Method for preparing low-absorptance high-emissivity thermal control coating on magnesium alloy surface through micro-arc oxidation technology

A micro-arc oxidation and thermal control coating technology, applied in anodizing and other directions, can solve the problems of non-dense, poor corrosion resistance, uneven coating film, etc., and achieve good adhesion, good corrosion resistance, and film coating. Even and dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

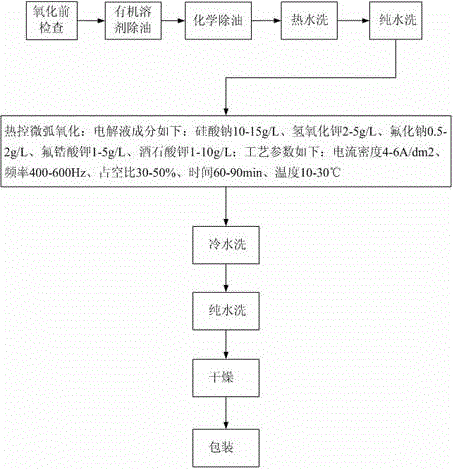

[0015] see figure 1 , the present invention prepares the method for low-absorption high-emission thermal control coating on the surface of magnesium alloy by micro-arc oxidation process and comprises the following steps:

[0016] Inspection before oxidation → organic solvent degreasing → chemical degreasing → hot water washing → pure water washing → micro-arc oxidation → cold water washing → pure water washing → drying → packaging.

[0017] The above-mentioned process steps are detailed as follows:

[0018] 1. Organic solvent degreasing: use aviation gasoline for degreasing, and then transfer to the next process after natural drying.

[0019] 2. Chemical degreasing: the process conditions are as follows:

[0020] Sodium carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com