High-orbit optical remote sensor vacuum hot test external heat flow simulation method

An optical remote sensor and vacuum thermal test technology, which is used in simulation devices for space navigation conditions, space navigation equipment, transportation and packaging, etc. Engineering Realizability, Improve Heat Flow Simulation Accuracy, Reduce the Effect of Rotation Amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

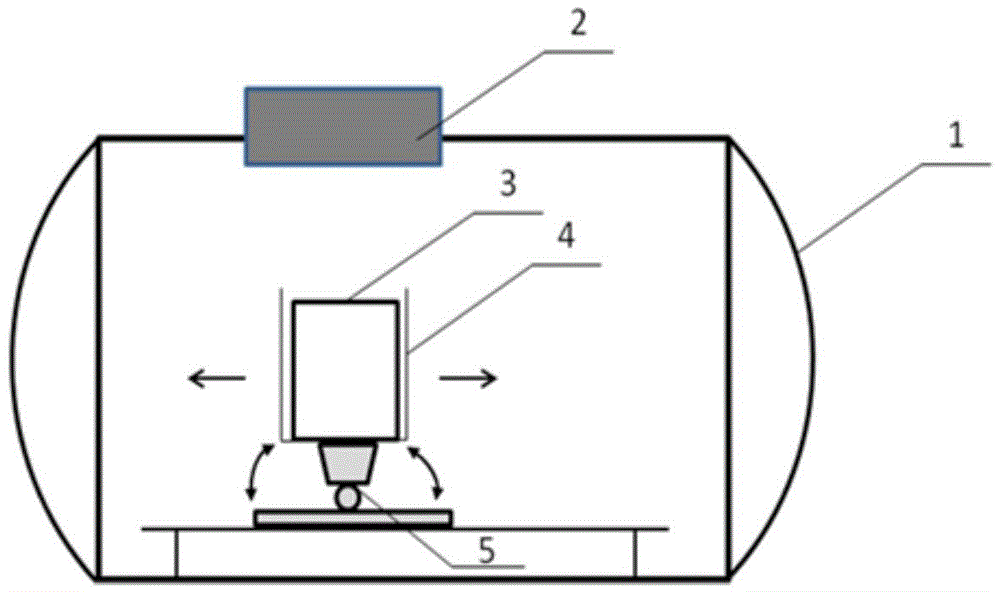

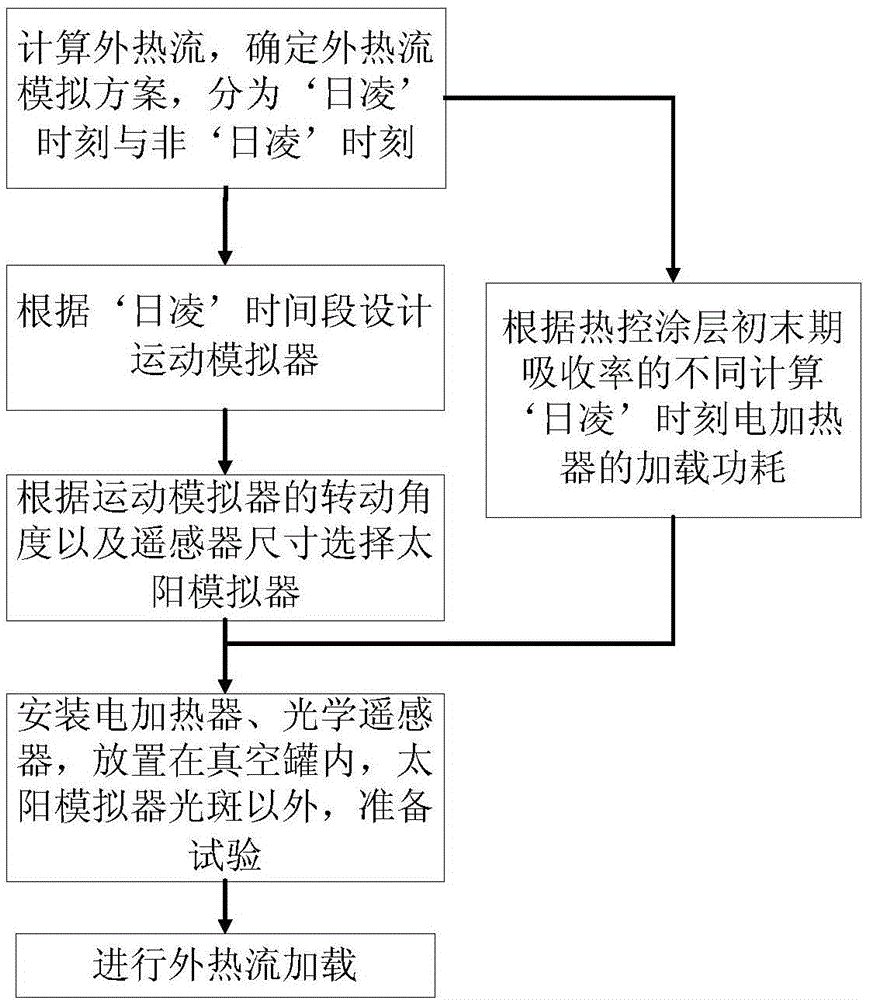

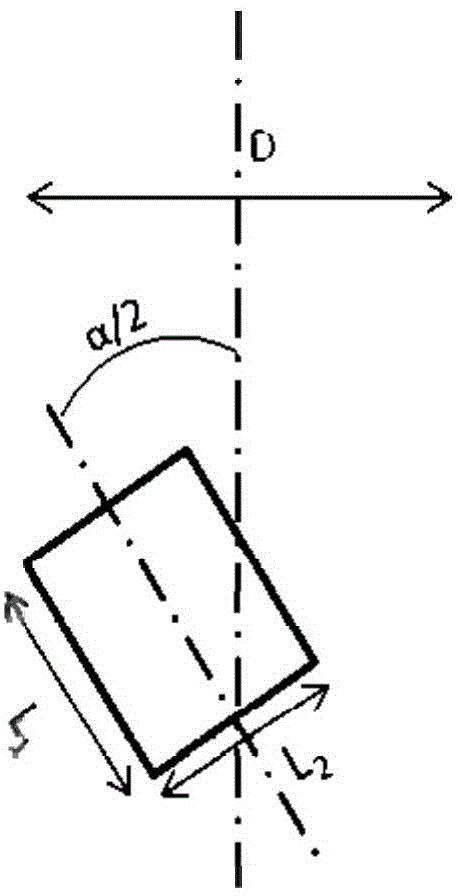

[0024] The optical system of the high-orbit space remote sensor may face a long-term "sun transit" phenomenon in orbit. The contact external heat flow simulation method will destroy the surface structure of the optical system, which cannot be applied in the identification and normal ground thermal test. simulator. However, if a solar simulator is used for the entire track, and considering the relative position changes between the sunlight and the remote sensor, there are high requirements for the spot size of the solar simulator, the space of the vacuum simulation system, and the ability of the motion mechanism. Determine the external heat flow simulation scheme according to the external heat flow received by the remote sensor.

[0025]In the present invention, the optical remote sensor is divided into two parts for consideration, one part is the optical system that must adopt the non-contact external heat flow simulation scheme, and the other part is the shading cover and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com