Preparing process for vanadium dioxide powder

The technology of vanadium dioxide and vanadium pentoxide is applied in the fields of functional materials and inorganic chemistry, which can solve the problems of long reaction route, complicated control process and high reaction temperature, and achieve the effects of less environmental pollution, simple operation process and simple raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

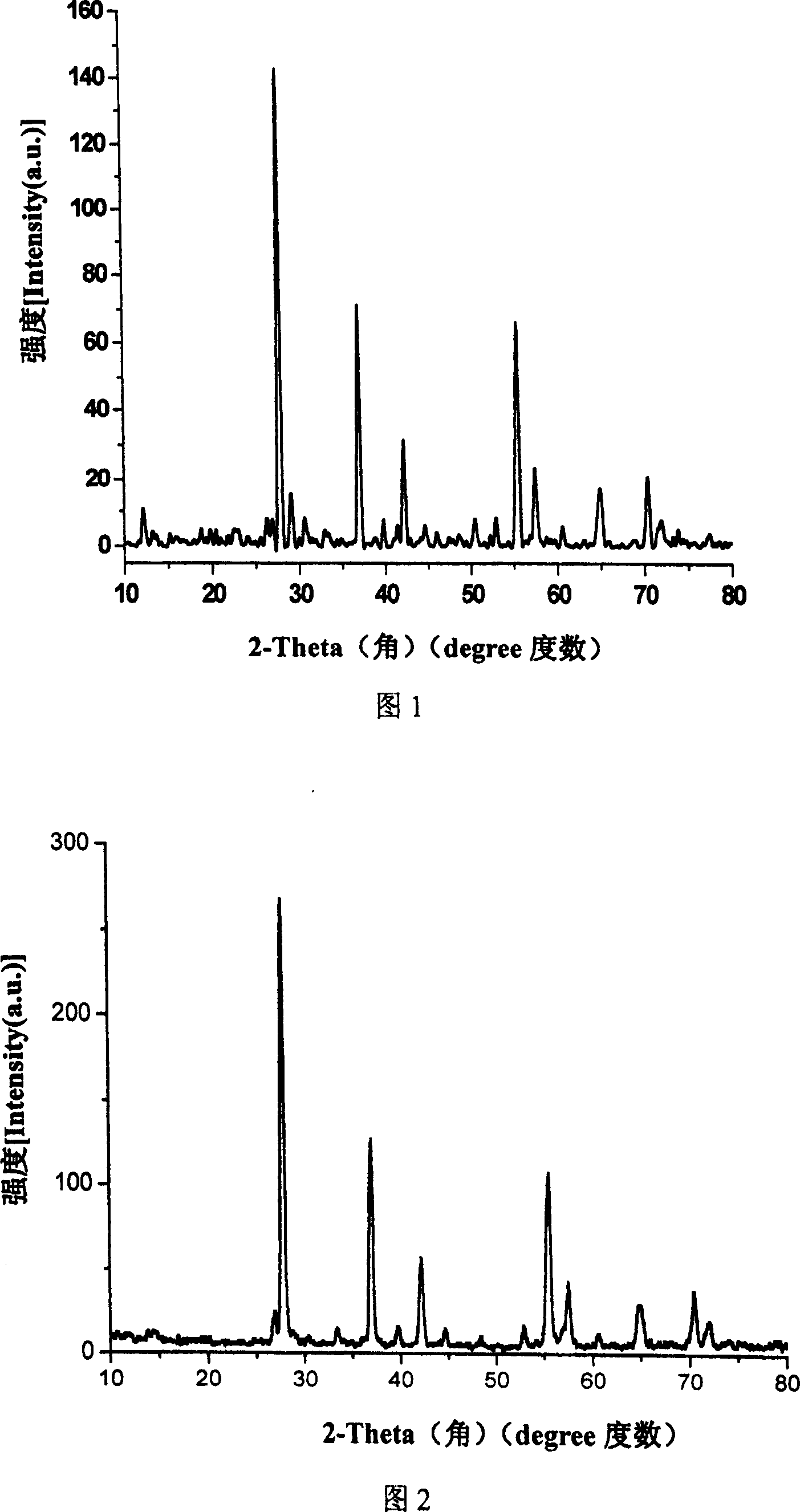

[0022] Place 0.90 g of V 2 o 5 Disperse the powder into 40mL of methanol, then transfer it to an autoclave or a pressure-resistant tubular reactor, and after sealing it, gradually raise the temperature to 180°C, and the pressure at this time is 2.8Mpa. Maintained under these conditions for 6h. Turn off the heating, let the material cool down naturally, wash with deionized water and absolute ethanol, and dry it under vacuum at 60°C to obtain vanadium dioxide powder, and obtain 0.7962g of black VO 2 powder. Under the protection of nitrogen, a certain mass of the above-mentioned black powder was calcined at 500° C. for 3 h, and the XRD spectrum of the obtained black powder is shown in Figure 1 . As can be seen from accompanying drawing 1: gained product is crystallized VO 2 (M).

