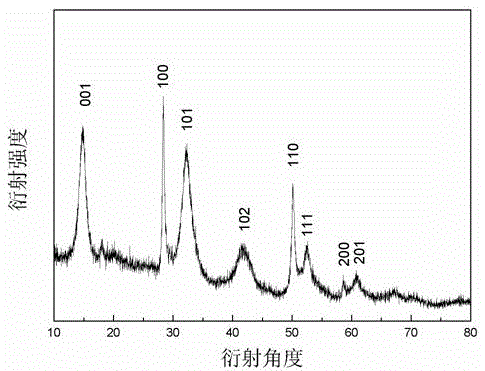

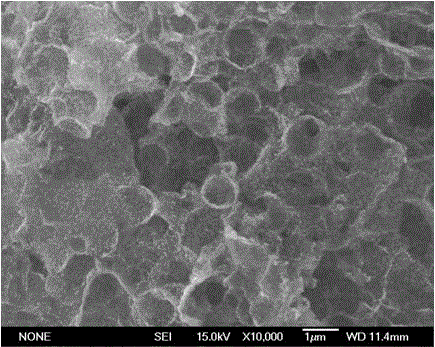

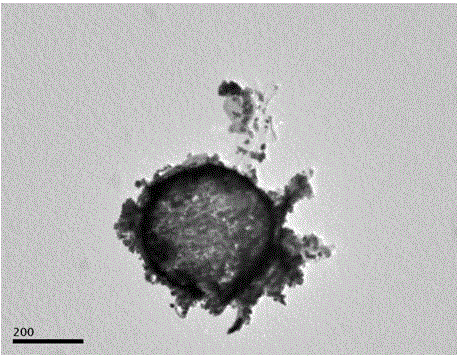

Composite material with hollow graphene spheres loaded with nanometer tin disulfide and method for preparing composite material

A graphene ball, tin disulfide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of volume expansion, electrode powderization, storage capacity and cycle life decline, etc., Achieve the effect of inhibiting agglomeration, low cost of raw materials, and improving transportation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of hollow graphene sphere loaded nano-tin disulfide composite material, the steps of the method are as follows:

[0023] Take 0.3g of the initiator potassium persulfate and add it to a three-neck round-bottomed flask, then add 50mL of deionized water, add the rotor to stir the potassium persulfate solution, pass in nitrogen protection, heat to 60°C, then add 2mL of styrene monomer, condense and reflux Reacted for 24 hours, condensed and refluxed for 7 hours, then added 500 μL of methacryloyloxyethyltrimethylammonium chloride, after the reaction, washed with deionized water, dried in vacuum for 12 hours, and the solid obtained after drying was the cation type polystyrene ball;

[0024] Disperse the obtained cationic polystyrene balls in water, sonicate for 1h, take a certain amount of graphene oxide solution and sonicate for 1h, after ultrasonication, mix the dispersed graphene oxide aqueous solution with cationic polystyrene balls in a mass ratio of...

Embodiment 2

[0029] A kind of preparation method of hollow graphene sphere loaded nano tin disulfide composite material, the steps of the method are as follows

[0030] Take 0.25g of initiator potassium persulfate into a three-neck round-bottomed flask, add 50mL of deionized water, add a rotor to stir the potassium persulfate solution, pass in nitrogen protection, heat to 75°C, then add 5mL of styrene monomer, condense and reflux React for 24 hours, condense and reflux for 5 hours, then add 500 μL of methacryloyloxyethyltrimethylammonium chloride. After the reaction, wash with deionized water and dry in vacuum for 6 hours. The solid obtained after drying is the cation type polystyrene ball;

[0031] Disperse the obtained cationic polystyrene balls in water, sonicate for 1 hour, take a certain amount of graphene oxide solution and sonicate for 1 hour, after ultrasonication, mix the dispersed graphene oxide aqueous solution with cationic polystyrene balls at a mass ratio of 1:3, and then Ul...

Embodiment 3

[0034] A kind of preparation method of hollow graphene sphere loaded nano tin disulfide composite material, the steps of the method are as follows

[0035] Take 0.5g of the initiator potassium persulfate and add it to a three-neck round-bottomed flask, then add 50mL of deionized water, add the rotor to stir the potassium persulfate solution, pass in nitrogen protection, heat to 85°C, then add 8mL of styrene monomer, condense and reflux React for 24 hours, condense and reflux for 10 hours, then add 400 μL of methacryloyloxyethyltrimethylammonium chloride. After the reaction, wash with deionized water and dry in vacuum for 12 hours. The solid obtained after drying is the cation type polystyrene ball;

[0036] Disperse the obtained cationic polystyrene balls in water, sonicate for 1 hour, take a certain amount of graphene oxide solution and sonicate for 1 hour, after ultrasonication, mix the dispersed graphene oxide aqueous solution with cationic polystyrene balls at a mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com