Measuring method of solar absorptance of thermal control coating

A technology of solar absorptivity and thermal control coating, applied in the direction of material thermal development, can solve the problems of thermal control coating performance recovery, low measurement accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

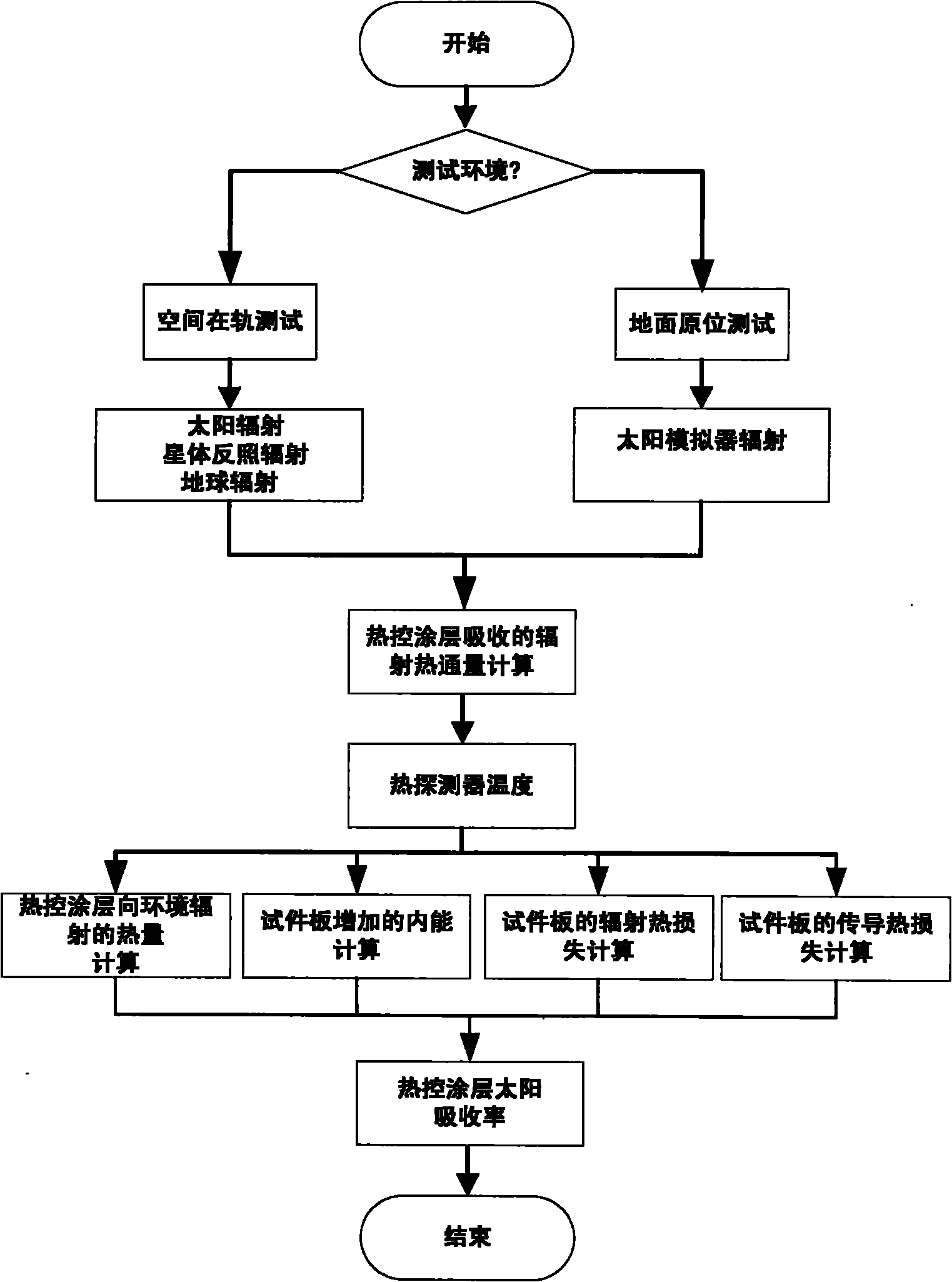

[0029] Such as figure 1 Shown, the implementation steps of the present invention are:

[0030] (1) Spread the thermal control coating evenly on the thin metal test piece that can measure the temperature in real time.