Embodiment 2

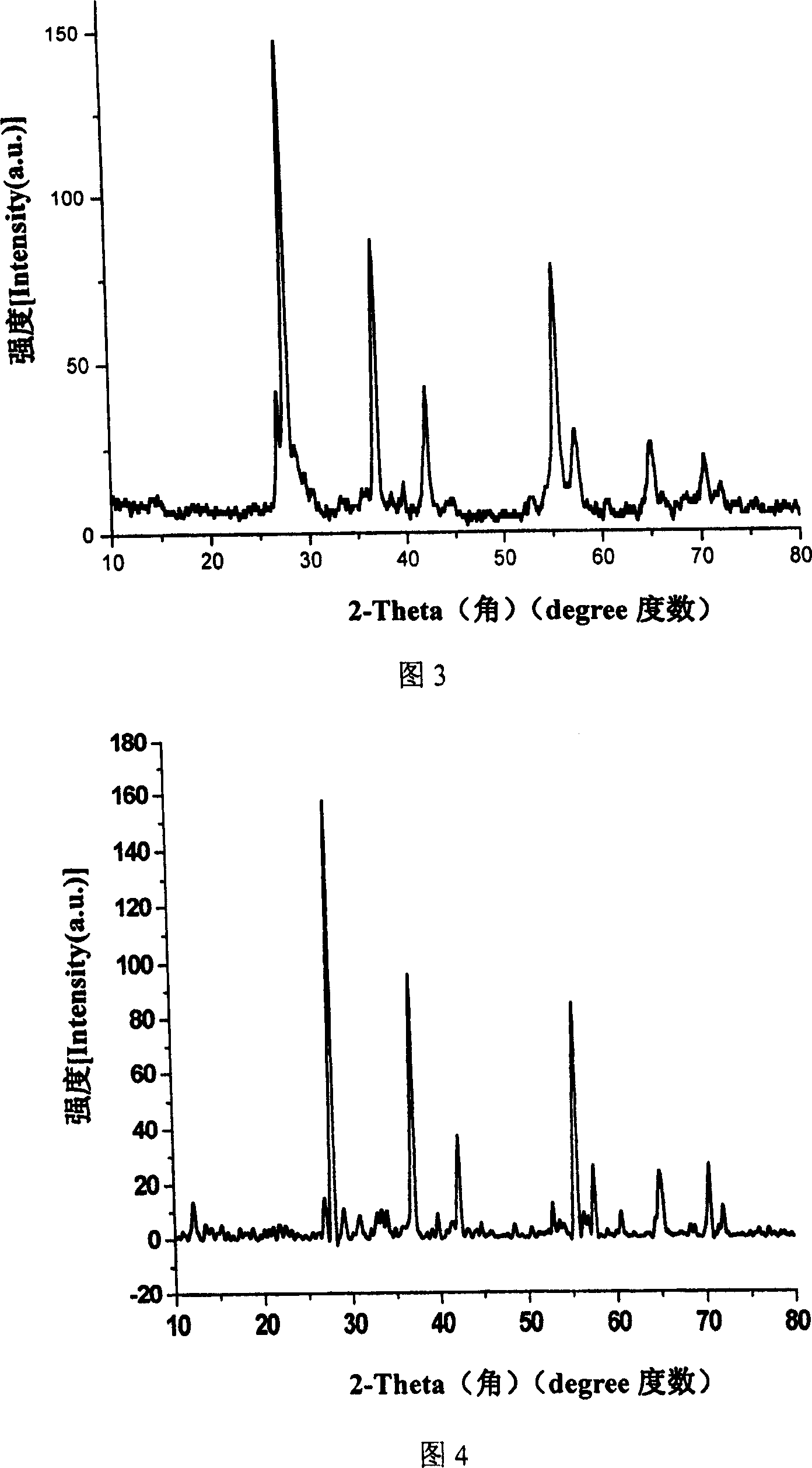

[0024] Place 0.90 g of V 2 o 5 The powder was dispersed in 40mL of ethanol, then transferred to an autoclave, and after sealing, the temperature was gradually raised to 180°C, and the pressure was 2.00Mpa at this time. Maintained under these conditions for 6h. Turn off the heating, let the material cool down naturally, wash with deionized water and absolute ethanol, and dry it under vacuum at 60°C to obtain vanadium dioxide powder, and obtain 0.2107g of black VO 2 powder. Under the protection of nitrogen, a certain mass of the above-mentioned black powder was calcined at 500°C for 3 hours, and the XRD spectrum of the obtained black powder is shown in Figure 2. As can be seen from accompanying drawing 1: gained product is crystallized VO 2 (M).

Embodiment 3

[0026] Place 0.90 g of V 2 o 5 The powder was dispersed into 40mL of hexanol, then transferred to an autoclave, and after sealing, the temperature was gradually raised to 180°C, and the pressure was 0.10Mpa at this time. Maintained under these conditions for 6h. Turn off the heating, let the material cool down naturally, wash with deionized water and absolute ethanol, and vacuum dry at 60°C to obtain vanadium dioxide powder, and obtain 0.3783g of black VO 2 powder. Under the protection of nitrogen, a certain mass of the above-mentioned black powder was calcined at 500° C. for 3 hours. The XRD spectrum of the obtained black powder is shown in Fig. 3 . As can be seen from accompanying drawing 3: gained product is crystallized VO 2 (M).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com