High temperature oxidation-resistant material for low-density niobium alloy and method for preparing high temperature oxidation-resistant coating from high temperature oxidation-resistant material

A high-temperature anti-oxidation, niobium alloy technology, applied in heating inorganic powder coating and other directions, can solve the problem that the thermal expansion performance of anti-oxidation coating cannot meet the requirements of use, and achieve strong defect self-healing ability, excellent mechanical properties, surface uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

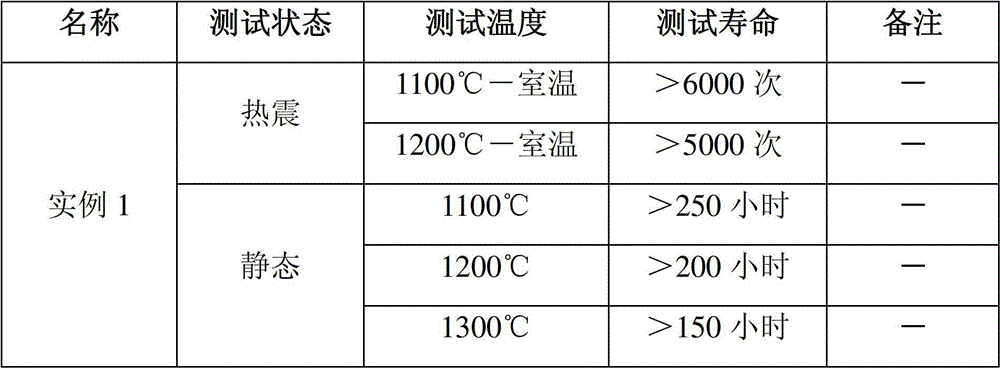

Embodiment 1

[0020] The high-temperature anti-oxidation material contains the following components by weight percentage:

[0021] Nb: 2Wt%, Si: 13Wt%, B: 1.5Wt%, Ge: 2Wt%, Ti: 2.5Wt%, S: 0.30Wt%, Mo: 1.5Wt%, HfO 2 : 1Wt%, Fe: 3% W: 0.8Wt%, the balance is Al.

[0022] Make the above-listed components into a powder with a particle size of 450 mesh and put it into a container. Use absolute ethanol that is 4 times the volume of the aforementioned powder as a carrier, add 2.5% of the mass of the aforementioned powder to sodium chloride, and mix evenly. Polyethylene glycol with 0.25% of the total mass of the aforementioned powder was used as a binder, mixed with the coating powder and ground for 5 hours in a ball mill to obtain a slurry. Coating the coating slurry on the low-density niobium alloy substrate, the coating thickness is controlled at 100 microns, and then at a temperature of 1300 ° C, a vacuum greater than 1×10 -1 Carry out melting under Pa condition, keep warm for 25 minutes, fina...

Embodiment 2

[0030] Take a composite material of the following components:

[0031] Si is 13Wt%, Ti is 2.5Wt%, Mo is 1.5Wt%, HfO 2 1Wt%, W is 0.8Wt%, and the balance is Al.

[0032] Make the above composite material into a powder with a particle size of 400 mesh and put it into a container, use absolute ethanol with 3.5 times the volume of the aforementioned powder as a carrier, add 3.0% of the aforementioned powder mass of potassium chloride and mix evenly, and add an additional 0.3% of the aforementioned powder mass Mix evenly again after the polyethylene glycol, adopt ball mill to grind 4 hours and make coating slurry, then this coating slurry is coated on the low-density niobium alloy base material, coating thickness is controlled at 80 microns, at temperature 1350℃, vacuum greater than 1×10 -1 Melt and burn under Pa conditions, and keep warm for 15 minutes to form a high-temperature anti-oxidation coating.

Embodiment 3

[0034] Composite material with the following components:

[0035] B is 0.5Wt%, Si is 10Wt%, Ti is 2Wt%, Ge is 1.5Wt%, Mo is 1Wt%, HfO 2 0.8Wt%, W is 0.7Wt%, S is 0.25Wt%, and the balance is Al.

[0036]Make the above-mentioned composite material into a powder with a particle size of 350 mesh and put it into a container, use anhydrous ethanol that is 3 times the volume of the above-mentioned powder as a carrier, add 1.5% of the above-mentioned powder mass of sodium chloride and mix evenly, and add another 0.15% of the above-mentioned powder mass Mix evenly again after the polyethylene glycol, adopt ball mill to grind 3 hours and make coating slurry, then this coating slurry is coated on the low-density niobium alloy base material, coating thickness is controlled at 60 microns, at temperature 1200℃, vacuum greater than 1×10 -1 Melt and burn under Pa conditions, and keep warm for 10 minutes to form a high-temperature anti-oxidation coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com