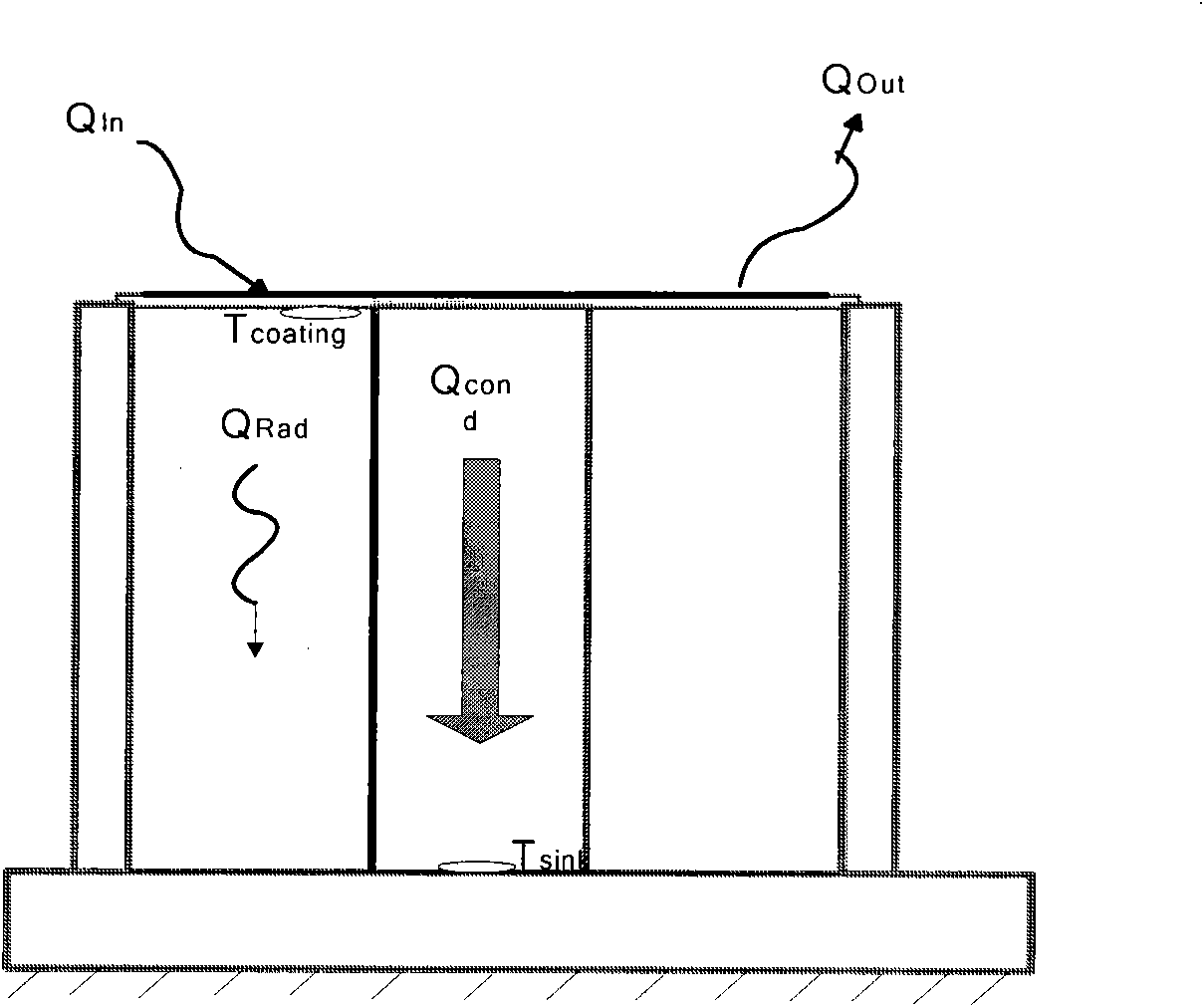

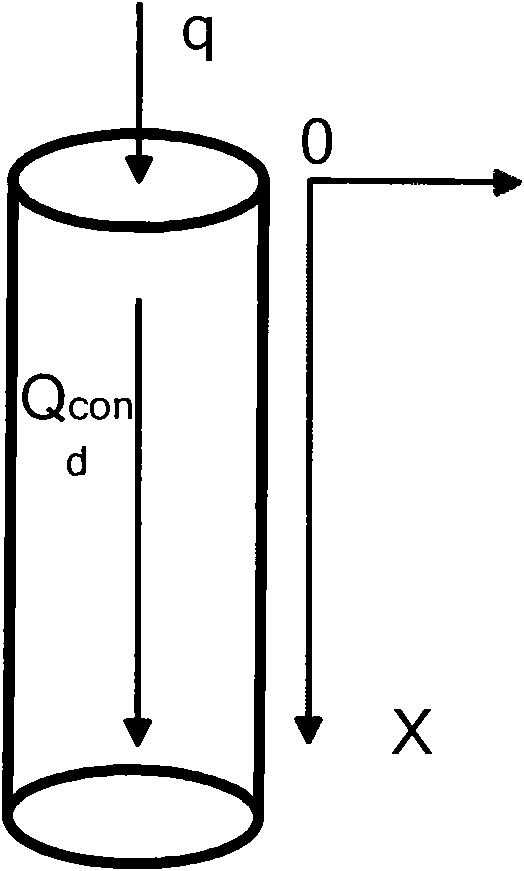

[0031] (2) Analyze the components of the space radiation received by the thermal control coating, and the radiation Q received by the thermal control coating in the orbital space environment In Includes: Solar Radiation Q solar , stellar albedo radiation Q albedo , Earth radiation Q earth-IR ; The radiation Q received by the thermal control coating in the simulated space environment on the ground In Irradiance Q for a solar constant of the solar simulator sun-simulator . Among them, Q solar =F s alpha s AE,Q albedo =F α alpha β ArE, Q earth-IR =F e alpha e AE e , Q sun-simulator = α s AE.

[0032] In the formula, E, E e Respectively represent the amount of solar radiation and the amount of infrared radiation of the earth; F s , F a , F e a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com