percentage:

[0021] Nb: 2Wt%, Si: 13Wt%, B: 1.5Wt%, Ge: 2Wt%, Ti: 2.5Wt%, S: 0.30Wt%, Mo: 1.5Wt%, HfO 2 : 1Wt%, Fe: 3% W: 0.8Wt%, the balance is Al.

[0022] Make the above-listed components into a powder with a particle size of 450 mesh and put it into a container. Use absolute ethanol that is 4 times the volume of the aforementioned powder as a carrier, add 2.5% of the mass of the aforementioned powder to sodium chloride, and mix evenly. Polyethylene glycol with 0.25% of the total mass of the aforementioned powder was used as a binder, mixed with the coating powder and ground for 5 hours in a ball mill to obtain a slurry. Coating the coating slurry on the low-density niobium alloy substrate, the coating thickness is controlled at 100 microns, and then at a temperature of 1300 ° C, a vacuum greater than 1×10 -1 Carry out melting under Pa condition, keep warm for 25 minutes, fina...

Embodiment 2

[0030] Take a composite material of the following components:

[0031] Si is 13Wt%, Ti is 2.5Wt%, Mo is 1.5Wt%, HfO 2 1Wt%, W is 0.8Wt%, and the balance is Al.

[0032] Make the above composite material into a powder with a particle size of 400 mesh and put it into a container, use absolute ethanol with 3.5 times the volume of the aforementioned powder as a carrier, add 3.0% of the aforementioned powder mass of potassium chloride and mix evenly, and add an additional 0.3% of the aforementioned powder mass Mix evenly again after the polyethylene glycol, adopt ball mill to grind 4 hours and make coating slurry, then this coating slurry is coated on the low-density niobium alloy base material, coating thickness is controlled at 80 microns, at temperature 1350℃, vacuum greater than 1×10 -1 Melt and burn under Pa conditions, and keep warm for 15 minutes to form a high-temperature anti-oxidation coating.

Embodiment 3

[0034] Take a composite material of the following components:

[0035] B is 0.5Wt%, Si is 10Wt%, Ti is 2Wt%, Ge is 1.5Wt%, Mo is 1Wt%, HfO 2 0.8Wt%, W is 0.7Wt%, S is 0.25Wt%, and the balance is Al.

[0036]Make the above-mentioned composite material into a powder with a particle size of 350 mesh and put it into a container, use anhydrous ethanol that is 3 times the volume of the above-mentioned powder as a carrier, add 1.5% of the above-mentioned powder mass of sodium chloride and mix evenly, and add another 0.15% of the above-mentioned powder mass Mix evenly again after the polyethylene glycol, adopt ball mill to grind 3 hours and make coating slurry, then this coating slurry is coated on the low-density niobium alloy base material, coating thickness is controlled at 60 microns, at temperature 1200℃, vacuum greater than 1×10 -1 Melt and burn under Pa conditions, and keep warm for 10 minutes to form a high-temperature anti-oxidation coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com