Vanadium dioxide intelligent temperature control film and preparation method thereof

A vanadium dioxide intelligent and vanadium dioxide technology is applied in the field of vanadium dioxide intelligent temperature control film and preparation, and can solve the problems of high cost of precursor organic vanadium source, complicated process, complicated preparation process of organic salt sol method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] with V 2 o 5 The powder, benzyl alcohol and isopropanol were mixed in a molar ratio of 1:4:50, and stirred in an oil bath at 80°C for 2 hours to obtain VO x (2.0x film, then at 410°C, H 2 / Ar mixed atmosphere for reduction for 3 hours, the desired VO can be obtained after natural cooling 2film.

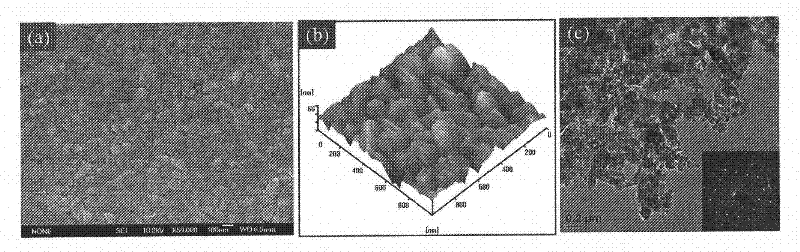

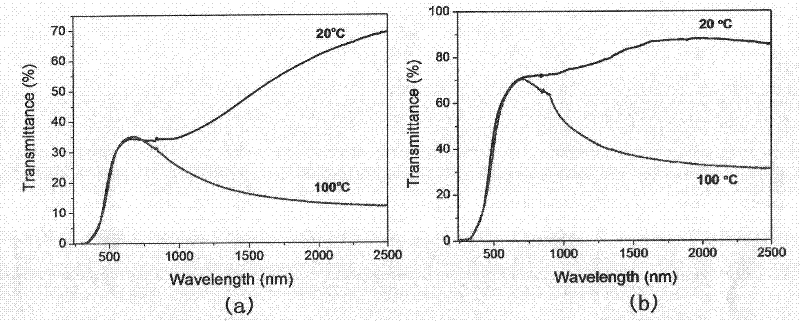

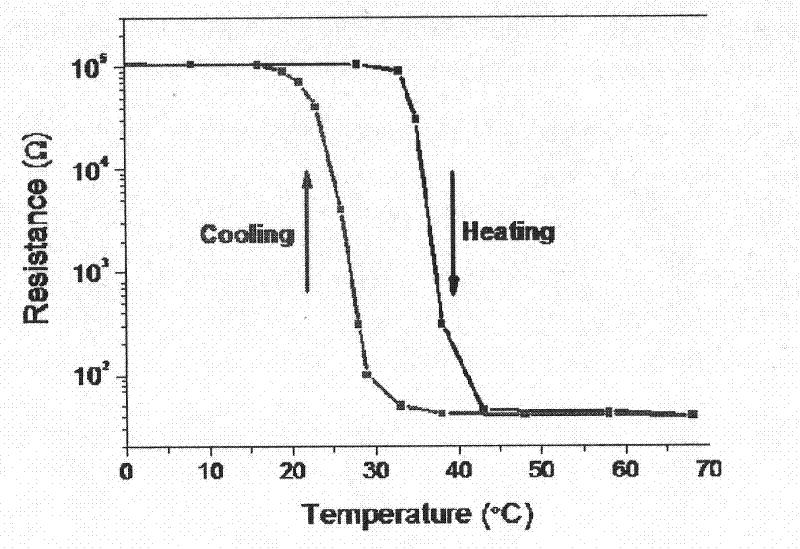

[0031] figure 1 a corresponds to VO 2 The SEM image of the surface morphology of the film, the grain diameter is about 80-120nm; figure 1 b corresponds to the AFM image, the average roughness of the film is 8.02nm; figure 1 c is a TEM image, crystal grains of about 100nm can be observed, and the inset is electron diffraction of a selected area, showing VO 2 Thin monoclinic phase structure. figure 2 (a) is pure phase VO 2 The light transmittance diagram of the thin film sample before and after the metal-insulator phase transition, during the heating process, VO 2 The light transmittance of the film in the visible region remains unchanged, and the transmittance is 70%....

Embodiment 2

[0034] with V 2 o 5 The powder, benzyl alcohol and isobutanol were mixed in a molar ratio of 1:4:50, and stirred in an oil bath at 80°C for 2 hours to obtain VO x Organic dispersion solution. W by sol-gel method 6+ Ions and PVP are doped, the V:W molar ratio is 3:1, and the PVP mass fraction is 1.5%. Prepare VO by pulling coating technology (speed is 50mm / min) x film, then at 410°C, H 2 / Ar mixed atmosphere for 3 hours, and after natural cooling, W-doped porous VO can be obtained 2 film. VO 2 The light transmittance of the film sample before and after the metal-insulator phase transition changes by 61%; the resistivity changes by 10 3 order of magnitude; its phase transition temperature is 35°C.

Embodiment 3

[0036] with V 2 o 5 The powder, benzyl alcohol and ethanol were mixed in a molar ratio of 1:4:60, and stirred in an oil bath at 80°C for 2 hours to obtain VO x Organic dispersion solution. W by sol-gel method 6+ Ions and PVP are doped, the V:W molar ratio is 4:1, and the PVP mass fraction is 1.5%. Prepare VO by pulling coating technology (speed is 50mm / min) x film, then at 410°C, H 2 / Ar mixed atmosphere for 3 hours, and after natural cooling, W-doped porous VO can be obtained 2 film. VO 2 The light transmittance of the film sample before and after the metal-insulator phase transition changes by 62%; the resistivity changes by 10 3 order of magnitude; its phase transition temperature is 41°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com